Professional Documents

Culture Documents

QS W01 PDF

Uploaded by

HMAOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

QS W01 PDF

Uploaded by

HMACopyright:

Available Formats

WELDER PERFORMANCE QUALIFICATION (WPQ)

07 .Rue El Moulazem El Bjeoui, El Manz.ah

V. 2037 Ariana, TUNISIE Tl:

71 231

735 // Fax: 71 231 745

CERTIFICAT DE QUALIFICATION DU SOUDEUR

(AWS D1.1 Stuctural Welding Code Steel )

Date : 22/11/2016

Location of exam/ Lieu de test : SFAX

Rapport N/ Report N : QS 255/16

Welder's name/ Nom de soudeur : Naser Lahwel

Identification N :

W 01

Client : Jupiter

CIN/ Passport N : 05334209

TEST DESCRIPTION / DESCRIPTION DU TEST

Test coupon

WPS/ PQR N : WPS-01

Production weld

Specification of base metal(s)/ Spc, de mtal de base : A 106 Gr B

Thickness/ Epaisseur : 7,11 mm

Type of joint (Groove or fillet)/ Type de joint : Groove weld

Welding position/ Position de soudage : 6G

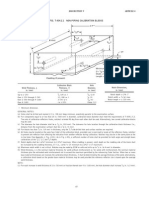

TESTING CONDITIONS & QUALIFICATION LIMITS/ CONDITIONS DE TEST & LIMITES DE QUALIFICATION

Welder Variables (QW-350)

Actual Values

Range Qualified

GTAW / SMAW

GTAW / SMAW

Manuel

Manuel

Without Backing

With and Without Backing

6"

2" 7/8

P-No. 1/1

P-No. 1 through P-No. 15F,

P-No. 34, and P-No. 41 through P-No. 49

SFA 5.18 / SFA-5.1

***

Welding process(es)/ Procds de soudage

Type of welding / Type de soudure: (manual, semi-auto, automatic, machine)

Backing (metal, weld metal, double-welded,ect)/

Support l'envers (Matriaux, mtal d'apport, soudure des deux cot, etc.)

Plate/ T le

Pipe/ Tube

(Enter diameter if pipe)

Base metal P-Number or S-Number

Filler metal or electrode specification(s) (SFA)

Filler metal or electrode classification(s) (AWS)

Filler metal F-Number(s)

ER70S6 / E7018

***

F-No. 6/1 / F-No.4/1

(F-No. 1, F-No. 2, F-No. 3, F-No. 4) With Backing

and ALL F-N6

flux coted solid

flux coted solid

Filler metal product form (solid/metal or flux cored/powder)

Deposit thickness of each process (mm) [ 3 layers]

Process 1: SMAW

3 layers minimum

Yes

No

Process 2: GTAW

3 layers minimum

Yes

No

Process 1: 3 mm

Process 1:

T 6 mm

Process 2:

Process 2:

T 8,22 mm

Position qualified / Position qualifie (2G, 6G, 3F, etc.)

All Groove and Fillet

6G

Welding progression (uphill or downhill)

Fillet weld qualified with groove

4,11 mm

Uphill

Yes

Qualified to make fillet weld of any size on all base material thicknesses and pipe

diameters of any size.

No

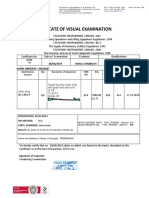

TESTING AND EXAMINATION/ ESSAIS ET EXAMEN

TEST

Performed by

Visual Examination

RT examination

UT examination

PT examination

MT examination

Bend test

Report No

PIC

Macrographic test

Fracture test

Results

Acceptable

PIC

IE0173/RT/01

Laboratory CMEM

Acceptable

Acceptable

Others Tests

Welding supervised by: Naser Lahwel

Assistance sheet for the qualification No.:

Cutting & machining performed by: NA

Mechanical tests performed by: Laboratory CMEM

RESULT/ RESULTATS

The welder is declared qualified and can weld within the above range of parameters.Le soudeur est dclare qualifi et peut souder dans l'intervalle des paramtres ci-dessus.

We certify that the statements in this record are correct and that the test coupons were prepared, welded, and tested in accordance with the requirements of section IX of the ASME code.

Nous certifions que les dclarations de cet enregistrement sont correctes et que les prouvettes d'essai sont prpars souds et tests en conformit avec les exigences de la section IX code ASME

Inspector/ Inspecteur

Checked by/ Vrifi par

Date:

10/12/2016

Date:

Name:

Maher ben hmida

Name :

Function :

Visa :

10/12/2016

Mourad hamdi

Technical Manager

Visa :

07 .Rue El Moulazem El Bjeoui, El Manz.ah V. 2037 Ariana, TUNISIE Tl: 71 231 735 // Fax: 71 231 745

You might also like

- WPQ Ejcom Nr476Document13 pagesWPQ Ejcom Nr476Touil HoussemNo ratings yet

- Bs en Iso 17637 PreviewDocument8 pagesBs en Iso 17637 PreviewUlviyye ElesgerovaNo ratings yet

- Radiography CalculationsDocument1 pageRadiography CalculationsAhmadiBinAhmadNo ratings yet

- Coflexip Hose (Tr1-031851clm303)Document1 pageCoflexip Hose (Tr1-031851clm303)RonniNo ratings yet

- 021 002 362 - Rev9 Phasor - XsDocument202 pages021 002 362 - Rev9 Phasor - XsAnonymous qz5pEMh44100% (1)

- BS en 1371-1 2011 PDFDocument30 pagesBS en 1371-1 2011 PDFMaximiliano O.No ratings yet

- 186-19 Wpqc-W162-2''-Asme XiDocument1 page186-19 Wpqc-W162-2''-Asme Xibouchoucha jebaliNo ratings yet

- NDT Services Offer LetterDocument1 pageNDT Services Offer LettersdlincNo ratings yet

- Macrographic Examination Report: Fillet SizeDocument1 pageMacrographic Examination Report: Fillet SizenourhenNo ratings yet

- En 13927 - 2003Document12 pagesEn 13927 - 2003gorkembaytenNo ratings yet

- Radiographic Examination Procedure For Asme CodeDocument33 pagesRadiographic Examination Procedure For Asme CodeEdAlmNo ratings yet

- Chain Block ChecklistDocument1 pageChain Block ChecklistChinedu AchilikeNo ratings yet

- Weld-Solution en LTR 201712 WebDocument8 pagesWeld-Solution en LTR 201712 WebLương Hồ VũNo ratings yet

- 4#600 Body RSSDocument1 page4#600 Body RSSRavi patelNo ratings yet

- Esl Industrial Support Services TRICHY-09: Instrument ListDocument2 pagesEsl Industrial Support Services TRICHY-09: Instrument ListJayaneela Prawin100% (1)

- Almansoori Inspection Services: Lifting Equipment Thorough Examination ReportDocument2 pagesAlmansoori Inspection Services: Lifting Equipment Thorough Examination ReportRanjithNo ratings yet

- Exam Azure - 533 - March - 2015Document95 pagesExam Azure - 533 - March - 2015AlexanderNo ratings yet

- Radiograph Acceptance Criteria ChartDocument1 pageRadiograph Acceptance Criteria ChartTURNO100% (2)

- Pmi Louis Proserv 3Document6 pagesPmi Louis Proserv 3Ebit TrisnoNo ratings yet

- TCR Arabia Company Magnetic Particle Testing ReportDocument1 pageTCR Arabia Company Magnetic Particle Testing ReportRonel John Rodriguez CustodioNo ratings yet

- 13. 0983-23 RT-056-056 DNE-USE จ.พะเยา Pipe Ø 1800 T. 16.0 mm 19-7-23Document14 pages13. 0983-23 RT-056-056 DNE-USE จ.พะเยา Pipe Ø 1800 T. 16.0 mm 19-7-23Wisüttisäk PeäröönNo ratings yet

- CCJ 3q 2014 Full Issue PDFDocument136 pagesCCJ 3q 2014 Full Issue PDFJeeEianYannNo ratings yet

- PA Probe Catalog EN 201608 Web PDFDocument32 pagesPA Probe Catalog EN 201608 Web PDFDennis Chai100% (1)

- Penetrameter SelectionDocument13 pagesPenetrameter SelectionShailendra BhadoriaNo ratings yet

- Examination Procedure: G.C. Van Der Stoep Procedure TechnicianDocument30 pagesExamination Procedure: G.C. Van Der Stoep Procedure TechnicianEdAlmNo ratings yet

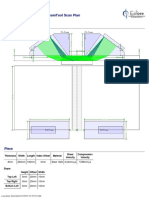

- Beamtool Scan Plan: Inspection LayoutDocument4 pagesBeamtool Scan Plan: Inspection LayoutMohan RajNo ratings yet

- Adhesion Cross-Cut Test ExampleDocument2 pagesAdhesion Cross-Cut Test ExampleRaduNo ratings yet

- Corporate Profile: For A Secure SocietyDocument14 pagesCorporate Profile: For A Secure SocietyAjay SinghNo ratings yet

- CND Normes StandardsDocument4 pagesCND Normes StandardsRebecca RileyNo ratings yet

- Defective Sample & PhotographsDocument10 pagesDefective Sample & PhotographssanNo ratings yet

- International Limited: Certificate of Visual Examination and MpiDocument2 pagesInternational Limited: Certificate of Visual Examination and MpiMichael OkwuwaNo ratings yet

- 2037-PL-PL-0058-FR-T-025 Dated 18.12.19Document12 pages2037-PL-PL-0058-FR-T-025 Dated 18.12.19Dadaso Baburao JamdarNo ratings yet

- Tofd & Pe ReportDocument1 pageTofd & Pe ReportLuong Ho VuNo ratings yet

- Austenitic Weld Inspection Solution OverviewDocument17 pagesAustenitic Weld Inspection Solution OverviewRupam BaruahNo ratings yet

- Quotation - Cotation: Description Du Travail / Work DescriptionDocument1 pageQuotation - Cotation: Description Du Travail / Work DescriptionmkpqNo ratings yet

- Lrut Job Preparation Questionnaire Long Range Guided Wave InspectionDocument4 pagesLrut Job Preparation Questionnaire Long Range Guided Wave Inspectionkucing_batamNo ratings yet

- 1303-9 Chain Sling..Document2 pages1303-9 Chain Sling..khalilNo ratings yet

- NDT ArabicDocument38 pagesNDT Arabicinsiderr0% (1)

- Excel slicer shape guideDocument317 pagesExcel slicer shape guideallen zacariasNo ratings yet

- IAEA Module - Basic Math for Radiation ProtectionDocument91 pagesIAEA Module - Basic Math for Radiation Protectionado666eddie100% (1)

- Annex Form J2 D1.1 D1.1M 2020 PDFDocument3 pagesAnnex Form J2 D1.1 D1.1M 2020 PDFDarioNo ratings yet

- Requirements For Non-Destructive Examination Methods Eddy CurrentDocument21 pagesRequirements For Non-Destructive Examination Methods Eddy Currentzemog001No ratings yet

- BLOQUEDocument1 pageBLOQUEAlvaro Alexis Mendoza PradaNo ratings yet

- Manual USLT2000 PDFDocument66 pagesManual USLT2000 PDFvrapciudorianNo ratings yet

- NullDocument9 pagesNullMichael OkwuwaNo ratings yet

- Modular Fabrication Facility Welder Qualification RecordDocument7 pagesModular Fabrication Facility Welder Qualification RecordAvijit DebnathNo ratings yet

- 8c 3 Dao Caulder AOS TPAC Next Generation Phased Array UT Total Focusing MethodDocument52 pages8c 3 Dao Caulder AOS TPAC Next Generation Phased Array UT Total Focusing Methodmkjbkm,sbkjm,nNo ratings yet

- 2018 NDT Product Catalog A17323 3Document48 pages2018 NDT Product Catalog A17323 3Pedro DonatoNo ratings yet

- 3.PAUT Qualification ProcedureDocument8 pages3.PAUT Qualification ProcedurePhan Tri ThongNo ratings yet

- EPOCH LT Training Presentation: Introduction and Basic OperationDocument58 pagesEPOCH LT Training Presentation: Introduction and Basic Operationdhasdj100% (1)

- E1079Document2 pagesE1079Renato Barreto100% (1)

- Procedure: "Straight Beam/Angle Beam Manual Ultrasonic Testing"Document21 pagesProcedure: "Straight Beam/Angle Beam Manual Ultrasonic Testing"mangalraj900No ratings yet

- Astm Reference Block For MetalDocument10 pagesAstm Reference Block For MetalrupamNo ratings yet

- TOFDDocument39 pagesTOFDLương Hồ Vũ100% (1)

- Experienced NDT engineer CVDocument6 pagesExperienced NDT engineer CVTrung Tinh HoNo ratings yet

- Lecture 18-UTDocument50 pagesLecture 18-UTsamrn850% (2)

- Example Report TOFD 2 INT-GP1186-09-70 PDFDocument1 pageExample Report TOFD 2 INT-GP1186-09-70 PDFEMTC EMTCNo ratings yet

- WPQ Template (Asme Ix) No LogoDocument4 pagesWPQ Template (Asme Ix) No LogorcpretoriusNo ratings yet

- Weld Joint 1Document81 pagesWeld Joint 1rajibali27100% (1)

- Invitation Task 2Document4 pagesInvitation Task 2Muhammad Shandy AdityaNo ratings yet

- Undulating Periodization For Bodybuilding PDFDocument24 pagesUndulating Periodization For Bodybuilding PDFEva Alam Nejuko Chan100% (1)

- Shop Crue Product DataDocument7,232 pagesShop Crue Product DataMehul DasNo ratings yet

- NY Giants Strength ProgramDocument15 pagesNY Giants Strength Programxarxacalcio100% (1)

- Argentina 9 Contents PDFDocument13 pagesArgentina 9 Contents PDFceciliaNo ratings yet

- Rooms For Fhsaa Region MeetDocument3 pagesRooms For Fhsaa Region Meetosho99No ratings yet

- 45 06 Parkour Vaults PDFDocument4 pages45 06 Parkour Vaults PDFDudeNo ratings yet

- Paket Data Elektrik TerbaruuuuDocument3 pagesPaket Data Elektrik TerbaruuuuNanto SNo ratings yet

- Velocity, Distance & Acceleration 1 QPDocument11 pagesVelocity, Distance & Acceleration 1 QPsarkodie kwameNo ratings yet

- ml7 Se ch05 Sec5 2 Page165to170Document6 pagesml7 Se ch05 Sec5 2 Page165to170charlesshijo1No ratings yet

- The BBTT Program REV PDFDocument40 pagesThe BBTT Program REV PDFBianca Lacramioara Florea100% (3)

- MERIDA Bikes Catalogue 2017 INT Web PDFDocument228 pagesMERIDA Bikes Catalogue 2017 INT Web PDFSan Ban CastroNo ratings yet

- Eclectic Bassist Timothy Emmons ProfileDocument4 pagesEclectic Bassist Timothy Emmons ProfileSelçuk Canberk DağtekinNo ratings yet

- ATA-HandBook-SCHOOL WORKSHEET PDFDocument34 pagesATA-HandBook-SCHOOL WORKSHEET PDFcepolNo ratings yet

- Automotive Systems and Components GuideDocument5 pagesAutomotive Systems and Components GuideManiKjNo ratings yet

- Anatomy of Hip JointDocument5 pagesAnatomy of Hip JointSneha ParveenNo ratings yet

- Lab Aula2 ParametrosDocument1 pageLab Aula2 ParametrosMarcoNo ratings yet

- BD 2022.periodo BD 2022.cedula BD 2022.nombre Horas 059Document24 pagesBD 2022.periodo BD 2022.cedula BD 2022.nombre Horas 059ejbohorqNo ratings yet

- Behaviour Checklist For Primary SchoolsDocument4 pagesBehaviour Checklist For Primary SchoolsElliot Alfaro FallasNo ratings yet

- Toyota R150 R151Document4 pagesToyota R150 R151Christian Rhadames Barkley Chavez100% (1)

- Trepel HighloaderDocument97 pagesTrepel HighloaderWaleed LemsilkhiNo ratings yet

- 01 Viktor Korchnoi - WikipediaDocument8 pages01 Viktor Korchnoi - WikipediaAThaddeusAntonioNo ratings yet

- 2018 COSSA Track and Field ResultsDocument41 pages2018 COSSA Track and Field ResultsPeterborough ExaminerNo ratings yet

- Case Presentation - Closed Fracture Radius Ulna PediatricDocument30 pagesCase Presentation - Closed Fracture Radius Ulna PediatriciamboredtiredNo ratings yet

- William's Doll: by Marlo ThomasDocument1 pageWilliam's Doll: by Marlo ThomasJanice CrenciaNo ratings yet

- Britain and Ghana: A Comparison of Daily LifeDocument4 pagesBritain and Ghana: A Comparison of Daily LifeNicoll RodríguezNo ratings yet

- Ties - Hr+sbaDocument3 pagesTies - Hr+sbatkarrardohaNo ratings yet

- Unit 4 Final DraftDocument8 pagesUnit 4 Final Draftapi-284490400No ratings yet

- Rear Suspension: SectionDocument22 pagesRear Suspension: SectionLino Bello RezamanoNo ratings yet

- Ancient Indian SportsDocument43 pagesAncient Indian Sportsgagansharma84100% (2)