Professional Documents

Culture Documents

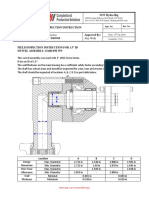

Kingpin Mounting Instructions

Uploaded by

Pablo César Suárez NogalesCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Kingpin Mounting Instructions

Uploaded by

Pablo César Suárez NogalesCopyright:

Available Formats

Wallace Forge Co.

3700 Georgetown Rd.

Canton, Ohio

KINGPINS Phone: 330-488-1203

Fax: 330-488-1217

Www.WallaceForge.com

INSTALLATION AND MAINTENCE

WARNINGS

1. Standard SAE dimensional tolerances apply to all of the dimensions.

2. Wallace Forge 2 diameter kingpins are not for off the road equipment. A 3-1/2 diameter.

3. Kingpins are forged out of 8630 alloy steel and heat treated to 302-363 Brinell, Unless otherwise noted.

4. Wallace Forge kingpins will hold approximately 150,000 PSI ultimate and yield strength.

5. All kingpin and 100% Brinell hardness checked, magnetic particle inspected, and weldable.

6. Rockwell reading may be different as there may be some surface carbonization.

7. The use of a lube plate alters the kingpin dimensions from SAE standards and may prevent proper coupling.

8. If the kingpin is not securely mounted rapid wear will occur.

WELDING RECOMMENDATIONS

1. Welding procedures should be in accordance with those published by the American Weld Society or other

technical groups. All welding personnel should be properly trained and certified.

2. Proper bracing should be ensured, and in accordance with SAE J133.

3. The area being welded must be clean to the bare metal. The area must be free of paint, scale, dirt, or other

foreign substances.

4. Preheat approximately one inch of the eight inch diameter at the base of the kingpin and mounting surface to

400 500F. This is your welding area.

5. Low hydrogen welding rod (5/32) or low carbon wire (.045) should be used.

6. A welding procedure which alternates from side to side and minimizes wear buildup is recommended to avoid

distortions.

7. Surrounding area, and welded area should be normalized to 600F and allowed to slowly cool.

8. Inspect weld to ensure that it is free of cracks and slag inclusions.

INSPECTION AND MAINTENCE

All instructions are based on SAE J2228 recommendations.

1. Inspect the kingpin for damage before every use. If any nicks, cracks, deformations, or gouges are noticed the trailer

should not be operated, and the king pin should be replaced immediately.

2. If kingpin is worn more than a 1/8 (.125) on 2 or 2.88 kingpin should be replaced.

3. Check straightness of kingpin and upper coupler plate. An uneven kingpin or coupling plate can cause kingpin to not lock

Properly, or cause excessive wear.

4. Do not modify or add to any product.

Page 1

You might also like

- Axelson 6Document12 pagesAxelson 6Amit MakwanaNo ratings yet

- CAD Control Systems ManualDocument27 pagesCAD Control Systems Manualnds2006sNo ratings yet

- Regulator3 4 DSDocument4 pagesRegulator3 4 DSargaNo ratings yet

- 2.3.B. Manual de Operación y Mantenimiento Bloque ViajeroDocument40 pages2.3.B. Manual de Operación y Mantenimiento Bloque ViajeroD VNo ratings yet

- Cross Reference of Steel StandardsDocument4 pagesCross Reference of Steel StandardsNugroho Adhi SaputroNo ratings yet

- Hercules Model 131 Deadline Anchor SpecsDocument2 pagesHercules Model 131 Deadline Anchor SpecsAaron HigginsNo ratings yet

- 130 Kit Deadline Anchor (En)Document19 pages130 Kit Deadline Anchor (En)c.valderrabano81No ratings yet

- Model Number Part Number Description M5307 100 Kip Deadline Anchor 53070000 100-DEADLINEDocument29 pagesModel Number Part Number Description M5307 100 Kip Deadline Anchor 53070000 100-DEADLINEc.valderrabano81No ratings yet

- 2.superfinishing ProcessDocument9 pages2.superfinishing ProcessVikrant Sharma100% (1)

- Machinists Tools by Williams 1944Document32 pagesMachinists Tools by Williams 1944OSEAS GOMEZNo ratings yet

- Boxes 2C Bowls and BasketsDocument116 pagesBoxes 2C Bowls and BasketsFranco Mauricio92% (39)

- Inspección de King PinDocument2 pagesInspección de King PinCarlos Felipe Orjuela RamírezNo ratings yet

- ClarifierDocument10 pagesClarifierrasithapradeep0% (1)

- ELECTRIC MOTORS TYPE 3SIE IE3 FOR 50/60HZ OPERATIONDocument9 pagesELECTRIC MOTORS TYPE 3SIE IE3 FOR 50/60HZ OPERATIONAmandaNo ratings yet

- Manual Stinger Mts FTDocument16 pagesManual Stinger Mts FTFabian Andres CelyNo ratings yet

- Ad-1, Adl-1, C-1Document4 pagesAd-1, Adl-1, C-1Yaqoob IbrahimNo ratings yet

- Specification:: Hammer UnionsDocument5 pagesSpecification:: Hammer Unionscmpuck100% (1)

- 65590-gd Cutsheet Template gd-600 2015 LRDocument2 pages65590-gd Cutsheet Template gd-600 2015 LRjys_yanqui100% (1)

- OperatingManual PilecoDocument130 pagesOperatingManual PilecoERIC RAFAEL MENDEZ CHINCHAYNo ratings yet

- Laser Cladding Technology GuideDocument2 pagesLaser Cladding Technology GuideLe Duy TuanNo ratings yet

- Anneaux Levage CATDocument13 pagesAnneaux Levage CATA100% (1)

- Glossary of Furnace TermsDocument7 pagesGlossary of Furnace TermsMohsin Raza MaitlaNo ratings yet

- Sae j700 2020 King Pin Servicio RegularDocument3 pagesSae j700 2020 King Pin Servicio RegularCristian GordilloNo ratings yet

- Asm Speciality Handbook Stainless SteelsDocument3 pagesAsm Speciality Handbook Stainless SteelsVihari17% (12)

- Din en 12195-2-2001 PDFDocument25 pagesDin en 12195-2-2001 PDFPablo César Suárez Nogales0% (1)

- EN 1494+A1 2008 Jacks PDFDocument48 pagesEN 1494+A1 2008 Jacks PDFFariz Safarulla100% (2)

- 회사소개서 SGO (English) 테스트 바이어리스트 제외 1Document30 pages회사소개서 SGO (English) 테스트 바이어리스트 제외 1dada kolekarNo ratings yet

- Tenmat Feroform T14 DatasheetDocument1 pageTenmat Feroform T14 DatasheetmusebladeNo ratings yet

- Kanchipuram Alterplastmanufact061218Document20 pagesKanchipuram Alterplastmanufact061218office office100% (1)

- Wearlimitgauge PDFDocument1 pageWearlimitgauge PDFAbrar HussainNo ratings yet

- Usa Mvss108Document259 pagesUsa Mvss108Gonca DedeNo ratings yet

- Marine FlexenDocument67 pagesMarine FlexenpayaljeevaNo ratings yet

- 8008 ControlSwitches EK00 III enDocument8 pages8008 ControlSwitches EK00 III enLaurence Malanum100% (1)

- Bomba Triplex National JWS-185 - BrochureDocument4 pagesBomba Triplex National JWS-185 - BrochureNicoFocheNo ratings yet

- Weir SPM Ball Injector Specification Rev0Document4 pagesWeir SPM Ball Injector Specification Rev0Doni KurniawanNo ratings yet

- 10P-130 Mud Pump Brochure PDFDocument2 pages10P-130 Mud Pump Brochure PDFprillaNo ratings yet

- LCI 550SpecSheetDocument3 pagesLCI 550SpecSheetandy131078No ratings yet

- TECHWELD - Catalog - F2019 2020Document48 pagesTECHWELD - Catalog - F2019 2020Alquin Lunag100% (1)

- National Oilwell W600S OMEGA OPERATION MAINTENANCE MANUALDocument37 pagesNational Oilwell W600S OMEGA OPERATION MAINTENANCE MANUALariel feNo ratings yet

- Maintenance Interval Schedule c15 MCW PDFDocument3 pagesMaintenance Interval Schedule c15 MCW PDFVictor NunezNo ratings yet

- Rigging Information: Block and Sheave InspectionDocument1 pageRigging Information: Block and Sheave InspectionGokul GNo ratings yet

- 1887 125HP Union TD 120 Triplex Sour Pump PackageDocument11 pages1887 125HP Union TD 120 Triplex Sour Pump PackageIvan Jojic100% (1)

- NutsDocument8 pagesNutsGerry Dan ChanliongcoNo ratings yet

- Air-Winch Manual PDFDocument56 pagesAir-Winch Manual PDFQuyet Nguyen0% (1)

- Drill Collar SlipsDocument10 pagesDrill Collar SlipsAdrian CantaragiuNo ratings yet

- Stock Piston Rod Cylinders SpecificationsDocument9 pagesStock Piston Rod Cylinders SpecificationsALdinoNo ratings yet

- 2M Tek Torq Tek ZIIDocument1 page2M Tek Torq Tek ZIIamghardjillali_449230% (1)

- Series 5000B4 Manual - Revision D 12 30 2010Document16 pagesSeries 5000B4 Manual - Revision D 12 30 2010mektroNo ratings yet

- Ferraz Shawmut Fuses Applications TransfoDocument5 pagesFerraz Shawmut Fuses Applications TransfoSimon PelletierNo ratings yet

- Pro 6042Document2 pagesPro 6042Ankur MestryNo ratings yet

- 279D Combination GearboxDocument1 page279D Combination GearboxJorge Vásquez CarreñoNo ratings yet

- FKQ50-2 Use R ManualDocument56 pagesFKQ50-2 Use R ManualMuthia AstriNo ratings yet

- Cotizacion o Drill PDFDocument2 pagesCotizacion o Drill PDFJulio RamosNo ratings yet

- 9P-100 Mud Pump Brochure PDFDocument2 pages9P-100 Mud Pump Brochure PDFSIOP IPC100% (1)

- Parveen Stabilizers Guide Drilling ToolsDocument2 pagesParveen Stabilizers Guide Drilling ToolsGonzalo Guzman Jaimes100% (1)

- Pro 6035Document2 pagesPro 6035Ankur MestryNo ratings yet

- Sae J2228 2011Document5 pagesSae J2228 2011Cristian GordilloNo ratings yet

- 34 Model AD-1 Tension PackerDocument2 pages34 Model AD-1 Tension PackerDenier RubianoNo ratings yet

- Pipe Data Sheet with Dimensions and SpecificationsDocument1 pagePipe Data Sheet with Dimensions and Specifications087825550697No ratings yet

- 5 7/8" VM-165 R2 Pipe SpecsDocument2 pages5 7/8" VM-165 R2 Pipe SpecsTiffany DacinoNo ratings yet

- Bem-650-Shale - Shaker PDFDocument8 pagesBem-650-Shale - Shaker PDFWilliamNo ratings yet

- JFEBEAR - JFEBEAR Interchangeability Rules Rev 0 PDFDocument2 pagesJFEBEAR - JFEBEAR Interchangeability Rules Rev 0 PDFnayrNo ratings yet

- P20658 - Proto Torque WrenchesDocument2 pagesP20658 - Proto Torque Wrenchesdionisio emilio reyes jimenezNo ratings yet

- Swivel Interface - CD420160Document1 pageSwivel Interface - CD420160ralph100% (1)

- Jereh Deadline AnchorDocument1 pageJereh Deadline AnchorVijay KotiNo ratings yet

- 100T Pump Parts List PDFDocument30 pages100T Pump Parts List PDFGabriel Andres ValenciaNo ratings yet

- Unions, Swivels, Treating Irons & Circulating Heads GuideDocument7 pagesUnions, Swivels, Treating Irons & Circulating Heads GuideSakthivel MurthyNo ratings yet

- 760 BKDocument12 pages760 BKEulerNo ratings yet

- Office of Materials and Testing Qualified Products List: QPL-60 Steel Bridge FabricatorsDocument2 pagesOffice of Materials and Testing Qualified Products List: QPL-60 Steel Bridge FabricatorsShajit KumarNo ratings yet

- ARP Main Bolt InstructionsDocument1 pageARP Main Bolt InstructionsDamien DrakeNo ratings yet

- Trademark index provides contact info for firearms manufacturersDocument36 pagesTrademark index provides contact info for firearms manufacturersatacan küçükşahinNo ratings yet

- Burr King Model 562 Three Wheel Grinder Instruction ManualDocument16 pagesBurr King Model 562 Three Wheel Grinder Instruction ManualESTEBAN RAFAEL CISNEROS LOPEZNo ratings yet

- Specials LtTruckCatalog Fifth Wheel HitchesDocument3 pagesSpecials LtTruckCatalog Fifth Wheel HitchesPablo César Suárez NogalesNo ratings yet

- LT-169 Instructions Ultra NTDocument32 pagesLT-169 Instructions Ultra NTPablo César Suárez NogalesNo ratings yet

- Kingpincard PDFDocument2 pagesKingpincard PDFPablo César Suárez NogalesNo ratings yet

- Holland KingpinsDocument8 pagesHolland KingpinsPablo César Suárez NogalesNo ratings yet

- NIST Guide to Length Calibration ProceduresDocument70 pagesNIST Guide to Length Calibration ProceduresPablo César Suárez NogalesNo ratings yet

- Astm-E340-2015 MacroataqueDocument11 pagesAstm-E340-2015 MacroataquePablo PerdomoNo ratings yet

- Module 1: Electrical Discharge Machining (EDM) IntroductionDocument71 pagesModule 1: Electrical Discharge Machining (EDM) IntroductionJoe ArNo ratings yet

- Sikacryl®-150: Product Data SheetDocument3 pagesSikacryl®-150: Product Data SheetMoatz HamedNo ratings yet

- G-Codes and M-Functions - Turning: © Peter Smid CNC Programming HandbookDocument1 pageG-Codes and M-Functions - Turning: © Peter Smid CNC Programming HandbookAmutha SaravananNo ratings yet

- Wang Cheng KCC English VersionDocument40 pagesWang Cheng KCC English VersionNacer IzriNo ratings yet

- Fire HazardDocument33 pagesFire HazardBey VictoriaNo ratings yet

- 3900 Series Pilot Operated Safety Relief Valve Spec Data Gea20255Document72 pages3900 Series Pilot Operated Safety Relief Valve Spec Data Gea20255peng chaowenNo ratings yet

- 304 vs 316 Stainless Steel Tubes: Key Differences ExplainedDocument1 page304 vs 316 Stainless Steel Tubes: Key Differences ExplainedAbdillah YassinNo ratings yet

- Bentone SD2Document2 pagesBentone SD2Kris SzongNo ratings yet

- Catalog BipicoDocument20 pagesCatalog Bipicoalingutan100% (1)

- Plasma Dicing of Si Wafers With Panasonic APX300Document45 pagesPlasma Dicing of Si Wafers With Panasonic APX300Pretty ChenNo ratings yet

- HMT Machine Tools Ltd. - Internship ReportDocument51 pagesHMT Machine Tools Ltd. - Internship ReportSwaroop Somanna33% (3)

- Seneca Falls Lathe MFG Co 1918 No26-BDocument58 pagesSeneca Falls Lathe MFG Co 1918 No26-BjjfugedyNo ratings yet

- Metaceram 25010: Aluminum Oxide PowderDocument2 pagesMetaceram 25010: Aluminum Oxide PowderTob NisapakulNo ratings yet

- Códigos de SoldagemDocument12 pagesCódigos de Soldagemvladimirsoler01No ratings yet

- TX434SDocument2 pagesTX434Sbedjo8No ratings yet

- Soudotape NiCrMo4 Strip Cladding AlloyDocument1 pageSoudotape NiCrMo4 Strip Cladding AlloycocoNo ratings yet

- Material Data Sheets For Piping and Valve Components: DecemberDocument262 pagesMaterial Data Sheets For Piping and Valve Components: DecemberJeromeNo ratings yet

- Stainless Steel 420 Material Chemical CompositionDocument3 pagesStainless Steel 420 Material Chemical Compositionr arumugamNo ratings yet

- Carbozinc 8705: Selection & Specification Data Mixing & ThinningDocument2 pagesCarbozinc 8705: Selection & Specification Data Mixing & ThinningDamen JohnsonNo ratings yet

- 3A Tumbler InstructionsDocument8 pages3A Tumbler InstructionsNumismática Oliveira100% (1)