Professional Documents

Culture Documents

Tema 9

Uploaded by

sudokuOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tema 9

Uploaded by

sudokuCopyright:

Available Formats

SEcnON5

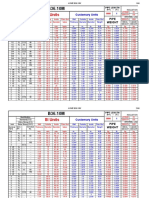

MECHANICAL STANDARDS TEMA CLASS ReB

TABLE RCB-4.52

MAXIMUM UNSUPPORTED STRAIGHT TUSE SPANS

Dimensions in Inches (mm)

Tube Materials and Temperature Limits 0 F (0 C)

TubeOD

1/4

3/8

1/2

5/8

3/4

7/8

1

1-1/4

1-1/2

2

2-1/2

3

Carbon Steel & High Allay Steel, 750

(399)

Low Alloy Steel, 850 (454)

Nickel-Copper, 600 (316)

Nickel, 850 (454)

Nickel-Chromium-Iron, 1000 (538)

26 (660)

35 (889)

44 (1118)

52 (1321)

60 (1524)

69 (1753)

74 (1880)

88 (2235)

100 (2540)

125 (3175)

125 (3175)

125 (3175)

(6.4)

(9.5)

(12.7)

(15.9)

(19.1)

(22.2)

(25.4)

(31.8)

(38.1)

(50.8)

(63.5)

(76.2)

Aluminum & Aluminum Allays, Copper &

Copper Alloys, Titanium Allays At Code

Maximum Allowable Temperature

22

30

38

45

52

60

64

76

87

110

110

110

(559)

(762)

(965)

(1143)

(1321)

(1524)

(1626)

(1930)

(2210)

(2794)

(2794)

(2794)

Notes:

(1) Above the metal temperature limits shown, maximum spans shall be reduced in direct

proportion to the fourth root of the ratio of elastic modulus at design temperature to

elastic modUlUS at tabulated limit temperature.

(2)

In the case of circumferentially finned tubes, the tube 00 shall be the diameter at the

root of the fins and the corresponding tabulated or interpolated span shall be reduced

in direct proportion to the fourth root of the r$,tio of the weight per unit length of the

tube, if stripped of fins to that of the actual finned tube.

(3) The maximum unsupported tube spans in Table RCB-4.52 do not consider potential

flow induced vibration problems. Refer to Section 6 for vibration criteria.

RCB-4.53 BAFFLE SPACING

Baffles normally shall be spaced uniformly, spanning the effective tube length. When this

is not pOSSible, the baffles nearest the ends of the shell, and/or tubesheets, shall be located

as close as practical to the shell nozzles. The remaining baffles normally shall be spaced

uniformly.

RCB-4.54 U-TUBE REAR SUPPORT

The support plates or t,laffles adjacent to the bends in U-tube exchangers shall be so

located that; for any individual bend, the sum ofihe bend diameter pitts the straight lengths

measured along both legs from supports to bend tangents does not exceed the maximum

unsupported span determined from Paragraph RCB-4.52. Where bend diameters prevent

compliance, special provisions in addition to the above shall be made for support of the

bends.

RCB-4.55 SPECIAL CASES

When pulsating conditions are specified by the purchaser, unsupported spans shall be as

short as pressure drop restrictions permit. If the span under these circumstances

approaches the maximum permitted by Paragraph RCB-4.52, consideration should be

given to alternative flow arrangements which would permit shorter spans under the same

pressure drop restrictions.

www.tema.org

Tubular Exchanger Manufacturers Association, Inc.

5.4-5

You might also like

- Pressure Vessel Handbook Fourteenth Edition Eugene R MegyesyDocument1,014 pagesPressure Vessel Handbook Fourteenth Edition Eugene R Megyesyluis sepulveda80% (10)

- The Essence of Success - Earl NightingaleDocument2 pagesThe Essence of Success - Earl NightingaleDegrace Ns40% (15)

- PIP VESV1002 Design and Fabrication Specification For Vessels ASME Code Section VIII, Divisions 1 and 2Document44 pagesPIP VESV1002 Design and Fabrication Specification For Vessels ASME Code Section VIII, Divisions 1 and 2d-fbuser-93320248No ratings yet

- Gost 14249-89 (E)Document67 pagesGost 14249-89 (E)CrstnScribidNo ratings yet

- Heat Exchanger Design Guide: A Practical Guide for Planning, Selecting and Designing of Shell and Tube ExchangersFrom EverandHeat Exchanger Design Guide: A Practical Guide for Planning, Selecting and Designing of Shell and Tube ExchangersRating: 4 out of 5 stars4/5 (13)

- 3-11-10 Pressure Vessels Carbon SteelDocument34 pages3-11-10 Pressure Vessels Carbon Steelsudoku100% (2)

- Astm A578 - 07 PDFDocument5 pagesAstm A578 - 07 PDFMuhammad Maulana100% (1)

- Heat Exchanger Equipment Field Manual: Common Operating Problems and Practical SolutionsFrom EverandHeat Exchanger Equipment Field Manual: Common Operating Problems and Practical SolutionsRating: 4 out of 5 stars4/5 (6)

- Piping Class - AS20Document2 pagesPiping Class - AS20Дмитрий РыбаковNo ratings yet

- Frangible Roof Joint, or Weak PDFDocument5 pagesFrangible Roof Joint, or Weak PDFseth_shelby007No ratings yet

- Pip Vefv1100-Jan. 2009 - Part1Document28 pagesPip Vefv1100-Jan. 2009 - Part1Ionut FloricaNo ratings yet

- AHF Bulk Transport, Distribution and HandlingDocument27 pagesAHF Bulk Transport, Distribution and HandlingShailesh RavalNo ratings yet

- Overview of TEMA Standard: Presented By: SAK SR Project Engineer Engineering DepartmentDocument107 pagesOverview of TEMA Standard: Presented By: SAK SR Project Engineer Engineering Departmentusmaniqbal15100% (4)

- Vortex-Breaking PDFDocument7 pagesVortex-Breaking PDFZeroRecoNo ratings yet

- Api 661Document6 pagesApi 661margarelliNo ratings yet

- Pressure Vessels Field Manual: Common Operating Problems and Practical SolutionsFrom EverandPressure Vessels Field Manual: Common Operating Problems and Practical SolutionsRating: 4 out of 5 stars4/5 (12)

- Handbook of Mechanical Engineering TermsDocument366 pagesHandbook of Mechanical Engineering Termsjakejohns95% (44)

- Formal 17 12 04 PDFDocument184 pagesFormal 17 12 04 PDFJose LaraNo ratings yet

- Tema 99Document302 pagesTema 99PRATIK P. BHOIR100% (1)

- 9TH EDITION TEMA STANDARD AND SOFTWARE UPDATESDocument4 pages9TH EDITION TEMA STANDARD AND SOFTWARE UPDATESbkprodh100% (1)

- PV Elite - Nozzle Interference - The SolutionDocument4 pagesPV Elite - Nozzle Interference - The Solutionayounga100% (3)

- PED 2014-68-EU Guidelines en v5.1Document241 pagesPED 2014-68-EU Guidelines en v5.1Uğur özdemirNo ratings yet

- PD5500 2009Document4 pagesPD5500 2009rgavilanb917390% (2)

- Engineering Failure Analysis of Two Reformer Heater TubesDocument16 pagesEngineering Failure Analysis of Two Reformer Heater TubesRajesh Johri100% (2)

- NTIW Tube Sheet PaperDocument10 pagesNTIW Tube Sheet PaperPankaj SinglaNo ratings yet

- Proposed New ASMEB31P Standard On Preheat & PWHT PDFDocument34 pagesProposed New ASMEB31P Standard On Preheat & PWHT PDFWitchfinder General100% (1)

- Code-compliant vessel design requirementsDocument90 pagesCode-compliant vessel design requirementsعصمت ضيف الله83% (12)

- DIN EN 12953-12: Shell BoilersDocument20 pagesDIN EN 12953-12: Shell BoilersBergechseNo ratings yet

- ASTM F1545 Plastic Lined Pipe 0803 PDFDocument6 pagesASTM F1545 Plastic Lined Pipe 0803 PDFdavi rodriguesNo ratings yet

- Comparison ASME B31.1, B31.3 and B31.8Document12 pagesComparison ASME B31.1, B31.3 and B31.8MAHESH CHAND100% (6)

- Materials For Hydrofluoric Acid Service in The New Millennium (51300-01345-Sg)Document48 pagesMaterials For Hydrofluoric Acid Service in The New Millennium (51300-01345-Sg)arnoldbatista55100% (1)

- STD PIP VECV1001 2012 Design Criteria and Purchasing Requirements For Vessels Div 1 & 2Document28 pagesSTD PIP VECV1001 2012 Design Criteria and Purchasing Requirements For Vessels Div 1 & 2Nikunj KNo ratings yet

- Compare ASME Vs EN CodeDocument10 pagesCompare ASME Vs EN CodeMPhamNo ratings yet

- Asme BPVC - Ssc.vii - Ii.v.ix - Xiii-2023Document54 pagesAsme BPVC - Ssc.vii - Ii.v.ix - Xiii-2023mmendozagNo ratings yet

- Asme Section 1 Ped GuideDocument89 pagesAsme Section 1 Ped Guide조의식67% (3)

- Shell - DEP - 31.22.20.31 PRESSURE VESSELS Table VIII-1Document1 pageShell - DEP - 31.22.20.31 PRESSURE VESSELS Table VIII-1Sulist N Wahyudie100% (1)

- Asme Sec Viii Div 1 Vs Asme Viii Div 2Document3 pagesAsme Sec Viii Div 1 Vs Asme Viii Div 2Jignesh ShahNo ratings yet

- Cryogenic Vessel Construction GuideDocument48 pagesCryogenic Vessel Construction Guideridershan05100% (1)

- Tema HexDocument7 pagesTema HexPrashanthMNairNo ratings yet

- Welcome To: Training Program On ASME Sec. VIII Div. 1Document120 pagesWelcome To: Training Program On ASME Sec. VIII Div. 1Wilson Wilfredo Yucra Paco100% (1)

- PED Awareness FouressDocument107 pagesPED Awareness FouressutreshwarmiskinNo ratings yet

- Design Life of Pressure VesselsDocument5 pagesDesign Life of Pressure VesselsChanchal GuptaNo ratings yet

- Pressure Vessel Specification - WoodsideDocument48 pagesPressure Vessel Specification - Woodsidevnedimovic100% (4)

- ExchangerDocument17 pagesExchangerJulio Adolfo López PortocarreroNo ratings yet

- Appendix 41Document5 pagesAppendix 41Rafael_YevgenyNo ratings yet

- TEMA Standards Inquiries 2020Document24 pagesTEMA Standards Inquiries 2020Nisarg Patel100% (1)

- Asme Sec 1 SimplifiedDocument16 pagesAsme Sec 1 Simplifiedramundt83% (6)

- SA-105/SA-105M Specification for Carbon Steel Forgings for Piping ApplicationsDocument8 pagesSA-105/SA-105M Specification for Carbon Steel Forgings for Piping Applicationsedisson_barrera100% (1)

- Item Rev Title Notes Units Design Data Supplier Data (Note B) Operation DataDocument4 pagesItem Rev Title Notes Units Design Data Supplier Data (Note B) Operation DataSteve WanNo ratings yet

- ASME CourseDocument283 pagesASME Courseeng_far100% (5)

- Air-Cooled Heat ExchangersDocument16 pagesAir-Cooled Heat Exchangersalex200301No ratings yet

- NEMA SM 23-1991 Steam Turbines For Mechanical Drive ServiceDocument64 pagesNEMA SM 23-1991 Steam Turbines For Mechanical Drive Serviceameltod100% (1)

- Anodes in Cooling Water Exchangers PDFDocument12 pagesAnodes in Cooling Water Exchangers PDFcbrittaivNo ratings yet

- Table A.2 NACE MR0175Document1 pageTable A.2 NACE MR0175azilahnazriNo ratings yet

- ASME Sec VIII - AwarenessDocument33 pagesASME Sec VIII - AwarenessNirmal100% (4)

- The Stress Analysis of Pressure Vessels and Pressure Vessel Components: International Series of Monographs in Mechanical EngineeringFrom EverandThe Stress Analysis of Pressure Vessels and Pressure Vessel Components: International Series of Monographs in Mechanical EngineeringS. S. GillRating: 3.5 out of 5 stars3.5/5 (3)

- Stress in ASME Pressure Vessels, Boilers, and Nuclear ComponentsFrom EverandStress in ASME Pressure Vessels, Boilers, and Nuclear ComponentsNo ratings yet

- Pressure Vessel and Stacks Field Repair ManualFrom EverandPressure Vessel and Stacks Field Repair ManualRating: 4 out of 5 stars4/5 (4)

- Hydrogen in Steel: Effect of Hydrogen on Iron and Steel During Production, Fabrication, and UseFrom EverandHydrogen in Steel: Effect of Hydrogen on Iron and Steel During Production, Fabrication, and UseNo ratings yet

- 09-00 - Shell and Tube Heat Exchangers For Routine ServiceDocument17 pages09-00 - Shell and Tube Heat Exchangers For Routine ServiceFolayemiNo ratings yet

- EGE13B10Document46 pagesEGE13B10Jhonny Rafael Blanco CauraNo ratings yet

- STD Spec - Pig TrapsDocument10 pagesSTD Spec - Pig TrapsArun MishraNo ratings yet

- Anchor Rods: ManufacturingDocument22 pagesAnchor Rods: Manufacturingjacopap100% (1)

- ASMEDocument7 pagesASMEASI.KHMED100% (1)

- Technical-specs-Heat ExchangersDocument96 pagesTechnical-specs-Heat ExchangerssudokuNo ratings yet

- 15250-194-EN04-SP-005-Rev 0 (Specification For Atmospheric Storage Tank)Document22 pages15250-194-EN04-SP-005-Rev 0 (Specification For Atmospheric Storage Tank)sudokuNo ratings yet

- Structural Analysis and Design of Process EquipmentDocument360 pagesStructural Analysis and Design of Process EquipmentSurya Tej88% (8)

- Standard Specification: UOP Engineering Department Date Status SPNSR ApvdDocument5 pagesStandard Specification: UOP Engineering Department Date Status SPNSR ApvdsudokuNo ratings yet

- Hot Insulation Specification GuideDocument55 pagesHot Insulation Specification Guideapply19842371No ratings yet

- 6-18-7 Flow Meters and Pressure InstrumentsDocument9 pages6-18-7 Flow Meters and Pressure InstrumentssudokuNo ratings yet

- 6-14-9 Control ValvesDocument14 pages6-14-9 Control ValvessudokuNo ratings yet

- Nozzle flange pressure calculationDocument2 pagesNozzle flange pressure calculationsudokuNo ratings yet

- ASTM A388 Standard Practice For Ultrasonic Examination of Heavy Steel ForgingsDocument8 pagesASTM A388 Standard Practice For Ultrasonic Examination of Heavy Steel ForgingsGonzalo TelleríaNo ratings yet

- E-001 - Hydrotest Device (Loose Ring) - OutDocument13 pagesE-001 - Hydrotest Device (Loose Ring) - OutsudokuNo ratings yet

- E010 - Hydrotest Gland RingDocument5 pagesE010 - Hydrotest Gland RingsudokuNo ratings yet

- Basics 2016Document81 pagesBasics 2016andy131078No ratings yet

- KettleDocument185 pagesKettlesudokuNo ratings yet

- PipeDocument44 pagesPipesudokuNo ratings yet

- 350 - Tray Installation Manual - EngDocument36 pages350 - Tray Installation Manual - EngRashid MadathilNo ratings yet

- Training Manual For PVelite Basic LevelDocument41 pagesTraining Manual For PVelite Basic LevelsudokuNo ratings yet

- 2917 HXGN LIVE 2917 DelaforceDocument58 pages2917 HXGN LIVE 2917 DelaforceVitor OlivettiNo ratings yet

- Allowable Stress PDFDocument6 pagesAllowable Stress PDFsudokuNo ratings yet

- NI-0253 - J Pressure Vessel DesignDocument45 pagesNI-0253 - J Pressure Vessel DesignsudokuNo ratings yet

- Rayleigh Method Versus Eigenvalue MethodDocument6 pagesRayleigh Method Versus Eigenvalue MethodCY Lee0% (1)

- B564Document11 pagesB564razvandanutNo ratings yet

- Buckling Stress Check For A Vertical VesselDocument11 pagesBuckling Stress Check For A Vertical Vesselmechengg01No ratings yet

- Standard Stud Heavy Hex Nut Specs Peste 4 InchDocument1 pageStandard Stud Heavy Hex Nut Specs Peste 4 InchsudokuNo ratings yet

- Declaration g4 g7Document1 pageDeclaration g4 g7sudokuNo ratings yet

- Astm A194m 15 PDFDocument13 pagesAstm A194m 15 PDFsudokuNo ratings yet

- Ultrasonic Examination of Heavy Steel Forgings: Standard Practice ForDocument7 pagesUltrasonic Examination of Heavy Steel Forgings: Standard Practice ForbatataNo ratings yet

- Research Design Elements for ScenariosDocument25 pagesResearch Design Elements for Scenariosrohizal ibrahimNo ratings yet

- Coupled Mode TheoryDocument5 pagesCoupled Mode TheoryRahul RoyNo ratings yet

- Sound Wave Interference and DiffractionDocument79 pagesSound Wave Interference and DiffractionMuhammad QawiemNo ratings yet

- ApudDocument53 pagesApudlatifahNo ratings yet

- Liability WaiverDocument1 pageLiability WaiverTop Flight FitnessNo ratings yet

- DEFCON ManualDocument13 pagesDEFCON Manualbuyvalve100% (1)

- Savable Data Page - Its Configuration, Usage & ExecutionDocument20 pagesSavable Data Page - Its Configuration, Usage & ExecutionsurmanpaNo ratings yet

- QDA Miner 3.2 (With WordStat & Simstat)Document6 pagesQDA Miner 3.2 (With WordStat & Simstat)ztanga7@yahoo.comNo ratings yet

- Responsibility Centres: Nature of Responsibility CentersDocument13 pagesResponsibility Centres: Nature of Responsibility Centersmahesh19689No ratings yet

- TransformerDocument50 pagesTransformerبنیاد پرست100% (8)

- Lecture7 PDFDocument5 pagesLecture7 PDFrashidNo ratings yet

- Risk Ology ManualDocument2 pagesRisk Ology ManualGregoryNo ratings yet

- Rejoinder To Adom Ochere's Misrepresentation - FinalDocument3 pagesRejoinder To Adom Ochere's Misrepresentation - FinalFuaad DodooNo ratings yet

- Lenex 3.0 Technical DocumentationDocument31 pagesLenex 3.0 Technical DocumentationGalina DNo ratings yet

- Successful Organizational Change FactorsDocument13 pagesSuccessful Organizational Change FactorsKenneth WhitfieldNo ratings yet

- Brightline Guiding PrinciplesDocument16 pagesBrightline Guiding PrinciplesdjozinNo ratings yet

- PB Engine Kappa EngDocument20 pagesPB Engine Kappa EngOscar AraqueNo ratings yet

- Laporan Mutasi Inventory GlobalDocument61 pagesLaporan Mutasi Inventory GlobalEustas D PickNo ratings yet

- Assignment 2 - p1 p2 p3Document16 pagesAssignment 2 - p1 p2 p3api-31192579150% (2)

- Verifyning GC MethodDocument3 pagesVerifyning GC MethodHristova HristovaNo ratings yet

- Unit 13 AminesDocument3 pagesUnit 13 AminesArinath DeepaNo ratings yet

- Sugar Milling Contract DisputeDocument3 pagesSugar Milling Contract DisputeRomy IanNo ratings yet

- Building A Computer AssignmentDocument3 pagesBuilding A Computer AssignmentRajaughn GunterNo ratings yet

- Equity AdvisorDocument2 pagesEquity AdvisorHarshit AgarwalNo ratings yet

- Triblender Wet Savoury F3218Document32 pagesTriblender Wet Savoury F3218danielagomezga_45545100% (1)

- WSM 0000410 01Document64 pagesWSM 0000410 01Viktor Sebastian Morales CabreraNo ratings yet

- Air Cycle Refrigeration:-Bell - Coleman CycleDocument21 pagesAir Cycle Refrigeration:-Bell - Coleman CycleSuraj Kumar100% (1)