Professional Documents

Culture Documents

Glenium 51

Uploaded by

SivakumarCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Glenium 51

Uploaded by

SivakumarCopyright:

Available Formats

GLENIUM 51

High range water reducing/superplasticizing admixture

CE Approved Certificate No. 0086-CPD-469071

EN934 part 2 tables 3.1 and 3.2.

Description of Product traditional superplasticizers. It consists of a

GLENIUM 51 in an admixture of a new carboxylic ether polymer with long side chains.

generation based on modified polycarboxylic

ether. The product has been primarily At the beginning of the mixing process it initiates

developed for the use in the concrete industry the same electrostatic dispersion mechanism as

where the highest durability and performance is the traditional superplasticizers, but the side

required. chains linked to the polymer backbone generate

a steric hindrance, which greatly stabilises the

GLENIUM 51 is free of chloride & low alkali. It cement particles' ability to separate and

complies with EN 934 part 2. GLENIUM 51 is disperse. Steric hindrance provides a physical

compatible with all types of cement. barrier (alongside the electrostatic barrier)

between the cement grains. With this process,

The new chemistry of GLENIUM 51 flowable concrete with greatly reduced water

What differentiates GLENIUM 51 from the content is obtained.

traditional superplasticizers is a new, unique

mechanism of action that greatly improves the Fields of Application

effectiveness of cement dispersion. Traditional The excellent dispersion effect makes

superplasticizers based on melamine and GLENIUM 51 the ideal admixture for the

naphthalene sulphonates are polymers, which high quality concrete industry.

are absorbed by the cement granules. They The ability to work with an extremely low

wrap around the granules' surface areas at the water/cement ratio allows for the

very early stage of the concrete mixing process. manufacture of high performance concrete

The sulphonic groups of the polymer chains with high early (18-24 hours) and final

increase the negative charge of the cement strengths. Concrete of high density, low

particle surface and disperse these particles by permeability is also produced.

electrical repulsion.

Features and Benefits

This electrostatic mechanism causes the cement

paste to disperse and has the positive Flowable concrete with the lowest

consequence of requiring less mixing water to water/cement ratio without segregation or

obtain a given concrete workability. GLENIUM bleeding.

51 has a different chemical structure from the Allows reduction of curing cycles - i.e. time or

temperature.

November 2003 Page 1 of 3 Ref No 0192

GLENIUM 51

Possibility of elimination of steam curing. Initial and final compressive strength.

Allows concrete production at low Initial and final flexural and tensile strength.

temperature. E-modulus.

Adhesion to reinforcement and prestressed

Features and Benefits steel.

Less vibration required even in case of Resistance to carbonation and chloride ion

congested steel reinforcement. attack of concrete.

Less workmanship required. Resistance to aggressive atmospheric

Improves concrete surface finish and texture. conditions.

Compared to traditional superplasticizers,

the addition of GLENIUM 51 will improve GLENIUM 51 decreases

the physical properties and thus the Risk of shrinkage.

durability of concrete: Creep.

GLENIUM 51 increases

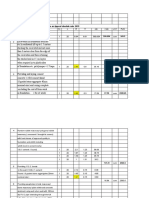

Manufacturers Stated Values

Alkali Chloride Chlorine

SG pH

% % %

less than or equal to less than or equal to less than or equal to

1.095 7.20

4.0 0.10 0.10

Application Procedure Other combinations that are recommended:

Compatibility of GLENIUM 51 Air entraining agents (such as MICRO-AIR

GLENIUM ACTIVATOR range) to optimise frost/thaw resistance.

Where elimination of steam curing is intended Silica fume for higher density.

(at ambient temperatures below 12C) while still Expanding agents (such as for controlled

achieving high early strength to enable early shrinkage).

demoulding within 24 hours, it may be necessary Synthetic and steel fibres.

to add GLENIUM ACTIVATOR with GLENIUM Curing agents against too quick evaporation

51. The recommended dosage of GLENIUM of mixing water.

ACTIVATOR is 1 litre per 100 kg of cement

(binder). This combination guarantees a uniform GLENIUM 51 is a ready to use admixture to be

and fast development of initial and final strength. added to the concrete mix as a separate

At temperatures above I2C the addition of component.

GLENIUM ACTIVATOR is not required.

Optimal concrete plasticising effect (and thus

Like GLENIUM 51, GLENIUM ACTIVATOR is maximum mixing water reduction) is obtained if

free of chloride and is low alkali and is GLENIUM 51 is added into the concrete after

compatible with all types of cements. the first 50-70% of the water has been mixed.

Avoid adding the admixture to the dry aggregate

or sand. In all cases the best effect is achieved

when GLENIUM 51 is added first and the other

admixtures subsequently.

November 2003 Page 2 of 3 Ref No 0192

GLENIUM 51

Dosage Storage

Depending on specific mix design and GLENIUM 51 must be stored in a place where

requirements, the normally recommended temperature does not drop below +5C. If

dosage rate is between: product has frozen, thaw at +3C and agitate

until completely reconstituted. Store under

By Volume - 0.2 to 1.0% per 100 Kg of cement cover, out of direct sunlight and protect from

(binder). extremes of temperature. Failure to comply with

the recommended storage conditions may result

By Mass - 0.219 to 1.095 kg per 100 Kg of in premature deterioration of the product or

cement (binder). packaging. For specific storage advice consult

Degussa Construction Chemicals (UK) Technical

Other dosages may be recommended in special Services Department.

cases according to specific job conditions

(consult Degussa Construction Chemicals (UK) Shelf Life

Technical Services Department for advice). Up to 12 months if stored according to

manufacturers instructions in unopened

Packaging containers.

GLENIUM 51 is available in 205 litre drums,

1000 litre container or in bulk.

GLENIUM 51 Degussa Construction Chemicals UK Version 4

Health and Safety Disclaimer:

*For full information on Health and Safety matters regarding this product the This information and all further technical advice is based on our

relevant Health and Safety Data Sheet should be consulted. present knowledge and experience. However, it implies no liability or

other legal responsibility on our part, including with regard to existing

The following general comments apply to all products. third party intellectual property rights, especially patent rights. In

particular, no warranty, whether express or implied, or guarantee of

As with all chemical products, care should be taken during use and storage product properties in the legal sense is intended or implied. We

to avoid contact with eyes, mouth, skin and foodstuffs, (which may also be reserve the right to make any changes according to technological

tainted with vapour until the product is fully cured and dried). Treat progress or further developments. The customer is not released from

splashes to eyes and skin immediately. If accidentally ingested, seek the obligation to conduct careful inspection and testing of incoming

medical attention. Keep away from children and animals. Reseal goods. Performance of the product described herein should be

containers after use. verified by testing, which should be carried out only by qualified

experts in the sole responsibility of a customer. Reference to trade

Spillage names used by other companies is neither a recommendation, nor

Chemical products can cause damage; clean spillage immediately. does it imply that similar products could not be used.

Novembert 2003 Page 3 of 3 Ref No 0192

You might also like

- Plastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965From EverandPlastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965No ratings yet

- Glenium 51: A High Performance Concrete Superplasticiser Based On Modified Polycarboxylic EtherDocument3 pagesGlenium 51: A High Performance Concrete Superplasticiser Based On Modified Polycarboxylic EtherFrancois-No ratings yet

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsFrom EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsRating: 5 out of 5 stars5/5 (1)

- MasterGlenium® 51Document4 pagesMasterGlenium® 51draganugNo ratings yet

- TDS - Glenium 51 PDFDocument3 pagesTDS - Glenium 51 PDFaahtagoNo ratings yet

- GRP and Buildings: A Design Guide for Architects and EngineersFrom EverandGRP and Buildings: A Design Guide for Architects and EngineersNo ratings yet

- TDS - Glenium 51Document3 pagesTDS - Glenium 51Alexi ALfred H. TagoNo ratings yet

- TDS - Glenium 51 PDFDocument3 pagesTDS - Glenium 51 PDFAlexi ALfred H. TagoNo ratings yet

- TDS - Glenium 51 PDFDocument3 pagesTDS - Glenium 51 PDFAlexi ALfred H. TagoNo ratings yet

- Glenium® Ace 30: Description and Field of Application Zero Energy SystemDocument2 pagesGlenium® Ace 30: Description and Field of Application Zero Energy SystemFrancois-No ratings yet

- Glenium 21Document3 pagesGlenium 21Karl FarrugiaNo ratings yet

- Glenium Sky 777 v4Document2 pagesGlenium Sky 777 v4babu_ssrNo ratings yet

- Duconmix G 501Document2 pagesDuconmix G 501FounTech612No ratings yet

- Glenium 27Document3 pagesGlenium 27Ct TanNo ratings yet

- TDS - Glenium 110 UN PDFDocument3 pagesTDS - Glenium 110 UN PDFAlexi ALfred H. TagoNo ratings yet

- Masterglenium-110m Technical Data SheetDocument3 pagesMasterglenium-110m Technical Data Sheetabukayes.abdinNo ratings yet

- TDS - Glenium 54Document3 pagesTDS - Glenium 54Alexi ALfred H. TagoNo ratings yet

- TDS - Glenium 54 PDFDocument3 pagesTDS - Glenium 54 PDFAlexi ALfred H. TagoNo ratings yet

- Masterglenium Ace 30 (JP) : Description PropertiesDocument3 pagesMasterglenium Ace 30 (JP) : Description PropertiesABHI MITRANo ratings yet

- TDS - Glenium 110 UNRDocument3 pagesTDS - Glenium 110 UNRAlexi ALfred H. TagoNo ratings yet

- Glenium 51 TDSDocument2 pagesGlenium 51 TDSTooma DavidNo ratings yet

- Masterglenium Sky 8522 v1Document3 pagesMasterglenium Sky 8522 v1kishor150688No ratings yet

- TDS - Glenium 21Document3 pagesTDS - Glenium 21Alexi ALfred H. TagoNo ratings yet

- Masterrheobuild 3250: High Range Water-Reducing Admixture For ConcreteDocument3 pagesMasterrheobuild 3250: High Range Water-Reducing Admixture For Concretemido_20067581No ratings yet

- Basf Masterglenium 27 TdsDocument4 pagesBasf Masterglenium 27 TdsJosé Luis CampelloNo ratings yet

- ADDMIX 315-v1Document2 pagesADDMIX 315-v1Ankita Baban GavadeNo ratings yet

- Xtreme WR55Document2 pagesXtreme WR55central labNo ratings yet

- Masterglenium Sky 8765: High-Performance Super Plasticiser Based On Pce (Polycarboxylic Ether) For ConcreteDocument3 pagesMasterglenium Sky 8765: High-Performance Super Plasticiser Based On Pce (Polycarboxylic Ether) For ConcreteVYASNo ratings yet

- Xtreme WR30Document2 pagesXtreme WR30central labNo ratings yet

- Masterrheobuild 623: Retarding Superplasticising Admixture For ConcreteDocument2 pagesMasterrheobuild 623: Retarding Superplasticising Admixture For ConcreteShihab AhamedNo ratings yet

- Basf Masterglenium Sky 920 Tds PDFDocument4 pagesBasf Masterglenium Sky 920 Tds PDFvikasNo ratings yet

- TDS - MasterGlenium ACE 30 (JP)Document2 pagesTDS - MasterGlenium ACE 30 (JP)Taposh PaulNo ratings yet

- X-Mix X500: Set Retarding / High Range Water-Reducing /super Plasticizing AdmixtureDocument2 pagesX-Mix X500: Set Retarding / High Range Water-Reducing /super Plasticizing Admixturediaa mohamedNo ratings yet

- Basf Masterglenium Sky 8851 TdsDocument2 pagesBasf Masterglenium Sky 8851 TdsMichael GelongNo ratings yet

- Glenium - Ace - 6 - Suretec - v4Document2 pagesGlenium - Ace - 6 - Suretec - v4Kuldeep ChakerwartiNo ratings yet

- Duconmix RB RS 110Document2 pagesDuconmix RB RS 110FounTech612No ratings yet

- Cemplast-Super 125: Ce YcreteDocument3 pagesCemplast-Super 125: Ce YcreteatiqurNo ratings yet

- Cemplast-Super 125: Ce YcreteDocument4 pagesCemplast-Super 125: Ce YcreteatiqurNo ratings yet

- TDS - MasterRheobuilld 1100Document2 pagesTDS - MasterRheobuilld 1100Taposh PaulNo ratings yet

- ENG MasterGlenium ACE 30 TdsDocument4 pagesENG MasterGlenium ACE 30 TdsPrateek ModyNo ratings yet

- Duconmix RBS 100 TDSDocument2 pagesDuconmix RBS 100 TDSmasudNo ratings yet

- Cempatch FL90 (23.02.2021)Document2 pagesCempatch FL90 (23.02.2021)Mohamed RusfanNo ratings yet

- Renderoc LA55Document2 pagesRenderoc LA55Mansoor AliNo ratings yet

- MasterGlenium Ace 30 v2Document3 pagesMasterGlenium Ace 30 v2Jagan Mohana Rao ChinnalaNo ratings yet

- Masterglenium Sky 8705Document2 pagesMasterglenium Sky 8705usenuyaNo ratings yet

- Pds - Glenium C 317Document2 pagesPds - Glenium C 317Doby YuniardiNo ratings yet

- Pdsgleniumc317 171211141713 PDFDocument2 pagesPdsgleniumc317 171211141713 PDFRavi AyyavuNo ratings yet

- Super Plasticizer For High Strength ConcreteDocument2 pagesSuper Plasticizer For High Strength Concretedachepalli963No ratings yet

- MasterRheobuild 1100 Formerly Known Rheobuild 1100 - EGDocument3 pagesMasterRheobuild 1100 Formerly Known Rheobuild 1100 - EGvahab_shaikNo ratings yet

- Rheomix 125: Binder 5Document3 pagesRheomix 125: Binder 5Raven James Angelo IgnacioNo ratings yet

- MasterGlenium 51 v1Document3 pagesMasterGlenium 51 v1Jaga NathNo ratings yet

- Glenium 27 CHDocument3 pagesGlenium 27 CHFrancois-No ratings yet

- 12.11.2018 BASF MasterGlenium Ace 30JP v2Document3 pages12.11.2018 BASF MasterGlenium Ace 30JP v2Prateek ModyNo ratings yet

- GLENIUM B233 v7Document2 pagesGLENIUM B233 v7syedarNo ratings yet

- TDS - Glenium Ace 340Document3 pagesTDS - Glenium Ace 340Alexi ALfred H. TagoNo ratings yet

- TDS - Rheobuild 1100Document3 pagesTDS - Rheobuild 1100Alexi ALfred H. Tago100% (1)

- Cembinder 8 TDSDocument1 pageCembinder 8 TDSkbkshanakaNo ratings yet

- 02 MCT Product Data SheetsDocument12 pages02 MCT Product Data SheetskunalscribduomNo ratings yet

- CEBEX112Document2 pagesCEBEX112reshmitapallaNo ratings yet

- Bathroom Furniture 2016-2017Document52 pagesBathroom Furniture 2016-2017SivakumarNo ratings yet

- TDS - Glenium 51Document3 pagesTDS - Glenium 51SivakumarNo ratings yet

- Glenium 7700 Data Sheet 1.08Document2 pagesGlenium 7700 Data Sheet 1.08SivakumarNo ratings yet

- D5300VRRM (En) 02Document308 pagesD5300VRRM (En) 02SivakumarNo ratings yet

- The Y BeamDocument7 pagesThe Y BeamSivakumarNo ratings yet

- Stability of Long Precast GirdersDocument10 pagesStability of Long Precast GirdersAriel D Urieta HNo ratings yet

- Whole GardnerMarkAlan2004 ThesisDocument380 pagesWhole GardnerMarkAlan2004 ThesisAnil kumar RNo ratings yet

- Design of Steel Baseplate To BS 5950 - PHILLIPS CONSULTING ENGINEERS LTDDocument4 pagesDesign of Steel Baseplate To BS 5950 - PHILLIPS CONSULTING ENGINEERS LTDLavanyan SatchithananthanNo ratings yet

- El As To Poxy PrimerDocument1 pageEl As To Poxy Primerpravi3434No ratings yet

- Ice Amice SyllabusDocument57 pagesIce Amice SyllabusBIJAY KRISHNA DAS100% (1)

- Capoxy GroutDocument2 pagesCapoxy GroutSayed Diab AlsayedNo ratings yet

- Design of ColumnDocument72 pagesDesign of ColumnmdrasheedkhanNo ratings yet

- Carpentry - TleDocument18 pagesCarpentry - TleRizalee PerezNo ratings yet

- Detailed Quty. For R/R Wall Estimate As HPPWD Shedule Rate 2019Document6 pagesDetailed Quty. For R/R Wall Estimate As HPPWD Shedule Rate 2019rahulNo ratings yet

- Strutural Analysis 3 StoreyDocument28 pagesStrutural Analysis 3 StoreyJohn kevin LlagasNo ratings yet

- Jointflex: Closed Cell Polyethylene FillerboardDocument2 pagesJointflex: Closed Cell Polyethylene Fillerboardkz shimantoNo ratings yet

- Reinforcement Placement in Slabs PDFDocument6 pagesReinforcement Placement in Slabs PDFLandel SmithNo ratings yet

- Estimate 2Document82 pagesEstimate 2shashirajhans2140No ratings yet

- Masterbrace Adh 2200: Description AdvantagesDocument2 pagesMasterbrace Adh 2200: Description AdvantagesHaseeb AhmedNo ratings yet

- Awash Bishole CIVIL & EL BOQ PricedDocument81 pagesAwash Bishole CIVIL & EL BOQ PricedHailuGelanHubenaNo ratings yet

- E 3134 - 17Document12 pagesE 3134 - 17Jacky LeongNo ratings yet

- Conveying and StoringDocument28 pagesConveying and StoringTin Nguyen100% (1)

- Construction and Building Materials: Ali Akbar Ramezanianpour, Amirreza Pilvar, Mahdi Mahdikhani, Faramarz MoodiDocument8 pagesConstruction and Building Materials: Ali Akbar Ramezanianpour, Amirreza Pilvar, Mahdi Mahdikhani, Faramarz Moodidevildriver_990No ratings yet

- Cahya Mata SarawakDocument147 pagesCahya Mata Sarawakvijsans7No ratings yet

- Ancon EdjPro Lifting SystemsDocument10 pagesAncon EdjPro Lifting Systems12378aNo ratings yet

- Cement Plants Located in India 1Document4 pagesCement Plants Located in India 1Graylab Technologies0% (1)

- GlassDocument4 pagesGlassShaik Asif AliNo ratings yet

- Anti Condensation CatalogueDocument8 pagesAnti Condensation CatalogueBoBo KyawNo ratings yet

- Enviroline 125LV Application GuidelineDocument17 pagesEnviroline 125LV Application GuidelineAhmed IbrahimNo ratings yet

- COARSE AGGREGATES - Summary SpecsDocument1 pageCOARSE AGGREGATES - Summary SpecsBrandon BaoasNo ratings yet

- Maharashtra Engineering Services (Civil), Gr. A & Gr. B (Main) ExamDocument3 pagesMaharashtra Engineering Services (Civil), Gr. A & Gr. B (Main) ExamErRajivAmieNo ratings yet

- Bit BankDocument10 pagesBit BankShiva SanviNo ratings yet

- DSR 2016 in Ms ExcelDocument749 pagesDSR 2016 in Ms ExcelsaravananNo ratings yet

- Training of Batching OperatorsDocument52 pagesTraining of Batching OperatorsMOREENo ratings yet

- Structural Drawing-Himel Vaiya-01-03-2020Document11 pagesStructural Drawing-Himel Vaiya-01-03-2020MD Shakil AhmedNo ratings yet

- Sodium Bicarbonate: Nature's Unique First Aid RemedyFrom EverandSodium Bicarbonate: Nature's Unique First Aid RemedyRating: 5 out of 5 stars5/5 (21)

- Process Plant Equipment: Operation, Control, and ReliabilityFrom EverandProcess Plant Equipment: Operation, Control, and ReliabilityRating: 5 out of 5 stars5/5 (1)

- A New Approach to HAZOP of Complex Chemical ProcessesFrom EverandA New Approach to HAZOP of Complex Chemical ProcessesNo ratings yet

- Guidelines for Chemical Process Quantitative Risk AnalysisFrom EverandGuidelines for Chemical Process Quantitative Risk AnalysisRating: 5 out of 5 stars5/5 (1)

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsFrom EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsNo ratings yet

- Physical and Chemical Equilibrium for Chemical EngineersFrom EverandPhysical and Chemical Equilibrium for Chemical EngineersRating: 5 out of 5 stars5/5 (1)

- Phase Equilibria in Chemical EngineeringFrom EverandPhase Equilibria in Chemical EngineeringRating: 4 out of 5 stars4/5 (11)

- Lees' Process Safety Essentials: Hazard Identification, Assessment and ControlFrom EverandLees' Process Safety Essentials: Hazard Identification, Assessment and ControlRating: 4 out of 5 stars4/5 (4)

- Water-Based Paint Formulations, Vol. 3From EverandWater-Based Paint Formulations, Vol. 3Rating: 4.5 out of 5 stars4.5/5 (6)

- Well Control for Completions and InterventionsFrom EverandWell Control for Completions and InterventionsRating: 4 out of 5 stars4/5 (10)

- The HAZOP Leader's Handbook: How to Plan and Conduct Successful HAZOP StudiesFrom EverandThe HAZOP Leader's Handbook: How to Plan and Conduct Successful HAZOP StudiesNo ratings yet

- Coupled CFD-DEM Modeling: Formulation, Implementation and Application to Multiphase FlowsFrom EverandCoupled CFD-DEM Modeling: Formulation, Implementation and Application to Multiphase FlowsNo ratings yet

- Distillation Design and Control Using Aspen SimulationFrom EverandDistillation Design and Control Using Aspen SimulationRating: 5 out of 5 stars5/5 (2)

- First U.K. National Conference on Heat Transfer: The Institution of Chemical Engineers Symposium Series, Volume 2.86From EverandFirst U.K. National Conference on Heat Transfer: The Institution of Chemical Engineers Symposium Series, Volume 2.86No ratings yet

- Fundamentals of Risk Management for Process Industry EngineersFrom EverandFundamentals of Risk Management for Process Industry EngineersNo ratings yet

- Fun Facts about Hydrogen : Chemistry for Kids The Element Series | Children's Chemistry BooksFrom EverandFun Facts about Hydrogen : Chemistry for Kids The Element Series | Children's Chemistry BooksNo ratings yet

- Biotechnology of Metals: Principles, Recovery Methods and Environmental ConcernsFrom EverandBiotechnology of Metals: Principles, Recovery Methods and Environmental ConcernsNo ratings yet

- Nuclear Energy in the 21st Century: World Nuclear University PressFrom EverandNuclear Energy in the 21st Century: World Nuclear University PressRating: 4.5 out of 5 stars4.5/5 (3)

- The Stress Analysis of Pressure Vessels and Pressure Vessel Components: International Series of Monographs in Mechanical EngineeringFrom EverandThe Stress Analysis of Pressure Vessels and Pressure Vessel Components: International Series of Monographs in Mechanical EngineeringS. S. GillRating: 3.5 out of 5 stars3.5/5 (3)

- Coulson and Richardson’s Chemical Engineering: Volume 2B: Separation ProcessesFrom EverandCoulson and Richardson’s Chemical Engineering: Volume 2B: Separation ProcessesAjay Kumar RayNo ratings yet