Professional Documents

Culture Documents

LAMPIRAN Perhitungan

Uploaded by

Athia Hasna NurhanifahOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

LAMPIRAN Perhitungan

Uploaded by

Athia Hasna NurhanifahCopyright:

Available Formats

LAMPIRAN

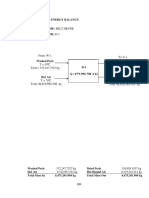

A. Perhitungan

Tabel L.1 Physical Properties Pada shell

Shell ( Etilen Oksida + Air)

Parameter

Notasi

Desain

Aktual

Satuan

Laju alir massa

Wh

23024,02193

16274,1494

kg/h

Suhu masuk

Thi

48

46,41

Suhu keluar

Tho

45

45,34

Kapasitas panas

Cph

1,7106

1,3079

kJ/kg

Konduktifitas Panas

Kf

0,0830

0,0153

W/m

Densitas (Campuran)

420,8566

6,7459

kg/m3

Viskositas (campuran)

0,000127

9,247E-06

kg/s-m

Panas Laten

545,1691

546,6336

kJ/kg

Tabel L.2 Physical Properties Pada Tube

Tube ( Cooling Water)

Parameter

Notasi

Desain

Aktual

Satuan

Laju alir massa

Wc

Suhu masuk

Tci

299395,8069

33

36,6

Suhu keluar

Tco

43

41

Kapasitas panas

Cpc

4,2250

4,226295233

kJ/kg

Konduktifitas Panas

kf

0,6288

0,629762967

W/m

Densitas (Campuran)

997,5381

997,1117

kg/m3

Viskositas (campuran)

0,0006821

0,0006696

kg/s-m

kg/h

1. Menghitung Overall Coefficient Aktual

a. Tube Side Coefficient

do: 0,01905 m, di: 0,01575 m, L: 5,93392 m, triangular pitch: 0,025m,

carbon steel, Number of tube: 1220 (4-tube passes)

Surface Area of one tube

=

= 3,14 x 0,01905 m x 5,93392 m

= 0,354949293 m

Cross sectional area

= (0,01575 m)

= 0,000194729 m

Area per pass

= Numb of tube/pass x Cross sectional area

= 305 x 0,000194729 m

= 0,059392364 m

Volumetrik Flow

=

=

x

3

= 0,123469276 m /s

Tube side velocity, vt

=

=

= 2,07887458 m/s

Tube side heat transfer coefficient

hi

=

=

= 9225,837568 W/m

)

2

b. Shell side Coefficient

Dari tabel 19.1 (Towler,2013), untuk alat penukar panas jenis

kondensor dengan fluida panas berupa Etilen oksida (organic vapors) dan

fluida dingin berupa air, nilai koefisien perpindahan panas menyeluruhnya

berada pada kisaran 700-1000 W/m

W/m

dan dipilih U assumsi sebesar 900

.

2

Asumsi koeffisien kondensat yaitu 5000 w/m .

Mean Temperature

Shell Side

=

= 45,875

Tube Side

=

= 38,65

(45,875

- Tw) x 5000 w/m .

= (45,875

- 38,65

Tw= 44, 5745

Mean temperature condensate =

= 45,22475

Physical Properties pada 45,22475

L

= 0,000245 kg/s.m

= 835,4835 kg/m3

= 5,970988 kg/m3

kL

= 0,151248 w/m.

= 0,0006244 kg/s.m

(

hc

=0,76 kL *

) x 900 w/m .

=0,76x0,151248W/m.

]

(

)

=3670 W/m

c. Overall Coefficient actual

Termal conuctivity of carbon stell = 45 W/m

Fouling factor light organic (hcd)

= 5000 W/m

Fouling factor Cooling water (hid) = 3000 W/m

=

2.

= 0,001047347 m

/W

= 954,7938437 W/m

Menghitung Overall Coefficient Desain

Diketahui

:A

= 430,7 m

1) Menghitung nilai Q

Menghitung Panas Laten

Qlaten

= mh x

x 545,1691 kJ/kg

= 3486,66282 kW

Menghitung Panas Sensibel

Qsensibel = mh x Cph x

=

=32,8199 kW

x 1,7106 kJ/kg

(48

- 45

Mengitung Panas Total

Q tot

= Qlaten + Qsensibel

= 3486,66282 kW + 32,8199 kW

= 3519,48277 kW = 3519482,77 W

2) Mengitung

LMTD

LMTD

) )

(

= 7,99572

)

(

)

()

= 0,3

= 0,67

Untuk R= 0,3 dan S= 0,67, maka dari gambar 19.19 (Towler, 2013)

diperoleh Ft= 0,92

lm

= Ft x

LMTD

= 0,92 x 7,99572

= 7,3560

3) Menghitung nilai U desain

Q

= UxAx

LMTD

=

= 1110,8585 W/m

Effisiensi

=

=

x 100% = 85,95 %

3.

Menghitung Pressure Drops Purification Colomn Condenser (E-411)

Pressure drop Aktual

a. Tube side

Re

=

=

= 48755,3683

-3

Dari gambar 19.24 (Towler, 2013), jf = 3,2 x 10

= Np *

+

(

=4*

= 104671,1556 N/m = 1,05 bar ( 15,2 Psi )

Syarat pressure drop pada tube (<10Psi)

b. Shell side

Baffle spacing: 0,377 m, Baffle cut 20%

Cross flow area (As)

(

)

=

=

)

2

= 0,09062 m

Mass Velocity (Gs)

=

=

x

2

= 49,8834 kg/s-m

Equivalent Diameter (de)

=

=

)

2

(0,025 0,917 x (0,01905 m) )

= 0,016874 m

Shell side velocity (vs)

=

=

= 8,3543 m/s

Re

=

=

= 91492,66

-2

Dari gambar 19.30 (Towler, 2013), untuk Re = 91492,66, jf = 4 x 10 ,

= 8 jf (

)(

)

(

)

= 8 x 4x 10-2 (

= 62820,65 N/m

)(

= 0,63 bar = ( 9,1 Psi )

Syarat Pressure drop pada shell (<1 Psi)

4.

Mendesain Ulang Purification Colomn Condenser (E-411) Berdasarkan

Data Aktual

Step 1 Spesification

Suhu rata-rata fluida panas dan dingin

Th av

Tc av

=

=

= 45,875

= 38,65

Menghitung Panas Laten

Qlaten

= mh x

x 546,6336 kJ/kg = 2471,11 kW

Menghitung Panas Sensibel

Qsensibel = mh x Cph x

=

x 1,3079 kJ/kg

(46,41

- 45,34

=6,3263 kW

Mengitung Panas Total

Q tot

= Qlaten + Qsensibel

= 2471,11 kW + 6,3263 kW

= 2477,437 kW = 2477437 W

Step 2 Phycical Properties

Tabel L.3 Physical Properties Purification Colomn Condensor (E-411)

Shell

Masuk

Rata-rata

Keluar

Temperatur

46,41

45,875

45,34

Kapasitas Panas

1,2139

1,3078

1,4018

kJ/kg

1,53E-02

0,0153

1,52E-02

W/m

6,1224

6,7459

7,3694

kg/m3

9,26E-06

9,25E-06

9,23E-06

kg/s-m

36,6

45,875

41

4,2266

4,2263

4,2259

kJ/kg

Konduktivitas termal

6,27E-01

0,6297

6,33E-01

W/m

Densitas

998,9074

997,1117

995,3160

kg/m3

Viskositas

7,00E-04

0,000669

6,39E-04

kg/s-m

Konduktivitas termal

Densitas

Viskositas

Satuan

Tube

Temperatur

Kapasitas Panas

Step 3 Overall Coefficient

Dari tabel 19.1 (Towler,2013), untuk alat penukar panas jenis kondensor

dengan fluida panas berupa Etilen oksida (organic vapors) dan fluida dingin

berupa air, nilai koefisien perpindahan panas menyeluruhnya berada pada kisaran

700-1000 W/m

dan dipilih U assumsi sebesar 900 W/m

Step 4 Exchanger Tipe and Dimensions

Satu shell pass dan empat tube pass

LMTD =

(

(

)

)

= 7,0704

)

()

= 0,2276

)

(

= 0,46488

)

(

Untuk R= 0,2276 dan S= 0,46488, maka dari gambar 19.19 (Towler, 2013)

diperoleh Ft=0,98

lm

= Ft x

LMTD

= 0,98 x 7,0704

= 6,9289

Step 5 Heat Transfer Area

Ao

=

=

= 397,2241 m

Step 6 Layout and Tube Size

Diameter Luar (do)

= 19,05 mm = 0,01905 m

Diameter dalam (di) = 14,83 mm = 0,01483 m

Panjang Tube (L)

= 3660 mm = 3,66 m

Pitch (Pt) (1,25.do)

= 23,813 mm = 0,023813 m

Step 7 Number Of Tube

Area Per Tube (At)

x d0 x Lt

x 0,01905 m x 3,66 m

2

= 0,2189 m

Number Of Tubes (Nt)

=

=

= 1814,3868

Tube Per Pass

=

= 455

Tube Cross Sectional Area

x di

x (0,01483 m)

= 0,0001726 m

Area Per Pass

=Tube Per Pass x Tube Cross Sectional Area

2

= 455 x 0,0001726 m

2

= 0,0786 m

Volumetric Flow

=

=

3

= 0,1235 m /s

Tube Side Velocity (vf)

=

=

= 1,5718 m/s

Step 8 Bundle and Shell Diameter

Dari tabel 19.4, untuk 4 tube passes, K1= 0,175 dan n1=2,285

Diameter Bundle (Db)

= d0 x ( )

= 19,05 mm x (

= 1091 mm

Menggunakan Fixed tube

Dari gambar 19.12 shell bundle clearance = 18 mm

Diameter Shell (Ds)

= 1091 mm + 18 mm

= 1109 mm = 1,109 m

Step 9 Tube Side Heat Transfer Coefficient

hi

)(

=

=

7465,9915 W/m

Step 10 Shell Side Heat Transfer Coefficient

2

Asumsi koefisien kondensat yaitu 5000 w/m .

Mean Temperature

Shell Side

=

= 45,875

Tube Side

=

= 38,65

(45,875

- Tw) x 5000 w/m .

= (45,875

- 38,65

Tw= 44, 5745

Mean temperature condensate =

`Physical Properties pada 45,22475

L

= 0,00024 kg/s.m

= 835,4835kg/m3

= 5,97099 kg/m3

kL

h

= 0,15125 W/m

=

= 0,000679 kg/s.m

) x 900 w/m .

= 45,22475

hc = 0,76 kL *

=0,76x0,15125w/m.

]

(

)

= 3591,0717 w/m

Nilai hc yang diperoleh dapat diterima, sehingga tidak perlu mengkoreksi nilai Tw

Step 11 Overall Coefficient

Termal conuctivity of carbon stell

= 45 W/m

Fouling factor light organic

(hsd)

= 5000 W/m

Fouling factor Cooling water (hid)

= 3000 W/m

= 0,001132 m

U

= 883,6158 W/m

x

+

/W

2

Nilai Uo yang diperoleh dapat diterima, dan selanjutnya mengecek nilai pressure

drop

Step 12 Pressure drop

Tube side pressure drop

Re

=

= 33898,789

-3

Dari gambar 19.24 (Towler, 2013), jf = 3,6 x 10

= Np *

+

(

=4*

= 47335,4834 N/m

= 0,47 bar ( 6,86 Psi )

dapat diterima karena syarat

(<10 Psi)

Shell side pressure drop

Menggunakan fixed tube

Memilih baffle spacing = shell siameter, Baffle cut 25%

(

Cross flow area (As)

=

=

)

2

= 0,2460 m

Mass Velocity (Gs)

=

=

x

2

= 18,3752 kg/s-m

Equivalent Diameter (de)

=

=

= 0,01353 m

Shell side velocity (us)

(0,023813 0,917x(0,01905m) )

=

=

= 3,0774 m/s

Shell side heat transfer coefficient

Re

=

=

= 26834,2547

-3

Dari gambar 19.30 (Towler, 2013), untuk Re = 26834,2547 jf = 4,2 x 10 ,

= 8 jf (

)(

)

(

)

= 8 x 3,2x 10-2 (

= 2570,9589 N/m

)(

= 0,025 bar = ( 0,37 Psi )

dapat diterima karena syarat

(<1 Psi)

You might also like

- ThermodynamicsDocument33 pagesThermodynamicsJanneNo ratings yet

- Double Pipe Heat Exchanger Project #3 CalculationsDocument12 pagesDouble Pipe Heat Exchanger Project #3 CalculationsJames Buser100% (1)

- MATERIAL Mechanical DesignDocument11 pagesMATERIAL Mechanical DesignanisNo ratings yet

- ReviewerDocument84 pagesReviewerEdmil Jhon Ariquez100% (6)

- Cooling EquipmentDocument15 pagesCooling EquipmentRomelyn Suyom PingkianNo ratings yet

- BSGS Sample Problems 2 - BB CollabDocument21 pagesBSGS Sample Problems 2 - BB CollabNeo GarceraNo ratings yet

- Design Shell and TubeDocument15 pagesDesign Shell and TubeAhmad MaskurNo ratings yet

- MECHANICAL DESIGN: Superheater Design for Ammonia HeatingDocument13 pagesMECHANICAL DESIGN: Superheater Design for Ammonia HeatingSchaieraNo ratings yet

- Workbook Workbook Workbook Workbook Workbook: Try Yourself QuestionsDocument14 pagesWorkbook Workbook Workbook Workbook Workbook: Try Yourself QuestionsAnu Sandeep AggrawalNo ratings yet

- Tugas2 ParalelB 4Document14 pagesTugas2 ParalelB 4Thobroni AkbarNo ratings yet

- Energy Balance FINAL SUBMITDocument34 pagesEnergy Balance FINAL SUBMITRelaxing MusicNo ratings yet

- PIPE REVIEWER SOLUTIONSDocument189 pagesPIPE REVIEWER SOLUTIONSzxzzenNo ratings yet

- Problem Setsin PIPEDocument52 pagesProblem Setsin PIPEMIchael Cabungcal0% (1)

- Optimizing Sodium Nitrate ProductionDocument55 pagesOptimizing Sodium Nitrate ProductionRoni SetiawanNo ratings yet

- Bluebook With ElementsDocument207 pagesBluebook With ElementsFrenzel Annie LapuzNo ratings yet

- ESAS Actual Board. Thank Me LaterDocument5 pagesESAS Actual Board. Thank Me LaterRhea Pardo PeralesNo ratings yet

- Tutorium Refrigeration SolutionDocument20 pagesTutorium Refrigeration SolutionwanpudinNo ratings yet

- Thermo ProblemsDocument8 pagesThermo ProblemsChrister John UyNo ratings yet

- HW 5 SolnDocument7 pagesHW 5 SolnNik Hafiy HafiziNo ratings yet

- Unit 1 - 16 MarkDocument23 pagesUnit 1 - 16 MarkShanhoodNo ratings yet

- Cold Storage DesignDocument30 pagesCold Storage DesignMarjohn Lucidos100% (1)

- Detailed energy balance of belt dryer and sterilizerDocument31 pagesDetailed energy balance of belt dryer and sterilizerkennethmsorianoNo ratings yet

- Blue Book With SolutionDocument55 pagesBlue Book With SolutionMiguel BanzonNo ratings yet

- Blue Book PIPEDocument55 pagesBlue Book PIPEJohnMichaelCabungcalNo ratings yet

- CH 09Document22 pagesCH 09hirenpatel_universalNo ratings yet

- Basic Heat Exchanger DesignDocument10 pagesBasic Heat Exchanger DesignKvspavan KumarNo ratings yet

- Solved Problems in Heat TransferDocument16 pagesSolved Problems in Heat TransferAngelica Joyce Benito100% (3)

- Coulson Solution ManualDocument13 pagesCoulson Solution Manualmachine20No ratings yet

- Proposed Design of a 30-Ton Ice PlantDocument8 pagesProposed Design of a 30-Ton Ice Planteafz111No ratings yet

- Me6301 QBDocument46 pagesMe6301 QBNaveen Dhanuraj100% (1)

- CH 05Document14 pagesCH 05hirenpatel_universalNo ratings yet

- Double Pipe Heat Exchanger: Experiment 9Document6 pagesDouble Pipe Heat Exchanger: Experiment 9Jelain HumarangNo ratings yet

- Bab 2Document13 pagesBab 2Teguh Novri YansyahNo ratings yet

- Pipe Alcorcon1Document86 pagesPipe Alcorcon1Nelson Naval Cabingas100% (11)

- Spek EVADocument9 pagesSpek EVAafefNo ratings yet

- IntroTHT 2e SM Chap11Document1 pageIntroTHT 2e SM Chap11Govind RaoNo ratings yet

- Perhitungan 1. Laju Perpindahan KalorDocument6 pagesPerhitungan 1. Laju Perpindahan KalorAnggoro RestuNo ratings yet

- 7.flash DistilerDocument35 pages7.flash DistilerNa-na OktaviaNo ratings yet

- Condenser Without SubcoolingDocument19 pagesCondenser Without SubcoolingtatvaNo ratings yet

- Condensation and BoilingDocument14 pagesCondensation and BoilingCrislyn Akilit Bayawa100% (1)

- GENERAL SCIENCES (Key)Document4 pagesGENERAL SCIENCES (Key)HectorCabzNo ratings yet

- 7 12521039 Savannah Yonita Tugas2Document9 pages7 12521039 Savannah Yonita Tugas2Savannah Yonita CNo ratings yet

- AE 231 Thermodynamics Recitation 8 Problems - Diffuser, Turbine Cycle, Piston Spring SystemDocument13 pagesAE 231 Thermodynamics Recitation 8 Problems - Diffuser, Turbine Cycle, Piston Spring SystemOnur ÖZÇELİKNo ratings yet

- Rotary Dryer DesignDocument43 pagesRotary Dryer DesignsasitharNo ratings yet

- Panel RadiatorDocument9 pagesPanel RadiatorYusufcan DindarNo ratings yet

- Boiler CalculationDocument37 pagesBoiler CalculationFmJoy Dioko100% (2)

- A Proposed Design of Ice PlantDocument8 pagesA Proposed Design of Ice PlantNirob MahmudNo ratings yet

- PPD - Module IDocument9 pagesPPD - Module IJohn Babe CapiliNo ratings yet

- Chee Assignment 1Document13 pagesChee Assignment 1TSHEGOFATSO GOTSILENGNo ratings yet

- Heat Exchanger Design for Cooling Kerosene Using Light Crude OilDocument15 pagesHeat Exchanger Design for Cooling Kerosene Using Light Crude OilCharito Sollera AlbaricoNo ratings yet

- Result Assignment ThermoDocument6 pagesResult Assignment ThermoSuraya JohariNo ratings yet

- ALCORCON ENGINEERING REVIEW CENTER MECHANICAL ENGINEERING REFRESHER SET 1Document14 pagesALCORCON ENGINEERING REVIEW CENTER MECHANICAL ENGINEERING REFRESHER SET 1Neil SequioNo ratings yet

- Raft foundation design and soil data analysisDocument35 pagesRaft foundation design and soil data analysisManMan ArowganteNo ratings yet

- Appendix A.docx FinalDocument17 pagesAppendix A.docx FinalPeterNo ratings yet

- Fundamental Numerical Values Made SimpleDocument64 pagesFundamental Numerical Values Made SimpleFaiz Daud100% (1)

- Chapter 7 - Condensers Problems 7.2 A 1-1/2 Ton R 22 Air Conditioner, Operating at 58°C Condensing and 5°C EvaporatingDocument15 pagesChapter 7 - Condensers Problems 7.2 A 1-1/2 Ton R 22 Air Conditioner, Operating at 58°C Condensing and 5°C EvaporatingEriane GarciaNo ratings yet

- Daftar PustakaDocument2 pagesDaftar PustakaAthia Hasna NurhanifahNo ratings yet

- Yes PDFDocument1 pageYes PDFAthia Hasna NurhanifahNo ratings yet

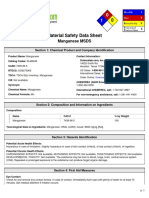

- Manganese MSDS: Section 1: Chemical Product and Company IdentificationDocument6 pagesManganese MSDS: Section 1: Chemical Product and Company IdentificationAthia Hasna NurhanifahNo ratings yet

- ICIS Chemicals EthyleneDocument3 pagesICIS Chemicals EthyleneAthia Hasna NurhanifahNo ratings yet

- Journal Benjamin BeckDocument7 pagesJournal Benjamin BeckAthia Hasna NurhanifahNo ratings yet

- TDocument3 pagesTAthia Hasna NurhanifahNo ratings yet

- Original Citation:: Warwick - Ac.uk/lib-PublicationsDocument9 pagesOriginal Citation:: Warwick - Ac.uk/lib-PublicationsAthia Hasna NurhanifahNo ratings yet

- Gas BumiDocument17 pagesGas BumiAthia Hasna NurhanifahNo ratings yet

- LAMPIRAN PerhitunganDocument14 pagesLAMPIRAN PerhitunganAthia Hasna NurhanifahNo ratings yet

- Designing Compact Heat ExchangersDocument6 pagesDesigning Compact Heat ExchangersAndrés Ramón Linares100% (1)

- Sheet Neraca Massa Dan EnergiDocument2 pagesSheet Neraca Massa Dan EnergiAthia Hasna NurhanifahNo ratings yet

- Process Flow DiagramsDocument42 pagesProcess Flow DiagramsAthia Hasna NurhanifahNo ratings yet

- DME Kel 1Document3 pagesDME Kel 1Athia Hasna NurhanifahNo ratings yet

- Flare, Venting, BD SystemDocument9 pagesFlare, Venting, BD SystemAthia Hasna NurhanifahNo ratings yet

- (Adrian Duncan) Introduction To Chemical EngineeriDocument177 pages(Adrian Duncan) Introduction To Chemical EngineeriΔέσποινα ΑνδρίκουNo ratings yet