Professional Documents

Culture Documents

Seasoning Defects PDF

Uploaded by

Jahangir MiltonOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Seasoning Defects PDF

Uploaded by

Jahangir MiltonCopyright:

Available Formats

Wood Seasoning

Forestry 240

Defects Due to Seasoning

Wood Seasoning

Most seasoning defects can be minimized by

careful air seasoning.

They can be largely eliminated by proper

control of drying conditions in the kiln.

End Checks

Usually confined to

the ends of the

pieces.

Normally follow the

rays.

May develop into

end splits.

Wood is anisotropic; as it dries below the fiber

saturation point, shrinkage is not equal in all

directions.

Longitudinal shrinkage is negligible, except in

reaction wood.

Tangential shrinkage can be 1.5 to 3 times higher

than radial shrinkage

This differential shrinkage sets up strains,

which, if they become too great, cause

fractures in the wood tissues, significantly

devaluing the product.

Checks

Ruptures along the grain

that develop during

seasoning either because

of a difference in radial

and tangential shrinkage

or because of uneven

shrinkage of the tissue in

adjacent portions of the

wood.

Surface Checks

Result from the separation of the thinnerwalled early-wood cells.

Typically follow the rays, and are confined to

the tangential surface.

More common in rough lumber than in that

planed smooth before drying due to the

formation of checks in the protruding ridges of

rough lumber where the drying is faster than in

smooth surfaces.

Checks

Loose Knots

Checks may close as drying progresses deeper

into the wood.

To minimize, must have less-rapid but uniform

evaporation of moisture by reducing moisture

gradient, shading boards, reducing circulation.

Due to differential drying, encased knots can

become loose during drying since their wood

is usually denser and shrinks more than the

surrounding tissue.

Warping

Warping

Any distortion in a piece of wood from its true plane that

may occur in seasoning. Types:

Bowing Longitudinal curvature, flat-wise, from a straight

line.

Crook longitudinal curvature, edgewise from a straight line.

Cupping curving of the face of a plank so that it assumes a

trough-like shape.

Twisting one corner of a piece of wood twists out of the plane

of the other three.

Diamonding uneven shrinkage that causes squares to become

diamond shaped on drying. Develops in pieces in which the

growth increments extend diagonally, so that the faces of the

piece are neither flat nor edge-grained.

Warping

Warping

Warping

Casehardening

Nearly uniform moisture

content, but residual stresses,

tension in the interior of the

piece (core), and compression

in the outer layers of cells

(shell).

Results from too rapid drying,

where the surface dries below

the FSP first, but cannot

shrink, putting tension on the

surface.

Collapse

Defect that sometimes develops above the

fiber saturation point when very wet

heartwood of certain species is dried.

Evidenced by abnormal and irregular

shrinkage.

Box-Heart Split

A split originating

in the wood

surrounding the pith

during drying.

Caused by stresses

set up because of

the differences in

tangential and radial

shrinkage of the

wood near the pith.

Honeycombing

Internal splitting in

wood that develops in

drying; cause by

internal stresses or by

closing of surface

checks.

Questions?

Redneck Flat-Screen TV

You might also like

- Guidelines For Conducting Islamic Banking Section I Introduction To Islamic BankingDocument1 pageGuidelines For Conducting Islamic Banking Section I Introduction To Islamic BankingJahangir MiltonNo ratings yet

- Training Course of BRTCDocument34 pagesTraining Course of BRTCJahangir MiltonNo ratings yet

- List of Associations in BangladeshDocument57 pagesList of Associations in BangladeshJahangir MiltonNo ratings yet

- How To Make White Mayonnaise - 7 Steps (With Pictures) - WikiHowDocument5 pagesHow To Make White Mayonnaise - 7 Steps (With Pictures) - WikiHowJahangir MiltonNo ratings yet

- List of 100 Animals With Their Male, Female, Young, Group, Home, SoundDocument3 pagesList of 100 Animals With Their Male, Female, Young, Group, Home, Soundsasauball82% (385)

- What Is Cold Pressed Oil?: Which One Should Be Chosen Hot or Cold Pressed?Document4 pagesWhat Is Cold Pressed Oil?: Which One Should Be Chosen Hot or Cold Pressed?Jahangir MiltonNo ratings yet

- What Is Cold Pressed Oil?: Which One Should Be Chosen Hot or Cold Pressed?Document4 pagesWhat Is Cold Pressed Oil?: Which One Should Be Chosen Hot or Cold Pressed?Jahangir MiltonNo ratings yet

- List of 100 Animals With Their Male, Female, Young, Group, Home, SoundDocument3 pagesList of 100 Animals With Their Male, Female, Young, Group, Home, Soundsasauball82% (385)

- Company Registration in BangladeshDocument2 pagesCompany Registration in BangladeshJahangir MiltonNo ratings yet

- City Corporation Ideal Tax Schedule 2016 BNDocument32 pagesCity Corporation Ideal Tax Schedule 2016 BNOGR LegalNo ratings yet

- F Mayonnaise Manufacture 2016 USDocument4 pagesF Mayonnaise Manufacture 2016 USJahangir MiltonNo ratings yet

- Cleaning Handwashing 5percent Liquid BleachDocument1 pageCleaning Handwashing 5percent Liquid Bleachmaite6969No ratings yet

- Solutions For Mayonnaise Production Lines - tcm11-38915 PDFDocument12 pagesSolutions For Mayonnaise Production Lines - tcm11-38915 PDFYasmine MonttNo ratings yet

- Most Profitable Mayonnaise & Salad Dressings Manufacturing Business-104583Document64 pagesMost Profitable Mayonnaise & Salad Dressings Manufacturing Business-104583Jahangir MiltonNo ratings yet

- Preserving Food Drying Fruits and VegetablesDocument12 pagesPreserving Food Drying Fruits and Vegetablespdxpharris100% (1)

- SaffronDocument12 pagesSaffronJahangir MiltonNo ratings yet

- Reliable Sauces: How To Find The Best Pasta ToppersDocument3 pagesReliable Sauces: How To Find The Best Pasta ToppersJahangir MiltonNo ratings yet

- 2017 All CladDocument14 pages2017 All CladJahangir MiltonNo ratings yet

- Cookbook:Mixed Herbs: Jump To Navigationjump To Search Cookbook Recipes Ingredients Spices and HerbsDocument4 pagesCookbook:Mixed Herbs: Jump To Navigationjump To Search Cookbook Recipes Ingredients Spices and HerbsJahangir MiltonNo ratings yet

- Intel NUC8I5BEH Mini PC NUC Kit: Egular Price: 38,300.00Document11 pagesIntel NUC8I5BEH Mini PC NUC Kit: Egular Price: 38,300.00Jahangir MiltonNo ratings yet

- Heritage TurkeyDocument4 pagesHeritage TurkeyJahangir Milton100% (1)

- BERC ActDocument27 pagesBERC ActA Hasib ChowdhuryNo ratings yet

- Honey and Bee FactsDocument1 pageHoney and Bee FactsMiltonNo ratings yet

- Benefits of Indian Salmon fishDocument15 pagesBenefits of Indian Salmon fishJahangir MiltonNo ratings yet

- Murad IV of TurkeyDocument10 pagesMurad IV of TurkeyJahangir MiltonNo ratings yet

- Business Plan TemplateDocument15 pagesBusiness Plan Templateama0290No ratings yet

- Product PhotographyDocument1 pageProduct PhotographyJahangir MiltonNo ratings yet

- Naked NeckDocument3 pagesNaked NeckJahangir MiltonNo ratings yet

- Dry Fish Book FinalDocument21 pagesDry Fish Book FinalJahangir MiltonNo ratings yet

- Bengal Subah PDFDocument17 pagesBengal Subah PDFJahangir MiltonNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5784)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- 2) Data Sheet VDek-703 Standard 2021 FTDocument1 page2) Data Sheet VDek-703 Standard 2021 FTJean CausilNo ratings yet

- Polymers 14 02684Document18 pagesPolymers 14 02684Hira KarimNo ratings yet

- CHEE2940 Mid-Semester Quiz 2012 - SolutionsDocument10 pagesCHEE2940 Mid-Semester Quiz 2012 - Solutionspetecooper7159No ratings yet

- Lab Manual IPCDocument21 pagesLab Manual IPCVijay Kumar TilakNo ratings yet

- Stain Removal GuideDocument1 pageStain Removal Guidekhamid arifNo ratings yet

- D2879-Standard Test Method For Vapor Pressure-Temperature Relationship and Initial Decomposition Temperature of Liquids by IsoteniscopeDocument6 pagesD2879-Standard Test Method For Vapor Pressure-Temperature Relationship and Initial Decomposition Temperature of Liquids by IsoteniscoperezaNo ratings yet

- ASTM C1017 - Chemical Admixtures For Use in Producing Flowing ConcreteDocument9 pagesASTM C1017 - Chemical Admixtures For Use in Producing Flowing Concretesugi zhuangNo ratings yet

- Air DryersDocument99 pagesAir Dryersapi-384214360% (5)

- Sumber Penelitian NaOH TerdahuluDocument7 pagesSumber Penelitian NaOH TerdahuluAulia NafarinNo ratings yet

- Model 25c and 25d: Descriptive Models of Comstock and Sado Epithermal VeinsDocument15 pagesModel 25c and 25d: Descriptive Models of Comstock and Sado Epithermal VeinsmiguelNo ratings yet

- Mod 2 BA PhysicsDocument412 pagesMod 2 BA PhysicsBenitoKameloNo ratings yet

- PJK Project 2011 Form 2 (Word 2010)Document30 pagesPJK Project 2011 Form 2 (Word 2010)Charmaine Yeo Shern LiNo ratings yet

- Metallurgy - Chapter (5) - Steels and Cast IronsDocument79 pagesMetallurgy - Chapter (5) - Steels and Cast IronsKarim Mamdouh100% (1)

- Gunj Glass Works. LTD Visit ReportDocument26 pagesGunj Glass Works. LTD Visit ReportHM Bhatti100% (1)

- Steel Que BankDocument26 pagesSteel Que BankyawaleapurvastNo ratings yet

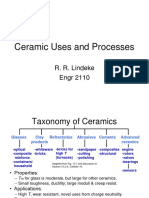

- Ceramic Uses and ProcessesDocument22 pagesCeramic Uses and ProcessesWang Zheng FengNo ratings yet

- ChemicalDocument1 pageChemicalTimothy John IgnacioNo ratings yet

- SCOPEDocument5 pagesSCOPEMel FNo ratings yet

- Guide For The Gas Shielded Arc Welding of Aluminum and Aluminum Alloy PipeDocument38 pagesGuide For The Gas Shielded Arc Welding of Aluminum and Aluminum Alloy PipeCGRRNo ratings yet

- Fatigue PDFDocument67 pagesFatigue PDFsabaris ksNo ratings yet

- Cement Technology: ReclaimerDocument17 pagesCement Technology: ReclaimerYana Damayanti100% (1)

- Photo Resist Etch InstructionDocument5 pagesPhoto Resist Etch Instructiondraku11No ratings yet

- 440 3R-12Table1 3Document1 page440 3R-12Table1 316562306No ratings yet

- Advanced Materials for Turbofan Engine Fan BladesDocument9 pagesAdvanced Materials for Turbofan Engine Fan BladesAhmed KhasawnehNo ratings yet

- Magnetically Impelled Arc Butt WeldingDocument23 pagesMagnetically Impelled Arc Butt WeldingMutiara Monica100% (1)

- Lizmontagens Group ProfileDocument5 pagesLizmontagens Group ProfileRui Carlos Delgado Lopes AlvesNo ratings yet

- SP-1097 DSS Welding Specs PDFDocument48 pagesSP-1097 DSS Welding Specs PDFHari Prakash GrandheyNo ratings yet

- 20 Ways To Boost Soil FertilityDocument8 pages20 Ways To Boost Soil FertilitymahderNo ratings yet

- TeccDocument8 pagesTeccChristian Galvez BarrantesNo ratings yet

- Confix HVDocument1 pageConfix HVGian ArevaloNo ratings yet