Professional Documents

Culture Documents

Datasheet Forsheda 945

Uploaded by

Abdel Nasser AdamCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Datasheet Forsheda 945

Uploaded by

Abdel Nasser AdamCopyright:

Available Formats

T REL L EB O RG PIPE S E A L S

Forsheda 945

Flexible connection

system for laterals to

pipelines and large

double walled plastic

manholes

SEAL DESIGN AND FUNCTION MATERIAL

Forsheda 945 is a rubber seal for flexible connec- Synthetic rubber SBR or EPDM

tion of pipes to manholes and laterals to pipelines. It Hardness 405 IRHD

can be used with both prefabricated and core drilled Approved in accordance with EN 681-1

holes. The multiple lip design allows ease of jointing

and provides excellent resistance to transvers shear Protected against ozone

load whilst allowing a high level of angular deflection Available in oil resistant material

in the joint. The extra wide profile can cover exposed

steel renforcement in core drilled holes protecting it QUALITY ASSURANCE

from potential corrosion. ISO 9001

SEAL PERFORMANCE British Standard Kitemark

The Forsheda 945 seal meets the requirement of all CE-marking

relevant current European standards.

SEAL MARKING AND BOX LABELS

Each seal is marked with the outside diameter

of the connecting pipes and period of manufac-

ture. The box is labelled with corresponding data.

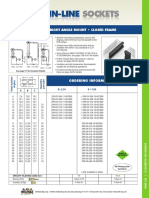

Seal Marking and Box Labels 355 25.8 40.9

Each seal is marked with seal dimension and period

400 28,0 44,9

of manufacture. The box is labelled with correspon-

ding data. 450 29,5 47,0

500 32,2 51,4

JOINT ASSEMBLY EXAMPLE OF SIZES

630 38.2 61.3

Press the Forsheda 945 Pipe Assembly

seal into the hole. Do not

use lubricant.

Example of sizes

Chamfer the edge of the Dimensions, mm

DN OD, mm Drilled hole

connecting Pipe

pipe size,

and lub-

mm A B

ricate it with Forsheda

63 10,4 17,8

110 142 138

lub. 75 11,6 19,9 1. Chamfer the spigot end.

160 190 186

90 12,7 21,7 2. Clean the socket.

100-S2 13.8 21.6 3. Apply

200 lubricant

233 on the spigot

226 before assembly.

4. Slide the spigot into the socket, thus compres-

110 13,8 22,0 250 287 276

sing the sealing lip.

125 13,8 23,6 315 351 341

Centre the end140 of the 14,8 25,3

pipe and push150-S2

it into the 17.2 23.5

400 439 426

seal, so that the

160

pipe 15,9 27,2

end is flush with the

180 17.5 28.8

inner wall.

200 16,9 29,0

200-S2 20.2 32

225 18,0 30,8 Please contact Trelleborg Pipe Seals for technical

225-S2 21.8 33.8 advice and joint design recommendations to meet

250 21,1 34,2 your performance requirements.

250-S2 23.6 37

Pipe connections with F-910 shall always be laid in

280 22,5 36,1

accordance with applicable standards and regula-

300-S2 23.7 40.4 Pipes

tions. with F-576 shall always be laid in accordance

315 23,6 37,6 with applicable standards and regulations.

Please contact Trelleborg Pipe Seals Lelystad BV for

technical advice and joint design recommendations

to meet your performance requirements.

Example of authorities Trelleborg Pipe Seals cooperates with:

Examples of

Trelleborg Pipe Seals Lelystad B.V.

P.O.Box 62, 8200 AB Lelystad, the Netherlands. Visiting address: Pascallaan 80, 8218 NJ Lelystad, the Netherlands.

Tel: +31(0)320267979, Fax: +31(0)320267980.

W W W.T REL L EB www.Trelleborg.com/pipeseals

O RG .C O M/PIPE- S E A L S

Trelleborg Pipe Seals Lelystad 2011/01. We reserve the right to make changes without prior notification.

You might also like

- Ps 001222Document16 pagesPs 001222Lassané KINDONo ratings yet

- Resin Injected Bolted Connections: A Step Towards Achieving Slip-Resistant Joints in FRP Bridge EngineeringDocument11 pagesResin Injected Bolted Connections: A Step Towards Achieving Slip-Resistant Joints in FRP Bridge EngineeringElma GrizovicNo ratings yet

- Reinforcement CouplersDocument24 pagesReinforcement CouplersvishalgoreNo ratings yet

- App B3-DEWA Tech & STD SpecsDocument2 pagesApp B3-DEWA Tech & STD SpecsanooppattazhyNo ratings yet

- Fichas TécnicasDocument22 pagesFichas TécnicasCarlos LopezNo ratings yet

- Copperbenelux Large Diameter TubesDocument15 pagesCopperbenelux Large Diameter TubesRuben PauwelsNo ratings yet

- QueryDocument2 pagesQueryTu PhamNo ratings yet

- Assembly InstructionsDocument8 pagesAssembly InstructionsEduardo Farrera RedondoNo ratings yet

- 1 2 2 System Description 2 3 Material and Identification 4 4 Load Capacity 4 5 Production 4 6 Installation 7 7 Quality Assurance 7 8 Applications 8Document8 pages1 2 2 System Description 2 3 Material and Identification 4 4 Load Capacity 4 5 Production 4 6 Installation 7 7 Quality Assurance 7 8 Applications 8Vagany7No ratings yet

- BRICK Book6Document5 pagesBRICK Book6nextomegagenNo ratings yet

- Vitrified Clay Drainage SystemDocument24 pagesVitrified Clay Drainage SystemAshwin DSNo ratings yet

- E Fire Piping FM Approval Certificate Including Min Wall ThicknessDocument4 pagesE Fire Piping FM Approval Certificate Including Min Wall ThicknessDejan DosljakNo ratings yet

- Lokfix: Mix and Place Polyester Resin Anchoring GroutsDocument4 pagesLokfix: Mix and Place Polyester Resin Anchoring GroutsMuhamad HisyamNo ratings yet

- Ancon MBT Couplers International VersionDocument14 pagesAncon MBT Couplers International Versionjcunha4740No ratings yet

- Tie Technology DK SKDocument32 pagesTie Technology DK SKVladimir PleșcaNo ratings yet

- Ancon Tapered Thread Couplers International Version PDFDocument16 pagesAncon Tapered Thread Couplers International Version PDFAhmadHamdyNo ratings yet

- Fosroc Lokfix: Mix and Place Polyester Resin Anchoring Grouts Uses DescriptionDocument4 pagesFosroc Lokfix: Mix and Place Polyester Resin Anchoring Grouts Uses DescriptionMostafa MashhourNo ratings yet

- S.No. Description Unit No L B H QtyDocument69 pagesS.No. Description Unit No L B H QtyRamLalJatNo ratings yet

- GF Pe Ecofit CatDocument146 pagesGF Pe Ecofit CatThein Zayar OoNo ratings yet

- Ancon MBT Couplers International Version PDFDocument14 pagesAncon MBT Couplers International Version PDFAhmadHamdyNo ratings yet

- Sanitary Fittings Best PracticesDocument8 pagesSanitary Fittings Best PracticesAbraham GarciaNo ratings yet

- Mos3200 Bs 2000m FP Product DataDocument4 pagesMos3200 Bs 2000m FP Product DataJeromeNo ratings yet

- 10 Inch Expansion BellowDocument1 page10 Inch Expansion BellowASHWINI BHOSALENo ratings yet

- Specification For Double Pipes: Rev. Date Revision Description Issued by Checked by Approved byDocument11 pagesSpecification For Double Pipes: Rev. Date Revision Description Issued by Checked by Approved byvishal bhamreNo ratings yet

- Duct and PVC in ConcreteDocument6 pagesDuct and PVC in ConcreteAli AimranNo ratings yet

- 443Document2 pages443nile_asterNo ratings yet

- Piping - ValvesDocument270 pagesPiping - ValvesAHMED GAMALNo ratings yet

- Taco Brazed Plate HX Install ManualDocument11 pagesTaco Brazed Plate HX Install ManualTEMPNo ratings yet

- Lokfix : (Formerly Known As Lokset)Document4 pagesLokfix : (Formerly Known As Lokset)Jose ManjooranNo ratings yet

- Robor Ductile Iron Brochure5Document12 pagesRobor Ductile Iron Brochure5Christiaan SnydersNo ratings yet

- Lokfix PDFDocument4 pagesLokfix PDFmangjitNo ratings yet

- FMC Weco Wing Union CatalogDocument16 pagesFMC Weco Wing Union CatalogSargunam Sankaravadivel100% (2)

- LokfixDocument4 pagesLokfixstructdesignNo ratings yet

- 1 s2.0 0010436183900137 MainDocument8 pages1 s2.0 0010436183900137 Mainprem kumarNo ratings yet

- Dual in LineDocument1 pageDual in LineWin RobinNo ratings yet

- File 1488Document8 pagesFile 1488Hamed GeramiNo ratings yet

- Lokfix PDFDocument3 pagesLokfix PDFtalatzahoorNo ratings yet

- Bartec Headed Bars Qualification File and References 2017.09.08Document35 pagesBartec Headed Bars Qualification File and References 2017.09.08Andres Hermoso MeijideNo ratings yet

- Splices, Development and STD - HooksDocument6 pagesSplices, Development and STD - Hooksjem guiNo ratings yet

- Roof Erectors Handbook Vol 11Document87 pagesRoof Erectors Handbook Vol 11forbeskaNo ratings yet

- Bending PVC ASTM D3034Document4 pagesBending PVC ASTM D3034Oscar PachecoNo ratings yet

- Avk Gate Valve, Flanged, Pn25 02/67-030: EN 558-2 S.15/DIN F5, Bronze CC499K Wedge Nut, DN50-300Document2 pagesAvk Gate Valve, Flanged, Pn25 02/67-030: EN 558-2 S.15/DIN F5, Bronze CC499K Wedge Nut, DN50-300kad-7No ratings yet

- Din 2460-1Document5 pagesDin 2460-1karthikNo ratings yet

- ODU Heavy Duty Connector Assembly Guide Lines PDFDocument2 pagesODU Heavy Duty Connector Assembly Guide Lines PDFM Usman ChaudharyNo ratings yet

- Injection-Molding Problems in Engineering Thermoplastics: Causes and SolutionsDocument70 pagesInjection-Molding Problems in Engineering Thermoplastics: Causes and SolutionsPhucNo ratings yet

- Kimmco-Isover Rigid Pipe Covering (K450)Document8 pagesKimmco-Isover Rigid Pipe Covering (K450)amirNo ratings yet

- Corus Clad PipeDocument7 pagesCorus Clad PipeDBasak_1974No ratings yet

- 1 1 122 eDocument2 pages1 1 122 edjkruggerNo ratings yet

- WSeal CatalogDocument4 pagesWSeal CatalogwalidNo ratings yet

- Flowline Products and Services: World Proven Chiksan and Weco EquipmentDocument15 pagesFlowline Products and Services: World Proven Chiksan and Weco Equipmentcanales117No ratings yet

- Clay - NEW-Clay-Drainage-0616Document24 pagesClay - NEW-Clay-Drainage-0616AMOLNo ratings yet

- Wireline Completion Tools PDFDocument124 pagesWireline Completion Tools PDFSea CostNo ratings yet

- Dutile IronDocument9 pagesDutile IronSaravanan ManiNo ratings yet

- Annexure-6 FOSROC - Lokfix & Nitobond Technical DataDocument10 pagesAnnexure-6 FOSROC - Lokfix & Nitobond Technical DatadineshNo ratings yet

- Heyco-Flex Liquid Tight Conduit FittingsDocument1 pageHeyco-Flex Liquid Tight Conduit FittingsRodney LanagNo ratings yet

- Siemens Flow SwitchDocument6 pagesSiemens Flow Switcheng.abdullrahmanNo ratings yet

- Design Guidelines for Surface Mount TechnologyFrom EverandDesign Guidelines for Surface Mount TechnologyRating: 5 out of 5 stars5/5 (1)

- Manufacturing Technology for Aerospace Structural MaterialsFrom EverandManufacturing Technology for Aerospace Structural MaterialsRating: 5 out of 5 stars5/5 (2)

- Records ModelsDocument9 pagesRecords ModelsAbdel Nasser AdamNo ratings yet

- VR - Polymers & Packaging RIDocument9 pagesVR - Polymers & Packaging RIAbdel Nasser AdamNo ratings yet

- Tool Selection MatrixDocument4 pagesTool Selection MatrixAbdel Nasser AdamNo ratings yet

- Print ALL Strategy Output Worksheets: Think Plan ActDocument51 pagesPrint ALL Strategy Output Worksheets: Think Plan ActAbdel Nasser AdamNo ratings yet

- P&B PresentationDocument39 pagesP&B PresentationAbdel Nasser AdamNo ratings yet

- Manufacturing ProcessesDocument5 pagesManufacturing ProcessesAbdel Nasser AdamNo ratings yet

- WaxesDocument3 pagesWaxesAbdel Nasser AdamNo ratings yet

- Elastic Properties of PVC PipesDocument1 pageElastic Properties of PVC PipesAbdel Nasser AdamNo ratings yet

- Gauge / Instruments - Calibration History Card: Identification No.Document1 pageGauge / Instruments - Calibration History Card: Identification No.simsonNo ratings yet

- Waxes PDFDocument3 pagesWaxes PDFAbdel Nasser AdamNo ratings yet

- Msds TalcDocument5 pagesMsds TalcSiva KumarNo ratings yet

- Productivity كتاب هتتعلم منه كتير ياريت تقراه اكتر من مره PDFDocument35 pagesProductivity كتاب هتتعلم منه كتير ياريت تقراه اكتر من مره PDFمجدي الشيخNo ratings yet

- 4.53 Change Management ProcedureDocument4 pages4.53 Change Management ProcedureAbdel Nasser AdamNo ratings yet

- Nickel BrightenerDocument3 pagesNickel BrightenerAbdel Nasser AdamNo ratings yet

- SWOT TemplateDocument6 pagesSWOT TemplatearnisasaniNo ratings yet

- UPVC Pipes For Sewer As Per DIN 19534Document1 pageUPVC Pipes For Sewer As Per DIN 19534Abdel Nasser AdamNo ratings yet

- O RingsDocument9 pagesO RingsAbdel Nasser AdamNo ratings yet

- Modifiable Skills MatrixDocument88 pagesModifiable Skills MatrixAbdel Nasser AdamNo ratings yet

- Exh6alv 3Document17 pagesExh6alv 3Abdel Nasser AdamNo ratings yet

- Extrusion TroubleshootingDocument2 pagesExtrusion TroubleshootingAbdel Nasser AdamNo ratings yet

- Kaizen FormsDocument25 pagesKaizen FormsAbdel Nasser AdamNo ratings yet

- Quality Circles 263Document14 pagesQuality Circles 263Ajashra SharmaNo ratings yet

- Lean Hospitals Arabic SmallDocument280 pagesLean Hospitals Arabic SmallAbdel Nasser AdamNo ratings yet

- Compression Spring ChecklistDocument1 pageCompression Spring ChecklistAbdel Nasser AdamNo ratings yet

- Guidance For Documented Information ISO 9001 2015Document5 pagesGuidance For Documented Information ISO 9001 2015Abdel Nasser AdamNo ratings yet

- Quality ManualDocument22 pagesQuality ManualRajeeb MohammedNo ratings yet

- 5S BasicsDocument26 pages5S BasicsAnonymous ZBMKga2LINo ratings yet

- 2011 06 20 Plastics Europe Guidelines For GMP Updated June 2011 FinalDocument8 pages2011 06 20 Plastics Europe Guidelines For GMP Updated June 2011 FinalNabil BuenoNo ratings yet

- مقاومة الموادDocument60 pagesمقاومة الموادhasnen83100% (5)

- Battle Healing PrayerDocument9 pagesBattle Healing PrayerSolavei LoanerNo ratings yet

- Corporate Security Policy TemplateDocument4 pagesCorporate Security Policy TemplateCoronaNo ratings yet

- Bad Effects of Festivals On The EnvironmentDocument10 pagesBad Effects of Festivals On The EnvironmentSahil Bohra85% (52)

- Radfet DatasheetDocument6 pagesRadfet DatasheetNicholas EspinozaNo ratings yet

- Phillips LoFloDocument29 pagesPhillips LoFlokawaiiriceNo ratings yet

- Trophic Levels - 10% RuleDocument5 pagesTrophic Levels - 10% RulerebbiegNo ratings yet

- Ship Captain's Medical Guide - 22nd EdDocument224 pagesShip Captain's Medical Guide - 22nd EdcelmailenesNo ratings yet

- Sacrament ChartDocument3 pagesSacrament ChartXam PerezNo ratings yet

- ASNT QuestionsDocument3 pagesASNT Questionsshabbir626100% (1)

- Park Ch. 1 - A1000 - Spring13Document21 pagesPark Ch. 1 - A1000 - Spring13lingyeeNo ratings yet

- Tiling Checklist UpdatedDocument3 pagesTiling Checklist UpdatedSayed Taimoor shahNo ratings yet

- Knopp2017 Article OnceACheaterAlwaysACheaterSeriDocument11 pagesKnopp2017 Article OnceACheaterAlwaysACheaterSeriAnda F. CotoarăNo ratings yet

- Colonel SandersDocument17 pagesColonel SandersAmandaNo ratings yet

- Publication PDFDocument152 pagesPublication PDFAlicia Mary PicconeNo ratings yet

- Shelf Life ControlDocument7 pagesShelf Life ControlRushikesh Deshpande100% (1)

- (Template) The World in 2050 Will and Wont Reading Comprehension Exercises Writing Creative W 88793Document2 pages(Template) The World in 2050 Will and Wont Reading Comprehension Exercises Writing Creative W 88793ZulfiyaNo ratings yet

- A Novel Procedure For Transient CFD Modeling of Basin Solar Stills, Coupling of Species and Energy EquationsDocument16 pagesA Novel Procedure For Transient CFD Modeling of Basin Solar Stills, Coupling of Species and Energy EquationsAverroesNo ratings yet

- Translating Child Development Research Into Practice - Can Teachers Foster Children's Theory of Mind in Primary SchoolDocument14 pagesTranslating Child Development Research Into Practice - Can Teachers Foster Children's Theory of Mind in Primary SchoolpecescdNo ratings yet

- Sikament®-4101 NS: Product Data SheetDocument2 pagesSikament®-4101 NS: Product Data SheetShihab AhamedNo ratings yet

- Performantele MTADocument5 pagesPerformantele MTAana aNo ratings yet

- State/ District-Dehradun, Uttarakhand Year 2016-17Document20 pagesState/ District-Dehradun, Uttarakhand Year 2016-17jitendra rauthanNo ratings yet

- Scots-Supply Chain ManagementDocument3 pagesScots-Supply Chain Managementgamer godNo ratings yet

- Kolano - Plastrowanie DynamiczneDocument9 pagesKolano - Plastrowanie DynamiczneRobert WadlewskiNo ratings yet

- SM Electrical Guidelines: General Notes:: Site HereDocument1 pageSM Electrical Guidelines: General Notes:: Site HereNathaniel DreuNo ratings yet

- FPSB 2 (1) 56-62oDocument7 pagesFPSB 2 (1) 56-62ojaouadi adelNo ratings yet

- 6L45, 6L50, 6L80, 6L90: Time Tested - Industry TrustedDocument1 page6L45, 6L50, 6L80, 6L90: Time Tested - Industry TrustedCelso BidinotiNo ratings yet

- CRISIL Mutual Fund Ranking: For The Quarter Ended September 30, 2020Document48 pagesCRISIL Mutual Fund Ranking: For The Quarter Ended September 30, 2020MohitNo ratings yet

- HooksDocument7 pagesHooksapi-233765416No ratings yet

- What Is Nursing?: What Exactly Do Nurses Do?Document3 pagesWhat Is Nursing?: What Exactly Do Nurses Do?mabel yapuraNo ratings yet

- 8291 w13 Ms 22Document8 pages8291 w13 Ms 22Caterina De LucaNo ratings yet