Professional Documents

Culture Documents

Liquid Level Control System V2

Uploaded by

Shisanu SenOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Liquid Level Control System V2

Uploaded by

Shisanu SenCopyright:

Available Formats

NATIONAL INSTITUTE OF TECHNOLOGY, DURGAPUR

DEPARTMENT OF ELECTRICAL ENGINEERING

Experiment No. 1.

Objective: Design and Implementation of liquid level control System.

Introduction

The industrial application of liquid level control is tremendous especially in process industries.

Various applications where liquid level control is crucial are boiler drums level control in power plant,

liquid level control in evaporator system, food processing, dairy and beverages industry, chemical

production, processing and storage plants, Petroleum and Petro chemical Industry etc.

The system under investigation is a laboratory scale model setup of overhead tank liquid level

control system. The main objective is to maintain a constant liquid level independent of the output flow

rate of liquid from the tank by controlling the inflow rate of liquid into the tank. Another application where

liquid level control system plays an important role is to control flow, which occur due to gravitational

force.

Description of the Level Control System

The liquid level control system consists of two water tanks as shown in figure 1, each are mounted

on a platform such that lower one sump tank (reservoir) which stores the water and overhead tank in which

water level is to be controlled. Two water tanks vertically positioned in such a manner so that outflow

from the top tank (overhead) serves as inflow for the lower tank (sump) due to gravitational force. The

water level in the overhead tank is measured by an ultrasonic non-contact type liquid level sensor and

controlled by controlling the inflow rate into the overhead tank with the help of a control valve. From the

overhead tank, water drains out due to gravitational force, so depending upon the potential head of the

water in the overhead tank its flow through the output valve will vary. When level in the overhead tank is

high then water drains through outlet with high pressure and velocity and vice versa otherwise. A pump

is used to deliver the water from sump tank to overhead tank. Thus to maintain a constant level in the

overhead tank, inlet flow must be controlled in such a manner that it becomes equal to outflow rate at the

desired set value of the liquid level. A photograph of the actual setup is shown in figure 2. The details of

the different components are given in ANNEXURE I.

ADVANCED ELECTRICAL ENGINEERING LABORATORY

Experiment:

A. Study the program to read the current liquid level from the Analog Input (AI) port (Tag. RAW USTX

SIGNL) and user given remote set point (Tag. OT SCADA SP). Use a PID controller block to generate

a control signal accordingly and then send the output to the Analog Output (AO) port (Tag. OT CV

Out).

In addition to this continuous control, turn off the pump if any one of these situations occurs.

i) Water level in Sump tank is below the lower level.

ii) Water level in the Overhead tank is above upper level limit.

Read the corresponding digital inputs from DI ports (Tag. GT USLSW IND and OT USLSW IND)

generate the logic with OR function-block and send the output decision to the pump through DO port

(Tag. PUMP SW RESET).

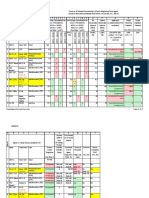

B. Run the SCADA program, set the PID controller in P control mode with P=1, calculate settling time,

rise time, delay time etc. for three different set point values.

C. Now use different P, I and D values and observe the control action, collect three set of ridings for three

different set point values and record the parameters according to Table I.

Different set of Controller parameter Record

readings P I D Set Point Liquid Level Controller Output

Exp. 1

Set Point 1 Exp. 2

Exp. 3

Exp. 1

Set Point 2 Exp. 2

Exp. 3

Exp. 1

Set Point 3 Exp. 2

Exp. 3

ADVANCED ELECTRICAL ENGINEERING LABORATORY

D. Simulate the mathematical model (see ANNEXURE-II) of the system in MATLAB/SIMULINK

observe the response and tune model parameters to approximate the response of the simulated system

closer to experimental response.

i) Obtain the step and impulse response of the process transfer function.

ii) Find the Root locus, Nyquist and Bode plot and also find gain and phase margins.

iii) Apply different PID tuning techniques to estimate the proper P, I and D values.

iv) Suggest an optimum P, I and D values for the controller.

v) Simulate the total system along with the controller with optimum P, I and D values.

Report the followings in next experiment day (One Group one Copy):

I. Provide the results obtained from B, C and D.

II. Describe in detail with suitable figures

III. Experimental Procedure (with screen snap shots)

Electrical Actuator and Control valve (Type: as in experiment).

Ultrasonic Level Sensor and Ultrasonic contact type level switch

Solenoid Valve

DCS (HC 900 Hardware Details)

DCS (SCADA Software Details)

ANNEXURE-I

Description of the different components

Sump Tank: This is the tank in which water is collected from overhead tank and is stored. A pump is

used to pump the water into the overhead tank from this tank. A level switch is placed into this tank to

sense lower level of the liquid. This switch can be used as protection for the pump, i.e. when water level

into the sump tank is low, and then pump will not start to avoid any dry run.

Water pump: The delivery pump is used to pump the water from sump tank to overhead tank, a control

valve is placed in the delivery side of the pump to control the inflow rate to the tank, a bypass line is

placed before the control valve to protect pump in overload condition i.e. when control valve will be in

100% close condition. The pump is driven by the single phase induction motor, rated 220V, 50 Hz, 2.5

Amps and 3000 rpm.

Overhead tank: The liquid level in the overhead tank needs to be controlled with the help of PID control

action. The liquid level is measured with the help of an ultrasonic level sensor placed at the top of the

tank. A level switch is also placed in the top of the overhead tank to sense high liquid level, this is used to

protect overflow of water from the overhead tank.

Control Valve: The function of the control valve is to control the flow through the pipe; there is a

electrically actuated control valve placed in the inflow line of the overhead tank.

A cross section view of a control valve is shown in Figure 2. The valve plug is movable and can regulate

the flow rate by varying the effective flow area.

ADVANCED ELECTRICAL ENGINEERING LABORATORY

Figure 2. Cross section view of single seat two port globe valve.

The movement or position of the valve plug is controlled by an electrical actuator placed at the top of the

valve. The internal diagram of an electrical actuator is shown in Figure 3.

Figure 3. Internal diagram of an electrical actuator

A positioning circuit may is also included in the actuator, which accepts an analogue control signal

(typically 0-10 V or 4-20 mA) from the controller. The actuator then interprets this control signal, as the

valve position between the limit switches. The actuator has a position sensor (usually a potentiometer),

which feeds the actual valve position back to the positioning circuit. In this way the actuator can be

positioned along its stroke in proportion to the control signal. A schematic of the modulating actuator is

shown in Figure 4.

ADVANCED ELECTRICAL ENGINEERING LABORATORY

Figure 4. Functional diagram of an electrical actuator

Level sensors: Ultrasonic level sensor is used and which is mounted on the top of the overhead tank at a

certain height so that it can measure the tank water level by transmitting and receiving the ultrasonic wave.

Ultrasonic sensors use sound waves to measure distance. A sensor would normally be mounted at the top

of a tank and direct a sound wave down towards the surface of the product. When the sound wave hits the

product it is reflected and returned to the sensor. The greater the distance between the sensor and the

product, the longer it will take for the sound wave to travel down and back up again. The sensors calculate

this time interval and give a signal proportional to the distance. They also compensate for the changes in

the speed of sound due to changes in temperature. A scheme for measurement of level using ultrasound is

shown in Figure 5.

The ultrasonic transmitter generates analog output (4-20mA) according to the water level in the tank, 4

mA when water level at lowest position and 20 mA when it is at maximum position and in between values

for in between level.

Figure 5. Measurement of level using ultrasound

Outflow from Overhead tank: A pipe along with the solenoid valve is connected at the bottom of the

overhead tank and at the top of the sump tank, which allows flowing water from overhead tank to sump

tank, occur due to gravitational force. This flow can be stopped by operating the solenoid valve.

ADVANCED ELECTRICAL ENGINEERING LABORATORY

Solenoid valve: A solenoid valve is an electro-mechanical device that when energized or de-energized

either opens or closes valve opening. A functional diagram of a Solenoid Valve is shown in Figure 6.

Figure 6. Functional diagram of a solenoid valve

Level Switch: A level switch is a device which can sense whether the water level is above or below to

certain value. Thus it gives a signal (ON/OFF), i.e. in binary. Contact ultrasonic level switches use ceramic

discs called piezoelectric crystals to transmit and receive ultrasonic energy. A transmit crystal (T) is on

one side of a transducer gap and a receive crystal (R) is on the opposite side. The side-gap must be (as

shown in Figure 7.) completely filled with fluid before liquid level is sensed and the switches goes to ON

position.

Figure 7. Ultrasonic contact type level switch

Controller: A controller is provided for controlling the water level of the tank, the information about the

current water level is sensed by the ultrasonic sensor and transmitted to the analog input (4-20mA) of the

controller, the controller then send a corrective signal (4-20mA) on the basis of the user given desired

value (set value) of the liquid level to the final control element 9electrical actuator). The final control

element then controls the flow rate by opening and closing the valve to control the liquid level. The

switches provide a digital output (ON/OFF) signal which goes to Digital input of the controller and the

Solenoid valve which also accept digital signal is connected to the Digital output of the controller. The

ADVANCED ELECTRICAL ENGINEERING LABORATORY

use of these switches and solenoid valve is to avoid unusual events and for safety purpose. Different

component of a controller is shown in Figure 8.

Figure 8. Controller (HC900)

For the control action a Distributed Control System (DCS) is provided for all the loops in the laboratory.

Various sensors/transmitters are connected to the Analog/Digital Input card of the DCS and all the

actuators, pumps, compressor etc. are connected to the Analog/Digital output card of the DCS. The

controller communicates with users and is programmed with the help of SCADA (Supervisory Control

and Data Acquisition System) software. The program to control the liquid level is given in Figure 9, and

the SCADA, HMI (Human Machine Interface) is shown in Figure 10.

Figure 9. SCADA Program for liquid level control.

ADVANCED ELECTRICAL ENGINEERING LABORATORY

Figure 10. SCADA HMI Interface

Description of different functional blocks:

1) Analog input:

Function:

Reads value of an Analog Input from a specified real I/O address. Convert analog input value to

corresponding output (OUT) in engineering units based on the necessary scaling and conversions

performed.

Input:

Analog value from specified I/O address.

DIS = disable the AI channel

Output:

OUT= Analog input value in engineering units.

WARN= Warning input indication-sensor failure possibility.

FAIL= Digital status of channel.

Digital low (0)= OK

2) PID

ADVANCED ELECTRICAL ENGINEERING LABORATORY

The PID label stands for Proportional, Integral, and Derivative (3-mode) control action. This block is part

of the Loop Blocks category.

Function:

Provides Proportional (P), Integral (I) and Derivative (D), 3-mode control action based on the deviation

or error signal created by the difference between the set point (SP) and the Process Variable analog input

value (PV).It provides two digital output signals for alarms based on configured parameters. The PID

function block provides for Feed forward, Cascade, and Ratio control. Automatic tuning with Fuzzy Logic

Overshoot Suppression can be configured.

Inputs:

PV = Process Variable Analog Input value in Engineering Units to be controlled.

RSP= Remote Set point Analog Input value in Engineering Units or Percent to provide external set

point.

FFV = Feed forward value in percent. The Feed forward value is multiplied by the Feed forward Gain,

then directly summed into the output of the PID block

TRV = Output Track value in Percentage (PID Output = TRV Input when TRC = ON.

TRC = Output Track Command [ON, OFF (On -Enables TRV.) (Mode = Local Override)

BIAS = Remote Bias value for Ratio PID

SWI = Switch Inputs (from SWO on LPSW function block).

MDRQI = External Mode request (typically connected to the MDRQO output of a MDSW function

block that encoded discrete switch inputs).

BCI = Back Calculation Input (for blocks used as Cascade Primary).

Output:

OUT = Control Output.

WSP = Working Setpoint in Engineering Units for monitoring.

AL1 = Alarm 1 - Digital Signal.

AL2 = Alarm 2 - Digital Signal.

DIRECT = Direct Acting control (ON = Direct, OFF = Reverse Acting).

ATI = Auto tune Indicator (ON = Auto tune in Progress).

MODE = Loop mode status (typically connected to the Mode Flags block for encoding).

BCO= Back Calculation Output (for blocks used as Cascade Secondary)

3) Analog output:

Function:

ADVANCED ELECTRICAL ENGINEERING LABORATORY

Range High and Range Low are used to specify the Engineering Unit values for 100% and 0% of this

blocks input span. For reverse outputs, Range High may be set to a value less than Range Low. The

output range high and range low values (0-20 max) set the milliamp output values that correspond to

the 0 to 100% span limits of the inputs.

Input:

IN = Analog value

Output:

OUT = Converted value sent to specified real I/O address (mA).

FAIL = Failed Output indication - Module Error.

4) Compare:

Function:

Compares value of X input to value of Y input and turns ON one of three outputs based on this

comparison.

If X input is greater than Y input, then: XGY = ON.

If X input equals Y input, then: XEY = ON.

If X input is less than Y input, then: XLY = ON.

Input:

X = First analog value.

Y = Second analog value

Output:

XGY = Digital signal state based on calculation.

XEY = Digital signal state based on calculation.

XLY = Digital signal state based on calculation

5) Discrete output:

Function:

Provides a digital status from the algorithms and functions to a physical logic output.

The output status may be inverted.

Input:

X = Input Status Signal.

ADVANCED ELECTRICAL ENGINEERING LABORATORY

Output:

FAIL = Failed Input indication - Module error.

OUT = Physical Output Value.

6) Input OR

The 4OR label stands for the OR(4 inputs) boolean logic function. This block is a part of the logic category.

Function:

Turns digital output(OUT) OFF when input X1 to X4 are OFF thus,

When input X1 or X2 or X3 or X4 is ON then OUT=ON

If all input are off then OUT=OFF

Input:

X1=First digital signal.

X2=Second digital signal.

X3=Third digital signal.

X4=fourth digital signal.

Output:

OUT= digital signal controlled by the status of the input signal.

ANNEXURE-II

Mathematical model of the process

The system is modelled as a first-order system. The tank acts as a fluid capacitor where fluid enters

the tank (behaving as charged particles entering a capacitor) and leaves the tank. According to mass

balance relation between the incoming fluid and outgoing fluid can be written as:

{rate of accumulation mass in the system}= {rate of mass entering in the system}-

{rate of mass leaving in the system}

Q=Qin +Qout

where Qin is the flow rate of water coming into the tank, Q the net rate of water storage in the tank, and

Qout is the flow rate of water going out from the tank. If A is the cross-sectional area of the tank, and h is

the height of water inside the tank at any instant, Equation can be written as:

= +

where is the rate of change of height of water inside the tank.

The net flow rate (Qout) of water coming out of the tank depends on the discharge coefficient of the tank,

the height of the liquid at any instant inside the tank (h), the gravitational constant (g), and the area of the

tank outlet (a),and can be expressed as:

= (2)

ADVANCED ELECTRICAL ENGINEERING LABORATORY

where Cd is the discharge coefficient of the tank outlet, a is the area of the tank outlet, and g

is the gravitational constant (9.8m/s2).

From the above equations we obtain:

= + (2)

As we can see from the flow equation, it is a nonlinear relationship between the inflow rate (Qin) and the

height of the water inside the tank (h).This equation can be linearized for small perturbations about an

operating point.

When the input flow rate (Qin) becomes constant i.e. water comes at a constant rate, the height of the

water level in the tank also stays at certain set point. Out flow depend on the height only, if for steady Qin

height changes the Qout also change as follows:

Qout = Q0

And the height of the water h becomes a constant value h0, and we can write as:

0 = (20)

If we now consider a small perturbation (Qin) in input flow rate around the steady-state value Qo, we

obtain.

Qin = Qin Q0

And, as a result, the fluid level h will be perturbed around the steady-state value h0 by

h = h0 h

Now, substituting above equations in to flow equation we obtain:

This Equation can be linearized by using the Taylor series and all terms are neglected except the first term.

From Taylor series as:

Considering only the first term,

or

Now linearizing equation becomes:

Equation using above Equation, we obtain

Taking the Laplace transform of above Equation, we obtain the transfer function of the tank for small

perturbations about the steady-state value as a first-order system:

ADVANCED ELECTRICAL ENGINEERING LABORATORY

The pump, level sensor, and the power amplifier are simple units and can be approximated to have just

proportional gains and no system dynamics. The inputoutput relations of these units can be written as

follows:

For the pump,

Qo = KpVp;

For control valve

Vc = KvU (U = controller signal).

For delay in control valve the transfer function become

Gc(s) = +1 = Kv

for the level sensor,

Vl = Kl h;

Here Qo is the pump flow rate, Vp the voltage applied to the pump, Vl the level sensor output voltage and

Kp, Kl, Kv are constants.

So the block diagram of the level control system can be obtained as shown in Figure below:

Fig.4 block diagram of level control system

ADVANCED ELECTRICAL ENGINEERING LABORATORY

Figure 10. Model diagram of level control process

ADVANCED ELECTRICAL ENGINEERING LABORATORY

You might also like

- PID Control of Water Level in A Coupled Tank SystemDocument9 pagesPID Control of Water Level in A Coupled Tank SystemEioAsan100% (1)

- Water Flow Control System V2 PDFDocument12 pagesWater Flow Control System V2 PDFAayushSrivastava100% (1)

- Closed loop temperature controlDocument6 pagesClosed loop temperature controlsjsujiprasadNo ratings yet

- Electropneumatic and Hydraulic DNT241: Experiment No. 4Document7 pagesElectropneumatic and Hydraulic DNT241: Experiment No. 4Izz Hanzalah AhmadNo ratings yet

- Control Engineering I PDFDocument15 pagesControl Engineering I PDFkipkorir kemboiNo ratings yet

- Lab11a - SERVO TRAINER 3 Proportional Control of Servo Trainer SpeedDocument9 pagesLab11a - SERVO TRAINER 3 Proportional Control of Servo Trainer SpeedsairafiNo ratings yet

- Experiment 4Document5 pagesExperiment 4verboseNo ratings yet

- Bernoulli Lab ExperimentDocument7 pagesBernoulli Lab ExperimentAmbesiwe Amatshawe RauzelaNo ratings yet

- Experiment 24: The Potentiometer: PurposeDocument6 pagesExperiment 24: The Potentiometer: PurposekirtiNo ratings yet

- KE30501 Lab 1 - Open and Close Loop SystemDocument24 pagesKE30501 Lab 1 - Open and Close Loop SystemAlvin Tung Kwong ChoongNo ratings yet

- Shakil LVDT Lab ReportDocument11 pagesShakil LVDT Lab ReportShakil MalikNo ratings yet

- PLC Question BankDocument3 pagesPLC Question BankAjay kumarNo ratings yet

- Lab11b - SERVO TRAINER 4 Proportional Plus Integral Control of Servo Trainer SpeedDocument11 pagesLab11b - SERVO TRAINER 4 Proportional Plus Integral Control of Servo Trainer Speedsairafi100% (3)

- PID Controller Back UpDocument114 pagesPID Controller Back Upluli_pedrosaNo ratings yet

- Time Constant of Thermocouple & ThermometerDocument8 pagesTime Constant of Thermocouple & Thermometerprashant_cool_4_uNo ratings yet

- Oscilloscope & Function Generator Operation: Department of Electrical Engineering Network Analysis LabDocument3 pagesOscilloscope & Function Generator Operation: Department of Electrical Engineering Network Analysis LabUsairum MirzaNo ratings yet

- Electro-Pneumatics: Understanding Pneumatic and Electro-Pneumatic Elements for Automation ControlDocument30 pagesElectro-Pneumatics: Understanding Pneumatic and Electro-Pneumatic Elements for Automation ControlPrakash KumarNo ratings yet

- Automatic Water Level Control of A TankDocument44 pagesAutomatic Water Level Control of A TankTadele AmogneNo ratings yet

- 7 PotentiometerDocument4 pages7 PotentiometerBreno Oliveira0% (1)

- SKEM 3742 Electro Hydraulic LabsheetDocument6 pagesSKEM 3742 Electro Hydraulic Labsheetcikgu_relaNo ratings yet

- Control Exp 7 Student ManualDocument10 pagesControl Exp 7 Student ManualrakibNo ratings yet

- Clipper and Climper Circit PDFDocument6 pagesClipper and Climper Circit PDFOmar Said Abu RabieNo ratings yet

- PLC and SCADA Based Smart Distribution System: Submitted in Partial Fulfillment of The Requirement of The Degree ofDocument95 pagesPLC and SCADA Based Smart Distribution System: Submitted in Partial Fulfillment of The Requirement of The Degree ofNkosilozwelo SibandaNo ratings yet

- Water LevelDocument36 pagesWater LevelPreet ChahalNo ratings yet

- Schmitt TriggerDocument4 pagesSchmitt TriggerAssini HussainNo ratings yet

- Lab Report #1Document5 pagesLab Report #1Jorge GuerreroNo ratings yet

- Pneumatic ControllersDocument9 pagesPneumatic Controllerspavan_1988No ratings yet

- Experiment 1Document11 pagesExperiment 1Aneef Azlan50% (2)

- Experiment 01 The Hydraulic Bench PDFDocument2 pagesExperiment 01 The Hydraulic Bench PDFAzooNo ratings yet

- Fourier Series MATLAB GUI P-Code Doc 011905Document7 pagesFourier Series MATLAB GUI P-Code Doc 011905Julio FerreiraNo ratings yet

- Control Systems LectureDocument217 pagesControl Systems LectureJames Joseph100% (1)

- DanielGwapo PDFDocument144 pagesDanielGwapo PDFalexisNo ratings yet

- Lab10b - SERVO TRAINER 2 Response Calculating and MeasurementsDocument8 pagesLab10b - SERVO TRAINER 2 Response Calculating and MeasurementssairafiNo ratings yet

- MAPÚA UNIVERSITY WRITTEN REPORT ON HYDRAULICS EXPERIMENTDocument16 pagesMAPÚA UNIVERSITY WRITTEN REPORT ON HYDRAULICS EXPERIMENTAndreNo ratings yet

- Control Systems (1-135) PDFDocument128 pagesControl Systems (1-135) PDFAnonymous huaIYe1No ratings yet

- Vibrations SyllabusDocument5 pagesVibrations SyllabusAli SabahNo ratings yet

- Practical Verification of Bernoulli'S Theorem: StructureDocument3 pagesPractical Verification of Bernoulli'S Theorem: StructureVívék SâíNo ratings yet

- Flow Measurement Using Venturi and Orifice MetersDocument6 pagesFlow Measurement Using Venturi and Orifice Metersleo besaNo ratings yet

- Mechatronics Systems PDFDocument23 pagesMechatronics Systems PDFRamanathan DuraiNo ratings yet

- Expt. 4 - Pressure ControlDocument16 pagesExpt. 4 - Pressure Controlpleco4meNo ratings yet

- Lab Manual Hydraulics and Pneumatics .Document56 pagesLab Manual Hydraulics and Pneumatics .Aniket ChavanNo ratings yet

- Time Domain AnalysisDocument24 pagesTime Domain Analysisvinviv2222No ratings yet

- Experiment No.5 Forced Convection: Heat Transfer Laboratory (MECH3123)Document6 pagesExperiment No.5 Forced Convection: Heat Transfer Laboratory (MECH3123)Raj PratyushNo ratings yet

- How to Use an Oscilloscope for Electrical Signal AnalysisDocument10 pagesHow to Use an Oscilloscope for Electrical Signal Analysisric_napigkitNo ratings yet

- Pid Tuning ClassicalDocument18 pagesPid Tuning ClassicalVo Quang HuyNo ratings yet

- Process Control LabDocument25 pagesProcess Control LabShubhashish Bhakta100% (1)

- Experiment 1 - Process Control RigDocument15 pagesExperiment 1 - Process Control Rigzimbabwe100No ratings yet

- Lab Report Kirchoff LawDocument2 pagesLab Report Kirchoff LawLee Pin Yang0% (1)

- Linear PotentiometerDocument3 pagesLinear PotentiometerProdip KhanikarNo ratings yet

- MMC PPT 3.2Document21 pagesMMC PPT 3.2arbaz khanNo ratings yet

- Open Loop Control Systems Lack FeedbackDocument8 pagesOpen Loop Control Systems Lack FeedbackFrances RaphaelNo ratings yet

- Proposal Lab Thermo Topic 2 COMPLETEDocument10 pagesProposal Lab Thermo Topic 2 COMPLETEsaperuddinNo ratings yet

- Self Evaluation Questions and Answers: Lecture 20 - Flow Control VavlesDocument14 pagesSelf Evaluation Questions and Answers: Lecture 20 - Flow Control VavlesDân NguyễnNo ratings yet

- User Manual: Couple Tank ExperimentDocument22 pagesUser Manual: Couple Tank ExperimentRUBEN DARIO TAMAYO BALLIVIANNo ratings yet

- Compensation in Control SystemDocument10 pagesCompensation in Control Systemshouvikchaudhuri0% (1)

- Lab1 MEE30004 - Lab1 - 2021 Sem2 - Raw DataDocument7 pagesLab1 MEE30004 - Lab1 - 2021 Sem2 - Raw DataAbidul IslamNo ratings yet

- Particle Technology Lab Safety RulesDocument1 pageParticle Technology Lab Safety RulesUsamaNo ratings yet

- Loughborough University Process Control Lab ManualDocument16 pagesLoughborough University Process Control Lab Manualabmuqeet2No ratings yet

- Lab ReportDocument13 pagesLab ReportHemal MenukaNo ratings yet

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGFrom EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGNo ratings yet

- Screening SheetDocument1 pageScreening SheetShisanu SenNo ratings yet

- SG-39 Safety Guideline For Steel Melting ShopDocument32 pagesSG-39 Safety Guideline For Steel Melting ShopKìràñ ÀryàNo ratings yet

- Material Status Report for SCAVENGING COMPOUNDDocument3 pagesMaterial Status Report for SCAVENGING COMPOUNDShisanu SenNo ratings yet

- Electrostatic Precipitator Knowledge Base PDFDocument9 pagesElectrostatic Precipitator Knowledge Base PDFShisanu Sen100% (1)

- Sr. No. Material Number Material DescDocument4 pagesSr. No. Material Number Material DescShisanu SenNo ratings yet

- ZprattachDocument1 pageZprattachShisanu SenNo ratings yet

- PR AttachmentDocument1 pagePR AttachmentRakeshKrNo ratings yet

- Introduction Associative MemoryDocument3 pagesIntroduction Associative MemoryShisanu SenNo ratings yet

- (WWW - Entrance-Exam - Net) - AFCAT SyllabusDocument3 pages(WWW - Entrance-Exam - Net) - AFCAT SyllabusShisanu SenNo ratings yet

- 3 14Document1 page3 14Shisanu SenNo ratings yet

- Notification NLC Graduate Executive Trainee PostsDocument5 pagesNotification NLC Graduate Executive Trainee PostsPiyush BhadaniNo ratings yet

- Latest General Awareness Part 1 Questions AnswersDocument15 pagesLatest General Awareness Part 1 Questions AnswersSreeraj KpNo ratings yet

- SAILDocument5 pagesSAILAnjith AkNo ratings yet

- National Power Training Institute 12 Weeks Thermal Power CourseDocument6 pagesNational Power Training Institute 12 Weeks Thermal Power CourseShisanu SenNo ratings yet

- Tata Motor Project ReportDocument60 pagesTata Motor Project ReportHarendra Choudhary67% (3)

- Automatic Voltage Regulator (AVR)Document18 pagesAutomatic Voltage Regulator (AVR)Kumar Aravind93% (15)

- HandbookDocument95 pagesHandbookK Kunal RajNo ratings yet

- Electrical Engineering & Computer Science Research InterestsDocument1 pageElectrical Engineering & Computer Science Research InterestsShisanu SenNo ratings yet

- Gate Form 12Document2 pagesGate Form 12shafignits_123No ratings yet

- Esp (Document1 pageEsp (Shisanu SenNo ratings yet

- FormDocument1 pageFormShisanu SenNo ratings yet

- NTPC AshDocument2 pagesNTPC AshShisanu Sen100% (1)

- DWLDDocument1 pageDWLDShisanu SenNo ratings yet

- Pressure Proc.Document1 pagePressure Proc.Shisanu SenNo ratings yet

- Circuit BreakerDocument12 pagesCircuit BreakerAnonymous zzMfpoBxNo ratings yet

- Florence Walking Tour MapDocument14 pagesFlorence Walking Tour MapNguyễn Tấn QuangNo ratings yet

- PCSE_WorkbookDocument70 pagesPCSE_WorkbookWilliam Ribeiro da SilvaNo ratings yet

- 2.4 Avogadro's Hypothesis+ Equivalent MassesDocument12 pages2.4 Avogadro's Hypothesis+ Equivalent MassesSantosh MandalNo ratings yet

- Finance at Iim Kashipur: Group 9Document8 pagesFinance at Iim Kashipur: Group 9Rajat SinghNo ratings yet

- Identifying The TopicDocument2 pagesIdentifying The TopicrioNo ratings yet

- Honors Biology Unit 2 - Energy Study GuideDocument2 pagesHonors Biology Unit 2 - Energy Study GuideMark RandolphNo ratings yet

- Scharlau Chemie: Material Safety Data Sheet - MsdsDocument4 pagesScharlau Chemie: Material Safety Data Sheet - MsdsTapioriusNo ratings yet

- Factsheet B2B PunchOut en 140623Document2 pagesFactsheet B2B PunchOut en 140623Curtis GibsonNo ratings yet

- WWW - Istructe.pdf FIP UKDocument4 pagesWWW - Istructe.pdf FIP UKBunkun15No ratings yet

- Corn MillingDocument4 pagesCorn Millingonetwoone s50% (1)

- Spsi RDocument2 pagesSpsi RBrandy ANo ratings yet

- Bandung Colonial City Revisited Diversity in Housing NeighborhoodDocument6 pagesBandung Colonial City Revisited Diversity in Housing NeighborhoodJimmy IllustratorNo ratings yet

- PharmacologyAnesthesiology RevalidaDocument166 pagesPharmacologyAnesthesiology RevalidaKENT DANIEL SEGUBIENSE100% (1)

- Cells in The Urine SedimentDocument3 pagesCells in The Urine SedimentTaufan LutfiNo ratings yet

- Distinguish Between Tax and FeeDocument2 pagesDistinguish Between Tax and FeeRishi Agarwal100% (1)

- Transformer Oil Testing MethodsDocument10 pagesTransformer Oil Testing MethodsDEE TOTLVJANo ratings yet

- Liber Chao (Final - Eng)Document27 pagesLiber Chao (Final - Eng)solgrae8409100% (2)

- Digital Communication Quantization OverviewDocument5 pagesDigital Communication Quantization OverviewNiharika KorukondaNo ratings yet

- Henny Penny 500-561-600 TM - FINAL-FM06-009 9-08Document228 pagesHenny Penny 500-561-600 TM - FINAL-FM06-009 9-08Discman2100% (2)

- May, 2013Document10 pagesMay, 2013Jakob Maier100% (1)

- Victron MultiPlus 48 1200-13-16 Datasheet enDocument1 pageVictron MultiPlus 48 1200-13-16 Datasheet enBAHJARI AMINENo ratings yet

- Module - No. 3 CGP G12. - Subong - BalucaDocument21 pagesModule - No. 3 CGP G12. - Subong - BalucaVoome Lurche100% (2)

- Assessing Gross Efficiency and Propelling Efficiency in Swimming Paola Zamparo Department of Neurological Sciences, Faculty of Exercise and Sport Sciences, University of Verona, Verona, ItalyDocument4 pagesAssessing Gross Efficiency and Propelling Efficiency in Swimming Paola Zamparo Department of Neurological Sciences, Faculty of Exercise and Sport Sciences, University of Verona, Verona, ItalyVijay KumarNo ratings yet

- Guide to Fair Value Measurement under IFRS 13Document3 pagesGuide to Fair Value Measurement under IFRS 13Annie JuliaNo ratings yet

- CGSC Sales Method - Official Sales ScriptDocument12 pagesCGSC Sales Method - Official Sales ScriptAlan FerreiraNo ratings yet

- Clean Agent ComparisonDocument9 pagesClean Agent ComparisonJohn ANo ratings yet

- Practical Research 2: Self-Learning PackageDocument3 pagesPractical Research 2: Self-Learning PackagePrinces BaccayNo ratings yet

- Report Daftar Penerima Kuota Telkomsel Dan Indosat 2021 FSEIDocument26 pagesReport Daftar Penerima Kuota Telkomsel Dan Indosat 2021 FSEIHafizh ZuhdaNo ratings yet

- PW CDocument4 pagesPW CAnonymous DduElf20ONo ratings yet

- Equipment, Preparation and TerminologyDocument4 pagesEquipment, Preparation and TerminologyHeidi SeversonNo ratings yet