Professional Documents

Culture Documents

Automationmethodology PDF

Uploaded by

juniorOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Automationmethodology PDF

Uploaded by

juniorCopyright:

Available Formats

Process Automation A methodology

A paper for automation engineers

Process Automation a methodology

Overview

This paper describes an approach to the development of highly automated process automation

systems. The methodology covers all aspects of the life cycle from requirements definition through

implementation to validation, and can be applied concurrently with the project design engineering

on a fast-track project.

The paper demonstrates how the use of diagrams, matrices, data classification, and databases can

provide excellent documentation improve visibility of the development process and reduce errors in

the final system. It discusses the advantages of software tools.

Key issues include

Involving the process engineers and the users

Using their experience and process knowledge

The value of modelling

Prototyping

The paper includes a modular diagrammatic analysis of a hygienic storage area as an example.

ControlDraw Ltd, 2002

Author Francis Lovering1

11

Francis Lovering has had a long a diverse career in the process control industries, working at all stages of the life

cycle. He now runs ControlDraw Ltd, and concentrates on providing tools to assist suppliers and users in the automation

industry, whilst still working as a practitioner of control systems design.

Copyright ControlDraw Ltd, 2002

www.controldraw.com

Page 1 of 16

Process Automation A methodology

Contents

Overview ...............................................................................................................................................1

Introduction ..........................................................................................................................................3

Establishing the Requirements ..........................................................................................................3

Functional Requirements Analysis.....................................................................................................4

The Model .............................................................................................................................................5

Process Cell Diagrams ........................................................................................................................5

Unit diagrams .....................................................................................................................................6

Equipment modules diagrams ............................................................................................................7

Control Modules diagrams..................................................................................................................8

Recipe Procedure diagrams................................................................................................................9

Operation and Phase diagrams ........................................................................................................10

Model Review Process.......................................................................................................................11

Prototyping .........................................................................................................................................12

Get the right team .............................................................................................................................13

Succeeding at speed .........................................................................................................................14

Find out more.....................................................................................................................................15

Copyright ControlDraw Ltd, 2002

www.controldraw.com

Page 2 of 16

Process Automation A methodology

Introduction

This paper describes an approach for process automation engineers to use to provide process

automation systems for bio/chemical/food processes.

The approach covers all aspects of the life cycle from requirements definition through

implementation to validation.

The methodology described in this paper was originally developed, and could still be achieved using

standard PC diagramming tools, along with spreadsheets and databases and of course word

processing. The method adapts well developed software engineering practises and adds knowledge

of modern process control and the capabilities of DCS and PLC systems via an IEC61113 type of

structure.

Note: Production using ControlDraw is much faster and more accurate, since all the diagrams, data

and matrices are stored in a single database file. There are many other benefits from using

ControlDraw that this paper does not discuss.

Establishing the Requirements

The detailed requirements are to be found in several places including

Engineering diagrams such as Process Flow sheets and Piping & instrument diagrams

The Control and operability philosophy if one exists

Process descriptions

Peoples Heads

The last of these is always the most difficult to obtain. What is required is a way to elucidate this

knowledge and build it into the Functional Design. This is achieved by the clarity of the design and

the Review procedure, which is described later in the paper.

Copyright ControlDraw Ltd, 2002

www.controldraw.com

Page 3 of 16

Process Automation A methodology

Functional Requirements Analysis

This includes finding out and then describing the detailed functional requirements what the

objects are and how they should be controlled.

The process should ensure that:

End users have the opportunity to input and can make sure that their requirements are

considered.

Design is carried out in a rational and documented way

Important design decisions are not made by programmers whilst coding (which can be a

recipe for problems)

The process includes

The decomposition of the process and recipes into the S88 physical and procedural objects

The detailed design of each of these objects

Mapping these into the standard system functions. During the system independent stage the

mapping is done into generic standard modules.

The resulting design is contained in a Functional Requirements Model, hereafter just called the

model.

The process uses the Models and Terminology defined in the ISA standard S88.01. There are

however many interpretations of S88. Different understandings of operations versus phases are

common the same sometimes applies to Equipment Modules versus Control Modules. Unless the

standard is narrowed down, there is still a lot of room for inconsistencies and misunderstanding.

For this a document the Design Principles document - is written to clarifies the extent to which

the choices that are allowed in S88 apply to the particular project. It also shows the way Units,

Equipment Modules, Operations are defined. The Design Principles document also provides a

description of generic control mechanisms that are common to the entire process, and describes in

general terms how the diagrams and tables define the required Control and Operational activities.

This includes:

Generic control requirements for both normal operation and exception handling.

The structure of the model.

The use of diagrams.

The use of matrices.

The use of tables and lists of data.

How various control objects (items such as units, equipment modules, control modules,

recipe procedures etc) are defined.

HMI aspects of the model

Standard module designs

Note The Design Principles document could also be a ControlDraw model - see also Reference

models in other ControlDraw papers.

Copyright ControlDraw Ltd, 2002

www.controldraw.com

Page 4 of 16

Process Automation A methodology

The Model

The Model comprises a collection of linked diagrams and tables.

The S88 Physical and Procedural Hierarchies are captured in the relationships between the

diagrams. For example, on a process cell diagram a single symbol represents a Unit. This Unit is

then detailed on a diagram containing the Equipment and Control modules in the Unit. Thus the

Process Cell contains the Unit and the Unit contains the EMs and CMs exactly as per the S88

Physical model

The details of what is shown on each diagram depend on the type of diagram.

All Diagrams contain relevant references for example the P&ID number and revision are shown on

physical model diagrams, and on procedural diagram references to the process description. These

helps to provide an audit trail back to the preceding documentation

The following are examples on the diagrams in a model. Note - yellow boxes with numbers in

represent links to diagrams that contain the description of the particular object.

Process Cell Diagrams

A process flow diagram of the Units and Common Resource,

Icons for each Recipe

Recipes

123

Matrl A Receive Store Deliver

Storage A or B

124

Matrl B Receive Store Deliver

Storage A or B

125

Matrl C Receive Store Deliver

Storage A or B

126

Matrl D Receive Store Deliv

Storage A or B

PID 0123456

CIP Supply

un1A

un1B

Matrl B

Matrl B

Matrl A and Matrl B

Supply

6

cr1X

Matrl B

Delivery

un2A

un2B

Matrl A,

Matrl A,

17

9

cr2X

Matrl A

Delivery

18

11

cr3Y

Matrl C

Supply

un3B

Matrl C

Matrl C

13

13

cr2Z

cr3Z

CIP Return Pump

CIP Return Pumps

CIP Return Pumps

90

90

90

CIP return

CIP return

cr3X

Matrl C

Delivery

20

11

cr1Z

un3A

CIP return

Sterilisation

36

Copyright ControlDraw Ltd, 2002

www.controldraw.com

Page 5 of 16

Process Automation A methodology

Unit diagrams

These comprise:

A process flow diagram of the equipment modules and control modules (such as

Measurement devices) that are in the unit. Note if a control module is only relevant within

an equipment module then it is shown in the Equipment module rather than in the unit

diagram.

A symbol for each operation.

Interface Objects modules that control the communication between units and common

resources.

The Unit state matrix a table that shows the settings for the equipment modules for each

state that the Unit can be set to.

Parent Symbols:

5 - Process Cell 1

.... , un1A, un1B

P&ID 012345 Rev x

Unit Operations

134

Stop

115 IF to/from CIP Unit

194A

CIP Supply A

CIP Supply

140

143

Filling

JT001

101

em03

em02

Agitator

Cooling

142

LT001

Notes

101

Storage Tank

17

Can NOT fill vessel on top of a previous batch.

CIP after each consumed batch

Simutaneous Filling and Delivery NOT required

TT001

em01

CIP

CIP Vessel

Brine

T01

117 IF from Brine

136

Delivery

15

16

Discharge

101

Graphic Note

10

The graphic for this unit w ill include the

details of all the equipment modules

CIP

17

Matrl A or Matrl B

Supply

6

Matrl B Delivery

17

IF to/from Distribution Unit 113

113 IF to/from Supply Unit

CIP Return

90

IF to/from CIP Unit 116

Run

un StorageTank

Passive

Ready to Fill

Ready to

Deliver

Ready to

CIP Vessel

Stop

Fill

Deliver

CIP Vessel

Hold

Store

Discharge

CIP Vessel

Drain

Passive

Stop

Hold

Ready to Fill

Fill

Store

Ready to Deliver

Deliver

Discharge

Ready to CIP Vessel

CIP Vessel

CIP Vessel Drain

em01

em02

em03

Off

Off

Off

Ready to Fill

Fill

Store

Ready to Deliver

Deliver

Discharge

Ready to CIP

CIP

CIP Drain

Off

Off

Off

Off

Run

Run

Run

Run

Off

Off

Off

Off

Off

Off

Off

Off

On

On

On

On

Off

Off

Off

Off

Copyright ControlDraw Ltd, 2002

www.controldraw.com

Page 6 of 16

Process Automation A methodology

Equipment modules diagrams

A process flow diagram showing the control modules that are in the equipment

A symbol for each state of the equipment module

An Equipment state matrix that shows the settings for the control modules for each state

that the EM can be set to.

V902

CIP Supply

CIP Supply

94

V914

93

Parent Symbols:

9 - un StorageTank

.... , em01

T01

Weight

0

Calculation 103

LT001

V201

96

ZSL001

V211

CIP

Matrl B Delivery

Line

95

V212

Fill

Matrl A / Matrl B

CIP

95

V205

V901

93

EM States

94

Off

V931

Ready to Fill

Ready to

Deliver

Ready to

CIP

Fill

Deliver

CIP

Store

Discharge

CIP Drain

CIP Return

93

Unit to CIP IF

119

Supply to Storage IF

Note

34

Storage to Sterilser IF

This Valve is Applicable

to Matrl C only

35

0

em01 SDOS Storage Main

Off

Ready to Fill

Fill

Store

Ready to Deliver

Deliver

Discharge

Ready to CIP

CIP

CIP Drain

V902

V914

V201

V211

V212

V901

V931

V205

V210

Thru

Thru

Thru

Thru

Thru

Thru

Thru

Divert

Divert

Thru

Close

Close

Close

Close

Close

Close

Close

Open

Open

Open

Close

Open

Open

Open

Open

Open

Open

Open

Open

Open

Through

Through

Through

Through

Mix

Mix

Through

Through

Through

Through

Through

Mix

Mix

Through

Through

Through

Through

Through

Through

Through

Thru

Thru

Thru

Thru

Thru

Thru

Thru

Divert

Divert

Thru

Close

Close

Close

Close

Close

Close

Close

Open

Open

Open

Close

Close

Close

Close

Close

Close

Open

Close

Close

Close

Close

Close

Enable

Enable

Enable

Enable

Close

Close

Close

Close

Note in this particular model the equipment modules do not have their own operations or phases.

They are set to the required state by the Unit Operations. This is not the only way that the

methodology can be organised.

Copyright ControlDraw Ltd, 2002

www.controldraw.com

Page 7 of 16

Process Automation A methodology

Control Modules diagrams

A symbol for each operator interface, such as auto-manual switches

A symbol for each control system input and output

A definition of the control logic of the module

DCS Lib "ValveCIPMP_xxx

Valve type per physical valve type (xxx) - from

valve spec

Manual

Manual Command

0 = close, 1 = Open

Operator set

Valve Driver

Auto / Manual

Auto/Manual

0 = manual, 1 = Auto

Fail

'Fail to Close' Alarm and 'Fail to Open' on valve w ith ZSC.

Alarm tagname on Sattline in both cases = "Unit_Vnnn_Alarm"

(Note: Alarm can be disabled)

Auto

Auto Command - From EM

State Matrix

From Unit Hold

Standard Auto/Manual.

Stroke Count

Travel is timed in each

direction. Timeout causes

Fail to Open or Fail to Close

Alarm.

The same Travel Time value

is used in the case of 2 limit

s w itches

Hold

Hold Action

Determines w hether to

open, close, be controlled

or stay put if in Hold.

Default to Close (for Fail

closed valves)

can be Reset

Open / Close

Valve status Log

can be Enabled / Disabled

Stroke Count - Upper

can be Reset

TMR

Maximum Travel Time

Stroke Count Lower

can be Reset

OVRC

Override Closed - If set to

1 the Limit sw itch is

ignored (Open = OVRO)

DIClosed

ZSC

Closed Limit Sw itch

(Open = ZSO)

Sov

Interlock Condition

Set false by interlock

logic if required to

deenergize output

CIP Station Flip number

From CIP Unit

efSov

States

Compare

SovU

Out = ValveFlip =

CIPStnFlip

Valve Flip Group Number 1

Upper SOV

Low er SOV

Thru

Clean

Upper

Open =

Mix

Clean

Lower

Sov

Compare

Valve Flip Group Number 2

Close =

SovL

Out = ValveFlip =

CIPStnFlip

Sov

Flip Group handling

Clean Upper w hen the value from the CIP station = Valve Flip group 1

Clean Low er w hen the value from the CIP station = Valve Flip group 2

Can Not Clean Upper and Low er at the same time. (Upper takes preference)

Can Not Clean w hen in Mix position

Note

Separate drivers w ill not be provided for fail open or fail

closed types or ZSO or ZSC types, these w ill be

identified in the instances table

Copyright ControlDraw Ltd, 2002

www.controldraw.com

Page 8 of 16

Process Automation A methodology

Recipe Procedure diagrams

The recipe logic in S88.02 Procedure Function Chart format

A symbol for each Unit Procedure, Operation, Synchronisation etc

Acquire Mix Unit

Acquire Vessel

Batch

makeup

6

Matrl B

Delivery

Filling

140

Stop

6

Release Mix Unit

Delivery

142

Vessel Not Empty

Discharge

143

Vessel Empty

Note

Must run a CIP

recipe procedure

once vessel is

empty

Stop

144

Release Vessel

Copyright ControlDraw Ltd, 2002

www.controldraw.com

Page 9 of 16

Process Automation A methodology

Operation and Phase diagrams

The phase logic in SFC format

A symbol for each Recipe parameter and equipment parameter

Note that the steps in the operation act by setting the Unit to one of the unit states.

Init

T01_UnitRun

S01_Initialised

T02_Source Ready

Source "Ready" signal Set

S02_Store Weight

Store current Weight

To rpStore_Temp/In

Diagram 16

T03_Temp. OK

rpStore_Temp

Matrl B = x - y degC

Matrl C = x - y degC

Matrl A = N/A

Matrl D = N/A

T10_Temp not OK

TT001 <= epFill_Temp

Note

S03_Ready to Fill

'Set to Ready to Fill

epFill_Temp

The CM for the manual

valve V201 w ill prompt the

operator if the valve is not

in the correct state

Matrl B = x deg

Matrl A = x deg

Matrl C = x deg

Matrl D = N/A

T04_States Confirm

TT001 > epFill_Temp

S09_Prompt

"Can not start filling

temperature too high"

Confirm

EM States confirmed

rpStore_Time

Matrl B = 48 hours

Matrl A = N/A

Matrl C = N/A

Matrl D = N/A

S04_Set Ready

Destination "Ready" signal

Set

T05_Source Active

Source "Active" signal Set

Reset and Start

'Storage_Timer'

S05_Fill

Set to Fill

T06_Fill Complete

LT001 => epFill_Vol

OR

Source "Ready" signal Reset

epFill_Vol

Matrl B =x% volume

Matrl A = x% volume

Matrl C = x% volume

Matrl D = x% volume

S06_Reset Ready

Destination "Ready" signal

Reset

Note

T07_Source Reset

This timer is :Reset & Started in the Filling Operation

Stopped in the Delivery Operation

Source "Ready" signal Reset

S07_Calc Mat added

If Timer Preset Reached - give an

Operator Batch Manager sage

For Matrl C and Matrl D, the Timer is not

restarted if it is already running (filling

on top of a previous lot)

142

Store curent w eight and

calculate amount of material

added

BL_Received_Qty

Batch Log Total Received

T08_Logged by LMES

S08_Store

Set to Store

T09_States Confirm

EM States confirmed

End

Copyright ControlDraw Ltd, 2002

www.controldraw.com

Page 10 of 16

Process Automation A methodology

Model Review Process

The model is subject to regular and detailed reviews with all the parties involved in the project.

Typically this process is organised to work through the process cells and the units and into the

operations and phases. Prior to the review an Archive copy is taken of the model, and the review is

carried out using the Archived copy. The model is not generally changed during the review, instead

minutes are taken of the required changes and these are then implemented prior to the next

review.

The reviews begin with an introduction to the model, and a review of the Design Principles

document.

Generic Control Modules such as motors and valves are reviewed next. Since these provide much of

the manual operation facilities in the plant it is important that the functionality available through

these modules is understood before going into the details of the operations and phases.

Then the reviews move into the actual detail of the various process cells, units etc. This can include

simple simulations where the valves are opened and closed, motors started etc to show dynamically

the states of the equipment.

In fast track projects this is often timed to reflect the development of the process itself. It also

helps to start with some of the simpler areas so that by the time the more complex areas are

developed everyone has a good understanding of the methodology.

V902

Parent Symbols:

9 - un215A/B Vitamin StorageTank

.... , Filling

11 - un216A/B Salt Storage Tank

.... , Filling

13 - un138A/B Yeast Storage Tank

.... , Filling

25 - un137A/B Glucose Storage Tank

.... , Filling

CIP Supply

Init

P&ID KA JC 7 23 21601 00Rev 1(2)

CIP Supply

62

V210

Pluronic

V914

T01_UnitRun

61

Note

Parent Symbols:

13 - un138A/B Yeast Storage Tank

.... , em01

S01_Initialised

65

This valve can be manually

operated when enabled by

the PCS.

T02_Source Ready

Source "Ready" signal Set

S02_Store Weight

Store current Weight

1 9 3 - 3 K 2 .3 .1

2 0 1 - 2 K 2 .3 .1

Yeast Extract Storage Tank

Filling cannot start if the temperature in the storage tank is higher than 55C,

An operator message is given for temp. higher than T> 55C

Vitamin Buffer Tank

To rpStore_Temp/In

Diagram 16

T01

2 0 1 - 3 K 2 .3 .1

Salt Stock Storage Tank

Weight

Calculation

rpStore_Temp

V itamin = 5 - 10 degC

Yeast = 5 - 10 degC

Salt = N/A

Glucose = N/A

TT001 <= epFill_Temp

The CM for the manual

valve V201 will prompt the

operator if the valve is not

in the correct state

S09_Prompt

Vitamin = 55 deg

Salt = 55 deg

Yeast = 55 deg

Glucose = N/A

"Can not start filling

temperature too high"

V201

64

ZSL001

Confirm

T04_States Confirm

EM States confirmed

V211

138X

138X

CIP Supply

rpStore_Time

V itamin = 48 hours

Salt = N/A

Yeast = N/A

Glucose = N/A

LT001

TT001 > epFill_Temp

epFill_Temp

Note

S03_Ready to Fill

'Set to Ready to Fill

71

T10_Temp not OK

T03_Temp. OK

T05_Source Active

Source "Active" signal Set

S05_Fill

S05_Fill

Reset and Start

'Storage_Timer'

Set to Fill

Yeast Delivery Line

63

S04_Set Ready

Destination "Ready" signal

Set

V212

1 9 3 - 2 K 2 .3 .3

1 9 3 - 3 K 2 .3 .4

Carbohydrate Storage Tank

When the tank has reached its maximum

level, the pump on the filling line has to stop

(clear signal from control room is

cancelled).

Set point for maximum level (calculated

weight) within:

Yeast Extract Storage Tank

138Y

138Y

Yeast & CIP

CIP Return

63

2 0 1 - 2 K 2 .3 .2

V itamin Buffer Tank

V901

Manual Valve

2 0 1 - 3 K 2 .3 .2

EM States

Sewer

62

Off

V931

Ready to Fill

Ready to

Deliver

Ready to

CIP

Fill

Deliver

CIP

61

Active as

Source

Store

Discharge

CIP Drain

Active as

138Z

CIP Return

Note

78

This Valve is Applicable

to Vitamins only

The Diagram reviews are conducted by displaying each diagram on a screen using the ControlDraw

Reviewer and if there are any comments to be recorded then these are added as Yellow notes

during the meeting.

This automatically builds an MS Access database of the comments. If preferred reviewers can make

comments in the same way and send their comments database back to the modellers

Copyright ControlDraw Ltd, 2002

www.controldraw.com

Page 11 of 16

Process Automation A methodology

Prototyping

Software should be implemented in exact accordance with the design!

So they say. But programmers need some freedom, and direct influence; the following diagram

shows how Prototyping helps

Prototyping Partnership

ControlDraw Model

Functional Requirement

Specification

Requirement

Specification

Team

Prototype Producers

Prototype

Reviews

Test, Use

and Evaluate

Construct and Revise

Software

Recommendation - Build a prototype for a subset of the Model.

Use it:

Test the Functional Requirements Specification

Get Metrics about how long different tasks take

Test the Testing

Start code level standard modules.

Try Alternative software designs

Agree the User interface early on

Get the programmers to improve the model

Copyright ControlDraw Ltd, 2002

www.controldraw.com

Page 12 of 16

Process Automation A methodology

Get the right team

The project team should consists of the stakeholders in the whole life cycle - representatives of the

key areas. The following lists the ideal collection of team members:

The End users

They review the model for operational aspects, and often have detailed knowledge that can

help.

The Process Experts

Process engineers are needed to provide the process know how, often from Engineering

Contractors

They review the model in particular to look at the process aspects

They are also able to liase with other process engineers to ensure that the system design is

integrated with the process design.

The Model Builders

They have detailed knowledge of Process Control, S88, the methodology and the tools

Their primary role is to gather the available data and build the model, to conduct the model

reviews and ensure that the experts comments are taken on board.

The System Programmers

They have detailed knowledge of the target system.

Their primary role is to program the system according to the model. In the early stages,

when prototyping they have a key input into developing the methodology in order to ensure

that the resulting model will be easily programmed.

The Test and Validation Experts

They have knowledge of the requirements for FDA validation and experience of testing.

Their primary role is to review the model for testability and the carry out the test and

validation work.

It should noted that in fact all the team members contribute in their role but that they can also

contribute outside their official role if they have relevant knowledge. Often this is the case.

Copyright ControlDraw Ltd, 2002

www.controldraw.com

Page 13 of 16

Process Automation A methodology

Succeeding at speed

The implementation of successful Control Systems depends on having accurate detailed information

about the process under control. If the detailed process design could be completed before the

control system is started then there would not be a problem. However, it is in the nature of fast

track projects that changes occur, information arrives late and detail continues to develop late in

the detailed engineering phase.

For example:

Development of P&IDs still continuing into the detailed design.

Valves and instruments get added during Hazops

Changes of scope removing and adding equipment

Details of process packages become available late in the detailed design

The users who are going to have to run the plant do not get involved until late, and then

they wish to make changes and improvements to what they find.

On fast track projects the sheer speed of the project development forces the Control Systems

programming activity into a short time period. That is only possible if the information is present,

Consequently in order to provide the systems on time the development process must support

Rapid progress

The ability to cope with frequent change.

A data store that can be added to as soon as the information becomes available

The means to identify information and its validity - for example its release status.

Key points of the methodology that results in fast progress are:

The Functional Design is detailed, reviewed and approved before code is fully implemented.

The design, review and implementation activities are carried out almost concurrently. This is

of course phased so that the activities are serial for each small part of the project, such as

one Unit.

The closeness of the modellers to the Users and experts. Expertise and detailed

requirements are captured in developing the model before code is generated. It is far

quicker to modify a model than it is to change actual code.

The proximity of the modellers to the programmers. This greatly reduces the time spent by

for example the programmers trying to understand what was meant.

The Model forms the basis of the testing and validation.

Copyright ControlDraw Ltd, 2002

www.controldraw.com

Page 14 of 16

Process Automation A methodology

Find out more

ControlDraw and associates can provide:

the software to establish the system

the training to get you going

consulting on the management issues

skilled staff to help on your project

Contact fl@controldraw.com for quotations

Copyright ControlDraw Ltd, 2002

www.controldraw.com

Page 15 of 16

Process Automation A methodology

ControlDraw competes with:

Existing 20th century practises that are still widely in use.

Visio, Word, Excel, low grade Access databases

Not invented here syndrome.

We are not going to change mentality.

Some company internal standards

And Spec-Soft PFS

Copyright ControlDraw Ltd, 2002

www.controldraw.com

Page 16 of 16

You might also like

- SiteDocument2 pagesSitejuniorNo ratings yet

- Thermal Plant DiagramDocument1 pageThermal Plant DiagramjuniorNo ratings yet

- Fet UB Internship Report DetailDocument2 pagesFet UB Internship Report DetailjuniorNo ratings yet

- Organisational Structure of PamolDocument2 pagesOrganisational Structure of Pamoljunior100% (1)

- InteruptDocument3 pagesInteruptjuniorNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5784)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Lean & Environment ToolkitDocument96 pagesLean & Environment Toolkittinyplankton100% (7)

- EC6302 - Digital ElectronicsDocument6 pagesEC6302 - Digital ElectronicsAdal ArasuNo ratings yet

- Richard GrisenthwaiteDocument25 pagesRichard GrisenthwaitecaarthiyayiniNo ratings yet

- Masterful WiiFlow v4.2.3 Pack with Numerous UpdatesDocument4 pagesMasterful WiiFlow v4.2.3 Pack with Numerous UpdatesYulianNo ratings yet

- IJET 15473 Lavanya PDFDocument5 pagesIJET 15473 Lavanya PDFDr.S.Sujatha Asst.Prof.No ratings yet

- Accuret-A20: Electrical SpecificationsDocument2 pagesAccuret-A20: Electrical SpecificationsClaudio CalabreseNo ratings yet

- SEP2 MeterViewDocument23 pagesSEP2 MeterViewmarcofffmota3196No ratings yet

- Hazardous Area ClassificationDocument15 pagesHazardous Area ClassificationpmnasimNo ratings yet

- SLVR Cartas PDFDocument18 pagesSLVR Cartas PDFEdgar David Ruelas ClarosNo ratings yet

- Checklist for Training Cleaning StaffDocument1 pageChecklist for Training Cleaning StaffharrydrivesucrazyNo ratings yet

- Accedian Networks EtherNID MetroNID 2pg FINAL 083112 PDFDocument2 pagesAccedian Networks EtherNID MetroNID 2pg FINAL 083112 PDFMark LamondNo ratings yet

- Purwoko Arie Sujadi: ExperienceDocument4 pagesPurwoko Arie Sujadi: Experienceeriant014No ratings yet

- Manufacturing Process of Piston Rings and Cylinder LinersDocument26 pagesManufacturing Process of Piston Rings and Cylinder Linersanish jain100% (6)

- Euro FirefighterDocument2 pagesEuro FirefighterGustavo VydraNo ratings yet

- Beer and Johnston Detailed Table of ContentsDocument10 pagesBeer and Johnston Detailed Table of Contentsdhruv001No ratings yet

- Denison Hydraulics Goldcup Digital Hi-Iq Control: Electronic Control Card User Manual Software Version 2.2BDocument62 pagesDenison Hydraulics Goldcup Digital Hi-Iq Control: Electronic Control Card User Manual Software Version 2.2BHassan Haghighi TajvarNo ratings yet

- MEEN 364 Lecture 4 Examples on Sampling and Aliasing PhenomenaDocument5 pagesMEEN 364 Lecture 4 Examples on Sampling and Aliasing PhenomenaHiren MewadaNo ratings yet

- Gearbox Efficiency and LubricationDocument6 pagesGearbox Efficiency and Lubricationrashm006ranjanNo ratings yet

- Ernest H Hill Ltd Equipment Catalogue SummaryDocument17 pagesErnest H Hill Ltd Equipment Catalogue SummaryhillpumpsNo ratings yet

- AN2295Document52 pagesAN2295Fernando ArrowNo ratings yet

- NACA Report 184 The Aerodynamic Forces On Airship HullsDocument16 pagesNACA Report 184 The Aerodynamic Forces On Airship Hullsshatal16No ratings yet

- Max 223C Pipeline Welding InverterDocument2 pagesMax 223C Pipeline Welding InvertermtonellyNo ratings yet

- Structural Analysis With The Finite Element Method. Linear StaticsDocument1 pageStructural Analysis With The Finite Element Method. Linear StaticsluchogilmourNo ratings yet

- VAS5054ADocument3 pagesVAS5054AKarim ElmahrokyNo ratings yet

- THE William Francis Galvin, Secretary of The Commonwealth State Publications and RegulationsDocument54 pagesTHE William Francis Galvin, Secretary of The Commonwealth State Publications and Regulationsbubbo07No ratings yet

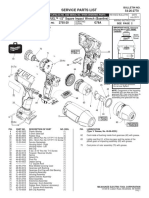

- 2755 22 (G78A) Milwaukee PBDocument2 pages2755 22 (G78A) Milwaukee PBZeckNo ratings yet

- Computer Software Testing TerminologyDocument99 pagesComputer Software Testing TerminologyoluninjaaNo ratings yet

- Viscosity and Normal Stress Differences in Molten PlasticsDocument30 pagesViscosity and Normal Stress Differences in Molten PlasticsAzizol WahabNo ratings yet

- Jsa-Wif-9 Pulling CableDocument12 pagesJsa-Wif-9 Pulling CableY a n i. A h m e dNo ratings yet

- Terminal Blocks: KasugaDocument6 pagesTerminal Blocks: KasugaKs MuraliNo ratings yet