Professional Documents

Culture Documents

US3126422 English

Uploaded by

Marike Bunga HarfintanaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

US3126422 English

Uploaded by

Marike Bunga HarfintanaCopyright:

Available Formats

Mam}!

24, 1964

J. A. PLANCHARD, JR

3,126,422

VAPOR PHASE DISPROPORTIONATION 0F AROMATICS

>

Filed March 16, 1961

a

:5

FEED: 9&5 % c,a

1.5 % ccl. 4

.1

E '0

>-

V,

/

/"

I

//

I!

I;

A50: 100% c7148

m>_

/

a

.J

FEED:98.5% c-ma

LSKy/

20

2g

>

1|

XFEED: 100% 07119

z

o

100

1 0

son

a o

900

950

TEMPERATURE, "F.

I000

CONVERSION AND XYLENE YIELD vs. TEMPERATURE

BENZENE

l9

I6

(20

TOLUENE

"R 22

23

7'77

///6

REACTION

///// -' l4

zous 7" /,///

//

"'7

"3

Fncnonrnou

zous

"-'

TOLUENE

INVENTOR.

JEROME A. PLANCHARD,

BY

FIG.2.

ATT RN

United States Patent O? ice

3,126,422

Patented Mar. 24, 1964

1

3,126,422

VAPOR PHASE DTSPROPORTIONATEON

0F AROMATICS

Jerome A. Planchard, Jr., Baytown, Tex., assignor, by

lnesne assignments, to Esso Research and Engineering

Company, Elizabeth, N.J., a corporation, of Delaware

Filed Mar. 16, 1961, Ser. No. 96,264

7 Claims. (Cl. 260671)

or as compounds thereof. When carbon tetrachloride is

employed, it may be injected with the feed. The amount

of chlorine may be within the range from about 0.5 to

about 5% by volume based on the feed hydrocarbon,

preferably within the range from about 0.5 to about 2.5%

by volume particularly when toluene is the feed. When

chlorine or anhydrous hydrogen chloride is used, they

also may be injected With the feed or, if desired, the

silica~alumina catalyst may be treated with the anhydrous

The present invention is directed to a method for dis 10 chlorine or hydrogen chloride prior to contacting same

proportionation of aromatic hydrocarbons.

More spe

ci?cally the invention is concerned with converting aro

With the aromatic feed hydrocarbon.

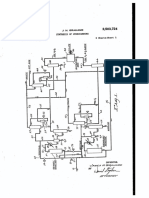

The present invention will be further described by ref

erence to the drawing in which:

matic hydrocarbons to other aromatic hydrocarbons. In

FIG. 1 is a plot of data showing the relationship be

its more speci?c aspects, the invention is concerned with

the production of aromatic hydrocarbons having a dif 15 tween temperature and conversion and between xylenes

yield and temperature; and

ferent number of carbon atoms than the aromatic feed

FIG. 2 is a flow diagram of preferred mode of prac

stock from which the product is found.

doing

the invention.

The present invention may be brie?y described as a

Referring now to the drawing and particularly to FIG.

method for disproportionation of aromatic hydrocarbons

in which a single ring aromatic hydrocarbon is contacted 20 2, numeral 11 designates a charge-line through which a

with a silica-alumina catalyst in the presence of a small

but su?icient amount of a halogen such as chlorine under

temperature and pressure conditions and in the presence

of free hydrogen for a length of time sui?cient to form

feed hydrocarbon such as toluene may be introduced

from a source not shown.

Hydrogen is introduced by

line 9 controlled by valve 10. Numeral 12 designates a

valve which controls line 11 and the aromatic feed hy

a disproportionated product. The disproportionated 25 drocarbon is introduced into line 13 leading into a re

action zone 14 provided with a bed 15 of silica-alumina

product is then recovered and may be separated into vari

catalyst. The toluene introduced by lines 11 and 13 is

ous component hydrocarbons.

in a heated condition su?icient to maintain a tempera

The feed stock of the present invention is the single

ture within the range from about 650 to about 1000 F.

ring aromatic hydrocarbons boiling within the range

from about 200 to about 600 F. The aromatic hydro 30 in reaction zone 14 under a pressure in the range from

about 200 p.s.i.g. to about 600 p.s.i.g. Conditions are

carbon feed may be a petroleum fraction containing aro

adjusted in zone 14 such that the toluene contacts the

matics or it may be a puri?ed aromatic hydrocarbon.

catalyst for a period of time from about 5 to about 40

As examples of the aromatic hydrocarbons found in the

seconds. Under these conditions, a product is formed

feed stock of the present invention may be mentioned

toluene, ortho-, meta- and para-Xylenes, ethylbenzene, 35 and in which the aromatic hydrocarbon feed is dispro

trimethylbenzene, tetramethylbenzene, ethylrnethylben

zene and the like. Other aromatic hydrocarbons may be

employed within the boiling range mentioned.

The catalyst employed in the practice of the present

portionated. The product discharged from zone 14 by

line 16 and introduced thereby into a fractionation zone

17 illustrated by a distillation tower which may be a

plurality of distillation towers as may be desired. Zone

invention is a silica-alumina catalyst having a ratio of 40 17 is provided with suitable internal vapor-liquid con

tacting means to allow separation among the products

silica to alumina within the range from about 9:1 to

of the disproportionation reaction. Conditions of tem

about 1:1. A satisfactory silica-alumina catalyst con

perature and pressure are adjusted in zone 17 by a heat

tains from about 25% of alumina oxide and about 75%

ing means illustrated by a steam coil 18. Under the

of silicon dioxide, both percentages being by weight.

The hydrogen employed in the practice of the present 45 distillation conditions prevailing in zone 17, an over

head fraction containing benzene is withdrawn by line 19

invention may be puri?ed hydrogen or may be a free

and a toluene side stream fraction is withdrawn by line

hydrogen containing gas. The amount of hydrogen em

20, which is the unconverted material. Xylenes are dis

ployed should be sui?cient to provide a ratio of hydrogen

charged and recovered by line 21. The unconverted

to feed aromatic hydrocarbon in the range from about

toluene may be discharged from the system by opening

0.5:1 to about 5:1. An amount of hydrogen from about

valve 22, but preferably the unconverted toluene is routed

600 cubic feet to about 6000 cubic feet per barrel of feed

through line 13 by opening valve 23 therein. Pump 24

may be used.

in line 13 allows the unconverted toluene to be reintro

The chlorine employed in the practice of the present in

duced into reaction zone 14.

vention may be provided from various compounds. For

By virtue of an operation such as described in FIG. 2,

example, gaseous chlorine or hydrogen chloride may be

benzene and xylene may be produced from toluene and

used both in an anhydrous condition. Liquid carbon

the toluene recycled to extinction.

v

tetrachloride may also be used, such as those having 2

In order to illustrate the invention further, several runs

to 6 alkyl groups on the ring, said alkyl groups contain

have been carried out in which a silica-alumina catalyst

ing 1 to 6 carbon atoms. Other chlorine-providing com

pounds may be employed, such as, methyl chloride, meth

was employed. In one series of runs, the feed stock had

ylene chloride, CHCls and the corresponding ?uoride and

added to it, carbon tetrachloride, and in another series

of runs, the feed stock did not contain carbon tetrachlo

bromide compounds. Iodine may also be used as such

3,126,422

ride. The conditions for the several runs, and the results

thereof, as well as the analysis of the products, are shown

for a sufficient length of time to form a disproportion

ated product, said alkyl benzene being selected from the

group consisting of toluene, ethylbenzene, and alkyl ben

in the following table:

TABLE I

Vapor Phase Toluene Disproportionation

Run ________________________________________ __

Catalyst ____________________________________ __

AlzO:-SiO2 (25-75% by Wt.)

Feed, Percent by Vol _______________________ __ (98.5% toluene G1; 1.5% 001i)

(100% toluene)

Run Conditions:

Temperature, F ________ __

750

851

943

751

848

947

Press. (p.s.i.g.)

Flow rate, volumes/ho

400

258

400

237

400

218

400

257

400

257

400

217

Hg/oi _______________ __

1. 1

0. 9G

1. 1

1. 07

1. 07

0. 94

26

27

26

27

25

28

6.17

8.55

Time of contact, seconds.

Liquid Composition, Wt. Percent:

Benzene ________________________________ __

Xylene ____ __

Toluene_ _ _ __

12.00

12.83

75. 17

19. 66

13. 64

66. 70

1.83

2. 55

7. 48

8. 98

15. 25

13.12

85. 28

95. 62

83. 54

71. 63

Total ________________________________ __

100. 00

100. 00

100. 00

100. 00

100. 00

100. 00

Conversion, Wt. Percent ____________________ _.

14. 7

24. S

33. 3

4. 4

16. 5

28. 3

The data in Table I are plotted in FIG. 1.

zenes having 2 to 6 alkyl groups on the ring, said alkyl

Referring to FIG. 1 and Table I, it may be seen that

groups containing from 1 to 6 carbon atoms, and recover

under identical conditions the feed stock containing the 30 ing said product.

carbon tetrachloride provided three times the conversion

2. A method in accordance with claim 1 wherein said

of toluene at 750 F. while the xylene yield was 8.5%

halogen is present in an amount within the range from

compared to 2.6% where the feed was free of chlorine.

about 0.5 to about 5.0% by volume.

A great advantage of the present invention is that the

3. A method in accordance with claim 2 wherein said

same xylene yield may be obtained from toluene at ap 35 time is within the range from about 5 to about 40 sec

proximately a 100 F. lower reaction temperature. For

onds to form said disproportionated product.

example, at 950 F. in the chlorine~free feed, a xylene

4. A method in accordance with claim 3 wherein said

yield of 13.1% was obtained, while in the chlorine-con

alkyl benzene is toluene.

taining feed at 850 F., the yield was 12.8%. It may also

5. A method in accordance with claim 3 wherein said

be noted that at 850 F. in the chlorine-containing feed, 40 alkyl benzene is xylene.

the conversion was approximately 3% less than in the

6. A method which comprises introducing into a dis

chlorine-free feed at 950 F. indicating a higher selec

proportionation zone an aromatic hydrocarbon consist

tivity to disproportionation, which may be obtained at the

ing essentially of toluene containing from about 0.5 to

lower temperature without sacri?cing xylene yield. The

about 2.5% by volume of carbon tetrachloride to con

45

lower temperatures therefore decrease the percentage of

tact a silica-alumina catalyst at a temperature within the

gas and coke for a given yield. If high yields of benzene

range from about 650 F. to about 1000 F. under a

are desired, a 41/2 % increase in benzene yield may be ob

pressure within the range from about 200 to about 600

tained by operating under identical conditions, say for

pounds per square inch in the presence of a sui?cient

example, 950 F.

amount of free hydrogen to provide a ratio of hydrogen

to toluene within the range from about 0.5 :1 to about 5:1

It may be seen from the following data that the present

for a length of time within the range from about 10 to

invention is quite advantageous and useful in that the

about 60 seconds to form a disproportionated product,

presence of chlorine in the reaction zone provides for in

and recovering benzene and xylene from said product.

creases in yields at the same temperature or the same

7. A method which comprises introducing into a dis

yield at substantially lower temperatures. The present

proportionation zone an aromatic hydrocarbon consisting

invention is therefore advantageous and useful in that

essentially of a single alkyl benzene selected from the

aromatic hydrocarbons may be produced at substantial

group consisting of toluene, ethylbenzene, and alkyl ben

savings in operating costs and investment.

zenes having 2 to 6 alkyl groups on the ring, said alkyl

The nature and objects of the present invention having

1been completely described and illustrated, what I wish 60 groups containing 1 to 6 carbon atoms to contact a silica

alumina catalyst in the presence of a halogen selected

to claim as new and useful and secure by Letters Patent

from the group consisting of chlorine and chlorine-pro

1s:

viding compounds at a temperature and under a pressure

1. A method which comprises introducing into a dis

and in the presence of free hydrogen for a length of time

proportionation zone an aromatic hydrocarbon consist

su?icient to form a disproportionated product, and recov

ing essentially of a single alkyl benzene to contact a

silica-alumina catalyst in the presence of a halogen 65 ering said product.

selected from the group consisting of chlorine and chlo

rine-providing compounds at a temperature within the

range from about 650 F. to about 1000 F. under a

pressure within the range from about 200 to about 600

70

pounds per square inch and in the presence of a su?icient

amount of free hydrogen to provide a ratio of hydrogen

to feed within the range from about 0.5:1 to about 5:1

References Cited in the ?le of this patent

UNITED STATES PATENTS

2,349,834

2,385,524

Schmerling et al _______ __. May 30, 1944

Mattox _____________ __ Sept. 25, 1945

2,739,991

Hervert _____________ __ Mar. 27, 1956

2,834,821

Bergsteinsson ________ __ May 13, 1958

You might also like

- US3093691Document2 pagesUS3093691Ayu GirlsNo ratings yet

- S SSS L, SS S SS SN S SS S: March 19, 1968 N. L. Carr Etal 3,374,280Document4 pagesS SSS L, SS S SS SN S SS S: March 19, 1968 N. L. Carr Etal 3,374,280toastcfhNo ratings yet

- United States Patent Office: As The Central Atom On A CarrierDocument4 pagesUnited States Patent Office: As The Central Atom On A CarrierRasoulNo ratings yet

- Light Monoolefins From Methanol And/or Dimethyl Ether: BonifazDocument12 pagesLight Monoolefins From Methanol And/or Dimethyl Ether: BonifazSp4rkZ87No ratings yet

- 49 2 Philadelphia 10-04 1181Document4 pages49 2 Philadelphia 10-04 1181lumengentiunNo ratings yet

- Separating C8 Aromatic Hydrocarbons by Series Column DistillationDocument4 pagesSeparating C8 Aromatic Hydrocarbons by Series Column DistillationAnonymous 8dSjJVHsEkNo ratings yet

- Us 4899000Document5 pagesUs 4899000Karen Vanessa GonzalezNo ratings yet

- US1915354Document6 pagesUS1915354Muhammad Akbar FahleviNo ratings yet

- Us 2498806Document7 pagesUs 2498806regina pramuditaNo ratings yet

- United States Patent Office: Patented Feb. 6, 1951Document3 pagesUnited States Patent Office: Patented Feb. 6, 1951karmilaNo ratings yet

- United States Patent Of?ce: Patented June 17, 1969Document3 pagesUnited States Patent Of?ce: Patented June 17, 1969Rawlinson TolentinoNo ratings yet

- United States Patent 0: Patented Feb. 4, 1969Document3 pagesUnited States Patent 0: Patented Feb. 4, 1969Stella AguirreNo ratings yet

- Coking Kinetics On The Catalyst During Alkylation of FCC Off-Gas With Benzene To EthylbenzeneDocument7 pagesCoking Kinetics On The Catalyst During Alkylation of FCC Off-Gas With Benzene To EthylbenzeneAndres PeñaNo ratings yet

- US2462413 FormaldehydeDocument5 pagesUS2462413 FormaldehydeRuchita PoilkarNo ratings yet

- Manufacture of Ethyl Benzene Using Zeolite CatalystDocument8 pagesManufacture of Ethyl Benzene Using Zeolite CatalystMario VensfiseCrewNo ratings yet

- Catalytic alkylation of alkyl-substituted aromatics with graphite catalystDocument4 pagesCatalytic alkylation of alkyl-substituted aromatics with graphite catalystMOHAMMED SHAKEIBNo ratings yet

- Manufacturing Proceses for Styrene ProductionDocument9 pagesManufacturing Proceses for Styrene ProductionMohd Zulazreen50% (2)

- Edz 1Document14 pagesEdz 1Joshua Peter Evangelista CadoyNo ratings yet

- 4-Hydroxy Coumarin PatentDocument4 pages4-Hydroxy Coumarin PatentAfzal PathanNo ratings yet

- MetoxidoDocument8 pagesMetoxidocessavelinoNo ratings yet

- United States Patent Office: Patented Mar. 21, 1950Document2 pagesUnited States Patent Office: Patented Mar. 21, 1950alexNo ratings yet

- Non-Catalytic Pyrolysis of Ethane To Ethylene in The Presence of CO2 With or Without Limited O2Document7 pagesNon-Catalytic Pyrolysis of Ethane To Ethylene in The Presence of CO2 With or Without Limited O2Sharry ApudNo ratings yet

- Process For AADocument15 pagesProcess For AASantiago BorgesNo ratings yet

- Material Balance SheetDocument4 pagesMaterial Balance Sheetsyed waheed ul hasanNo ratings yet

- Us 3767726Document4 pagesUs 3767726Sujan BasyalNo ratings yet

- United States Patent: Patented Dec. 5, 1967Document6 pagesUnited States Patent: Patented Dec. 5, 1967Attila TamasNo ratings yet

- Solute Leaching and Dissolution Rate CalculationDocument13 pagesSolute Leaching and Dissolution Rate CalculationHayley AñonuevoNo ratings yet

- Production of Specialty Chemicals From A Coal Gasification Acid Gas Waste StreamDocument26 pagesProduction of Specialty Chemicals From A Coal Gasification Acid Gas Waste StreamAbubakar Ahmed MagzoubNo ratings yet

- Efficient Process for Preparing Acetic Anhydride from AcetoneDocument3 pagesEfficient Process for Preparing Acetic Anhydride from AcetoneMary Grace VelitarioNo ratings yet

- Jan-27, 1959 ' - G. Baecklund 2,870,866: Method of Obtaining Acetaldehyde ' Filed June 14, 1952Document3 pagesJan-27, 1959 ' - G. Baecklund 2,870,866: Method of Obtaining Acetaldehyde ' Filed June 14, 1952MuhlisaApriliaNo ratings yet

- Process of Production CS2 PDFDocument9 pagesProcess of Production CS2 PDFDinii Lathiifah PertiwiNo ratings yet

- United States Patent (10) Patent N0.: US 6,743,952 B2Document8 pagesUnited States Patent (10) Patent N0.: US 6,743,952 B2Rizka AndhikaNo ratings yet

- United States Patent (191: (75) Inventor: Roy B. Flay, Concord, CalifDocument4 pagesUnited States Patent (191: (75) Inventor: Roy B. Flay, Concord, CalifArunNo ratings yet

- Improved method for concentrating cumene hydroperoxide from oxidation productsDocument3 pagesImproved method for concentrating cumene hydroperoxide from oxidation productsSiswand BIn Mohd AliNo ratings yet

- EP0884278A1Document7 pagesEP0884278A184105851No ratings yet

- United States Patent 1191: Tu (45) Sep. 7, 1982Document4 pagesUnited States Patent 1191: Tu (45) Sep. 7, 1982AdyNo ratings yet

- United States Patent O?ice: 15H: LLQ?ZDocument3 pagesUnited States Patent O?ice: 15H: LLQ?ZadamNo ratings yet

- Jozmim: Feb. 17, 1953 B. V. Aller EtalDocument7 pagesJozmim: Feb. 17, 1953 B. V. Aller EtalFatonaRifkyPNo ratings yet

- CHE 202 TUTORIAL QUESTIONSDocument6 pagesCHE 202 TUTORIAL QUESTIONSFawziyyah AgboolaNo ratings yet

- AMMONIA PROCESS SIMULATIONDocument8 pagesAMMONIA PROCESS SIMULATIONChecoCastilloNo ratings yet

- Cooling Tower and Absorption Column CalculationsDocument3 pagesCooling Tower and Absorption Column CalculationsSummer Wynn Dacwag0% (1)

- United States Patent Office: Patented June 23, 1970Document2 pagesUnited States Patent Office: Patented June 23, 1970MãdãlinaStanciuNo ratings yet

- ISOBUTYLENE SYNTHESIS FROM SLURRY AND TRICKLE BED REACTORSDocument5 pagesISOBUTYLENE SYNTHESIS FROM SLURRY AND TRICKLE BED REACTORSDHe Vic'zNo ratings yet

- United States Patent Office: Patented June 29, 1948Document3 pagesUnited States Patent Office: Patented June 29, 1948jhartmann8No ratings yet

- US2179218Document2 pagesUS2179218LESLI RODRIGUEZ BENDEZUNo ratings yet

- Overview of The ProcessDocument10 pagesOverview of The ProcessChaitanya PottiNo ratings yet

- Us2503724 - Ca2941105a1Document8 pagesUs2503724 - Ca2941105a1Facundo MendezNo ratings yet

- Iso 2Document3 pagesIso 2AnnisaDwiOctavianiNo ratings yet

- Conversion of Glycerol To AcroleinDocument7 pagesConversion of Glycerol To AcroleinShahzaib IftikharNo ratings yet

- Process For The Production of Alkylbenzene: ResumenDocument19 pagesProcess For The Production of Alkylbenzene: ResumenEliana MejiaNo ratings yet

- Integrated Process For The Production of Vinyl Acetate From Acetic Acid Via Ethyl AcetateDocument44 pagesIntegrated Process For The Production of Vinyl Acetate From Acetic Acid Via Ethyl Acetatearif ihwandaNo ratings yet

- Acetaldehyde Methods 2520of 2520 ProductionDocument6 pagesAcetaldehyde Methods 2520of 2520 Productionapi-3714811100% (3)

- European Patent Application: Process and Plant For Ammonia-Urea ProductionDocument16 pagesEuropean Patent Application: Process and Plant For Ammonia-Urea ProductionRashminda AttanayakeNo ratings yet

- Practice QuestionsDocument2 pagesPractice QuestionsAhmad MuzammilNo ratings yet

- CALCULATIONDocument4 pagesCALCULATIONYushene Sarguet100% (1)

- New organic compounds and methods of manufacturing themDocument3 pagesNew organic compounds and methods of manufacturing themmac9papNo ratings yet

- Heat and MassDocument13 pagesHeat and MassMohammed AliraqiNo ratings yet

- Transition Metal Catalyzed Furans Synthesis: Transition Metal Catalyzed Heterocycle Synthesis SeriesFrom EverandTransition Metal Catalyzed Furans Synthesis: Transition Metal Catalyzed Heterocycle Synthesis SeriesNo ratings yet

- Process Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersFrom EverandProcess Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersNo ratings yet

- US3126422 EnglishDocument3 pagesUS3126422 EnglishMarike Bunga HarfintanaNo ratings yet

- Uni Sttutgart Fixed Packed Bed ReactorsDocument40 pagesUni Sttutgart Fixed Packed Bed ReactorsMoises RomeroNo ratings yet

- Chap01 PDFDocument24 pagesChap01 PDFMarike Bunga HarfintanaNo ratings yet

- Lamp IranDocument5 pagesLamp IranMarike Bunga HarfintanaNo ratings yet

- US3126422 EnglishDocument3 pagesUS3126422 EnglishMarike Bunga HarfintanaNo ratings yet

- Reactors Series ParallelDocument17 pagesReactors Series ParallelMarike Bunga HarfintanaNo ratings yet

- US7176339 Xylene Using ReformateDocument14 pagesUS7176339 Xylene Using ReformateMarike Bunga HarfintanaNo ratings yet

- BpsfileDocument1 pageBpsfileMarike Bunga HarfintanaNo ratings yet

- Reactors Series ParallelDocument17 pagesReactors Series ParallelMarike Bunga HarfintanaNo ratings yet

- ) : Failed To Open Stream: HTTP Request Failed! HTTP/1.1 404 Not Found in /home/20ebooks/public - Html/libs/curl - Force - Download - PHP On Line 52Document1 page) : Failed To Open Stream: HTTP Request Failed! HTTP/1.1 404 Not Found in /home/20ebooks/public - Html/libs/curl - Force - Download - PHP On Line 52Marike Bunga HarfintanaNo ratings yet

- Fuels: Classification and Calorific ValueDocument79 pagesFuels: Classification and Calorific ValueRahul Reddy100% (1)

- Latihan HydrocarbonDocument9 pagesLatihan HydrocarbonThilagaNo ratings yet

- ChemestryDocument71 pagesChemestryTophani BarisalaNo ratings yet

- Aromatic CompoundsDocument55 pagesAromatic CompoundsNadine Bacalangco100% (1)

- Paraffin & Asphaltene Chemicals IES-World-Oil-ArticleDocument4 pagesParaffin & Asphaltene Chemicals IES-World-Oil-Article1mmahoneyNo ratings yet

- Tests For The Functional Groups (Theory) - Class 12 - Chemistry - Amrita Online Lab PDFDocument17 pagesTests For The Functional Groups (Theory) - Class 12 - Chemistry - Amrita Online Lab PDFAkhil Mishra100% (1)

- Properties of Hydrocarbon- (n-hexane, cyclohexene and tolueneDocument4 pagesProperties of Hydrocarbon- (n-hexane, cyclohexene and tolueneChan Jiun Haur83% (6)

- Chem 120.1 (R141) - Group2, Exercise 7&8Document8 pagesChem 120.1 (R141) - Group2, Exercise 7&8Jerwin JavierNo ratings yet

- IP391 - 2007 - Determination of Aromatic Hydrocarbon Types in Middle Distillates - High Performance Liquid Chromatography Method With Refractive Index Detection (RID)Document12 pagesIP391 - 2007 - Determination of Aromatic Hydrocarbon Types in Middle Distillates - High Performance Liquid Chromatography Method With Refractive Index Detection (RID)Constantinos ChristodoulouNo ratings yet

- Answer All Questions in This SectionDocument6 pagesAnswer All Questions in This SectionAri AdiantariNo ratings yet

- Experiment No. 1: Hydrocarbon ReactionsDocument8 pagesExperiment No. 1: Hydrocarbon ReactionsBitterground Corp.No ratings yet

- MEL1 (3) Fuels& CombustionDocument22 pagesMEL1 (3) Fuels& CombustionEnriv Yasilad83% (6)

- A-Level Chemistry NotesDocument10 pagesA-Level Chemistry NotesHannah Bryson-JonesNo ratings yet

- Organic Chemistry Homologous Series Boiling PointsDocument82 pagesOrganic Chemistry Homologous Series Boiling PointsJm GarciaNo ratings yet

- Petroleum Refining Composition and ClassificationDocument5 pagesPetroleum Refining Composition and ClassificationSaad NadeemNo ratings yet

- Lecture Planner - Organic Chemistry - Prayas JEE 2024Document2 pagesLecture Planner - Organic Chemistry - Prayas JEE 2024tannan75ptNo ratings yet

- Chapter 13 HydrocarbonsDocument23 pagesChapter 13 HydrocarbonsTreasure SeekerNo ratings yet

- Chapter 12. Practice Problems Part I. Do As IndicatedDocument2 pagesChapter 12. Practice Problems Part I. Do As IndicatedAlwyn Dave AmbataliNo ratings yet

- FAQ On Hydrocarbons in Compressed Air SystemsDocument3 pagesFAQ On Hydrocarbons in Compressed Air Systemshadi.pgdNo ratings yet

- Petroleum Gases, Liquefied Petroleum Gas: IdentificationDocument4 pagesPetroleum Gases, Liquefied Petroleum Gas: IdentificationdigecaNo ratings yet

- Cambridge IGCSE™ Chemistry 4th Edition (Bryan Earl, Doug Wilford) (Z-Library)Document18 pagesCambridge IGCSE™ Chemistry 4th Edition (Bryan Earl, Doug Wilford) (Z-Library)Muhammad TayyabNo ratings yet

- The Non-Organic Theory of The Genesis of PetroleumDocument20 pagesThe Non-Organic Theory of The Genesis of Petroleumzaroia100% (8)

- Basra University For Oil and Gas (BUOG) : PETE210, 1 SemesterDocument34 pagesBasra University For Oil and Gas (BUOG) : PETE210, 1 SemesterBa NeenNo ratings yet

- Organic chemistry notesDocument41 pagesOrganic chemistry notesrana alweshah100% (1)

- Woody biomass combustion catalyzed by manganese dioxideDocument99 pagesWoody biomass combustion catalyzed by manganese dioxideVILLAINZ83No ratings yet

- c15368hc PDFDocument118 pagesc15368hc PDFLuis ArayaNo ratings yet

- Siemens Transformers Materials Influence Diagnostics Stray GassingDocument6 pagesSiemens Transformers Materials Influence Diagnostics Stray GassingmanuelNo ratings yet

- Technical Guide On Internal Audit Issued by ICAI - Oil & Gas (Downstream)Document117 pagesTechnical Guide On Internal Audit Issued by ICAI - Oil & Gas (Downstream)Sarang SinghNo ratings yet

- Physical Sciences P2 Additional Exemplar Eng 2008Document22 pagesPhysical Sciences P2 Additional Exemplar Eng 2008quikgoldNo ratings yet

- Chemical Recycling of Plastic Wastes Made From Polyethylene (LDPE and HDPE) and Polypropylene (PP)Document7 pagesChemical Recycling of Plastic Wastes Made From Polyethylene (LDPE and HDPE) and Polypropylene (PP)Imanol FuenNo ratings yet