Professional Documents

Culture Documents

EPGL/F&S/F/206 Task Hazard Assessment

Uploaded by

Mohammad AsifOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

EPGL/F&S/F/206 Task Hazard Assessment

Uploaded by

Mohammad AsifCopyright:

Available Formats

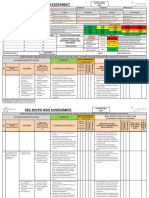

Doc No EPGL/F&S/F/206

Essar Power Gujarat Limited, Salaya Date 01/12/2016

Task Based Hazard Identification & Risk Assessment (Qualitative) Rev. No.

Page

00

01 / 02

Reference : PTW No./ Type:.... Dated: .. List of Equipment/ Machines/ Accessories to be used:

Main Task :

.. Welding Machine (Arc/ Argon) Gas Cutting Set Grinding Machine

... Aerial Lift Crane/ Hydra/ Fork Lift EOT Crane/ Hoist

Sub Tasks: TBHIRA No.: ....

Lifting Tools & Tackles Hand Tools Drilling Machine

1. ..

Concrete Breaking Machine Electrical Measuring Equipment Electrical Extension Board

2. ..

Workshop Machineries Others .

3. ..

4. .. List of Common OHS Hazards: Conflicting Activity

5. .. Slip/ Trip & Fall Pressure above atmospheric pressure

6. .. Striking against/ Struck by Fire & Explosion

7. .. Fall of Objects/ Material from Height Electric Shock

8. .. Contact with Sharp Edge Electric Arc Flash

TBHIRA is one of the best input to conduct effective TBT in addition to task specific Exposure to Coal Dust/ Fly Ash/ Foreign

Exposure to Harmful Rays (UV/ IR)

DOs & DONTs. This document is a part of PTW system. Particles

Exposure to High Noise Exposure to Dangerous Smoke

No. of Persons Involved/ Population at Risk:

List of Activity Specific OHS Hazards: Exposure to Insulation (Fiber Glass)

SN Contractors Strength Remarks

1. Fall from Height (Person) Exposure to Radiant Heat

Opening/ unprotected edge Exposure to Flying Particles (Projectiles)

2.

Contact with Hot Surface Exposure to CO

3.

Contact with Acid/ Alkali Exposure to Welding Fumes

Permit Issuer Permit Acceptor

Dept. Dept. Contact with Ammonia Solution Exposure to Chlorine/ Ammonia

Signature Contact with Steam/ Hot Water Exposure to Pesticides

Name Contact with Grease, Lube Oil, Fuel Oil Oxygen Deficiency/ Enrichment

Designation Poor Illumination Ergonomics (MSD)

Date Unguarded Rotating Part/ Pinch Point Drowning

Put Tick Mark ( ) wherever applicable

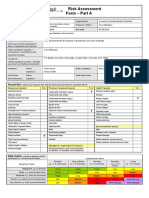

Doc No EPGL/F&S/F/206

Essar Power Gujarat Limited, Salaya Date 01/12/2016

Task Based Hazard Identification & Risk Assessment (Qualitative) Rev. No.

Page

00

02 / 02

Control Measures:

PPEs [Mandatory PPES Safety Helmet, Safety Shoes, Assessment of highest

Engineering Procedural/ Administrative

Safety Spectacles, Ear Plug/ Ear Muff] ranking hazard severity

Competent/ Authorized/ Welding Shield (potential) with control

Process Isolation Certified Welding Machine Chemical Suit

Skilled workers deployed (IR Shade Lens #10+) measures in place

Fitness for Working at Face Shield with Helmet

Electrical Isolation Certified Cutting Set Cotton Coverall Multiple Fatality

Height. (Clear Vision)

Certified & adequately selected Active Line of Safety Goggles

Certified ELCB 30 mA Alumina Suit Single Fatality

Lifting Tools & Tackles Communication (Chemical Splash Proof)

Certified Hoist/ EOT/ Hydra/ Gas Cutting Goggles

Flash back Arrester Rescue Awareness Electric Arc Flash Suit LTI/ RWC

Crane etc. (IR Shade Lens #5)

Laying of Cord/ Cable across Stand by Person Particulate Respirator

Grinding Wheel Guard Full Body Harness MTC

toe guard/ overhead Attendant/ Fire Watch (at Dust prone areas)

Guarding of Rotating Supply Cable length of Gas Testing by Retractable Fall

Welding Mask FAC

Parts/ pinch points Welding m/c 2.5 m Competent Person Arrestor

Plug & Socket Ascending/

Certified Scaffolding/ Ladder Personal CO/ O2 Detector Knitted Cotton HG Risk Ranking

Arrangement Descending Device

Double Insulated/ 3 core Confined Space Entry/ High/ alarm level

Check sheet Aerial Lift PVC HG Safety Net

Electrical Cable Exit Register task must not be

SCBA/ Air Line proceed without

Equipment Earthing Check sheet Radiography Fire Extinguisher Nitrile HG

Trolley HOD consultation

Maintaining Proper Life Jacket/ Life Buoy

Mechanical Ventilation Check sheet Road Closure Leather HG Medium level task

Housekeeping (Marine Safety)

may be proceed

SCUBA Set

Local Exhaust Ventilation Check sheet Excavation Welding Booth Electrical HG with caution

(for Divers)

Temporary Electrical Cautionary Board/

Hot Insulation Heat Resistant HG .. Low/ ALARP Level

Connection Request Barricading

task may be proceed

Proper coordination Lumbar Belt/ Back

Hard Barricading Multiple Lock out/ Tag out .. with care

between diff. agencies. support

Adequate Lighting (Main/ Safety Clearance from live Others:

Tool Box Talk Gum Boot ...

Alternate or both) electrical lines.

Mechanical Material

Competent Supervision Eye wash & shower Leather Apron ...

Handling Aid (Ergonomic)

Manual Handling < 50 kg per

Life Line PVC Apron ...

person

Put Tick Mark ( ) wherever applicable

Special Instructions:

For effectively conducting TBT, please refer the Booklet titled as TBT DOs & DONTs

Ensure adherence to applicable EPGL Golden Safety Rules & Life Saving Rules

Refer PPE Matrix for selection of Hazard Specific PPEs.

You might also like

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Job Risk Asessment. Excavation 8-6-22Document3 pagesJob Risk Asessment. Excavation 8-6-22Mohammed Ali Qazi100% (1)

- UG RA 009 - Light Materials and Equipment Loading and UnloadingDocument6 pagesUG RA 009 - Light Materials and Equipment Loading and Unloadingshamshuddin100% (1)

- Rmdjv-pj74-Hiradc-subc 03 (Hoisting & Rigging)Document1 pageRmdjv-pj74-Hiradc-subc 03 (Hoisting & Rigging)myn maliQueNo ratings yet

- Incident Reporting Form (Ir 01) : Fatality Lti I RWC Accident NEAR MissDocument1 pageIncident Reporting Form (Ir 01) : Fatality Lti I RWC Accident NEAR Missmuhammadumar412296No ratings yet

- Hazard Identification FormDocument1 pageHazard Identification Formabdulrazzaq hatem100% (1)

- Risk AssessmentDocument2 pagesRisk AssessmentFaraiMbudaya0% (1)

- Jha 2022Document8 pagesJha 2022Sandeep KumarNo ratings yet

- Risk Assessment For Installation of Toilet Exhaust FanDocument10 pagesRisk Assessment For Installation of Toilet Exhaust FanMaria Carmela Rachel GazilNo ratings yet

- Risk Assessment Register: Prepared By: Toolpusher / Hse AdvisorDocument1 pageRisk Assessment Register: Prepared By: Toolpusher / Hse Advisorcmrig740% (1)

- Risk Assess - 98-Installation Fuel Oil ConditioniDocument4 pagesRisk Assess - 98-Installation Fuel Oil ConditioniRochdi BahiriNo ratings yet

- Sample-Risk Assessment & Safe Work Method StatementDocument4 pagesSample-Risk Assessment & Safe Work Method StatementioanchiNo ratings yet

- Risk Assessment (5x5 Matrix) : R.A Team Leader / Members: Name: Designation: Signature: Approved By: Reference NumberDocument27 pagesRisk Assessment (5x5 Matrix) : R.A Team Leader / Members: Name: Designation: Signature: Approved By: Reference NumberMd ShahinNo ratings yet

- Permit To Work FormDocument2 pagesPermit To Work FormNate JamesNo ratings yet

- Using Hand Drill (WS)Document2 pagesUsing Hand Drill (WS)John KalvinNo ratings yet

- JSA G20 Scaffolding Erection DismantlingDocument4 pagesJSA G20 Scaffolding Erection DismantlingemmyNo ratings yet

- 4.5.3!01!02 Incedent Injury Report Rev 1 - QTEL CABLE - C1Document4 pages4.5.3!01!02 Incedent Injury Report Rev 1 - QTEL CABLE - C1loveson709No ratings yet

- Contractor Ehs Risk Assessment For NDT TestingDocument6 pagesContractor Ehs Risk Assessment For NDT TestingBernard PenuliarNo ratings yet

- 3.jsa - Arc Welding-NDocument5 pages3.jsa - Arc Welding-NVivek NaikNo ratings yet

- Chemical Manifest and Hazardous Chemical Substance List KathuDocument13 pagesChemical Manifest and Hazardous Chemical Substance List KathuVictorNo ratings yet

- Greinfield Manufacturing Plant For VELO Job Safety Analysis & Risk Assessment for Scrapping and Grading Activity (Rev-00Document1 pageGreinfield Manufacturing Plant For VELO Job Safety Analysis & Risk Assessment for Scrapping and Grading Activity (Rev-00Azhar Mushtaq100% (1)

- Ev05 - Safety Task Analysis Reduction - Star Card in Different LanguageDocument3 pagesEv05 - Safety Task Analysis Reduction - Star Card in Different LanguageFrancis Enriquez TanNo ratings yet

- Cable Pulling Risk AssessmentDocument6 pagesCable Pulling Risk AssessmentKevin ColmoNo ratings yet

- 4.5.3!01!06 First Aid Property Environmental ReportDocument4 pages4.5.3!01!06 First Aid Property Environmental Reportloveson709No ratings yet

- Safe Work Practice: Title General Application Protective MechanismsDocument1 pageSafe Work Practice: Title General Application Protective MechanismseankiboNo ratings yet

- Crane Safety TipsDocument4 pagesCrane Safety Tipssetiawanaji407100% (1)

- Risk Assessment - Repairing The Damaged LV Cable at Sea Water Intake Area (Back Side of BLDG 2221)Document3 pagesRisk Assessment - Repairing The Damaged LV Cable at Sea Water Intake Area (Back Side of BLDG 2221)nsadnan100% (1)

- Hse-Swms-018-A - Traffic Signal Maintenance - NSWDocument12 pagesHse-Swms-018-A - Traffic Signal Maintenance - NSWapi-326016071No ratings yet

- Near Miss Report: Complete This Form and Email It ToDocument1 pageNear Miss Report: Complete This Form and Email It Toloveson709No ratings yet

- Self Leveling - Epoxy Work (R-A)Document3 pagesSelf Leveling - Epoxy Work (R-A)anisaanNo ratings yet

- JSA Safety AnalysisDocument3 pagesJSA Safety AnalysisLusy Gusti EfendiNo ratings yet

- Tracking Problems SolvedDocument23 pagesTracking Problems SolvedMohammad AsifNo ratings yet

- Risk Assessment of Trees MaintenanceDocument9 pagesRisk Assessment of Trees Maintenanceطارق رضوان100% (1)

- Risk Ass. - AD 417 - Installation of SocketDocument6 pagesRisk Ass. - AD 417 - Installation of SocketnsadnanNo ratings yet

- JCA Full SetDocument68 pagesJCA Full SetaymenmoatazNo ratings yet

- Site Specific Job Hazard Assessment FormDocument4 pagesSite Specific Job Hazard Assessment FormshaestoverNo ratings yet

- (Task Specific Risk Assessment) : No Name Signature Position Date N Name Signature Position DateDocument5 pages(Task Specific Risk Assessment) : No Name Signature Position Date N Name Signature Position DateRavi Shankar TurlapatiNo ratings yet

- Week 1 Day 1Document2 pagesWeek 1 Day 1arens100% (1)

- Basic HydraulicDocument58 pagesBasic HydraulicMohammad Asif100% (1)

- Fire Extinguisher Inspection Record Jan-2021Document12 pagesFire Extinguisher Inspection Record Jan-2021Sarmad HussainNo ratings yet

- 2-1-2021 Response To LandlordDocument2 pages2-1-2021 Response To LandlordJessica SwarnerNo ratings yet

- Maintance PlanningDocument0 pagesMaintance PlanningSHIVAJI CHOUDHURY100% (1)

- Burnett: The First Non-Conformist HomeopathDocument4 pagesBurnett: The First Non-Conformist Homeopathsimiliadoc100% (1)

- Acetabular and Hip FractureDocument133 pagesAcetabular and Hip FractureJuanita HenryNo ratings yet

- Non-Routine Hazards and Risk Assessment SummaryDocument42 pagesNon-Routine Hazards and Risk Assessment SummaryGanesh Murugesan0% (1)

- Evidence Based Practices For Young Children With AutismDocument11 pagesEvidence Based Practices For Young Children With Autismkonyicska_kingaNo ratings yet

- JSA G17 Lift Container With CraneDocument4 pagesJSA G17 Lift Container With Cranesetiawanaji407No ratings yet

- 17 Emergency Response Plan Flow ChartDocument3 pages17 Emergency Response Plan Flow ChartRosli Bin Abdul Shukor100% (1)

- People Pleasing Patterns Are Learned When Needs Are Not Met PDFDocument10 pagesPeople Pleasing Patterns Are Learned When Needs Are Not Met PDFPamela RodriguezNo ratings yet

- PPE Matrix AgrocelDocument2 pagesPPE Matrix AgrocelBhakti MahbubaniNo ratings yet

- ACTION PLAN FOR JUVENILE PRISONERS IN ILOILO CITYDocument22 pagesACTION PLAN FOR JUVENILE PRISONERS IN ILOILO CITYJohn Christian LopezNo ratings yet

- SWMS Bored PilingDocument17 pagesSWMS Bored PilingnaraNo ratings yet

- TRA 58 Unloading and Rigging Up Test EquipmentDocument4 pagesTRA 58 Unloading and Rigging Up Test EquipmentPirlo PoloNo ratings yet

- FINAL Shivani Confined Space PermitDocument1 pageFINAL Shivani Confined Space PermitVimal SinghNo ratings yet

- 01 JSA CLEANING MgO Rev 05 017 BIDocument7 pages01 JSA CLEANING MgO Rev 05 017 BIMohd KhaidirNo ratings yet

- Emergency PlanDocument1 pageEmergency Planapi-285003764No ratings yet

- Confined Space Entry Permit DetailsDocument2 pagesConfined Space Entry Permit DetailsradeepNo ratings yet

- Job Safety Observation Report RecommendationsDocument1 pageJob Safety Observation Report RecommendationsFrancis Enriquez TanNo ratings yet

- DT-1 Cleaning PTWDocument2 pagesDT-1 Cleaning PTWsubhashkpn86No ratings yet

- Toolbox Talks Working Around ExcavatorsDocument2 pagesToolbox Talks Working Around ExcavatorspercyNo ratings yet

- Job Safety Analysis: Client: ContractorDocument7 pagesJob Safety Analysis: Client: Contractorloveson709No ratings yet

- Trestles and StagingDocument2 pagesTrestles and Stagingdak comeiNo ratings yet

- F.e.& Scba InspectionDocument5 pagesF.e.& Scba InspectionAviects Avie JaroNo ratings yet

- Permit Work at Qatar FoundationDocument1 pagePermit Work at Qatar FoundationJeffersonDeGuiaNo ratings yet

- Incident Investigation ReportDocument2 pagesIncident Investigation ReportRaajha MunibathiranNo ratings yet

- 017.JSA - SHE.IV.2013 (Sack Out Water Accumulation of MW)Document3 pages017.JSA - SHE.IV.2013 (Sack Out Water Accumulation of MW)siswanto sugengNo ratings yet

- Safety First: Safe Storage and Handling of Cleaning Agents and DisinfectantsDocument1 pageSafety First: Safe Storage and Handling of Cleaning Agents and DisinfectantsldmtrNo ratings yet

- PPE AnalysisDocument1 pagePPE AnalysisHaleem Ur Rashid BangashNo ratings yet

- Permit To Work: Surat Izin KerjaDocument3 pagesPermit To Work: Surat Izin Kerjaluki0% (1)

- Bagas P-0519140100-Tugas k3 Kimia m12Document3 pagesBagas P-0519140100-Tugas k3 Kimia m12Viodea Firlii RamadhaniarNo ratings yet

- Power Clearance FormDocument2 pagesPower Clearance FormBrajesh SinghNo ratings yet

- Metal Detector MchsDocument22 pagesMetal Detector MchsMohammad AsifNo ratings yet

- Belt Weigh Scale PDFDocument33 pagesBelt Weigh Scale PDFMohammad AsifNo ratings yet

- General Aptitude Questions With Explained Answers (WWW - Students3k.com)Document13 pagesGeneral Aptitude Questions With Explained Answers (WWW - Students3k.com)Sandhiya KalyanNo ratings yet

- General Aptitude Questions With Explained Answers (WWW - Students3k.com)Document13 pagesGeneral Aptitude Questions With Explained Answers (WWW - Students3k.com)Sandhiya KalyanNo ratings yet

- General Aptitude Questions With Explained Answers (WWW - Students3k.com)Document13 pagesGeneral Aptitude Questions With Explained Answers (WWW - Students3k.com)Sandhiya KalyanNo ratings yet

- Bearing 2007-08Document60 pagesBearing 2007-08Mahmoud NaelNo ratings yet

- Basic Yoga PosesDocument46 pagesBasic Yoga PosesMohammad AsifNo ratings yet

- Aptitude Problems On Numbers (WWW - Students3k.com)Document7 pagesAptitude Problems On Numbers (WWW - Students3k.com)Hemant KumarNo ratings yet

- General Aptitude Questions With Explained Answers (WWW - Students3k.com)Document13 pagesGeneral Aptitude Questions With Explained Answers (WWW - Students3k.com)Sandhiya KalyanNo ratings yet

- Less Adaptive or More Maladaptive? A Meta-Analytic Investigation of Procrastination and CopingDocument12 pagesLess Adaptive or More Maladaptive? A Meta-Analytic Investigation of Procrastination and CopingVALERIA BUSTAMANTE ALBERCONo ratings yet

- MASTER Unannounced Inspection ChecklistDocument13 pagesMASTER Unannounced Inspection ChecklistM Zeeshan AnsariNo ratings yet

- Burns Guide: Causes, Types, TreatmentDocument4 pagesBurns Guide: Causes, Types, TreatmentMartin KoaNo ratings yet

- Mdbsis09 CA A III 2017Document4 pagesMdbsis09 CA A III 2017Guneyden GuneydenNo ratings yet

- Brosur SucofindoDocument14 pagesBrosur SucofindoJay Van BuurninkNo ratings yet

- D A Up To 2 YearDocument7 pagesD A Up To 2 YearNischitha G CNo ratings yet

- Single/ Exam Zone Centre DetailsDocument5 pagesSingle/ Exam Zone Centre DetailsHarsh AroraNo ratings yet

- LVMH - Code of ConductDocument13 pagesLVMH - Code of ConductElena DianaNo ratings yet

- Veterans Handbook 2020Document69 pagesVeterans Handbook 2020Senator Cory BookerNo ratings yet

- Mapeh 10 2nd PrelimsDocument4 pagesMapeh 10 2nd PrelimsBlaize PascualNo ratings yet

- 1 s2.0 S2772569323000026 MainDocument8 pages1 s2.0 S2772569323000026 MainAditya RizkyNo ratings yet

- Acy 087Document14 pagesAcy 087johnsmithdosNo ratings yet

- Challenges and Opportunities in Preventive and Social MedicineDocument3 pagesChallenges and Opportunities in Preventive and Social MedicineIJAR JOURNALNo ratings yet

- Msds Coal PDFDocument4 pagesMsds Coal PDFGuntur Wijaya100% (1)

- YanBoy Trading Company Profile 2020Document6 pagesYanBoy Trading Company Profile 2020Andile NtuliNo ratings yet

- Spagyria vs Alchemy: Separating Myth from TruthDocument4 pagesSpagyria vs Alchemy: Separating Myth from Truthvas25No ratings yet

- Nursing Abbreviations, Acronyms and Symbols QuizDocument3 pagesNursing Abbreviations, Acronyms and Symbols QuizAjeng Citra S SeptiyantriNo ratings yet

- Tata AIA Life Insurance Fortune Guarantee Plus Savings PlanDocument13 pagesTata AIA Life Insurance Fortune Guarantee Plus Savings PlanAkshay SaxenaNo ratings yet

- High Yield Surgery Compatible VersionDocument77 pagesHigh Yield Surgery Compatible Version17kimpNo ratings yet

- Argumentative EssayDocument3 pagesArgumentative Essayapi-444150463No ratings yet

- Learning Kit - Q3W3 CeslDocument10 pagesLearning Kit - Q3W3 CeslJoselle Batas MagbanuaNo ratings yet

- Types of GuidanceDocument13 pagesTypes of GuidanceJomar Gasilla Navarro100% (1)

- Aiapget 2020 QPDocument29 pagesAiapget 2020 QPGanesh RadhakrishnanNo ratings yet