Professional Documents

Culture Documents

19

Uploaded by

Zaqy ZelanoCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

19

Uploaded by

Zaqy ZelanoCopyright:

Available Formats

ISSN: 2277- 7695

CODEN Code: PIHNBQ

ZDB-Number: 2663038-2

Received: 02-03-2013

Accepted: 03-04-2013

IC Journal No: 7725

Vol. 2 Issue 3 2013

Online Available at www.thepharmajournal.com

THE PHARMA INNOVATION - JOURNAL

Formulation and Evaluation of Rapidly Disintegrating

Tablet of Ibuprofen

Misra Shashi Kiran*, Himanshu Pandey1

1.

2.

University Institute of Pharmacy, Chhatrapati Shahu Ji Maharaj University, Kanpur-208024, Uttar Pradesh,

India.

[E-mail: saushi123@rediffmail.com; Tel: 9838095777]

Associate Professor, Department of Pharmaceutical Sciences, Faculty of Health Sciences,

SHIATS, Allahabad, UP, India.

Objective: The aim of the proposed work was to formulate and characterize fast dissolving tablets of ibuprofen for

rapid dissolution of drug and absorption, which may produce rapid onset of action. These dosage forms rapidly

disintegrate and/or dissolve to release the drug as soon as they come in contact with saliva, thus obviating the need

for water during administration, an attribute that makes them highly attractive for pediatric and geriatric patients.

Method: The fast dissolving tablets of ibuprofen were prepared by two methods named melt technology and super

disintegrant addition method. Comparatively evaluation parameters with respect to various physical parameters

(weight variation, hardness, friability, etc.) were evaluated and drug release profile was analyzed. The concentration

of sucrose and ac-di-sol were optimized for desired rapidly disintegrating formulations.

Result and conclusion: Both the methods of rapidly disintegrant tablets showed desirable results. The formulations

prepared by super disintegrant addition were having lesser wetting time, disintegration time, invitro dispersion time

and better drug release as compared to the formulations prepared by melt technology.

Keyword: Rapidly Disintegrating, Ibuprofen, Super Disintegrant Addition, Melt technology, ac-di-sol.

1. Introduction

Fast release tablets can disintegrate and dissolve

rapidly once placed into the oral cavity. These

tablets are prepared by using either of

effervescent melt technology, addition of super

disintegrant or melt technology[1]. All the

technologies formulate rapidly disintegrate tablet

and release desired drug concentration at the end

of 10 minutes. There are various patented

technologies such as Zydis, WOW TABS,

FLASH DOSE, CEFORM and ORAQUICK[2]. In

zydis technology tablets are prepared by

lyophilization process thats why it becomes

highly porous in nature which on contact with

Vol. 2 No. 3 2013

saliva get solublized and drug releases in

suspension form in oral cavity. WOW TAB

technology utilizes sugar or its substituent like

mannitol which show smooth melt action and

gets dissolve within 15 seconds[3]. Difficulty in

swallowing (Dysphagia) is a common problem of

all age groups, especially elderly and pediatrics,

because of physiological changes associated with

these groups of patients[4]. Solid dosage forms

that can be disintegrated, dissolved, or suspended

by saliva in the mouth resulting in easy

swallowing can provide significant benefits to the

pediatric and geriatric population, as well as other

patients who prefer the convenience of easily

www.thepharmajournal.com

Page | 44

The Pharma Innovation - Journal

swallowable dosage forms[5]. This tablet

disintegrates instantaneously when placed on

tongue, releasing the drug that dissolves or

disperses in the saliva[6]. In present study an

attempt has been made to formulate it as fast

dissolving tablets to increase its oral

bioavailability[7].

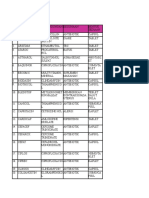

Table 1: Composition of fast disintegrating formulations of ibuprofen prepared by addition of super disintegration (S1S3) and melt technology method (M1-M3)

Ingredients

S1

(mg)

S2

(mg)

S3

(mg)

M1

(mg)

M2

(mg)

M3

(mg)

Ibuprofen

50

50

50

50

50

50

Mannitol

65

65

65

36

36.85

36.85

Microcrystalline

cellulose

65

60

62

30

20

32

Ac- di- sol

15.5

20

18

Sucrose+glucose

45

55

40

Sorbitol

35

35

35

Talc

3.68

3.68

3.68

3.68

3.68

3.68

Magnesium

stearate

1.8

1.8

1.8

1.8

1.8

1.8

2. Material and methods

Ibuprofen, Microcrystalline cellulose, Ac- di- sol

and mannitol were obtained as gift sample from

Ranbaxy fine chemical limited, New Delhi.

Sucrose was gifted by Qualigens Fine

Chemicals, Mumbai, talc and magnesium stearate

were obtained from S.D. fine chemical, limited

Mumbai.

2.1 Super Disintegrate Method:

Ibuprofen (50 mg) was mixed with mannitol and

microcrystalline cellulose in a glass mortar with

slight triturating [Table 1]. Super disintegrate

Ac-di-sol was added and granules were prepared

followed by addition of magnesium stearate and

talc[8].

Table 1: Composition of fast disintegrating

formulations of ibuprofen prepared by addition of

super disintegration (S1-S3) and melt technology

method (M1-M3)

Vol. 2 No. 2 2013

2.2 Melt Technology:

In this method Ibuprofen (50 mg) was mixed with

low mould ability sugar like mannitol, sucrose

and granulated using high mould ability

sachharides which worked as binder. Low

moldable sugars used for rapid dissolution and

high mould sachharides showed for good binding

property [Table 1]. Granules prepared were

lubricated and compressed into tablets. Prepared

tablets were dried in hot air oven to evaporate the

water and to form pores in the sugar melt[9].

2.3 Pre-formulation study

Standardization of the drug was carried out using

phosphate

buffer

pH

6.4

by

UV

spectrophotometer (UV-160A, SHIMADZU).

Solubility analysis of drug in various solvents

including water, phosphate buffer pH 6.4 and

organic solvents like ethanol, methanol[10,11].

www.thepharmajournal.com

Page | 45

The Pharma Innovation - Journal

2.4 Drug content

Twenty tablets were weighed and powdered. An

amount of the powder equivalent to 50 mg of

ibuprofen was dissolved in 100 ml of pH 6.4

phosphate buffer, filtered, diluted suitably and

analyzed for drug content at 264.5 nm using UVVisible spectrophotometer (UV 160- Shimadzu,

Japan)[10, 11].

2.5 Disintegration time

Three tablets per batch were evaluated for

disintegration time by employing a modified

dissolution

apparatus.

Instead

of

the

disintegration apparatus described in JP XII, a

modified dissolution apparatus (JP XII paddle

method) was employed. Water (900 ml),

maintained at 370.5 was stirred with a paddle

at 100 rpm. Disintegration time was recorded

when all the fragments of the disintegrated tablet

passed through the screen of the basket. [10, 11]

Fig 1: Comparative drug release profile of fast disintegrating formulations of ibuprofen prepared by addition of super

disintegrant

Vol. 2 No. 3 2013

www.thepharmajournal.com

Page | 46

The Pharma Innovation - Journal

2.6 Tablet Hardness

The strength of tablet is expressed as tensile

strength (Kg/cm2). The tablet crushing load,

which is the force required to break a tablet into

halves by compression. It was measured using a

tablet hardness tester (Monsanto Hardness

Tester)[10,11].

2.6.1 Friability: Ten tablets were weighed and

placed in a Roche friabilator and the equipment

was rotated at 25 rpm for 4 min. The tablets were

taken out, dedusted and reweighed.

percentage friability of the tablets

measured[10,11].

The

was

2.6.2 Wetting Time: A piece of tissue paper

folded twice was placed in a small Petri dish

containing 6ml of pH6.2 (simulated saliva fluid).

A tablet was put on the paper and the time for

complete wetting was measured6. Three trials for

each were performed[10,11].

Fig 2: Comparative drug release profile of fast disintegrating formulations of ibuprofen prepared by melt technology

method

2.6.3 In vitro dispersion time: In vitro dispersion

time was measured by dropping a tablet in a 10

ml measuring cylinder containing 6ml of buffer

solution simulating saliva fluid (pH 6.4).

Dissolution test was carried out in 900 ml of pH

6.4 phosphate buffer in dissolution apparatus

USP II at 50 rpm. An aliquot of dissolution

medium was withdrawn at regular interval and

absorbance was measured at 264.5 nm. An equal

volume of phosphate buffer was added to

maintain the sink condition. Dissolution was

carried out for all the formulations. Absorbance

of these solutions was measured at 264.5 nm

using a Thermospectronic-1 UV/Vis double beam

spectrophotometer. Cumulative percentage drug

release was calculated using an equation obtained

from a standard curve[10,11].

Vol. 2 No. 2 2013

3. Results and discussion

Several Technologies

are

available

to

manufacture orally distintegrating tablets. The

most common preparation methods are molding,

lyophilization

or

freeze

drying,

direct

compression, spray drying and sublimation. In the

present investigation fast release tablets of

ibuprofen were formulated by addition of super

disintegrant and melt technology. All the tablets

were prepared under similar conditions. All the

formulations exhibited white color, odorless,

convex shape with smooth surface.

The characteristics of prepared FDTs of

Ibuprofen are shown in Table 2. The average

weight of the FDTs prepared by addition of super

disintegrating method was 195.89- 202.65 mg.

Weight variation of FDTs was within 0.89%.

Hardness and friability of all formulations (S1-

www.thepharmajournal.com

Page | 47

The Pharma Innovation - Journal

S3) were within acceptable limits. Hardness of

tablets prepared by direct compression was 3.95

to 4.22 kg/cm2. The friability of all formulations

was found to be less than 1% indicating good

mechanical resistance. Disintegration time play a

important role for FDTs which is desired to be

less than 60 seconds for orally disintegrating

tablets. This rapid disintegration assists

swallowing and also plays a role in drug

absorption in buccal cavity, thus promoting

bioavailability. Disintegration time of prepared

FDTs was in the range of 45 to 55 seconds.

Wetting time is used as an indicator from the ease

of the tablet disintegration in buccal cavity. The

wetting time of the formulations was in the range

221.2 to 641.2. The wetting time was

decreased on increasing the concentration of Acdi- sol in formulations (S1 S3). This may be

due to the formation of pores in formulations on

increasing concentration of super disintegrant. In

vitro dispersion time was found to be 22 to 52

seconds. Which may be attributed to faster uptake

of water due to the porous structure formed (S1

S3). Fast release tablets of ibuprofen showed

different pattern of drug release. Tablet S2

prepared by super disintegrate method showed

maximum % drug release profile as compared to

S1 and S3 [Figure 1]. Similarly tablet formulated

by melt technology showed hardness within a

range of 3.44 kg/cm2 to 4.41 kg/cm2. M2 tablet

showed maximum drug release as compared to

remaining M1 and M3 tablets [Figure 2]. The

invitro drug release after 10 minutes was between

96.03 to 100.10 % indicating better drug release

and improved bioavailability. The formulations

(F1-F3) prepared by super disintegrant addition

were having lesser wetting time, disintegration

time, invitro dispersion time and better drug

release as compared to the formulations prepared

by melt technology (M1-M3). So it was

concluded that super disintegrant addition method

was excellent as compared to melt technology in

formulation of mouth dissolving tablets.

Patel DM, Patel NM, Shah RR, Jogani PD,

Balapatel AI. Studies in formulation of

orodispersible tablets of rofecoxib. Indian

Journal of Pharmaceutical Sciences 2004; 66:

621-625.

3. Reddy LH, Ghosh B, Rajneesh. Fast dissolving

drug delivery systems: A review of the literature.

Indian Journal of Pharmaceutical Sciences

2002;64:331-336.

4. Schiermeier S, Schmidt PC. Fast dispersible

ibuprofen tablets. European Journal of

Pharmaceutical Sciences 2002;15:295-305.

5. Sreenivas SA, Dandagi PM, Gadad AP, Godbole

AM,

Hiremath

SP,

Mastiholimath

VS.

Orodispersible tablets: New-fangled drug

delivery system-A review. Indian Journal of

Phramaceutical Education And

research

2005;39:177-181.

6. Kavitha K, Nalini CN, Kasturi GD, Merlin JP,

Varalakshmi V, Maragatham C. Effect of betadex

on the solubility and dissolution behavior of

rofecoxib. The Antiseptic 2004;101: 463-465.

7. Lalla JK, Mamania HM. Fast dissolving rofecoxib

tablets. Indian Journal of Pharmaceutical

Sciences 2004;66:350-352.

8. Nayak SM, Gopikumar P. Design and

optimization of fast dissolving tablets for

promethazine

theoclate.

Indian

Drugs

2004;41:554-556.

9. Shimizu T, Sugaya M, Nakano Y, Izutsu D,

Mizukami Y, Okochi K, Tabata T, Hamaquchi N,

Igari Y. Formulation study for lansoprazole fast

disintegrating tablet. III. Design of rapidly

disintegrating

tablets.

Chemical

And

Pharmaceutical Bulletin 2003;51: 1121-1127.

10. Chang RK, Guo X, Burnside BA, Couch RA. Fast

dissolving tablets. Pharmaceutical Technology

Europe 2000;12:52-58.

11. Martin TP, Hayes P, Collins DM. Tablet

dispersion as an alternative to formulation of

oral liquid dosage form. Aust J Hosp Pharm

1993; 23: 378-381.

2.

4. References

1.

Chien YW. Novel drug delivery systems. 2nd ed.

New York: Marcel Dekker; 1992. p. 139.

Vol. 2 No. 3 2013

www.thepharmajournal.com

Page | 48

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Brand Plan For Dienogest by Saqib AltafDocument13 pagesBrand Plan For Dienogest by Saqib AltafSakib ZabooNo ratings yet

- Drug of Abuse Substance of AbuseDocument10 pagesDrug of Abuse Substance of AbuseCARL ANGELA SISONNo ratings yet

- MCQ Pathways9th.IDocument4 pagesMCQ Pathways9th.Iareej alblowi100% (1)

- Psychoactive Drug UseDocument1 pagePsychoactive Drug UsePisay Shehannah Grail MedinaNo ratings yet

- Protokol KemoterapiDocument147 pagesProtokol KemoterapiDala VW100% (1)

- Antagonis AdrenergikDocument34 pagesAntagonis AdrenergikGde Ananda ArmanditaNo ratings yet

- Pain Medication (NON SELECTIVES NSAID)Document1 pagePain Medication (NON SELECTIVES NSAID)KyrrielJimenoCeladaNo ratings yet

- ١٩-ﺪﻴﻓﻮﻛ ﺎﻧورﻮﻛ سوﺮﻴﻓ ﺪﺿ ﻢﻴﻌﻄﺗ ةدﺎﻬﺷ COVID-19 Vaccination CertificateDocument1 page١٩-ﺪﻴﻓﻮﻛ ﺎﻧورﻮﻛ سوﺮﻴﻓ ﺪﺿ ﻢﻴﻌﻄﺗ ةدﺎﻬﺷ COVID-19 Vaccination CertificateYoga PratamaNo ratings yet

- Kode BarangDocument38 pagesKode BarangSindhu WinataNo ratings yet

- TOKOLITIKDocument2 pagesTOKOLITIKIgnatia NindyNo ratings yet

- Ticket Ticket: Medical FacultyDocument6 pagesTicket Ticket: Medical Facultyhealer sruthyNo ratings yet

- Diabetes DataDocument5 pagesDiabetes DataJust For You ArtsNo ratings yet

- Opioid-BenzosTapering FlowchartDocument1 pageOpioid-BenzosTapering FlowchartjuanchibarberoismNo ratings yet

- Lasa 1Document4 pagesLasa 1hesti widayaniNo ratings yet

- PCH 3801Document4 pagesPCH 3801Vikram LadvaNo ratings yet

- Pharmaco - Smoking Cessation DR Ho 2017Document55 pagesPharmaco - Smoking Cessation DR Ho 2017Keluang Man WinchesterNo ratings yet

- Cannabis and Cannabinoids 2016Document2 pagesCannabis and Cannabinoids 2016Marcus Vinícius SouzaNo ratings yet

- Nama ObatDocument49 pagesNama ObatDwianti Lestari IINo ratings yet

- Drug Study TadalafilDocument2 pagesDrug Study TadalafilNicole Anne TungolNo ratings yet

- Juvenile Delinquency The Core 6th Edition Siegel Test BankDocument24 pagesJuvenile Delinquency The Core 6th Edition Siegel Test Banknhatphelim2e5q100% (28)

- Dissecting The Opioid Heroin Epidemic To Discover Its Ugly RootsDocument7 pagesDissecting The Opioid Heroin Epidemic To Discover Its Ugly RootsThavamNo ratings yet

- PO FileDocument29 pagesPO FileLokesh GargNo ratings yet

- Loop Diuretics - Dosing and Major Side Effects - UpToDateDocument9 pagesLoop Diuretics - Dosing and Major Side Effects - UpToDatethelesphol pascalNo ratings yet

- Antibioticresistance PowerpointDocument51 pagesAntibioticresistance PowerpointOdy100% (1)

- 11 Antihypertensive AgentsDocument43 pages11 Antihypertensive AgentsnidsNo ratings yet

- CeftriaxoneDocument2 pagesCeftriaxoneunkown userNo ratings yet

- Advances in Orodispersible Films For Drug Delivery: ReviewDocument18 pagesAdvances in Orodispersible Films For Drug Delivery: ReviewKamran AlamNo ratings yet

- Bermain Terapeutik Puzzle Mempengaruhi Tingkat Kecemasan Pada Anak Usia Prasekolah (3-6 Tahun) Sebelum Pemberian Obat Intravena (Bolus)Document14 pagesBermain Terapeutik Puzzle Mempengaruhi Tingkat Kecemasan Pada Anak Usia Prasekolah (3-6 Tahun) Sebelum Pemberian Obat Intravena (Bolus)Farida MurtianiNo ratings yet

- Company List-14-04-2021: Company Name Contact Person Contact NumberDocument4 pagesCompany List-14-04-2021: Company Name Contact Person Contact NumberNitin ShenoyNo ratings yet