Professional Documents

Culture Documents

qsm11 g1nr2

Uploaded by

Eslam MansourOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

qsm11 g1nr2

Uploaded by

Eslam MansourCopyright:

Available Formats

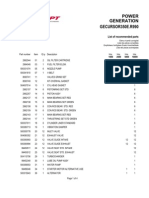

CUMMINS ENGINE COMPANY, INC

Basic Engine Model:

Curve Number:

QSM11-G1 Nonroad 2

FR-2930

Engine Critical Parts List:

Date:

CPL: 8062

18Sep01

Columbus, Indiana 47201

ENGINE PERFORMANCE CURVE

Displacement : 10.8 liter (661 in3)

Bore : 125 mm (4.92 in.) Stroke : 147 mm (5.79 in.)

No. of Cylinders : 6

Aspiration : Turbocharged and Charge Air Cooled

Engine Speed

Standby Power

Prime Power

G-DRIVE

QSM

1

Continuous Power

RPM

kWm

BHP

kWm

BHP

kWm

BHP

1500

257

345

234

314

199

267

1800

295

395

268

359

228

305

Emissions Certification

This engine complies with certain emissions requirements established by US EPA/CARB and the German TA-LUFT. See Exhaust Emissions Data Sheet for conformance specifics.

Engine Performance Data @ 1500 RPM

OUTPUT POWER

%

kWm

BHP

FUEL CONSUMPTION

kg/

kWmh

lb/

BHPh

liter/

hour

60.0

STANDBY POWER

100

257

345

0.199

0.327

61

40.0

100

234

314

0.201

0.331

56

14.7

75

176

236

0.201

0.331

42

11.0

50

117

157

0.204

0.335

28

7.5

25

59

79

0.223

0.367

16

4.1

30.0

20.0

10.0

CONTINUOUS POWER

199

1500 RPM

50.0

16.0

PRIME POWER

100

Litre / hour

70.0

U.S. Gal/

hour

267

0.0

.201

.331

48

12.5

25

50

75

100

125

150

175

200

225

250

275

Gross Engine Output - kWm

Engine Performance Data @ 1800 RPM

OUTPUT POWER

%

kWm

FUEL CONSUMPTION

kg/

kWmh

lb/

BHPh

liter/

hour

U.S. Gal/

hour

395

0.202

0.332

70

18.5

BHP

U.S. Gallons / hour

20.0

1800 RPM

15.0

STANDBY POWER

100

295

10.0

PRIME POWER

100

268

359

0.199

0.327

63

16.5

75

201

269

0.201

0.330

48

12.6

50

134

180

0.209

0.343

33

8.7

25

67

90

0.233

0.383

19

4.9

5.0

0.0

0

CONTINUOUS POWER

100

228

CONVERSIONS:

305

.200

.329

(liters = U.S. Gal x 3.785)

54

14.2

(Engine kWm = BHP x 0.746)

50

100

150

200

250

300

350

Gross Engine Output -BHP

(U.S. Gal = liters x 0.2642)

(Engine BHP = Engine kWm x 1.34)

Data shown above represent gross engine performance capabilities obtained and corrected in accordance with ISO-3046 conditions of 100 kPa (29.53 in Hg)

barometric pressure [110 m (361 ft) altitude], 25 C (77 F) air inlet temperature, and relative humidity of 30% with No. 2 diesel or a fuel corresponding to ASTM D2.

See reverse side for application rating guidelines.

The fuel consumption data is based on No. 2 diesel fuel weight at 0.85 kg/liter (7.1 lbs/U.S. gal).

Power output curves are based on the engine operating with fuel system, water pump and lubricating oil pump; not included are battery charging alternator, fan,

optional equipment and driven components.

TECHNICAL DATA DEPT.

STATUS: LIMITED PRODUCTION

CHIEF ENGINEER

400

G-DRIVE

QSM

2

QSM11-G1 Nonroad 2

QSM11-G1 Nonroad 2

1500 RPM

Ambient Temp (C / F)

Derate (% of Rated Power)

35

STANDBY / PRIME /

CONTINUOUS

30

50 / 120

25

20

40 / 104

15

10

32 / 90

5

0

0M

500 M

1000 M

1500 M

2000 M

2500 M

3000 M

Altitude ( Meters)

QSM11-G1 Nonroad 2

1800 RPM

Am b ien t T em p (C / F)

35

Derate (% of Rated Power)

30

50 / 120

STANDBY / PRIME /

CONTINUOUS

25

20

40 / 104

15

10

32 / 90

5

25 / 77

0

0 ft

2000 ft

4000 ft

6000 ft

Altitu de ( feet )

8000 ft

Reference Standards:

BS-5514 and DIN-6271 standards are based on ISO-3046.

Operation At Elevated Temperature And Altitude:

The engine may be operated at:

1800 RPM up to 1000m (3280 ft) and 50oC (122oF) without power deration.

1500 RPM up to 1000m (3280 ft) and 50oC (122oF) without power deration.

Note: Derates shown are based on 10 in H20 air intake restriction and 2 in Hg exhaust back pressure.

10000 ft

G-DRIVE

QSM11-G1 Nonroad 2

POWER RATING APPLICATION GUIDELINES

FOR

GENERATOR DRIVE ENGINES

These guidelines have been formulated to ensure proper application of generator drive engines

in A.C. generator set installations. Generator drive engines are not designed for and shall not be

used in variable speed D.C. generator set applications.

STANDBY POWER RATING is applicable

for supplying emergency power for the

duration of the utility power outage. No

overload capability is available for this rating. Under no condition is an engine

allowed to operate in parallel with the public utility at the Standby Power rating.

This rating should be applied

where reliable utility power is

available. A standby rated engine

should be sized for a maximum of

an 80% average load factor and

200 hours of operation per year.

This includes less than 25 hours

per year at the Standby Power

rating. Standby ratings should

never be applied except in true

emergency power outages.

Negotiated power outages contracted with a utility company are

not considered an emergency.

CONTINUOUS POWER RATING is applicable

for supplying utility power at a constant

100% load for an unlimited number of hours

per year. No overload capability is available

for this rating.

PRIME POWER RATING is applicable for supplying electric power in lieu of commercially

purchased power. Prime Power applications

must be in the form of one of the following two

categories:

UNLIMITED TIME RUNNING PRIME POWER

Prime Power is available for an unlimited number of

hours per year in a variable load application. Variable

load should not exceed a 70% average of the Prime

Power rating during any operating period of 250

hours.

The total operating time at 100% Prime Power shall

not exceed 500 hours per year.

A 10% overload capability is available for a period of

1 hour within a 12 hour period of operation. Total

operating time at the 10% overload power shall not

exceed 25 hours per year.

LIMITED TIME RUNNING PRIME POWER

Prime Power is available for a limited number of

hours in a non-variable load application. It is intended

for use in situations where power outages are contracted, such as in utility power curtailment. Engines

may be operated in parallel to the public utility up to

750 hours per year at power levels never to exceed

the Prime Power rating. The customer should be

aware, however, that the life of any engine will be

reduced by this constant high load operation. Any

operation exceeding 750 hours per year at the Prime

Power rating should use the Continuous Power

rating.

QSM

3

G-DRIVE

QSM

4

Cummins Engine Company, Inc.

Engine Data Sheet

ENGINE MODEL :QSM11-G1 Nonroad 2

CONFIGURATION NUMBER : D353017GX03

INSTALLATION DIAGRAM

Fan to Flywheel

: 3170471

DATA SHEET : DS-2930

DATE : 18Sep01

PERFORMANCE CURVE : FR-2930

CPL NUMBER

Engine Critical Parts List

:8062

GENERAL ENGINE DATA

Type ...............................................................................................................................................................

Aspiration .......................................................................................................................................................

Bore x Stroke.............................................................................................................. in x in (mm x mm)

Displacement.............................................................................................................................. in3 (liter)

Compression Ratio........................................................................................................................................

4 Cycle; In-line; 6-Cylinder Diesel

Turbocharged and Charge Air Cooled

4.92 x 5.79 (125 x 147)

661 (10.8)

16.3 : 1

Dry Weight ...................................................................................................................................... lb (kg)

Wet Weight ..................................................................................................................................... lb (kg)

2145

2220

(973)

(1007)

Moment of Inertia of Rotating Components

with FW 2141 Flywheel ........................................................................................... lbm ft2 (kg m2)

Center of Gravity from Front Face of Block .............................................................................. in (mm)

Center of Gravity above Crankshaft Centerline........................................................................ in (mm)

Maximum Static Loading at Rear Main Bearing.......................................................................... lb (kg)

62.4

17.7

7.5

TBD

(2.63)

(450)

(190)

(TBD)

1000

(1356)

3

11

(76)

(15)

45

(25)

25

15

(635)

(381)

4

2.5

10

10

8

46

180 - 200

10

220 / 212

(102)

(64)

(9.5)

(69)

(55)

(14)

(82 - 93)

(69)

(104 / 100)

Oil Pressure @ Idle Speed (Minimum).................................................................................. psi (kPa)

@ Pressure Range

Cold ............................................... psi (kPa)

Warm............................................. psi (kPa)

10

60 - 70

35 - 40

(69)

(414 - 483)

(242 - 276)

Maximum Oil Temperature.......................................................................................................... F (C)

Oil Capacity with OP 2082 Oil Pan : High - Low ............................................................... US gal (liter)

Total System Capacity (Including Filter) ............................................................................ US gal (liter)

Intermittant Angularity of OP 2082 Oil Pan

Front Down.........................................................

Front Up .............................................................

Side to Side........................................................

275

9.0 - 8.0

9.7

(135)

(34 - 30)

(36.7)

ENGINE MOUNTING

Maximum Bending Moment at Rear Face of Block ......................................................... lb ft (N m)

EXHAUST SYSTEM

Maximum Back Pressure at Standby Power Rating...................................................... in Hg (mm Hg)

Maximum Bending Moment to the Turbo Flange............................................................. lb ft (N m)

AIR INDUCTION SYSTEM

MaximumTemperature Rise Between Engine Air Inlet and Intake Manifold .................. F (C)

Maximum Intake Air Restriction Including Air Filter Plumbing

with Dirty Filter Element.......................................................................................... in H2O (mm H2O)

with Clean Filter Element........................................................................................ in H2O (mm H2O)

COOLING SYSTEM

Maximum Allowable Pressure Drop from Turbo Outlet to Intake Manifold

@ 1800 rpm......................... in Hg (mm Hg)

@ 1500 rpm......................... in Hg (mm Hg)

Coolant Capacity Engine Only..................................................................................... US qt (liter)

Maximum Coolant Friction Head External to Engine 1800 rpm ....................................... psi (kPa)

1500 rpm ....................................... psi (kPa)

Maximum Static Head of Coolant Above Engine Crank Centerline............................................. ft (m)

Standard Thermostat (Modulating) Range................................................................................. F (C)

Minimum Pressure Cap ........................................................................................................... psi (kPa)

Maximum Top Tank Temperature for Standby / Prime Power ................................................. F (C)

LUBRICATION SYSTEM

25

25

30

G-DRIVE

QSM

5

FUEL SYSTEM

Type Injection System......................................................................................................................................................................

Maximum Restriction

With Clean Fuel Filer........................... in Hg (mm Hg)

With Dirty Fuel Filer ............................. in Hg (mm Hg)

Maximum Allowable Head on Injector Return Line (Consisting of Friction Head and Static Head).............. in Hg (mm Hg)

Maximum Fuel Flow to Injection Pump.......................................................................................................... US gph (liter / hr)

Maximum Fuel Inlet Temperature................................................................................................................................... F (C)

Maximum Return Fuel Flow ........................................................................................................................... US gph (liter / hr)

Return Fuel Temperature @ 104F (40C) Fuel Inlet Temperature ............................................................................. F (C)

Cummins Celect

4

(102)

8

(204)

2.5

(63)

75.1

(284)

160

(71)

73.0

(276)

176

(80)

ELECTRICAL SYSTEM

Cranking Motor (Heavy Duty, Positive Engagement)......................................................................................................... volt

Maximum Allowable Resistance of Cranking Circuit......................................................................................................... ohm

Minimum Recommended Battery Capacity

Cold Soak @ 50 F (10 C) and Above ............................................................................................................. 0F CCA

Cold Soak @ 32 F to 50 F (0 C to 10 C)...................................................................................................... 0F CCA

Cold Soak @ 0 F to 32 F (-18 C to 0 C)....................................................................................................... 0F CCA

24

0.002

600

640

900

COLD START CAPABILITY

Minimum Ambient Temperature for Cold Start with Coolant Heater to Rated Speed ................................................ F (C)

Minimum Ambient Temperature for Unaided Cold Start to Low Idle Speed ............................................................... F (C)

Minimum Ambient Temperature for NFPA 110 Cold Start (90F minimum coolant temperature) ............................ F (C)

7

25

32

(-14)

(-4)

(0)

PERFORMANCE DATA

All data is based on:

Engine operating with fuel system, water pump, lubricating oil pump, air cleaner and exhaust

silencer; not included are battery charging alternator, fan, and optional driven components.

Engine operating with fuel corresponding to grade No. 2-D per ASTM D975.

ISO 3046, Part 1, Standard Reference Conditions of:

Barometric Pressure : 100 kPa (29.53 in Hg)

Air Temperature

: 25 C (77 F)

Altitude

: 110 m (361 ft)

Relative Humidity : 30%

Steady State Stability Band at any Constant Load .............................................................................................................. %

Estimated Free Field Sound Pressure Level of a Typical Generator Set;

Excludes Exhaust Noise; at Rated Load and 15 m (25 ft); 1800 rpm / 1500 rpm ....................................................... dBA

Exhaust Noise at 1 m Horizontally from Centerline of Exhaust Pipe Outlet Upwards at 45; 1800 rpm / 1500 rpm ........ dBA

STANDBY

Governed Engine Speed.............................................................. rpm

Engine Idle Speed ....................................................................... rpm

Gross Engine Power Output........................................... BHP (kWm)

Brake Mean Effective Pressure........................................... psi (kPa)

Piston Speed................................................................. ft / min (m / s)

Friction Horsepower ......................................................... HP (kWm)

Engine Water Flow at Stated Friction Head External to Engine:

2.5 psi Friction Head ....................................... US gpm (liter / s)

Maximum Friction Head.................................. US gpm (liter / s)

Turbo Compressor Outlet Pressure .................................... psi (kPa)

Turbo Compressor Outlet Temperature................................. F (C)

Intake Air Flow ................................................................ cfm (liter / s)

Exhaust Gas Temperature...................................................... F (C)

Exhaust Gas Flow .......................................................... cfm (liter / s)

Air-to-Fuel Ratio..................................................................... air : fuel

Radiated Heat to Ambient ..................................... BTU / min (kWm)

Heat Rejection to Coolant ...................................... BTU / min (kWm)

Heat Rejection to Exhaust ..................................... BTU / min (kWm)

Heat Rejection to Fuel * ......................................... BTU / min (kWm)

Heat Rejection to Aftercooler................................. BTU / min (kWm)

+/- 0.25%

80 / 75

124.5 / 123

PRIME POWER

60 hz

50 hz

60 hz

50 hz

1800

675 - 750

395

(295)

262 (1809)

1737

(8.8)

41 (30.6)

1500

675 - 750

345

(257)

275 (1899)

1448

(7.4)

30 (22.4)

1800

675 - 750

359

(268)

239 (1646)

1737

(8.8)

41 (30.6)

1500

675 - 750

314 (234)

250 (1727)

1448

(7.4)

30 (22.4)

91

(5.7)

78

(4.9)

28

(190)

333

(167)

820

(387)

916

(491)

2000

(940)

26.7 : 1

2050

(36)

4700

(83)

13450

(237)

200

(3.5)

2900

(51)

77

(4.8)

64

(4.0)

26

(177)

315

(157)

685

(320)

929

(498)

1660

(785)

25.6 : 1

2050

(36)

4250

(75)

11400

(201)

150

(2.6)

2200

(39)

91

(5.7)

78

(4.9)

25

(175)

315

(157)

780

(370)

851

(455)

1800

(850)

28.4 : 1

1950

(35)

4300

(75)

11850

(208)

200

(3.5)

2550

(45)

77

(4.8)

64

(4.0)

24 (167)

304 (151)

660 (310)

890 (477)

1565 (740)

26.9 : 1

1900

(33)

3950

(70)

10500 (185)

150

(2.6)

2000

(36)

* Maximum heat rejection which occurs at rated speed, no load.

N.A. - Data is Not Available

N/A - Not Applicable to this Engine

TBD - To Be Determined

CUMMINS ENGINE COMPANY, INC.

Columbus, Indiana 47202-3005

STATUS: LIMITED PRODUCTION

ENGINE MODEL :

DATA SHEET :

DATE :

CURVE NO. :

QSM11-G1 Nonroad 2

DS-2930

18Sep01

FR-2930

You might also like

- HỘP SỐ DRF100.Document21 pagesHỘP SỐ DRF100.Nguyễn Văn Hùng100% (1)

- Empty Container Handler 8-10 Tonnes: Technical Information Dce80-100Document12 pagesEmpty Container Handler 8-10 Tonnes: Technical Information Dce80-100MasroniNo ratings yet

- Instruction Dce70-90eDocument38 pagesInstruction Dce70-90eDeMen Nguyen100% (2)

- Ferrari - Cap6.2 Manutenzione F121618 EDocument36 pagesFerrari - Cap6.2 Manutenzione F121618 EjessicaNo ratings yet

- Spreader For Repair InstructionDocument8 pagesSpreader For Repair InstructionPinki SahayNo ratings yet

- Operator ManualDocument20 pagesOperator ManualЮрий Кулиуш100% (1)

- LMS Plus 7.5 Operator ManualDocument19 pagesLMS Plus 7.5 Operator ManualNguyễn Văn HùngNo ratings yet

- 500H FDC 25 K8 FantuzziDocument1 page500H FDC 25 K8 FantuzziMonir MekkaouiNo ratings yet

- DRF100 Technical InformationDocument8 pagesDRF100 Technical InformationOscar Acevedo MirandaNo ratings yet

- TAD870-873VE: Low Cost of OwnershipDocument2 pagesTAD870-873VE: Low Cost of OwnershipAaravGuptaNo ratings yet

- TAD1150-1152VE: Low Cost of OwnershipDocument2 pagesTAD1150-1152VE: Low Cost of OwnershipTioNo ratings yet

- APC200 ECM-ECI User Manual v1.0Document134 pagesAPC200 ECM-ECI User Manual v1.0Hasan Hamit Aydın100% (1)

- Aeb21105 WorksheetDocument96 pagesAeb21105 WorksheetBosko KalicaninNo ratings yet

- Kalmar DRT 450Document12 pagesKalmar DRT 450purushmicro100% (1)

- 520 WS3Document92 pages520 WS3Hassan HamdyNo ratings yet

- 21 1 21 - UsDocument3 pages21 1 21 - UsMinaSaeed100% (1)

- DCD320 500 TDCD01 - 03GBDocument344 pagesDCD320 500 TDCD01 - 03GBJarren GallmoreNo ratings yet

- Extendable Container Attachment (Elme) : PART NO. 1468990 5000 SRM 776Document48 pagesExtendable Container Attachment (Elme) : PART NO. 1468990 5000 SRM 776Juanjo Garcia JimenezNo ratings yet

- Volvo Engine RangeDocument2 pagesVolvo Engine Range3efooNo ratings yet

- Training Material DANA Calibration - 6196.513Document16 pagesTraining Material DANA Calibration - 6196.513mouloud100% (2)

- Electrical System p9000Document50 pagesElectrical System p9000tazjuan1No ratings yet

- QSX15-G8 XpiDocument3 pagesQSX15-G8 XpiMd ShNo ratings yet

- 康明斯 Parts Catalog - QSM11 - 35278791(零件目录) PDFDocument111 pages康明斯 Parts Catalog - QSM11 - 35278791(零件目录) PDFGohan Jay100% (1)

- TAD760VE: Volvo Penta Industrial DieselDocument2 pagesTAD760VE: Volvo Penta Industrial DieselDatNo ratings yet

- N45sm1a 51 To 59KWDocument3 pagesN45sm1a 51 To 59KWsaiyedasadNo ratings yet

- EG3000 Manual PDFDocument7 pagesEG3000 Manual PDFrepelindNo ratings yet

- DRT 450 (Volvo 1350ve)Document2 pagesDRT 450 (Volvo 1350ve)yodsakunNo ratings yet

- IQANdesignDocument333 pagesIQANdesignJian Guo100% (1)

- Engine TAD760 - ECU A3Document2 pagesEngine TAD760 - ECU A3Sang DinhNo ratings yet

- Piston Pumps Series P2 / P3: Variable DisplacementDocument52 pagesPiston Pumps Series P2 / P3: Variable DisplacementHASSANI AdelNo ratings yet

- DANA ECON.a Error Code List - Production Firmware 4.5Document30 pagesDANA ECON.a Error Code List - Production Firmware 4.5Mustafa Tam100% (1)

- 4 - Clark Omega - Operator Manual - Empty Container Handler - Revision 7dDocument92 pages4 - Clark Omega - Operator Manual - Empty Container Handler - Revision 7dAPLI MRNo ratings yet

- Transmission Dana-MaintenanceDocument16 pagesTransmission Dana-MaintenanceMohamed El Gamal100% (1)

- QSG12-G2: Specification SheetDocument3 pagesQSG12-G2: Specification SheetAlejandro Dominado100% (1)

- Kalmar DCG 80 100 Brochure PDFDocument11 pagesKalmar DCG 80 100 Brochure PDFslawny77No ratings yet

- TE32 Full flow -measure points (điểm đo và vị trí solennoi)Document7 pagesTE32 Full flow -measure points (điểm đo và vị trí solennoi)Nguyễn Văn HùngNo ratings yet

- InstallationDocument156 pagesInstallationAkhir Widada100% (1)

- Electronic Engine Governor Controller Operation ManualDocument7 pagesElectronic Engine Governor Controller Operation ManualVinhNo ratings yet

- Hyster Service TechDocument36 pagesHyster Service Techspam_rqlNo ratings yet

- Becx Verhuur Terberg YT182DT 4x2 E Version 2012-1 LogoDocument2 pagesBecx Verhuur Terberg YT182DT 4x2 E Version 2012-1 LogoAhmed Mostafa Youssef100% (1)

- Manual de Peças - c1250d6Document90 pagesManual de Peças - c1250d6Otoniel santos de abreu100% (1)

- Eletrica TAD760 VE-1Document174 pagesEletrica TAD760 VE-1Joao Paulo MatosoNo ratings yet

- ZF85A Marine Propulsion SystemDocument9 pagesZF85A Marine Propulsion SystemJun AballeNo ratings yet

- Kaup T411 T411D ENDocument8 pagesKaup T411 T411D ENJuan Francisco Canto DiezNo ratings yet

- Technical Data TAD 760 VE: GeneralDocument6 pagesTechnical Data TAD 760 VE: GeneralNoer RachNo ratings yet

- Thuy Luc Drd100-200Document27 pagesThuy Luc Drd100-200ANH LÊNo ratings yet

- Tad851ve Technical Data 22495852.04Document16 pagesTad851ve Technical Data 22495852.04Satria Agung Winoto100% (2)

- Ferrari: Chassis Electrical System InstrumentsDocument4 pagesFerrari: Chassis Electrical System InstrumentsJose LiraNo ratings yet

- General ElectricDocument21 pagesGeneral Electrichydro tec100% (1)

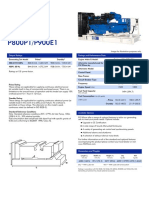

- P800p1-P900e1 (4PP) GB (0313) PDFDocument4 pagesP800p1-P900e1 (4PP) GB (0313) PDFNom YusNo ratings yet

- S3L2 61SD 3 ZylinderDocument135 pagesS3L2 61SD 3 ZylinderFranck MonnierNo ratings yet

- Empty Container Handlers: Strong Partners. Tough TrucksDocument24 pagesEmpty Container Handlers: Strong Partners. Tough TrucksEjaz EjazNo ratings yet

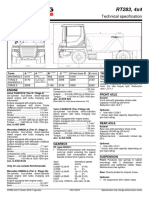

- Terberg RT283 PDFDocument2 pagesTerberg RT283 PDFHemerson FurtadoNo ratings yet

- Specification Manual: FD100N-160NDocument20 pagesSpecification Manual: FD100N-160NAdven Tius Surya SurbaktiNo ratings yet

- Perkins 2806D-E18TA Operation and Maintenance ManualDocument3 pagesPerkins 2806D-E18TA Operation and Maintenance ManualMostafa ShannaNo ratings yet

- Volvo FM D13A 400 EspecificacionesDocument2 pagesVolvo FM D13A 400 EspecificacionesRene VCNo ratings yet

- Generador 250kwDocument15 pagesGenerador 250kwmax_velasquezNo ratings yet

- Engine Performance Data at 1500 RPM: QSL 1 Cummins IncDocument4 pagesEngine Performance Data at 1500 RPM: QSL 1 Cummins IncEdgardo J. Mamani100% (1)

- Engine Performance Data at 1500 RPM: QSB 1 Cummins IncDocument4 pagesEngine Performance Data at 1500 RPM: QSB 1 Cummins IncMaged Beshara100% (3)

- How to Rebuild & Modify Rochester Quadrajet CarburetorsFrom EverandHow to Rebuild & Modify Rochester Quadrajet CarburetorsRating: 5 out of 5 stars5/5 (2)

- Stepway A4 Folded FlyerDocument4 pagesStepway A4 Folded FlyerEslam MansourNo ratings yet

- Sandero A4 Folded FlyerDocument4 pagesSandero A4 Folded FlyerAhmedNo ratings yet

- Safim S.P.A. General Sale ConditionsDocument1 pageSafim S.P.A. General Sale ConditionsEslam MansourNo ratings yet

- Logan A4 Folded FlyerDocument4 pagesLogan A4 Folded FlyerEslam MansourNo ratings yet

- Duster A4 Folded FlyerDocument4 pagesDuster A4 Folded FlyerEslam MansourNo ratings yet

- Sandero A4 Folded FlyerDocument4 pagesSandero A4 Folded FlyerAhmedNo ratings yet

- 4um ST FILTER Product Data SheetDocument2 pages4um ST FILTER Product Data SheetJean Claude EidNo ratings yet

- FINAL ENG Policy Brief FES OnlineDocument36 pagesFINAL ENG Policy Brief FES OnlineEslam MansourNo ratings yet

- Spare Parts Management - Intro Levels Notes PDFDocument6 pagesSpare Parts Management - Intro Levels Notes PDFEslam MansourNo ratings yet

- Actros BrochureDocument4 pagesActros BrochureAliNo ratings yet

- Key Performance Indicators (KPI)Document42 pagesKey Performance Indicators (KPI)Eslam MansourNo ratings yet

- مسودة بوليصة الشحنDocument1 pageمسودة بوليصة الشحنEslam Mansour100% (1)

- Spare Parts Management - Intro Levels Notes PDFDocument6 pagesSpare Parts Management - Intro Levels Notes PDFEslam MansourNo ratings yet

- Improved Productivity and Customer Satisfaction inDocument10 pagesImproved Productivity and Customer Satisfaction inEslam MansourNo ratings yet

- Chapter 1 Managing The Digital FirmDocument50 pagesChapter 1 Managing The Digital FirmEslam MansourNo ratings yet

- 5 Tips For Vetting ERP VendorsDocument5 pages5 Tips For Vetting ERP VendorsEslam MansourNo ratings yet

- - - ترجمة أيزو 9000-2015 باللغة العربيةDocument9 pages- - ترجمة أيزو 9000-2015 باللغة العربيةEslam MansourNo ratings yet

- - - ترجمة أيزو 9000-2015 باللغة العربية - PDFDocument51 pages- - ترجمة أيزو 9000-2015 باللغة العربية - PDFEslam Mansour100% (1)

- Roles & Responsibilities of A Maintenance Engineer - LinkedInDocument4 pagesRoles & Responsibilities of A Maintenance Engineer - LinkedInEslam MansourNo ratings yet

- Improved Productivity and Customer Satisfaction inDocument10 pagesImproved Productivity and Customer Satisfaction inEslam MansourNo ratings yet

- (Technical) Pipo140 47 enDocument7 pages(Technical) Pipo140 47 enEslam MansourNo ratings yet

- (Technical) Pipo130 37 enDocument8 pages(Technical) Pipo130 37 enEslam MansourNo ratings yet

- Gama InsuranceDocument3 pagesGama InsuranceEslam MansourNo ratings yet

- Heui 1-08Document42 pagesHeui 1-08diagnopro100% (2)

- Chapter (2) 2.0 Maintenance Management System: November 2017Document28 pagesChapter (2) 2.0 Maintenance Management System: November 2017Eslam MansourNo ratings yet

- Book 323Document93 pagesBook 323Eslam MansourNo ratings yet

- Book 4135Document147 pagesBook 4135Eslam MansourNo ratings yet

- Doosan Engine DX Serie NON DPF TrainingDocument136 pagesDoosan Engine DX Serie NON DPF TrainingEslam Mansour100% (5)

- Markting ExamDocument18 pagesMarkting ExamEslam MansourNo ratings yet

- Investment Cast Process PumpsDocument8 pagesInvestment Cast Process PumpsJaldhi PatelNo ratings yet

- Specification: Unit Description Specification RemarkDocument46 pagesSpecification: Unit Description Specification RemarkmanualNo ratings yet

- Ford Modular Engine - WikipediaDocument5 pagesFord Modular Engine - WikipediaDanivie CorderoNo ratings yet

- Diploma Board Examination - December 2020Document2 pagesDiploma Board Examination - December 2020Pradeep AppuNo ratings yet

- K 4700 CSK 5000 CCK 5500 CBK 5000 CSK 6000 CCK 6000 CSK 7500 CCDocument2 pagesK 4700 CSK 5000 CCK 5500 CBK 5000 CSK 6000 CCK 6000 CSK 7500 CCMIGUEL ÁNGEL TOMÉNo ratings yet

- d100306x012 PDFDocument32 pagesd100306x012 PDFChristopher RiceNo ratings yet

- Engine PDFDocument108 pagesEngine PDFteknikpembakaran2013No ratings yet

- Transmission - Install: Disassembly and AssemblyDocument7 pagesTransmission - Install: Disassembly and AssemblyTheo AnggaraNo ratings yet

- Air Cooled Water Chiller and Heat Pump 20kW-860kW: Vicot Air Conditioning Co., LTDDocument30 pagesAir Cooled Water Chiller and Heat Pump 20kW-860kW: Vicot Air Conditioning Co., LTDLeman Sihotang100% (2)

- Partes Motor 444 Aspiracion Natural 9812-0080 PDFDocument112 pagesPartes Motor 444 Aspiracion Natural 9812-0080 PDFDaniel Aguirre83% (6)

- rd-m592 2Document1 pagerd-m592 2faizgpNo ratings yet

- BT-MR 550Document2 pagesBT-MR 550David VallsNo ratings yet

- Ekm QB Jan 2010 Apr 2016Document34 pagesEkm QB Jan 2010 Apr 2016Amit Kumar NarayanNo ratings yet

- Turbo DataDocument5 pagesTurbo DataCesar Lazarte LunaNo ratings yet

- B WI C200-C1000 Non-Bolted Combustor Liner ReplacementDocument17 pagesB WI C200-C1000 Non-Bolted Combustor Liner ReplacementJefferson Mosquera PerezNo ratings yet

- Induction Motor - WikipediaDocument16 pagesInduction Motor - WikipediaagrajitNo ratings yet

- Power Front Disc Conversion Instructions MDC62DCDocument11 pagesPower Front Disc Conversion Instructions MDC62DCandrakin8No ratings yet

- Komatsu 7codesDocument3 pagesKomatsu 7codesSandor Jakab100% (8)

- Types: Positive Displacement PumpsDocument4 pagesTypes: Positive Displacement PumpsAnonymous hUxOtWChmINo ratings yet

- Shpindeli SLFDocument60 pagesShpindeli SLFrayss1978No ratings yet

- LECH3874-08 Industrial Engine Ratings GuideDocument34 pagesLECH3874-08 Industrial Engine Ratings GuideDDemin12345100% (1)

- 350EDocument62 pages350Esatellitel500No ratings yet

- Parts Manual SL 2012Document118 pagesParts Manual SL 2012Aleks BubaevNo ratings yet

- Work DoneDocument16 pagesWork DoneRobin Symone RomarateNo ratings yet

- Ed 03 (EN)Document38 pagesEd 03 (EN)Mesafint kassieNo ratings yet

- IWP Super Series: Serial Number RangeDocument140 pagesIWP Super Series: Serial Number RangeRaymundo MartinezNo ratings yet

- Mechanics of Machines II: Lec. 1: Turning Moment Diagrams and FlywheelDocument20 pagesMechanics of Machines II: Lec. 1: Turning Moment Diagrams and FlywheelMustafa AhdithyNo ratings yet

- P21-0161 Final Report Acm 315 Kw-LoherDocument19 pagesP21-0161 Final Report Acm 315 Kw-Loherdindin6666No ratings yet

- Event Codes 793F-797FDocument14 pagesEvent Codes 793F-797FrpumacayovNo ratings yet

- Stator MotorDocument8 pagesStator MotorMPENDULO MABILANo ratings yet