Professional Documents

Culture Documents

Appendix K - Bill of Quantity For Roads, Drains, Dykes, Fencing and G

Uploaded by

PiyushOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Appendix K - Bill of Quantity For Roads, Drains, Dykes, Fencing and G

Uploaded by

PiyushCopyright:

Available Formats

BILL OF QUANTITIES FOR BLACK OIL AT VISHAKHA MARKETING TERMINAL RESITEMENT PROJECT

TENDER FOR ROADS, FINISHED GRADING, STORM WATER DRAINS, CULVERTS, OWS PITS ETC.

Sr. No. D E S C R I P T I O N Unit Quantity

Excavation & Backfilling Works.

1.0 Excavation & Backfilling upto 1.5m depth below FGL/NGL M3 28100

Excavation and backfilling around foundation and trenches/pits in all types of soil viz.

earth, sand,gravel, clay, soft & hard murrum etc. (excluding soft/hard rock) for

general site grading, underground pipes, culverts, footings, steps, dyke wall

foundations, roads-storm water & OWS drains, trenches, manholes, underground

sumps/pits, etc including shoring strutting, dewatering where required (until foundation

work is complete). Item also includes carting, stacking if required, Spreading, levelling

and compacting/ consolidating ( 95 % MDD )surplus materials within HPCL's

premises or as per instructions of MMCI/HPCL Engineer In Charge (Rate includes

removal of any vegetation, small shrubs etc.)

2.0 from 1.5 m to 3.00 m below FGL/NGL M3 2000

same as item 1 above but for 1.5m to 3.0m depth

3.0 from 3.0 m to 4.50 m below FGL/NGL M3 100

same as item 1 above but for 3.0m to 4.5m depth

4.0 Carting away material M3 5000

Disposal / carting away surplus excavated earth / debris etc. outside HPCL's Black Oil

Plant premises to unobjectionable place identified by vendor.

5.0 Filling with good Earth M3 39800

Filling with selected excavated earth available (Excavation excluded) & stacked

elsewhere within HPCL's Black Oil Plant premises under floors or within plinth or

within open dyke yard, open trenches foundations etc.with approved quality of earth

laid in layers not exceeding 300 mm in loose thickness including watering, ramming,

levelling and compacting to 95% Modified Proctor Density with use of mechanical

rammers etc complete as directed and instructed by MMCI/HPCL Engineer in charge.

6.0 Filling with Murrum M3 23700

Supplying and filling murrum of approved quality with PI of 1 to 7(Low plastic)

containing not more than 20% cohesive fines namely clay and Max. dry density of

material not less than 1.80 gms/cc, under floors or within plinth or within open yard

etc. including identifying & locating of borrow pits, excavation at borrow pits outside

Plant premises; payment of Royalty to Owner of borrow pit, if applicable; payment of

applicable royalties, taxes, etc to Statutory Authority for operating the borrow pit;

loading at borrow pit end; transportation from borrow pit to HPCL Premises; removing

debris, organic matter, etc; spreading in layers not exceeding 300mm loose depth;

dewatering during course of filling, watering, compacting to obtain 95% of modified

proctor maximum laboratory dry density all complete as per specifications and

instructions of MMCI/HPCL Engineer-in-Charge

Concrete and Allied Works

NOTE: THE RATES FOR ALL ITEMS COVERED IN THIS SECTION SHALL

INCLUDE COST OF DEWATERING, IF REQUIRED TILL COMPLETION OF WORKS

UPTO GROUND LEVEL AND CHAMPHERS IN RCC WORKS SHALL BE

PROVIDED WHEREVER REQUIRED AT NO EXTRA COST TO THE HPCL.ALSO

THE CEMENT USED SHALL BE SLAG CEMENT.

7.0 PCC (1:4:8) M3 1400

Providing and laying Plain Cement Concrete of nominal volumetric mix 1:4:8(1

Cement: 4 Sand: 8 Crushed stone aggregates) with 40 mm and down size graded

aggregates below RCC foundations and grade slab & any other work as per

requirement including any required permanent brick masonry shuttering, dewatering,

tamping, ramming, curing, etc all complete as per instructions of MMCI/HPCL

Engineer-in-Charge.

d:\project\BOQ FOR ROADS,DRAINS,DYKE WORK 20.07.09(BOQ(ter-17) Page : 1

BILL OF QUANTITIES FOR BLACK OIL AT VISHAKHA MARKETING TERMINAL RESITEMENT PROJECT

TENDER FOR ROADS, FINISHED GRADING, STORM WATER DRAINS, CULVERTS, OWS PITS ETC.

Sr. No. D E S C R I P T I O N Unit Quantity

8.0 PCC (1:3:6) M3 1650

Providing and laying Plain Cement Concrete of nominal volumetric mix 1:3:6(1

Cement: 3 Sand: 6 Crushed stone aggregates) with 40 mm and down size graded

aggregates below Masonry Wall foundations & any other work as per requirement

including any required permanent brick masonry shuttering, dewatering, tamping,

ramming, curing, etc all complete as per instructions of MMCI/HPCL Engineer-in-

Charge.

9.0 PCC (1:2:4) Coping on compound wall M3 25

Providing and laying 60 mm average thickness coping in CC 1:2:4 mix using 20mm

and down size stone aggregate with 40 mm projection on either side of wall with drip

mould. Rate to include 20 mm thick plaster in cm 1:4 including mixing, providing

necessary shuttering, dewatering, compaction and curing. Thickness of coping at the

ends shall be 40 mm and 80 mm at centre and shall project beyond the wall thickness

by 20mm.,all complete as per instructions of MMCI/HPCL Engineer-in-Charge Rate

to include for fixing of broken glass pieces on top of the coping.

10.0 RCC M 30 Below & above ground upto 2 mts. M3 3350

Providing & laying in position Controlled grade M30 Reinforced cement Concrete with

design mix of required grade at all locations and upto 2 mts above FGL using 20mm

and down graded aggregates in all types of works [including formwork, leaving

pockets, placing of conduits, making openings, pockets, placing inserts, sleeves in

footings/walls/columns/ beams/ slabs etc.] machine mixing, lifting, placing, machine

vibrating, tamping, curing etc. as specified, complete as per drawings & / or as

directed by MMCI / HPCL Engineer in charge. The cement used shall be slag cement.

NOTE: 1) The rate also includes cost of providing offsets, cut-outs, formwork,

construction joints, making holes in or cutting formwork for taking out dowel bars,

hacking the exposed surfaces to receive plaster as necessary. Quoted rates to

exclude the cost of supplying and providing Reinforcement Steel.

All concrete for RCC works for footings/foundations, Retaining walls, raft slabs,

pedestals, columns, beams, walls, staircases, trenches, manhole pit, culverts, drains,

sumps, pits equipment foundations, grade slabs (including form-work expansion,

construction, control, isolation joints etc), kerbstones encasing of pipes etc at depth

below and upto plinth level.

RCC M25 Concrete Paving/Grade Slab using Vacuum dewatered concreting

11.0 M3 2250

method for eg. Tremix Concrete or equivalent

Providing, supplying and casting in situ RCC M25 Grade slab/paving with all required

equipments, machineries, tools & tackles etc. by using vacuum dewatering method

(tremix flooring or equivalent) inclusive of all formwork, leaving conduits & pockets,

cut-outs, construction, isolation, expansion joints & tests etc. complete as directed by

MMCI/HPCL Engineer In Charge. The reinforcement shall be paid separately.

12.0 RCC M20 Concrete Paving/Grade Slab M3 375

Providing, supplying and casting in situ RCC M20 Grade slab/paving with all required

equipments, machineries, tools & tackles etc. inclusive of all formwork, leaving

conduits & pockets, cut-outs, construction, isolation, expansion joints & tests etc.

complete as directed by MMCI/HPCL Engineer In Charge. The reinforcement shall be

paid separately.

13.0 RCC M 20 for underground Tanks, sumps, OWS pits, basins, catch pits etc. M3 350

Grade M20 concrete for water tanks, OWS pits, basins, sumps, pits, manholes etc

incl. addition of waterproofing compound of Fosroc/CICO or approved equivalent

make, including pressure cement grouting of mix 1:2 at construction joints, weak

spot/honey combs and testing the structure for water tightness as per requirement of

IS3370 and making good defects/leakages as instructed by MMCI/HPCL Engineer in

charge.

d:\project\BOQ FOR ROADS,DRAINS,DYKE WORK 20.07.09(BOQ(ter-17) Page : 2

BILL OF QUANTITIES FOR BLACK OIL AT VISHAKHA MARKETING TERMINAL RESITEMENT PROJECT

TENDER FOR ROADS, FINISHED GRADING, STORM WATER DRAINS, CULVERTS, OWS PITS ETC.

Sr. No. D E S C R I P T I O N Unit Quantity

14.0 M.S. Round bars of Grade fe 250 TM 0.5

Providing, laying & fixing in position M.S. reinforcement & or holdfasts as per dwg.

locations & levels including bar bending schedules & obtaining MMCI/HPCL

Engineer's approval, cutting,decoiling, straightening, cleaning, bending to required

shape & binding with contractor's own 16 SWG annealed binding wire including

placing proper concrete cover blocks, chair supports, Ceiling fan hooks etc. complete

as specified and directed by MMCI/HPCL Engineer in charge.

15.0 HYSD Bars of Grade Fe 415 TM 350

same as above item but with HYSD conforming to IS:1786 / TMT bars of grade fe

415.

16.0 Insert plates/ Nosing Angles/ Channels. TM 1

Providing, fabricating and fixing in position at required locations to correct lines and

levels, angles, inserts for pits in RC culverts, foundations, pedestals, columns, slabs,

beams & stairs , cable trenches and all types of RCC, PCC & masonry including

necessary holdfasts , welding, machining, grinding, threading etc.Exposed surface will

be thoroughly cleaned & painted with epoxy primer & paint. (All materials &

accessories required shall be provided by Contractor).

Masonry and Allied Works

230 mm thk. & above thickness Solid Fly Ash Brick Masonry in

17.0 M3 1165

foundations/substructure.

Providing & constructing Solid Fly Ash brick masonry in partition walls for dykes,

drains etc.(as per masonry & plaster specifications) using bricks of first quality (class

3.5 as per IS:12894, Compressive strength of Brick 35 kg/cm2) of approved source at

all locations and levels with cement mortar 1:5 including scaffolding, raking of joints,

watering but excluding cement plaster finish complete as directed and instructed by

MMCI / HPCL Engineer incharge.(up to a lift of 12 m locations). Portland Pozzolana

Cement (conforming to IS:1489 Part 1 & 2) to be used for the preparation of Cement-

Sand Mortar. Reinforcement in mullions & transoms shall not be separately paid.

Providing and placing formwork etc for transoms/mullions etc shall be included in the

quoted rate.

18.0 Uncoursed rubble masonry in foundations, plinth and superstructure M3 449

Providing and laying uncoursed rubble masonry in foundations, Retaining wall, plinth,

superstructure in cement mortar 1:5 including raking out joints, leaving pockets for

angle posts for chain link fencing , Providing and fixing 150 dia uPVC pipes of

required length for weep holes staggered in retaining wall where ever applicable

,staging, scaffolding and curing, etc. complete as specified and directed by

MMCI/HPCL Engineer-In-charge.

19.0 Cement Pointing and Painting SM 225

Providing raised cement pointing to stone / brick masonry in cement mortar 1:3 at all

locations to a minimum projection of 15 mm, thickness of minimum 30mm with small

groove in the centre and curing complete as per specifications and directions of

MMCI/HPCL Engineer in charge. Job includes for cleaning of existing racked RRM

joints, Appling cement slurry before start of job and curing the finished pointed surface

for a minimum period of 7 days. Rate to include for proper finishing of the pointing and

joining the same with the top coping. Measurements shall be made on the basis of

surface area of the pointed compound wall (height * length of Compound wall

pointed). Rate to include Providing 1 coat of approved primer and two coats of

Exterior Emulsion paint of Asian Make ( ACE Paint) or equivalent of approved shade

over the Raised pointing for a minimum min. width of 30mm. Painting shall also be

required to be done on the coping of the compound wall., all complete as per

instructions of MMCI/HPCL Engineer-in-Charge Rate to include curing the surface for

a minimum period of 4 days.

d:\project\BOQ FOR ROADS,DRAINS,DYKE WORK 20.07.09(BOQ(ter-17) Page : 3

BILL OF QUANTITIES FOR BLACK OIL AT VISHAKHA MARKETING TERMINAL RESITEMENT PROJECT

TENDER FOR ROADS, FINISHED GRADING, STORM WATER DRAINS, CULVERTS, OWS PITS ETC.

Sr. No. D E S C R I P T I O N Unit Quantity

20.0 150 mm thick Rubble Pitching in C.M. 1:4 SM 6600

Providing and Laying 150 mm thick Rubble pitching to slopes, grade separation and

sides of storm water drains/ water pond/embankment including breaking of rubble,

formations of neat slopes to required profile, watering, tamping, raking out joints and

grouting them in cement mortar 1:4 flush pointing, curing etc as specified and as

directed by MMCI/HPCL Engineer-In-Charge.

21.0 External Waterproof Cement plaster 20mm thk. SM 11800

Providing and doing waterproof external sandfaced plaster (on inner surfaces of

storm water drains as per drawings) 20mm thk in C.M. 1:4 in 2 coats to all RCC and

masonry works at all locations and levels including required grain finishing, curing

etc. complete as per specification and as directed and instructed by MMCI / HPCL

Engineer incharge.The cement used shall be Portland Pozzolana Cement (Uniform

Blended Portland cement with fine pozzolana) conforming to IS:1489 Part 1 and Part

2

NOTE: The rates includes the cost of the base coat of not less than 12mm thk.,

external patta, drip moulds, curing as well as providing and mixing waterproofing

compound of approved make in both coats as per manufacturers specifications.

22.0 230mm thk. Rubble Soling with Roller and or mechanical rammers SM 12900

Providing, supplying and doing 230 mm thick dry rubble stone packing/soling under

floor, foundation, pavement, roads, steps, ramps & other similar locations, handset

vertically in rectangular lines, interstices filled in with smaller stone chips including

watering, compacting/consolidating & finishing to the required levels and lines etc with

the use of 10 Ton roller and or with mechanical rammers complete as directed by

MMCI/HPCL Engineer-In- Charge. (Blinding layer shall be of metal, sand or murrum

supplied by contractor)

Floor Finishes,fencing and Allied Works

23.0 Gravel flooring SM 11550

Providing and laying 150 mm thick gravel floor of 20 mm size gravel around tank

within dykes, pump's kerbed areas, around DGs/ Transformers, equipments etc.

24.0 MS gate SM 50

Providing and fixing the MS Gate single/double shutter with L 75X75X8 Main Frame &

internal braced L members L65X65X6 conforming to IS:808 fitted with GI Chain link

mesh (50mm sq. meshx3.15 mm GI) and required fittings & accessories like tower

bolts & internally welded to L frames as per drgs & instructions of MMCI/HPCL

Engineer In Charge with two coats of Synthetic Enamel over two coats of red oxide

Primer Paints and primer shall be of SHALIMAR/ BERGER/ASIAN Make first quality

only.

25.0 Structural Steel - Iron angle Post for fencing TM 3.5

Supply, fabrication , erection and grouting of 65 x 65 x 6 ISA post and supporting

angles of specified length in 1:2:4 concrete grout at every 2.4 m C-C or as advised.

Rate to include fabrication of the post as per the specification, erecting, placing,

grouting and painting of the posts with two coats of Synthetic Enamel over two coats

of red oxide Primer Paints and primer shall be of SHALIMAR/ BERGER/ASIAN Make

first quality only. Excavation and concrete are included in the cost of this item.

Excavation shall be 450mm x 300mm x 300mm and Grouting shall be of 550mm x

300mm x 300mm.

Pipe Railing for fencing (Top & Bottom pipe railing to be considered together

26.0 TM 2

per unit length.)

Supply and fixing of 40 NB medium duty pipes conforming to IS 1161 latest addition

for top and bottom railings to the angle iron posts for fixing the edges of the chain link

fencing. Rate to include fabricating, cutting, bending of the MS pipe where ever

necessary. Supply and fixing of the required size MS clamps at every post, with

required size nuts and bolts and painting the railing with two coats of Synthetic

Enamel over two coats of red oxide Primer Paints and primer shall be of SHALIMAR/

BERGER/ASIAN Make first quality only.

d:\project\BOQ FOR ROADS,DRAINS,DYKE WORK 20.07.09(BOQ(ter-17) Page : 4

BILL OF QUANTITIES FOR BLACK OIL AT VISHAKHA MARKETING TERMINAL RESITEMENT PROJECT

TENDER FOR ROADS, FINISHED GRADING, STORM WATER DRAINS, CULVERTS, OWS PITS ETC.

Sr. No. D E S C R I P T I O N Unit Quantity

27.0 Chain Link fencing SM 1450

Supply and fixing of 50 x 50mm opening size 10 SWG GI chain link fencing to the

angle iron post with 8 SWG GI hooks and nuts and railing with 14 SWG GI continuous

wire (all details shall be as per enclosed drawing ) up to a height of 1.8 m from the

ground level. Rate to include unrolling the bundle, erecting, tightening and fixing at

300 mm C-C on the vertical portion of the posts to every top and bottom railing with 14

gauge GI wire. including all required accessories, labour, tools and tackles as per

instructions of MMCI/HPCL Engineer-In-Charge.

28.0 Y angle to be fixed to compound wall TM 0.3

Supply, fabrication and welding of Y angles of size 50x50x6mm as per drawing and

grouting the same in PCC 1:2:4 of size 300 sq.,450 mm deep. Rate to include

providing 8 drilled holes and anchor plates as per approved drawing. Rate also to

include aligning, painting of Y angles with two coats of ENAMEL paint of approved

make over two coats of red oxide primer on the exposed surface and bituminous paint

over suitable primer for the embedded portion, all complete as per instructions of

MMCI/HPCL Engineer-in-Charge

29.0 Concertina Coil MT 70

Supply and fixing of 610mm dia hot dip galvanized barbed razor tape concertina coil

fencing each coil having 80 circles, 200 clips with optimum openable stretch of 8 mtrs

length supported/tied with two rows of same razor runner wires to Y angle at the top

and one run wire at the bottom with U nails, clips etc. all complete as per instructions

of MMCI/HPCL Engineer-in-Charge. Rate to include supply and installation of

supporting wires. Length of the compound on which fencing is installed shall be

measured for payment purpose. General specification of concertina Razor

strips:0.5mm thick hot dip galvanized width 19mm(before wrapping on central core

wire) and wrapped on central core GI wire of 2.6mm dia. Zinc coating of 120 g/m2

Central core GI wire: UTS 145-160 Kg/mm2,Zinc coating 250-300 gm/m2,diameter

2.6mm Clips: GI 1.6mm thick

30.0 Barbed Wires MT 70

Providing & fixing of 8 Rows of Barbed wires (IS 278-1978) to the 'Y' angle on the

compound wall with concertina coil including all required accessories, labour,tools

and tackles all complete as per instructions of MMCI/HPCL Engineer-in-Charge

Length of the compound on which fencing is installed shall be measured for payment

purpose.

31.0 Neoprene Rubber SM 2

Supply, cutting to size, providing and fixing complete of Neoprene rubber of min

thickness 35mm to structural steel wherever specified. The Neoprene Rubber shall be

bolted to the structure by providing suitable size grove in the Neoprene Rubber so as

to ensure that the Head of the bolt is minimum 5mm below the surface of the rubber.

The purpose of this rubber is to prevent metal-to-metal contact. The same shall be

attained at all cost. At places where bolting is not possible the same shall be stuck to

the metal surface with suitable long lasting adhesive.

Underground Piping Works

32.0 RCC Pipe Class NP3-150mm Dia MT 680

Providing and laying to slopes at any depth Reinforce Concrete Pipes of Class NP3-

150 mm dia. (Conforming to IS:458) with collars including cutting out pockets for

collars, jointing in 1:1 cement mortar, cutting of pipes wherever required, curing and

testing of joints etc. complete as specified and directed (excavation and backfilling if

required included) by MMCI/HPCL Engineer-In-Charge.

33.0 RCC Pipe Class NP3-300mm Dia MT 560

same as above item but pipe diameter 300 mm

34.0 RCC Pipe Class NP3-600mm Dia MT 340

same as above item but pipe diameter 600 mm

35.0 RCC Pipe Class NP3-800mm Dia MT 150

same as above item but pipe diameter 800mm

d:\project\BOQ FOR ROADS,DRAINS,DYKE WORK 20.07.09(BOQ(ter-17) Page : 5

BILL OF QUANTITIES FOR BLACK OIL AT VISHAKHA MARKETING TERMINAL RESITEMENT PROJECT

TENDER FOR ROADS, FINISHED GRADING, STORM WATER DRAINS, CULVERTS, OWS PITS ETC.

Sr. No. D E S C R I P T I O N Unit Quantity

36.0 RCC Pipe Class NP3-1000mm Dia MT 130

same as above item but pipe diameter 1000 mm

37.0 UPVC Pipe -200mm Dia MT 1560

Providing and laying to slopes at any depth uPVC Pipes of Sch 40- 4 Kgs/cm2 -200

mm dia. as per manufacturer's specifications and as directed by MMCI/HPCL

Engineer Incharge.Scope include supply & laying of all the necessary pipe

bends,socket/collars required for joining the pipes etc. complete as directed by

MMCI/HPCL Engineer In charge

38.0 UPVC Pipe -100mm Dia MT 225

Providing and laying to slopes at any depth uPVC Pipes of Sch 40- 4 Kgs/cm2 -100

mm dia. as per manufacturer's specifications and as directed by MMCI/HPCL

Engineer Incharge.Scope include supply & laying of all the necessary pipe

bends,socket/collars required for joining the pipes etc. complete as directed by

MMCI/HPCL Engineer Incharge

39.0 2" Pipe,Heavy,Bevel End,IS 1239, CONT. WELDED MT 500

Supply, loading, unloading, stacking, hauling, transportation to HPCL store,

transportation from store to site, loading, unloading, Excavating, laying underground

pipes, erection, fabrication ,cutting, edge preparation, welding, testing, wrapping and

coating as per Specification No.- 254625-300-SP-PIP-016, all complete as per

instructions of MMCI/HPCL Engineer in charge and as per technical specification for

PIPE(SCH HEAVY) (BLACK).CONT.WELDED , BE. Confirm to IS 1239-part-1

40.0 4" Pipe,Heavy,Bevel End,IS 1239, CONT. WELDED MT 175

Same as above item but for pipe size 4"

41.0 6" Pipe,Heavy,Bevel End,IS 1239, CONT. WELDED MT 200

Same as above item but for pipe size 6"

42.0 10" Pipe,6.35 mm,Bevel End,IS 3589 Gr FE 410, ERW. Dim to ASME B 36.10 MT 385

Supply, loading, unloading, stacking, hauling, transportation to HPCL store,

transportation from store to site, loading, unloading,Excavating, laying underground

pipes, erection, fabrication ,cutting, edge preparation, welding, testing, wrapping and

coating as per Specification No.- 254625-300-SP-PIP-016, all complete as per

instructions of MMCI/HPCL Engineer in charge and as per technical specification for

PIPE(THK 6.35 mm) Bevel End, IS 3589 Gr FE410, ERW Confirm to 36.10

43.0 8" Pipe,6.35 mm,BE,IS 3589 Gr FE 410, ERW. Dim to ASME B 36.10 MT 750

Same as above item but with 8" pipe

Road Works

44.0 WBM 200 mm thk (90-45) SM 15600

Providing , Compacting & Laying 200 mm total thick sub-base course Water Bound

Macadam (WBM) layer (2 layers of 100 mm each) of coarse aggregates (hard granite

metal of approved quality) of size 90 mm to 45 mm as per specifications, laying in

regular lines and levels, filling in the interstices with stone chips, ramming, watering,

Rolling etc. as specified and directed as per instructions of MMCI/HPCL Engineer-In-

Charge.

45.0 WBM 150 mm thk (63-45) SM 15600

Providing , Compacting & Laying 150 mm total thick base course Water Bound

Macadam (WBM) layer (2 layers of 75 mm each) of coarse aggregates (hard granite

metal of approved quality) of size 63 mm to 45 mm as per specifications, laying in

regular lines and levels, filling in the interstices with stone chips, ramming, watering,

Rolling etc. as specified and directed as per instructions of MMCI/HPCL Engineer-In-

Charge.

d:\project\BOQ FOR ROADS,DRAINS,DYKE WORK 20.07.09(BOQ(ter-17) Page : 6

BILL OF QUANTITIES FOR BLACK OIL AT VISHAKHA MARKETING TERMINAL RESITEMENT PROJECT

TENDER FOR ROADS, FINISHED GRADING, STORM WATER DRAINS, CULVERTS, OWS PITS ETC.

Sr. No. D E S C R I P T I O N Unit Quantity

46.0 Premix carpet with seal coat SM 17350

Providing and laying premix carpet (hot process) using paving bitumen grade and

mechanical paver machine of following thickness with premix sand seal coat including

scarification of WBM surface, tack coat of hot bitumen @ 7.5 kg/10sqm as per

specification and instruction of MMCI/HPCL.

a) 50 mm thick premix carpet and premix seal coat of 12 mm thick (final compacted

thickness shall be 62 mm)

47.0 kerb stones PC 2000

Providing and fixing precast kerb stones made of PCC Grade M15 using 20 mm down

size coarse aggregates, curing, of following size including making necessary casting

yard, formwork, machine mixing, compacting, finishing, submerged curing, conveying

from casting yard to site of placing and laying (including excavation) in position to

correct line curve, levels, plumb over 20 mm thick bedding in CM 1:6, jointing &

pointing in CM 1:4 where ever required, painting with 2 coats of yellow/black approved

quality (Asian, Berger or ISI make) paint for exposed surface etc. all complete and as

directed. Size of kerb block 500mmx450mmx150mm.

48.0 Precast covers SM 150

Providing and fixing Precast M25 grade Concrete Cover upto 150 mm thk.

including shuttering, concreting,vibrating, tamping, finishing the top surface to give

smooth and even surface, curing, reinforcement with necessary provision for lifting

lugs, aligning and fixing in position with cement mortar 1:3 (1 cement, 3 sand) etc.,

complete as per specifications, drawings and as directed by MMCI/HPCL Engineer in

charge. (Reinforcement not to be paid separately)

49.0 Paver Blocks SM 600

Providing, laying and fixing 60mm medium duty Paver Block of cement concrete of

M30 grade, (Manufactured by Columbia machine or equivalent make of Grey colour

laid in Herring Bone and/or any pattern as approved by the Engineer, including

providing and laying sand/or stone grit bed upto 100 mm thickness, compaction with

all leads and lifts, as directed by the HPCL/MMCI engineer in charge.

50.0 Central Precast Verge (Road Divider) MT 430

Filling the space between two rows of masonry kerb stones wall 2 metres Wide by

good fertile soil with manure and developing green belt etc complete as per

instructions of MMCI/HPCL Engineer in charge.

51.0 Demolition of Concrete/Brick work. CUM 20

Demolishing / dismantling of existing RCC & masonry work in culverts, spreading the

Dismantled stuff with all leads and lifts within the site premises in layers not

exceeding 300 mm loose thickness and compacting etc. complete as directed by

MMCI/HPCL Engineer in Charge.

d:\project\BOQ FOR ROADS,DRAINS,DYKE WORK 20.07.09(BOQ(ter-17) Page : 7

You might also like

- Annexure - I BOQ For General Civil Works-1 PDFDocument5 pagesAnnexure - I BOQ For General Civil Works-1 PDFA. K. RoyNo ratings yet

- Estimate For Construction of R.C.C. Bridge Over River Buribalason, at Jalasnijamtara, Phansidewa, SiliguriDocument15 pagesEstimate For Construction of R.C.C. Bridge Over River Buribalason, at Jalasnijamtara, Phansidewa, SiliguriRio HandokoNo ratings yet

- Four Lanning of Lucknow-Kanpur NH-25 Project Cost EstimateDocument35 pagesFour Lanning of Lucknow-Kanpur NH-25 Project Cost EstimateRajiv Kumar SalotraNo ratings yet

- Delhi-Vadodara Expressway Package 12 BOQ SummaryDocument27 pagesDelhi-Vadodara Expressway Package 12 BOQ SummaryArpit VarshneyNo ratings yet

- BOQDocument93 pagesBOQshashirajhans2140No ratings yet

- Larsen & Toubro Limited Construction Heavy Civil Infrastructure IcDocument4 pagesLarsen & Toubro Limited Construction Heavy Civil Infrastructure IcAyush GuptaNo ratings yet

- Aecom Cc20 Temp 01 P r2 Design Calc. GWDocument9 pagesAecom Cc20 Temp 01 P r2 Design Calc. GWHarathi Venugopal Kishan100% (1)

- 11.sec.1100 (Pile Foundations)Document18 pages11.sec.1100 (Pile Foundations)Rakesh ParaliyaNo ratings yet

- MS of Segment Casting - 12345Document7 pagesMS of Segment Casting - 12345Anup SrivastavaNo ratings yet

- Book 1Document16 pagesBook 1ernarendersainiNo ratings yet

- Sample BOQ-1Document6 pagesSample BOQ-1Anonymous Of0C4dNo ratings yet

- K&J Quotation For Geotechnical - OLEODocument4 pagesK&J Quotation For Geotechnical - OLEORamakrishnaNo ratings yet

- TYcul LAYOUT 6 PDFDocument1 pageTYcul LAYOUT 6 PDFkanishka100% (1)

- Ds Proforma For Deviation Item StatementDocument74 pagesDs Proforma For Deviation Item StatementVemajala GaneshNo ratings yet

- Flyover QuantityDocument29 pagesFlyover QuantityHemant GaikwadNo ratings yet

- Topographical SurveysDocument27 pagesTopographical SurveysRomeo ZsurzsNo ratings yet

- Cube RegisterDocument3 pagesCube RegisterPartha GorainNo ratings yet

- General Arrangement Drawing: Section A-ADocument1 pageGeneral Arrangement Drawing: Section A-Aabhijeet sahuNo ratings yet

- Kattupalli Buildings BOQ Preliminary Rev.Document24 pagesKattupalli Buildings BOQ Preliminary Rev.VasanthakumarNo ratings yet

- RCC Drawing of Open Drain 11-10-2022Document16 pagesRCC Drawing of Open Drain 11-10-2022AKB CONSULTANTSNo ratings yet

- Construction of flyover cum ROB on UER-I at Narela TenderDocument39 pagesConstruction of flyover cum ROB on UER-I at Narela TenderRahul ChauhanNo ratings yet

- Bridge RepairDocument6 pagesBridge Repairharnishtanna212No ratings yet

- Karnataka Niravari Nigam LTD: RFP DocumentDocument115 pagesKarnataka Niravari Nigam LTD: RFP DocumentKA25 ConsultantNo ratings yet

- CH: 86+300 - Minor Bridge: 0.825 0.825 2.450 0.100 0.100 13.850 Abutment To DamohDocument6 pagesCH: 86+300 - Minor Bridge: 0.825 0.825 2.450 0.100 0.100 13.850 Abutment To DamohkadampNo ratings yet

- Flyover FormworkDocument13 pagesFlyover FormworkvrushankshahNo ratings yet

- Checklist For PMGSY Road WorksDocument4 pagesChecklist For PMGSY Road WorksrkpragadeeshNo ratings yet

- 02 - Part A - Earth WorkDocument28 pages02 - Part A - Earth WorkpvsvprasadcivilNo ratings yet

- Work ProgrammeDocument2 pagesWork ProgrammeEngineeri TadiyosNo ratings yet

- Bar Bending Schedule for Box CulvertDocument1 pageBar Bending Schedule for Box CulvertMaladi MustamilNo ratings yet

- Bailey Bridge Design Dwgs 39m Supstr+SubstrDocument16 pagesBailey Bridge Design Dwgs 39m Supstr+SubstrPrakash Singh RawalNo ratings yet

- 04-Filling Foundation Concrete Work PlumDocument4 pages04-Filling Foundation Concrete Work PlumBijay Krishna DasNo ratings yet

- Sr. No. Description Quantity Unit Rate (PKR) Amount (PKR) : KW&SB New 100Mgd Pump House at DhabejiDocument2 pagesSr. No. Description Quantity Unit Rate (PKR) Amount (PKR) : KW&SB New 100Mgd Pump House at DhabejigreatwellwisherNo ratings yet

- RCC Building Cost EstimateDocument15 pagesRCC Building Cost EstimateVirajee Civil Tech and consultantNo ratings yet

- Estimates SARNA TO MOHARGARHDocument40 pagesEstimates SARNA TO MOHARGARHTarunNo ratings yet

- Stormwater Drainage Design ParametersDocument6 pagesStormwater Drainage Design Parameterssagu27No ratings yet

- Analysis of RatesDocument1,986 pagesAnalysis of RatesMuhammad Ali DaanishNo ratings yet

- Precast Culvert DrawingDocument5 pagesPrecast Culvert Drawingraahul_nNo ratings yet

- Checklist For Bored Cast In-Situ Piles ConcretingDocument2 pagesChecklist For Bored Cast In-Situ Piles ConcretingHarlene Marie M. IlaganNo ratings yet

- Bridge Construction Project ManagementDocument2 pagesBridge Construction Project ManagementRishil ShahNo ratings yet

- MS 05 Cast-In-place Concrete Pile Method Statement (Bored Pile)Document18 pagesMS 05 Cast-In-place Concrete Pile Method Statement (Bored Pile)Abdullah Al MarufNo ratings yet

- Site Grading SpecsDocument5 pagesSite Grading SpecsdlloitNo ratings yet

- Basics of post-installed rebar connectionsDocument33 pagesBasics of post-installed rebar connectionsHaitham KayyaliNo ratings yet

- Adb V Boq Format r02Document26 pagesAdb V Boq Format r02ajay kumar guptaNo ratings yet

- Muthiga Apartments Structural Plans 5 Floors-Model5Document1 pageMuthiga Apartments Structural Plans 5 Floors-Model5Daniel OkereNo ratings yet

- Estimate: Public Works DepartmentDocument7 pagesEstimate: Public Works DepartmentRoopesh ChaudharyNo ratings yet

- Minor Bridge-Om-In - at 148Document4 pagesMinor Bridge-Om-In - at 148Khirai HelpNo ratings yet

- ICE Check Certificate Register for HK/2009/01 Contract WorksDocument10 pagesICE Check Certificate Register for HK/2009/01 Contract WorksKam LauNo ratings yet

- Complete - BOQ Format of Highway ProjectDocument53 pagesComplete - BOQ Format of Highway ProjectRajesh SinghalNo ratings yet

- BOQ and MeasurmentDocument12 pagesBOQ and MeasurmentBipin Ramesh JainNo ratings yet

- Dasarathi Naik and Engineers Pvt. Ltd. Concrete Pour Card: ClientDocument1 pageDasarathi Naik and Engineers Pvt. Ltd. Concrete Pour Card: ClientTusarranjan BhuyanNo ratings yet

- Pradhan Mantri Gram Sadak Yojana Cost Estimate For Road Construction Package CG03-234Document4 pagesPradhan Mantri Gram Sadak Yojana Cost Estimate For Road Construction Package CG03-234Lucky TraderNo ratings yet

- 7.Ms-External Plaster WorkDocument6 pages7.Ms-External Plaster WorkShenbagaraja PandianNo ratings yet

- Bill of QuantityDocument14 pagesBill of QuantityAshok KcNo ratings yet

- DSR ReportDocument451 pagesDSR ReportPramod Gaikwad100% (2)

- Earthworks Subfolder PK 61.30 - PK 75 - 14th July 2021 En.Document546 pagesEarthworks Subfolder PK 61.30 - PK 75 - 14th July 2021 En.Adrian FrantescuNo ratings yet

- Design of 15m Span Superstructure Re - 2Document1 pageDesign of 15m Span Superstructure Re - 2vivek100% (1)

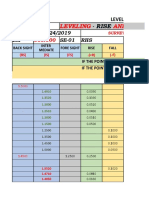

- Leveling AND Calculation: - Rise Fall MethodeDocument9 pagesLeveling AND Calculation: - Rise Fall MethodeKhajaNo ratings yet

- RCC OHSR TankDocument11 pagesRCC OHSR Tanksaxravi50% (4)

- BOQ for Road and Drainage WorksDocument20 pagesBOQ for Road and Drainage WorksVenkatesha Hebbar50% (2)

- BOQ For Civil-BhatindaDocument19 pagesBOQ For Civil-BhatindaRajesh ChowhanNo ratings yet

- Severe Acute Respiratory Syndrome - WikipediaDocument20 pagesSevere Acute Respiratory Syndrome - WikipediaPiyushNo ratings yet

- Nebula - WikipediaDocument9 pagesNebula - WikipediaPiyushNo ratings yet

- Ghatotkacha - WikipediaDocument5 pagesGhatotkacha - WikipediaPiyushNo ratings yet

- Vipassana PDFDocument6 pagesVipassana PDFPiyushNo ratings yet

- Vipassana PDFDocument6 pagesVipassana PDFPiyushNo ratings yet

- Earthquake Resistant Design of Low-Rise Open Ground Storey Framed Building: A ReviewDocument3 pagesEarthquake Resistant Design of Low-Rise Open Ground Storey Framed Building: A ReviewPiyushNo ratings yet

- Tenali Rama - WikipediaDocument4 pagesTenali Rama - WikipediaPiyushNo ratings yet

- COVID-19 Pandemic in Maharashtra - WikipediaDocument31 pagesCOVID-19 Pandemic in Maharashtra - WikipediaPiyushNo ratings yet

- Vipassana PDFDocument6 pagesVipassana PDFPiyushNo ratings yet

- Ekalavya - WikipediaDocument3 pagesEkalavya - WikipediaPiyushNo ratings yet

- Mahabharat (1988 TV Series) - WikipediaDocument15 pagesMahabharat (1988 TV Series) - WikipediaPiyushNo ratings yet

- Ramayana - Wikipedia PDFDocument28 pagesRamayana - Wikipedia PDFPiyushNo ratings yet

- IJTRD13590Document4 pagesIJTRD13590PiyushNo ratings yet

- Vipassana meditation course scheduleDocument6 pagesVipassana meditation course schedulePiyushNo ratings yet

- Theses - TUMDocument2 pagesTheses - TUMPiyushNo ratings yet

- Thesis Dissertation Template NPSDocument42 pagesThesis Dissertation Template NPSPiyushNo ratings yet

- Wadala - WikipediaDocument9 pagesWadala - WikipediaPiyushNo ratings yet

- SE Capstone Template NPSDocument44 pagesSE Capstone Template NPSPiyushNo ratings yet

- Design of Column Splice Web Splice for ShearDocument11 pagesDesign of Column Splice Web Splice for ShearPiyushNo ratings yet

- Sedam - WikipediaDocument3 pagesSedam - WikipediaPiyushNo ratings yet

- ThesisGdlnsFinal1 08Document30 pagesThesisGdlnsFinal1 08mohan1441No ratings yet

- An Unbiased Variance Estimator of A K-Sample U-Statistic With AppDocument46 pagesAn Unbiased Variance Estimator of A K-Sample U-Statistic With AppPiyushNo ratings yet

- Academic Essay Thesis Statement PDFDocument4 pagesAcademic Essay Thesis Statement PDFPiyushNo ratings yet

- Children's The New ToyDocument16 pagesChildren's The New ToyRuqia ZahraNo ratings yet

- Gsbs 24 Masters Thesis Prep GuideDocument17 pagesGsbs 24 Masters Thesis Prep GuidePiyushNo ratings yet

- How To Write A ThesisDocument14 pagesHow To Write A ThesisPiyushNo ratings yet

- Thesis Writing PDFDocument35 pagesThesis Writing PDFBrian Quintero ArboledaNo ratings yet

- How to Write Strong Thesis StatementsDocument1 pageHow to Write Strong Thesis StatementsPiyushNo ratings yet

- Maximum force and bearing capacity of boltsDocument4 pagesMaximum force and bearing capacity of boltsPiyushNo ratings yet

- Design of One-Way SlabsDocument15 pagesDesign of One-Way SlabsPankaj YadavNo ratings yet

- GYPROCK 547 Residential Installation Guide 2015Document84 pagesGYPROCK 547 Residential Installation Guide 2015stoicperson100% (2)

- ABB Stand L 435 Rue de LDocument3 pagesABB Stand L 435 Rue de LRohith KommuNo ratings yet

- NAFI Datafile SP1 (1989) - Timber SpecificationsDocument48 pagesNAFI Datafile SP1 (1989) - Timber Specificationssteveh49No ratings yet

- Pine Valley Brochure p19Document16 pagesPine Valley Brochure p19MohdFaridNo ratings yet

- Technology Sharing Initiative - TexasDocument28 pagesTechnology Sharing Initiative - TexasbazlitchfieldNo ratings yet

- Exporters in Keral1Document8 pagesExporters in Keral1Victor GopiNo ratings yet

- Plastic Piping HandbookDocument359 pagesPlastic Piping Handbookludwing_ulloa100% (13)

- Sikadur 732Document2 pagesSikadur 732Iskandar AlamsyaNo ratings yet

- Mechanical Properties ZA-8 ZA-27: Respectively. ZAPDocument1 pageMechanical Properties ZA-8 ZA-27: Respectively. ZAPs_padu3003@yahoo.comNo ratings yet

- En DIN Standards in Pipeline ConstructionDocument2 pagesEn DIN Standards in Pipeline ConstructionJohn Smith67% (3)

- TGA NotesDocument5 pagesTGA Notespatilamardip007No ratings yet

- Stone Masonry and Brick Stone MasonryDocument3 pagesStone Masonry and Brick Stone MasonryMuhafeez GoolabNo ratings yet

- E272Document4 pagesE272MoralesNo ratings yet

- CM7202-Applied Materials EngineeringDocument6 pagesCM7202-Applied Materials EngineeringJayaraman TamilvendhanNo ratings yet

- Hapri Insulation Materials Manufacturing Company ProfileDocument36 pagesHapri Insulation Materials Manufacturing Company ProfilesohebamNo ratings yet

- Renovation of Onups Ward BuildingDocument37 pagesRenovation of Onups Ward BuildingpaulomirabelNo ratings yet

- Brazing - Fundamentals - 1Document7 pagesBrazing - Fundamentals - 1Sadashiw PatilNo ratings yet

- 6 List of Supplier (1-28)Document6 pages6 List of Supplier (1-28)Joseph IngramNo ratings yet

- The economical alternative to steel fibers and steel meshDocument16 pagesThe economical alternative to steel fibers and steel meshourebooksNo ratings yet

- Aluminium Alloy 6061Document3 pagesAluminium Alloy 6061choobyNo ratings yet

- Concrete Encased Duct Bank PDFDocument8 pagesConcrete Encased Duct Bank PDF101079No ratings yet

- Cold Hot Working AnnealingDocument40 pagesCold Hot Working AnnealingBaljeet KaurNo ratings yet

- Macfoil Af 547: Technical ProductsDocument2 pagesMacfoil Af 547: Technical Productsfhsn84No ratings yet

- Rail CorrosionDocument71 pagesRail CorrosionkishanrwtNo ratings yet

- Precolumbian Gold Technology, Style, and IconographyDocument3 pagesPrecolumbian Gold Technology, Style, and Iconographysmayat08No ratings yet

- Vacman's Notes - Bag Penetration Fittings For CompositesDocument2 pagesVacman's Notes - Bag Penetration Fittings For CompositesopytnymoryakNo ratings yet

- Ficha Tecnica - Edgetherm - THM - 3000Document2 pagesFicha Tecnica - Edgetherm - THM - 3000edocducNo ratings yet

- Accelerating AdmixturesDocument5 pagesAccelerating AdmixturesFaraz TariqNo ratings yet

- SermaGard Engineered Protective CoatingsDocument2 pagesSermaGard Engineered Protective CoatingsFrank Maldonado D'JesusNo ratings yet