Professional Documents

Culture Documents

Studies On Performance of Metallic Wick Stove Incorporating External Cooling System

Uploaded by

Arjun NbOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Studies On Performance of Metallic Wick Stove Incorporating External Cooling System

Uploaded by

Arjun NbCopyright:

Available Formats

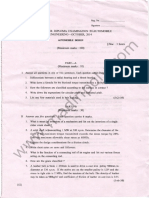

Studies on Performance of Metallic Wick

Stove Incorporating External Cooling System

Muhammed Sahal NK1

1

Final Year M.Tech in Manufacturing Engineering,

KMCT College of Engineering, Calicut, Kerala

Email: sahalkdy@gmail.com

Mob: +91 9847109846

AbstractCotton wicks are normally used for heating stove and lightening lamps. It is felt that

frequent changing of cotton wicks can be avoided by developing metallic wicks using powder

metallurgy techniques. Conventional stove cannot accommodate these metallic wicks. To

accommodate them the wick carrier is slightly modified. Existing lifting mechanism in stove is

modified for the sake of simplicity. The wick carrier tubes are slightly enlarged and shortened.

According to literature survey much work is not carried out in this direction. Hence the present

work is taken up to study the efficiency of metallic wick stove using cooling system and compare

it with metallic wick stove without cooling system.

Fabricated metallic wicks are fitted in the wick carrier. Further the performance characteristics

using metallic wick such as fuel consumption, fuel tank temperature, flame height and capillary

action are studied. The efficiency of metallic wick is compared with conventional stove and the

results are tabulated.

Metallic wick stove can be used for many hours but due to high thermal conductivity of metallic

wick the fuel gets hot within few hours. So to get prolonged working of metallic wick stove,

water bath is attached with the stove to reduce the fuel tank temperature.

Test results reveal that, Capillary action of metallic wicks depends on the depth of immersion

and length of wick in kerosene. Flame height of metallic wick depends on fuel level and tip

exposure. Flame height is enhanced with increase in diameter of metallic wick. Metallic wick is

made to operate for a longer duration by providing circumferential water stored container. Fuel

consumption is found to be much less in metallic wicks over conventional cotton wick.

Utilization efficiency of metallic wick stove is greater than that of conventional stove.

Hence it is concluded that the cooling system is viable for metallic wick stove and it improves

performance of metallic wick stove. The temperature is reduced and more working duration gets

before reaching the flash point of kerosene, hence problem solved.

You might also like

- Proceedings of the 2014 Energy Materials Conference: Xi'an, Shaanxi Province, China, November 4 - 6, 2014From EverandProceedings of the 2014 Energy Materials Conference: Xi'an, Shaanxi Province, China, November 4 - 6, 2014No ratings yet

- Analysis of Boiler Efficiency - CaseDocument89 pagesAnalysis of Boiler Efficiency - CaseSaritha Yadav100% (5)

- The Art of Lead Burning: A practical treatisening the apparatus and processesFrom EverandThe Art of Lead Burning: A practical treatisening the apparatus and processesNo ratings yet

- Advances in Oxy Fuel Fired Glass Melting TechnologyDocument17 pagesAdvances in Oxy Fuel Fired Glass Melting TechnologytedmozbiNo ratings yet

- Good Stoves Facilitation: How to Innovate and Change the WorldFrom EverandGood Stoves Facilitation: How to Innovate and Change the WorldNo ratings yet

- Intro Oxy-Fuel Fired Glass Melting TechnologyDocument17 pagesIntro Oxy-Fuel Fired Glass Melting TechnologymehariiNo ratings yet

- The Art of Lead Burning: A practical treatise explaining the apparatus and processesFrom EverandThe Art of Lead Burning: A practical treatise explaining the apparatus and processesNo ratings yet

- Project On Boiler, Metallurgy, Materials & Heat TreatmentDocument34 pagesProject On Boiler, Metallurgy, Materials & Heat Treatmentmohitamitabh20100% (3)

- Mechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesFrom EverandMechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesNo ratings yet

- 1 PDFDocument9 pages1 PDFAswini Kumar DashNo ratings yet

- Technological Developments in Annealing Furnaces For Performance Improvement Ijariie5717Document12 pagesTechnological Developments in Annealing Furnaces For Performance Improvement Ijariie5717Sontosh BhattacharjeeNo ratings yet

- Engr 103, Section 088, Group 01Document13 pagesEngr 103, Section 088, Group 01Maria TabbutNo ratings yet

- An Investigation On Tube Temperature Distribution in A Water Tube BoilerDocument6 pagesAn Investigation On Tube Temperature Distribution in A Water Tube BoilerKelvinWongNo ratings yet

- M Tech Eleventh BatchDocument11 pagesM Tech Eleventh BatchRanjith ChettichiveettilNo ratings yet

- Fire Tube BoilerDocument21 pagesFire Tube Boiler声原No ratings yet

- ME-216E Lab Manual for Energy ConversionDocument40 pagesME-216E Lab Manual for Energy ConversionmechgokulNo ratings yet

- Failure Analysis and Optimization of Reheater and Super Heater TubesDocument6 pagesFailure Analysis and Optimization of Reheater and Super Heater Tubeslagnajit jenaNo ratings yet

- Rotarykilnsizingdesign 160907141554Document39 pagesRotarykilnsizingdesign 160907141554Juan Ernesto SalazarNo ratings yet

- Boiler Tube FailureDocument4 pagesBoiler Tube FailurenileshNo ratings yet

- Advances in Delayed Coking Heat Transfer EquipmentDocument6 pagesAdvances in Delayed Coking Heat Transfer EquipmentBahar MeschiNo ratings yet

- Curing by Absorbing HeatDocument20 pagesCuring by Absorbing HeatPatrice Suerte FelipeNo ratings yet

- Pottery Kiln Design and SimulationDocument41 pagesPottery Kiln Design and SimulationSantiago Juan100% (1)

- For Review ISTP26 FudhailDocument7 pagesFor Review ISTP26 FudhailHERDI SUTANTONo ratings yet

- ST37 Steel Carburization With Coconut Charcoal: Melya Dyanasari SebayangDocument7 pagesST37 Steel Carburization With Coconut Charcoal: Melya Dyanasari SebayangAli ShdiefatNo ratings yet

- Crucible FurnacesDocument10 pagesCrucible FurnacesZara Saeed0% (1)

- Induction FurnaceDocument16 pagesInduction FurnaceDeepak VishwakarmaNo ratings yet

- Crucible FurnacesDocument10 pagesCrucible FurnacesZara SaeedNo ratings yet

- Microwave melting metals domestic ovenDocument6 pagesMicrowave melting metals domestic ovenHelena Zik100% (1)

- For Review ISTP26 FudhailDocument7 pagesFor Review ISTP26 FudhailHERDI SUTANTONo ratings yet

- Sesi PotteryDocument20 pagesSesi PotteryTefera Adugna100% (1)

- 1 s2.0 S2214157X21002100 MainDocument11 pages1 s2.0 S2214157X21002100 MainChayapon SaiboutongNo ratings yet

- Melting and Holding Furnaces For Die CastingDocument11 pagesMelting and Holding Furnaces For Die CastingVAP BOMBAYNo ratings yet

- Coeficien Heat Tranfer Boiler Fire Tube1Document8 pagesCoeficien Heat Tranfer Boiler Fire Tube1กี๋ แต่งงาม100% (1)

- Effects of Bath Temperature On Cooling Rate, Mechanical Properties and Microstructure of Medium Carbon Steel During Quenching OperationsDocument10 pagesEffects of Bath Temperature On Cooling Rate, Mechanical Properties and Microstructure of Medium Carbon Steel During Quenching OperationsInaamNo ratings yet

- ST37 Steel Carburization With Coconut Charcoal: Melya Dyanasari SebayangDocument8 pagesST37 Steel Carburization With Coconut Charcoal: Melya Dyanasari SebayangDaisy fieldsNo ratings yet

- Effect of Tempering Behavior On Heat Treated Medium Carbon (C 35 MN 75) SteelDocument6 pagesEffect of Tempering Behavior On Heat Treated Medium Carbon (C 35 MN 75) SteelMuhanad MamooriNo ratings yet

- Pattern of Kolkata BOE ExaminationDocument7 pagesPattern of Kolkata BOE ExaminationRaag SNo ratings yet

- Cokeless CupolaDocument12 pagesCokeless CupolaGovind RaoNo ratings yet

- Fire Tube BoilerDocument14 pagesFire Tube BoilersadvdsNo ratings yet

- ST37 Steel Carburization With Coconut Charcoal: Melya Dyanasari SebayangDocument7 pagesST37 Steel Carburization With Coconut Charcoal: Melya Dyanasari SebayangDaisy fieldsNo ratings yet

- Supercritical Turbine Analysis & DesignDocument29 pagesSupercritical Turbine Analysis & DesignEngr Imtiaz Hussain GilaniNo ratings yet

- Ijirt155149 PaperDocument8 pagesIjirt155149 PaperMohamed HassanNo ratings yet

- Coke Quality and Thermal Reserve Zone PDFDocument6 pagesCoke Quality and Thermal Reserve Zone PDFhalder_kalyan9216No ratings yet

- Steam Boiler Performance-1Document27 pagesSteam Boiler Performance-1Fagbolagun IdowuNo ratings yet

- Creep Failure of HP Modified Reformer TubeDocument20 pagesCreep Failure of HP Modified Reformer Tubearaujo angel100% (1)

- The Steam Produced Is Used ForDocument26 pagesThe Steam Produced Is Used ForAshna FelixNo ratings yet

- Istp 2015Document7 pagesIstp 2015HERDI SUTANTONo ratings yet

- Design of A Diesel Fired Heat-Treatment FurnaceDocument11 pagesDesign of A Diesel Fired Heat-Treatment FurnaceKhin Aung ShweNo ratings yet

- E Ciency Studies of Combination Tube Boilers: Alexandria Engineering JournalDocument10 pagesE Ciency Studies of Combination Tube Boilers: Alexandria Engineering JournalGeslane SchepersNo ratings yet

- Project ProposalDocument4 pagesProject ProposalRidwan BamideleNo ratings yet

- Furnaces Energy SavingDocument10 pagesFurnaces Energy SavingqaisarharisNo ratings yet

- Boilers NotesDocument16 pagesBoilers Notesjust randomNo ratings yet

- Modern Practices of Post Taphole Operation in Ferro Chrome Production and Its AdvantagesDocument10 pagesModern Practices of Post Taphole Operation in Ferro Chrome Production and Its Advantagesschakra14No ratings yet

- Sustainability 09 02154 v2Document21 pagesSustainability 09 02154 v2luiskNo ratings yet

- An Undesirable Effect During Thermal Cracking Is Coke Deposition On The Walls of The Tubular Reactor. Coke Deposits Build With Reactor Operation Time and Increase Up To A Point in WhichDocument2 pagesAn Undesirable Effect During Thermal Cracking Is Coke Deposition On The Walls of The Tubular Reactor. Coke Deposits Build With Reactor Operation Time and Increase Up To A Point in WhichWindhi Hoshi Yumemizu IINo ratings yet

- Forging Processes MEE 3024 2014Document25 pagesForging Processes MEE 3024 2014Ali M. ElghawailNo ratings yet

- Electric Arc Furnace Injection System For OxygenDocument7 pagesElectric Arc Furnace Injection System For OxygenIcilma LiraNo ratings yet

- Doosan Posiflow technology improves boiler efficiency and reliabilityDocument12 pagesDoosan Posiflow technology improves boiler efficiency and reliabilityKarthick VelayuthamNo ratings yet

- Study of Coke Oven BatteryDocument18 pagesStudy of Coke Oven BatteryYeswanth Kumar100% (1)

- Energies 13 03655 PDFDocument22 pagesEnergies 13 03655 PDFNavamani PrakashNo ratings yet

- 07 10 2020 14.49.38Document21 pages07 10 2020 14.49.38Arjun NbNo ratings yet

- Appointment Chart: Kerala Water AuthorityDocument34 pagesAppointment Chart: Kerala Water AuthorityArjun NbNo ratings yet

- Solid Works 112Document5 pagesSolid Works 112Arjun NbNo ratings yet

- Dealership Form PDFDocument4 pagesDealership Form PDFArjun NbNo ratings yet

- ApChart DR GR I 12.06.2023Document6 pagesApChart DR GR I 12.06.2023Arjun NbNo ratings yet

- 5 Automobil Design Oct 2014Document3 pages5 Automobil Design Oct 2014Arjun NbNo ratings yet

- Record: Public Transportation: Bus, Rail, Ridesharing, Paratransit Services, and Transit SecurityDocument219 pagesRecord: Public Transportation: Bus, Rail, Ridesharing, Paratransit Services, and Transit SecurityArjun NbNo ratings yet

- A B C D A B C D: Overseer/Draftsman (Mech.) GR - Iii/Tracer - Irrigation & Draftsman (Mech.) - Kamco LTDDocument1 pageA B C D A B C D: Overseer/Draftsman (Mech.) GR - Iii/Tracer - Irrigation & Draftsman (Mech.) - Kamco LTDArjun NbNo ratings yet

- SSC Railway Capsule 2018Document134 pagesSSC Railway Capsule 2018Sampath Kumar GuthalaNo ratings yet

- Metal Forming Processes - FullDocument5 pagesMetal Forming Processes - FullArjun NbNo ratings yet

- Numerical ControlDocument3 pagesNumerical ControlArjun NbNo ratings yet

- Thermodynamic processes and engine cycle efficienciesDocument18 pagesThermodynamic processes and engine cycle efficienciesArjun NbNo ratings yet

- Five-Year Plans of India - Wikipedia, The Free EncyclopediaDocument10 pagesFive-Year Plans of India - Wikipedia, The Free EncyclopediaArjun NbNo ratings yet

- A Resource For Teaching and Learning of Commerce PDFDocument107 pagesA Resource For Teaching and Learning of Commerce PDFArjun Nb100% (1)

- Customer Satisfaction of KTC Hyundai CustomersDocument58 pagesCustomer Satisfaction of KTC Hyundai CustomersArjun NbNo ratings yet

- Vehicle Dynamics: Chapter 2: Road LoadsDocument50 pagesVehicle Dynamics: Chapter 2: Road LoadsArjun NbNo ratings yet

- Ijmerr 5444c5f826f5aDocument10 pagesIjmerr 5444c5f826f5aArjun NbNo ratings yet

- International Journals Contact DetailsDocument1 pageInternational Journals Contact DetailsArjun NbNo ratings yet

- Reasoning 3Document8 pagesReasoning 3Prasad Durga DNo ratings yet

- Dept. of Mechanical Engg. 1 KMCT Ce, M-TechDocument14 pagesDept. of Mechanical Engg. 1 KMCT Ce, M-TechArjun NbNo ratings yet

- Ugc Net June 2014 CentresDocument6 pagesUgc Net June 2014 CentresArjun NbNo ratings yet

- IntroductionDocument13 pagesIntroductionArjun NbNo ratings yet

- DSDFGDFDFGDSFDF Sdgsgs Ss FSDF SDF SDF SDF FSDSF DGSDG DfzsgsdgdfgdfsDocument4 pagesDSDFGDFDFGDSFDF Sdgsgs Ss FSDF SDF SDF SDF FSDSF DGSDG DfzsgsdgdfgdfsArjun NbNo ratings yet

- SylabusDocument2 pagesSylabusArjun NbNo ratings yet

- A Text Book On Automobile Chassis and Body Engineering (ADocument58 pagesA Text Book On Automobile Chassis and Body Engineering (Ahunny29100% (2)

- DSDFGDFDFGDSFDF Sdgsgs Ss FSDF SDF SDF SDF FSDSF DGSDG DfzsgsdgdfgdfsDocument4 pagesDSDFGDFDFGDSFDF Sdgsgs Ss FSDF SDF SDF SDF FSDSF DGSDG DfzsgsdgdfgdfsArjun NbNo ratings yet

- AerfgDocument5 pagesAerfgArjun NbNo ratings yet