Professional Documents

Culture Documents

Yu 1980

Uploaded by

bookppOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Yu 1980

Uploaded by

bookppCopyright:

Available Formats

I he ttects of Composition and Carbide

Precipitation on Temper Embrittlement of 2.25

Cr-1 Mo Steel Part I. Effects of P and Sn

JIN YU AND C. J . McMAHON, J r .

T e m p e r e m b r i t t l e m e n t of 2.25 C r - 1 Mo s t e e l d o p e d with P and Sn was s t u d i e d s y s t e m a t i c -

a l l y . C a r b i d e e x t r a c t i o n by e l e c t r o l y s i s , X - r a y d i f f r a c t i o n , t r a n s m i s s i o n ( r e p l i c a ) e l e c -

t r o n m i c r o s c o p y , c h e m i c a l a n a l y s i s of the m a t r i x , and scanning A u g e r m i c r o p r o b e a n a l y -

s i s w e r e conducted to d e t e r m i n e the effect of c a r b i d e p r e c i p i t a t i o n and s u b s e q u e n t v a r i a -

tion of the Mo c o n c e n t r a t i o n in s o l u t i o n on the s e g r e g a t i o n of P . T h e s e a n a l y s e s w e r e

c o r r e l a t e d with the d u c t i l e - t o - b r i t t l e t r a n s i t i o n t e m p e r a t u r e ( m e a s u r e d by u s e of a s l o w -

bend t e s t ) , a s w e l l a s h a r d n e s s m e a s u r e m e n t s and f r a c t o g r a p h i c i n f o r m a t i o n obtained by

s c a n n i n g e l e c t r o n m i c r o s c o p y . The r e s u l t s i n d i c a t e that the p r i n c i p a l r o l e of Mo i s to

s u p p r e s s e m b r i t t l e m e n t by s c a v e n g i n g of P, p r e s u m a b l y by a M o - P compound f o r m a t i o n ,

t h e r e b y d i m i n i s h i n g P s e g r e g a t i o n . H o w e v e r , due to the s t r o n g e r i n t e r a c t i o n b e t w e e n

Mo and C, Mo is p r e c i p i t a t e d in an MaC c a r b i d e d u r i n g t e m p e r i n g o r aging, and the m a -

t r i x is d e p l e t e d of Mo. The P t h e r e b y r e l e a s e d s e g r e g a t e s at a r a t e c o n s i s t e n t with the

r a t e of M2C p r e c i p i t a t i o n . A t a Mo c o n c e n t r a t i o n > 0.7 p c t the b e n e f i c i a l effect of Mo is

d e c r e a s e d due to enhanced M2C p r e c i p i t a t i o n , the content of Mo in s o l u t i o n r e m a i n i n g

e s s e n t i a l l y c o n s t a n t . The M2C i s f o r m e d at the e x p e n s e of C r - r i c h MvC3; t h i s r e s u l t s in

m o r e C r in solution, t h e r e b y p e r m i t t i n g m o r e C r - P c o s e g r e g a t i o n , and e m b r i t t l e m e n t

i n c r e a s e s . T i n was found not to p r o d u c e t e m p e r e m b r i t t l e m e n t in t h i s s t e e l when p r e s e n t

at c o n c e n t r a t i o n s up to 0.04 p c t .

RESEARCHinto the p r o b l e m of t e m p e r e m b r i t t l e - with the e f f e c t s of Mn and Si in conjunction with P .

merit of a l l o y s t e e l s f r o m a p h e n o m e n o l o g i c a l point of It i s w i d e l y r e c o g n i z e d that the a d d i t i o n of Mo in

view has o v e r a p e r i o d of many d e c a d e s involved e x - s t e e l i n h i b i t s t e m p e r e m b r i t t l e m e n t . 1-3 H o w e v e r , the

p e r i m e n t s on both c o m m e r c i a l s t e e l s and s p e c i a l l y m e c h a n i s m by which t h i s o c c u r s i s not y e t c l e a r .

doped l a b o r a t o r y s t e e l s of c a r e f u l l y c o n t r o l l e d c o m - R e c e n t w o r k 4 on a N i - C r - M o s t e e l doped with 0.06 P

p o s i t i o n . M o s t of o u r p r e s e n t u n d e r s t a n d i n g has c o m e showed that e m b r i t t l e m e n t was i n i t i a l l y s u p p r e s s e d ,

f r o m the l a b o r a t o r y s t e e l s in which one f a c t o r at a but that it l a t e r o c c u r r e d s l o w l y with p r o l o n g e d aging

t i m e could be v a r i e d . A s t h e s e s t u d i e s have p r o g r e s s e d in a m a n n e r s u g g e s t i v e of c a r b i d e p r e c i p i t a t i o n k i -

the b e h a v i o r of the m o r e c o m p l i c a t e d c o m m e r c i a l n e t i c s . T h e r e f o r e , it was s u g g e s t e d that the p r i n c i p a l

s t e e l s has b e c o m e m o r e and m o r e u n d e r s t a n d a b l e . r o l e of Mo is to tie up P, but that the e v e n t u a l p r e -

Up to the p r e s e n t t i m e m o s t of the l a b o r a t o r y s t u d - c i p i t a t i o n of Mo in c a r b i d e s would allow P s e g r e g a t i o n

i e s have e m p l o y e d s t e e l s containing Ni, u s u a l l y s i m - in p r o l o n g e d e x p o s u r e to e l e v a t e d t e m p e r a t u r e s .

p l e N i - C r s t e e l s , s i n c e t h e s e u s u a l l y exhibit the g r e a t - One p u z z l i n g a s p e c t of the Mo effect, a p p a r e n t l y

e s t s u s c e p t i b i l i t y to t e m p e r e m b r i t t l e m e n t . H o w e v e r , f i r s t r e p o r t e d by P o w e r s , 5'6 is the e x i s t e n c e of an

o v e r the p a s t d e c a d e the r e a l i z a t i o n that C r - M o s t e e l s o p t i m u m a m o u n t of Mo. A d d i t i o n s of Mo b e y o n d 0.7

can a l s o be highly s u s c e p t i b l e has s p r e a d . T h e now p c t have been found to enhance e m b r i t t l e m e n t r a t h e r

f a m o u s H i n c k l e y Point t u r b i n e d i s c f a i l u r e in 1969 than r e d u c e i t . 7 P r e v i o u s c o n j e c t u r e s about t h i s p h e -

did much to s e t the s t a g e f o r the c u r r e n t i n t e r e s t in n o m e n o n have involved a p o s s i b l e effect of Mo on the

these steels. d i f f u s i v i t y of p8,9 o r on the h a r d n e s s of the t e m p e r e d

One of the m o s t w i d e l y used C r - M o s t e e l s for t h i c k - s t e e l , m One m a i n p u r p o s e of t h i s w o r k w a s to d i s c o v e r

w a l l e d s t r u c t u r a l a p p l i c a t i o n s has the b a s e c o m p o s i - the u n d e r l y i n g m e c h a n i s m by which Mo i n h i b i t s P i n -

t i o n 2.25 C r - 1 Mo, and c o m m e r c i a l h e a t s g e n e r a l l y d u c e d e m b r i t t l e m e n t and the o r i g i n of the high Mo

contain Mn and Si (added i n t e n t i o n a l l y ) a s w e l l a s r e - effect.

s i d u a l l e v e l s of P and Sn which a r e p o t e n t i a l e m b r i t -

t l i n g e l e m e n t s . The p r e s e n t t w o - p a r t r e p o r t g i v e s the

r e s u l t s of what i s a p p a r e n t l y the only c o m p r e h e n s i v e EXPERIMENTAL PROCEDURE

study for p u b l i c a t i o n of l a b o r a t o r y s t e e l s in which the

High purity Fe-2.25 Cr-I Mo-0.2 C steels to which

2.25 C r - 1 Mo c o m p o s i t i o n was u s e d a s a b a s e and the

were added P and Sn, individually, the compositions of

above e l e m e n t s w e r e a d d e d i n d i v i d u a l l y . The p r e s e n t

which are listed in Table I, were vacuum-induction

p a p e r d e a l s with the e f f e c t s of P and Sn and P a r t II

meRed from high purity Cr, Mo, and C and electro-

lyric Fe, and the ingots were hot forged and swaged

JIN YU is Post-doctoral Fellow, Max-Planck-Institut Fi~r Eisen-

forschung, 4 Di]sseldorf, West Germany. C. J. McMAHON, Jr. is and then machined into specimen blanks. These were

Professor of Materials Science and Engineering, Department of Materials heat treated in capsules of Vycor (below I000 ~ or

Science and Engineering, University of Pennsylvama, Philadelphia, PA quartz (above I000 ~ C) according to the diagram in

19104. Fig. l(a). The three austenitizing temperatures pro-

Manuscript submitted June 29, 1979. vided coarse, intermediate, and fine grains (ASTM

ISSN 0360-2133180/0211-0277500.75/0

METALLURGICAL TRANSACTIONS A 9 1980 AMERICAN SOCIETY FOR METALS AND VOLUMEl lA, FEBRUARY 1980-277

THE METALLURGICALSOCIETY OF AIME

G r a i n s i z e 3 to 3.5, b to 5.b, and t to 8, r e s p e c t i v e l y ) . A s e r i e s of 2.2b Ur s t e e l s having d i f f e r e n t a m o u n t s

T h e t e m p e r i n g t r e a t m e n t s g a v e high, i n t e r m e d i a t e , of Mo, p r e v i o u s l y s t u d i e d by Wuda and H a g e l , 7 w e r e

and low h a r d n e s s l e v e l s (R c 30, 20, and 13, r e s p e c - received as broken Charpy bars. The compositions

tively). l i s t e d in T a b l e I show that e a c h heat had e s s e n t i a l l y

s i m i l a r l e v e l s of r e s i d u a l e l e m e n t s and of Mn and Si.

T h e heat t r e a t m e n t s ( p e r f o r m e d a t C l i m a x M o l y b -

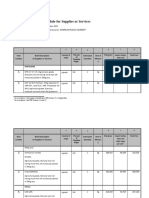

Table I. Chemical Compositions, Wt Pct d e n u m Co.) involved the following (see F i g . l(b) and

R e f . 7):

Des~.gnat~on C~" Mo C P Sn Mn Si S A1 1. A u s t e n i t ~ z a t i o n f o r 1 h at 9 5 5 ~ C, which g a v e an

a u s t e n i t i c g r a i n s i z e of ASTM No. 8.5 to 9.

0.02P 2.24 1.0" 0.2* 0,017 0.001

0.04 P 2.58 1.0" 0.2* 0,036 0.001 2. A d i f f e r e n t t e m p e r i n g t r e a t m e n t for e a c h heat

0.02Sn 2.26 1.0" 0.2* 0,002 0.024 (because of the d i f f e r e n c e s in Mo content) to p r o v i d e

0.04Sn 2.23 1.0" 0.2* 0.002 0.043 an a s - t e m p e r e d t e n s i l e s t r e n g t h of 100 k s i .

288 2.21 0.00 0.13 0,024 0.006 0.45 0.23 0,016 0.022 3. Step cooling to p r o v i d e an i d e n t i c a l condition of

288 2.21 0.48 0.13 0,024 0.45 0.23 0.016 0,024

e m b r i t t l e m e n t in a l l h e a t s .

288 2.2 1 0.71 0.13 0,024 0.45 0.23 0,016 0,025

288 2.21 0.92 0.13 0.024 0.45 0.23 0.016 0.028 T h e t e s t s p e c i m e n s w e r e 6.35 m m in d i a m , and c o n -

2]/4Cr-l.lMo 2.21 1,12 0.13 0.024 0.45 0.23 0,016 0.028 t a i n e d a 6 0 deg c i r c u m f e r e n t i a l n o t c h with a r o o t r a -

2 88 2.21 1.31 0.13 0.025 0.46 0.23 0.016 0.029 d i u m of 0.13 ram, 11 m m f r o m the end. The d i a m b e -

*Nominal composition. n e a t h the notch was 4.33 r a m . T h e t r a n s i t i o n t e m -

p e r a t u r e s w e r e m e a s u r e d by a s l o w - b e n d t e s t . n E a c h

AUSTENITIZE TEMPER AGE OR S T E P COOL

IGRAIN SIZE HARDNESS

INTER-_.[ I 170. 2 h

MEDIATE 9--

FINE --4-! bOff4h

6 9 0 ~ 12h

i,i LOW "--e, t6, 3.10h

IE INTER--..,.

3 MEDIATE- 593ji h

I-- HIGH - - - I .

~_~_~8 15h

Q: I

i. --~96,48 h

O.

=E

I 4~8,72 h

LIJ

I-- I ~ F U R N A C E

~ C O O L

~ 315

WQ WQ

TIMI i-

(a)

21/'~ Cr STEEL W ITPI VARYING AMOUNT OF Mo

AUSTENITIZE TEMPER I TEMPER 2 AGE

955, i h

2 1/4 Cr -- 0 MO

593, I h

"--~.4o, is h

~5,24h

L~95,48 h

AIR WATER

7z.

~,~U iRsNACECOOL

COOL QUENCH

~

AIR COOL Fig, l - H e a t treatments used to

produce temper e mbri ttlem en t

m: (a) 21A Cr-I Mo steels doped

2~'4 C r - 0 . 5 Mo ii wath P or Sn, (b) 2 88 Cr steels

with varying Mo content.

AIR

COOL

2~/4 Cr--O 7 Mo tt 690, 4 h

2~4 Cr-0.9 Mo tl 690, 5 h

21/4 C r - I I Mo ii 690, 6 h

2 [/4 C r - 1.3 Mo ii 690, 6 h

(b)

2 7 8 - V O L U M E 11A, FEBRUARY 1980 METALLURGICAL TRANSACTIONS A

s p e c i m e n was loaded to f r a c t u r e as a c a n t i l e v e r b e a m tube c u r r e n t of 20 mA was used with e x p o s u r e t i m e s

in a s p e c i a l l y d e s i g n e d jig attached to an I n s t r o n t e s t - of 12 to 18 h. The 20 v a l u e s of the l i n e s on the dif-

ing m a c h i n e at a d i s p l a c e m e n t r a t e of 0.085 mm//s f r a c t i o n p a t t e r n s were m e a s u r e d , and i n t e n s i t i e s

and at a t e m p e r a t u r e between - 1 9 6 and 200~ were m e a s u r e d by a m i c r o d e n s i t o m e t e r . The d e t a i l s

Liquid n i t r o g e n was s p r a y e d on the s p e c i m e n s for of the method used for q u a n t i t a t i v e a n a l y s i s of d i f f r a c -

the t e s t t e m p e r a t u r e s b e t w e e n - 196 and 0~C, and tion p a t t e r n s f r o m m i x t u r e s of m o r e than two c a r b i d e

s i l i c o n e oil was used a s a heating m e d i u m for the types a r e g i v e n in Ref. 38 and can be supplied by the

t e s t s done b e t w e e n 0 and 200~ An i r o n - c o n s t a n t i n a u t h o r s upon r e q u e s t .

t h e r m o c o u p l e was spot-welded to the s p e c i m e n j u s t C a r b i d e i d e n t i f i c a t i o n was a l s o done by t r a n s m i s s i o n

b e s i d e the notch in o r d e r to p r o v i d e t e m p e r a t u r e c o n - e l e c t r o n m i c r o s c o p y . C a r b o n v a p o r was d e p o s i t e d on

t r o l of I~ The f r a c t u r e e n e r g y was m e a s u r e d by the etched s u r f a c e and the thin f i l m was s t r i p p e d in

i n t e g r a t i n g the a r e a u n d e r the l o a d - d e f l e c t i o n c u r v e , 2 pct Nital. The e x t r a c t i o n r e p l i c a was e x a m i n e d with

and the r e s u l t s were e x p r e s s e d as a 5.4 J (4 ft-lb) a P h i l l i p s 300 e l e c t r o n m i c r o s c o p e .

t r a n s i t i o n t e m p e r a t u r e ; this was found to give the b e s t The s e p a r a t e d e l e c t r o l y t e solution was once again

d e f i n i t i o n of the t r a n s i t i o n t e m p e r a t u r e . f i l t e r e d by W a t t m a n n u m b e r 42 p a p e r and c h e m i c a l l y

M e t a l l o g r a p h i c s a m p l e s were etched with s a t u r a t e d a n a l y z e d to give the Mo, Cr, and F e c o n c e n t r a t i o n s in

aqueous p i c r i c acid with 1 g of s o d i u m t r i d e c y l b e n z e n e the s o l u t i o n . The r a t i o of M o : F e and C r : F e was c a l -

sulfonate added p e r 100 m l of solution as a wetting culated to give the wt pct of Mo and Cr r e m a i n i n g in

agent. 12 The g r a i n s i z e s were m e a s u r e d by the l i n e a r the f e r r i t e . The m o l y b d e n u m thiocyanate s p e c t r o -

i n t e r c e p t method, and the m e a s u r e d a v e r a g e g r a i n p h o t o m e t r i c method 2~ was used for the Mo a n a l y s i s ,

d i a m e t e r was c o r r e c t e d by a g e o m e t r i c a l factor of and the a t o m i c a b s o r p t i o n method was used for the

1.65 to a p p r o x i m a t e the r e a l g r a i n s a s t e t r a k a i d e c a - Cr a n a l y s i s . The d i c h r o m a t e t i t r a t i o n method was

hedra.13 used for the F e a n a l y s i s . 2~

To identify the f r a c t u r e mode, s c a n n i n g e l e c t r o n A s c a n n i n g A u g e r m i c r o p r o b e (SAM) was used for

m i c r o g r a p h s at 300 m a g n i f i c a t i o n were taken at the the study of g r a i n b o u n d a r y s e g r e g a t i o n . S p e c i m e n s

top and bottom notch root a r e a s , where f r a c t u r e were f r a c t u r e d in situ, u n d e r a v a c u u m of < 1 10-1~

s t a r t e d and ended, and in the c e n t r a l a r e a , and i n t e r - T o r r at a t e m p e r a t u r e of ~ - 1 0 0 ~ U s u a l l y about

g r a n u l a r f a c e t s were outlined on a s e m i t r a n s p a r e n t twenty s p e c t r a were r e c o r d e d f r o m d i f f e r e n t g r a i n

p a p e r . By cutting the p a p e r and m e a s u r i n g the weight b o u n d a r i e s , along with a n o t h e r five s p e c t r a f r o m

f r a c t i o n of i n t e r g r a n u l a r a r e a s , the i n t e r g r a n u l a r p e r - c l e a v a g e f a c e t s . A n i s o t r o p y in the g r a i n b o u n d a r y

centage was d e t e r m i n e d . The a v e r a g e value of those s e g r e g a t i o n was studied by use of a m u l t i p l e x s y s t e m ,

t h r e e a r e a s was used to r e p r e s e n t the f r a c t u r e mode. and for this over 100 g r a i n b o u n d a r y facets were

In o r d e r to s e p a r a t e the c a r b i d e s f r o m the f e r r i t i c a n a l y z e d in each s p e c i m e n . The o p e r a t i n g conditions

m a t r i x without c a r b i d e d i s s o l u t i o n , e l e c t r o l y s i s at for the A n g e r a n a l y s e s were as follows:

c o n s t a n t c u r r e n t d e n s i t y 14-16 was c a r r i e d out with an

Incident beam energy 5 KeV

e l e c t r o l y t e of 15 pct s o d i u m c i t r a t e - 1 pct p o t a s s i u m

Incident b e a m size 2O

t h i o c y a n a t e (KCNS) s o l u t i o n Y -19 About 0.6 g of the

Primary beam current 20 to 30 ~A

s a m p l e ( p r e v i o u s l y polished with no. 600 g r i t e m e r y

Modulation voltage 6 eV

p a p e r ) was d i s s o l v e d in 300 mt of the e l e c t r o l y t e u n -

E l e c t r o n m u l t i p l i e r voltage 1 keV

d e r a c u r r e n t d e n s i t y of 5 to 10 m A / c m 2 at 1 to 1.5 V

Time constant 0.1 s

for 24 to 30 h. is The s a m p l e was s u s p e n d e d in a P t

Sensitivity 20 (or 100

b a s k e t having n u m e r o u s holes to allow e a s y flow of

the e l e c t r o l y t e ; a Pt wire s e r v e d a s a cathode. When i n f o r m a t i o n on the s u r f a c e c o m p o s i t i o n p r o -

D u r i n g the e l e c t r o l y s i s , the pH of the e l e c t r o l y t e file was needed, ion s p u t t e r i n g was p e r f o r m e d with

tended to r i s e , and u n d e s i r a b l e compounds such as p u r i f i e d A r + gas u n d e r the following c o n d i t i o n s :

f e r r o u s or f e r r i c c i t r a t e c o m p l e x e s of unknown c o m -

Ar pressure 5 10-5 T o r r

position or Fe4(Fe(CN)6)3 could f o r m . Hence, the pH

Voltage d i f f e r e n c e b e t w e e n

of the solution was c o n s t a n t l y checked by a pH m e t e r

the anode and the t a r g e t 5 keV

and was c o n t r o l l e d at 7 + 0.2 by dropwise additions of

Filament current 5 mA

HC1. The e l e c t r o l y t e was c o n s t a n t l y s t i r r e d with a

p l a s t i c coated magnet in o r d e r to p r e v e n t any pH

g r a d i e n t or Fe r i c h zone n e a r the s p e c i m e n s u r f a c e .

A f t e r the e l e c t r o l y s i s , p r e c i p i t a t e s a d h e r i n g to the

RESULTS

s u r f a c e of the s a m p l e were r e m o v e d by flushing with

d i s t i l l e d w a t e r , and the m e t a l l i c deposit on the cathode A s i d e f r o m the i n t e n t i o n of studying the effect of

was d i s s o l v e d with c o n c e n t r a t e d HC1 and t r a n s f e r r e d h a r d n e s s per se, the t h r e e t e m p e r i n g t r e a t m e n t s were

b a c k into the e l e c t r o l y t e . The c a r b i d e p a r t i c l e s were chosen so that they p r o d u c e d d i s t i n c t l y d i f f e r e n t s t a g e s

s e p a r a t e d f r o m the e l e c t r o l y t e by a c e n t r i f u g e at of c a r b i d e f o r m a t i o n , thus t h r e e d i f f e r e n t l e v e l s of Mo

75,000 g r a v i t y . The c l e a n e l e c t r o l y t e solution was in s o l u t i o n in the f e r r i t e p h a s e . T h e s e t h r e e c o n d i -

pipetted and the c a r b i d e s were collected together, t i o n s a r e i n d i c a t e d in F i g . 2 which g i v e s the r e s u l t s

washed with d i s t i l l e d H20 many t i m e s u n t i l the c a r - of B a k e r and Nutting 22 on the k i n e t i c s of c a r b i d e f o r -

b i d e s were c o m p l e t e l y free of any o r g a n i c s u b s t a n c e m a t i o n in a 2.25 C r - 1 Mo s t e e l . Although t h e i r s t e e l

f r o m the e l e c t r o l y t e , and then the c a r b i d e s w e r e d r i e d . contained Mn and Si, which have some effect on c a r -

The e x t r a c t e d c a r b i d e s were identified by X - r a y dif- bide f o r m a t i o n , as will be shown s e p a r a t e l y , 23 t h e i r

f r a c t i o n using a D e b y e - S e h e r r e r c a m e r a (D = 114.6 r e s u l t s can be used as a p p r o x i m a t e g u i d e l i n e s in the

ram) with a V f i l t e r ; Cr K s r a d i a t i o n at 40 kV and a present report.

METALLURGICALTRANSACTIONSA VOLUME llA, FEBRUARY 1980 279

DATA ON C A R B I D E FORMATION I 1 0 0 4 ~.P // ' |

(FROM BAKER & NUTTING) O

o 0 FINE G.S

800 -

700

M6C -50 9 9

-75

-

- TEMPERINGTREATMENTS

9 . 65o-c Oh

/ Ip 6 9 0 " C 12h i

600 - ~ ~'-,~,.+ CrTC 3 ~ --100 I 2 3 //

t--

- Fe3C + M~ I I I I //

500

| ~ j.~

- 26o Rc

400

Fe3C + E C A R B I D E

9"r 9149

I I I I I I I, I I 180 I ~// I

I 2 3 7

1.0 5 I0 50 I00 500 I000 5000 I0000

AGEING TIME AT 5 2 0 " C (10 "~h)

TEMPERING TIME (h)

Fig. 3-Variation with aging time of the 4 ft-lb (5.4 J) transition tem-

Fig. 2-Data of Baker and Nutting 22 showing the sequence of carbide perature and the hardness of the fine-grained 0.04 P steel, aged at

formation during tempering of a quenched 288Cr-1 Mo steel. Symbols 520~ showing different embrittlement kinetics at three hardness

H, I, and L indicate high, intermediate and low hardness tempering levels.

treatments used in present study.

m e n c e d a f t e r s e v e r a l hundred h and continued beyond

E m b r i t t l e m e n t by P h o s p h o r u s 103 h. It was p o s t u l a t e d that t h i s b e h a v i o r was due to

T h e v a r i a t i o n of the t r a n s i t i o n t e m p e r a t u r e with the slow r e l e a s e of P f r o m the Mo s c a v e n g e d sta t e a s

aging t i m e at 520~ f o r the 0.04 P s t e e l with the fine Mo was r e m o v e d f r o m f e r r i t e by c a r b i d e f o r m a t i o n . *

g r a i n s i z e and s e v e r a l h a r d n e s s / c a r b i d e c o n d i ti o n s, *We do not know whetherMo and P form an actual compound m these steels

is g i v e n in F i g . 3. (Note that the t i m e s c a l e is in or somekind of clusterm the fernte phase; for conveniencewe refer to the Mo

t h o u s a n d s of h o u r s . ) It can be s e e n that the t e m p e r not in carbides as beingin the fernte.

e m b r i t t l e m e n t s u s c e p t i b i l i t y of this s t e e l is not l a r g e It can be s e e n f r o m F i g . 2 that the t h r e e conditions

in any c a s e ; the t r a n s i t i o n t e m p e r a t u r e shift (A0) of the p r e s e n t C r M o s t e e l can be c h a r a c t e r i z e d as

h a r d l y e x c e e d s 40~ e v e n in the m o s t e m b r i t t l e d c o n - follow s:

di t i o n . T h i s i s in c o n t r a s t with the much l a r g e r e m -

b r i t t l e m e n t by P in N i - C r s t e e l s . 24,29. o r in c o m m e r - H a r d n e s s Condition Stage of C a r b i d e F o r m a t i o n

*ANI. Cr - 0.4 C steel doped with 0.02 pct P showeda A0 of 150 ~ after 20 h High (H) M2C f o r m a t i o n about to c o m -

at 520~ 24 mence

e i a l C r - M o steels25'z6t- (which c o n ta in Mn and Si). I n t e r m e d i a t e (I) M2C f o r m a t i o n a l m o s t c o m -

?For commercialCr-Mosteels,40 valuesover 100~ are not uncommon.25"26 plete

Low (L) M2C about to be r e p l a c e d by

H o w e v e r , the low s u s c e p t i b i l i t y of the p r e s e n t s t e e l M~C3 and M23C6

to e m b r i t t l e m e n t is c o n s i s t e n t with p r e v i o u s r e p o r t s

about the b e n e f i c i a l r o l e of Mo, 1-4 the n a t u r e of which

T h e r e f o r e , one would e x p e c t that the aging t r e a t m e n t

r e m a i n s to be made c l e a r .

at 520~ would have r e l a t i v e l y l i t t l e e f f e c t on the Mo

It is a p p a r e n t that the k i n e t i c s of e m b r i t t l e m e n t a r e

c o n c e n t r a t i o n in the f e r r i t e in the L and I c o n d i t i o n s ,

not the s a m e f o r the d i f f e r e n t h a r d n e s s l e v e l s . In the

but that M2C f o r m a t i o n at 520~ in the H condition

s a m p l e s with low o r i n t e r m e d i a t e h a r d n e s s the e m -

b r i t t l e m e n t is rapid, and a s t e a d y s t a t e is r e a c h e d would p r o d u c e s i g n i f i c a n t c h a n g e s in the a m o u n t of

within ~ 100 h; t h i s type of b e h a v i o r is to be e x p e c t e d Mo a v a i l a b l e to s c a v e n g e P .

if the s e g r e g a t i o n is c o n t r o l l e d by the d i f f u s i o n r a t e In o r d e r to i n v e s t i g a t e this f u r t h e r , X - r a y a n a l y s e s ,

of the P . H o w e v e r , f u l l - s c a l e e m b r i t t l e m e n t t a k e s of e x t r a c t e d c a r b i d e s and c h e m i c a l a n a l y s e s of the

liquid e x t r a c t ( r e p r e s e n t i n g the m a t r i x ) w e r e c a r r i e d

m u c h l o n g e r in the high h a r d n e s s condition; w e l l o v e r

out. F i g u r e 4 g i v e s a c o m p a r i s o n of the r a t e s of i n-

1000 h is r e q u i r e d to r e a c h a s t e a d y s t a t e . T h u s , the

c r e a s e of i n t e r g r a n u l a r f r a c t u r e at ~ - 1 0 0 ~ (an a l -

C r - M o s t e e l d i f f e r s f r o m the N i - C r s t e e l not only in

t e r n a t i v e m e a s u r e of the r a t e of e m b r i t t l e m e n t ) with

the o v e r a l l e m b r i t t l e m e n t s u s c e p t i b i l i t y , but a l s o in

the t y p e s of c a r b i d e found at v a r i o u s s t a g e s of the

the k I n e t i c s of e m b r i t t l e m e n t in s o m e conditions of

aging p r o c e s s . A s a n t i c i p a t e d , the slow e m b r i t t l e m e n t

heat t r e a t m e n t . (See a l s o F i g . 4(a).)

in the H s a m p l e s was a c c o m p a n i e d by the slow p r e -

Th e b e h a v i o r in the h i g h - h a r d n e s s condition is c o n -

c i p i t a t i o n of M2C. F o r I and L s a m p l e s m o s t of the

s i s t e n t with that o b s e r v e d e a r l i e r in a N i C r M o s t e e l

M2C had a l r e a d y p r e c i p i t a t e d d u r i n g the t e m p e r i n g

doped with P w h e r e slow e m b r i t t l e m e n t at 500~ co r n -

280-VOLUME l lA, FEBRUARY 1980 METALLURGICAL TRANSACTIONS A

9 HIGH HARDNESS 0.8 pet Mo was p r e s e n t in s o l u t i o n in the H s t e e l when

9 INTERMEDIATE HARDNESS a l l the c a r b i d e was MsC is p r e s u m a b l y due to the p a r -

(27 9 LOW HARDNESS

.~ (30 ~ I t i t i o n i n g of Mo to the MaC. T h i s l e v e l of d i s s o l v e d

(a) Mo is a p p a r e n t l y enough to s u p p r e s s most of the e m -

Z

b r i t t l e m e n t in the f i r s t few h u n d r e d h of aging (see

(.9

_b?_ 20

+ F i g . 3). However, d u r i n g the prolonged aging t r e a t -

ment, the c o n c e n t r a t i o n of d i s s o l v e d Mo d e c r e a s e d

s t e a d i l y as the M2C c a r b i d e p r e c i p i t a t e d , t h e r e b y

o

p e r m i t t i n g m o r e e m b r i t t l e m e n t . Tile s i m u l t a n e o u s

~)tz

cku- 0 drop in the d i s s o l v e d Cr content in the H s t e e l i n d i -

c a t e s the p a r t i t i o n i n g of Cr to M2C. F o r the I and L

0.6 i i

LLO~ (b) s a m p l e s in the a s - t e m p e r e d condition, the c o n c e n t r a -

t i o n s of d i s s o l v e d Mo were a l r e a d y low due to the

~ 04 M2C and M7C3 p r e c i p i t a t i o n . T h e r e f o r e , with l e s s

,.---" MzC + FesC

l---r

<DO ~ Mo a s s o c i a t e d with P, m o r e P s e g r e g a t i o n could o c c u r .

H e r e , the d e c r e a s e of d i s s o l v e d alloy content d u r i n g

the aging t r e a t m e n t was v e r y s m a l l c o m p a r e d to that

~-Ld

in the H s p e c i m e n s . However, this s m a l l d e c r e a s e

tgN 0 J I I // I

I 2 3 7 s e e m s to have allowed enough P s e g r e g a t i o n to offset

the softening effect (see F i g . 3).

AGEING TIME A T 5 2 0 * C ( l O S h )

T h e s e r e s u l t s support the idea that the e m b r i t t l e -

Fig. 4-Correlation between the rate of increase of: (a) intergranular

fracture at ~- 100~ and (b) M2C precipitation in the 0.04 P steel, at ment k i n e t i c s depend on the a m o u n t of d i s s o l v e d Mo,

three hardness levels. which can change due to c a r b i d e p r e c i p i t a t i o n . How-

e v e r , it should be noted that the c o n c e n t r a t i o n of d i s -

t r e a t m e n t , and the f r a c t i o n of M2C i n c r e a s e d only solved Cr d e c r e a s e s d u r i n g the aging t r e a t m e n t in a

slightly, if at all, d u r i n g aging. T h i s was c o n f i r m e d m a n n e r s i m i l a r to that of Mo. Since Cr is known to

by the e x t r a c t i o n r e p l i c a s in which the H s a m p l e s e x - e n h a n c e P s e g r e g a t i o n , z4,29,s~ a d e c r e a s e in the d i s -

hibited none of the n e e d l e - s h a p e d M2C p a r t i c l e s b e - solved Cr content ( p a r t i c u l a r l y at the high h a r d n e s s

fore aging, but an i n c r e a s i n g amount of t h e m d u r i n g level) is expected to be b e n e f i c i a l , in c o n t r a s t with

the aging t r e a t m e n t . In the I and L s a m p l e s , the the o b s e r v e d b e h a v i o r . T h e r e f o r e , the effect of the

t y p e s and m o r p h o l o g i e s of c a r b i d e r e m a i n e d m o r e or d e c r e a s i n g Cr m u s t be o v e r p o w e r e d by that of the d e -

l e s s c o n s t a n t d u r i n g aging. It should be noted that the c r e a s i n g Mo. A n o t h e r point is that, despite the p r e s -

lattice p a r a m e t e r of the MzC was found to be c o n s i d - ence of m o r e Mo to s c a v e n g e P, the I s a m p l e s show

e r a b l y s m a l l e r than that of Mo2C, i n d i c a t i n g that C r at l e a s t as much i n t e r g r a n u l a r f r a c t u r e a s the L s a m -

had p a r t i t i o n e d into the M2C carbide.27'28 p l e s . T h i s may be a s c r i b e d to the effect of h a r d n e s s ,

The r e s u l t s of c h e m i c a l a n a l y s i s of the m a t r i x e x - per se.

t r a c t , given in Fig. 5, show that, as expected, the H

s a m p l e s had the l a r g e s t a m o u n t of dissolved* Mo and 9 HIGH HARDNESS

*Meaningin the fernte phase, ratherthanin carbides. 9 INTERMEDIATE HARDNESS

P 9 LOW HARDNESS

Cr in the a s - t e m p e r e d condition. The fact that only

FeTo3 Ir ] "

0 F i " i i I/ i

o 08T_~

I (o)

[0 f~"""~ONE FACET

m 06 ~ /H I o /

> [/CLEAVAGE

J

o 04 oI t [ i 41 I

0.2 ~ 2 ~ " \L

I--

0/

CI

M~ I (b) f J

I I I 2 I 0

26 I r , 2 r I

I (b) i~~ , . . ~ CLEAVAGE

H w

(~ 2.2 9 0I I i //

/I

LtJ

>

j

o

o~

(/)

1.8

I ~ .

9

Cr529 I (C)

Fez~ I~ - -

I I

i =i--

I " - - - - - - CLEAVAGE

I

o I I I , II i

f 2 3 7

l.O I I ~ # J AGEING TIME AT 520 *C (lOSh)

I 2 3 7

Fig. 6-Averaged Auger peak height ratios from fracture surfaces of the

AGEING TIME AT 5 2 0 ~ (lOSh) 0.04 P steel aged at 520~ and fractured at ~-100~ (a) Px20/FeT03,

Fig. 5-Variation of: (a) Mo and (b) Cr in solution with aging time for (b) Mo186/FeTo3,(c) Crs29/Fe?o3.Error bars represent range of values

the 0.04 P steel at three hardness levels. measured.

METALLURGICAL TRANSACTIONS A VOLUME IIA, FEBRUARY 1980 281

H I L Oh

IOOh

[

l ' ' ' ' I ' ' ' I ' ' IO00h

A 3000h

U

o

I I

0.02

i

P

I i I I

x

i

STEP COOL 0 0 4

] 1

P

I

LOW HARDNESS LOW HARDNESS

'" -25

O - 0

I--

ne-

uJ

W

-50 o'.--...._ -40 -40

I--

z -75 -80 -80

o

I--

k L I i I , I , l , I q l

z -I00 3 5 7 3 5 7 9

I.--

W

oc I I I I

~ -125 D INTERMEDIATE HARDNESS

n- 0 o

bJ

0_

300

I , , i

HARDNESS

,

250

I L ,

(DPH)

, J [

200

, , J =E

-40 -4o -..<

Fig. 7-Effect of hardness on 5.4 J transition temperature of the fine- V- -eO -8o

grained 0.04 P steel at various aging times.

Z

I = I = I L I

T h e i n t e r g r a n u l a r f a c e t s on s p e c i m e n s f r a c t u r e d at I- 3 5 7 9 3 5 7 9

~ - 1 0 0 ~ in UHV w e r e a n a l y z e d in the SAM. T h e r e -

suit s w e r e e x p r e s s e d as a p e a k - h e i g h t - r a t i o (PHR) =5 I t , '~,.i ' i ~lG~ '

using the F e 703 eV peak as the r e f e r e n c e , and a r e HIGH HARDNESS

~x\, HARDNESS

shown in F i g . 6. Th e v a r i a t i o n of the a v e r a g e i n t e r - -

g r a n u l a r P c o n c e n t r a t i o n a p p e a r s to be s i m i l a r to

that of the p e r c e n t a g e of i n t e r g r a n u l a r f r a c t u r e . Th e

-4( -

-40

i n c r e a s e of the P12o PHR is c o n s i s t e n t with the slow

e m b r i t t l e m e n t k i n e t i c s f o r the H s a m p l e s and the

r a p i d k i n e t i c s in the I and L s a m p l e s . T h u s , t h e s e -8( -80

r e s u l t s show that in the H condition both the p e r c e n t -

I , 1 , I , I I , I ~ I , I

age of e m b r i t t l e d b o u n d a r i e s and the P c o n c e n t r a t i o n 3 5 7 9 .3 5 7 9

on t h e s e b o u n d a r i e s i n c r e a s e d s l o w l y with aging at

PRIOR AUSTENITIC GRAIN SIZE (ASTM No )

520~ Th e Mo~s6, Cr529, and C273 P H R s w e r e much

Fig. 8-Influence of austenitic grain size on the 5.4 J transition tem-

l a r g e r on g r a i n b o u n d a r i e s than on c l e a v a g e f a c e t s , perature of the 0.02 and 0.04 P steels at three hardness levels.

p r e s u m a b l y due m a i n l y to i n t e r g r a n u l a r a l l o y e a r -

b i d e s , but a l s o to s e g r e g a t e d a l l o y e l e m e n t s . h i g h e r m a t r i x h a r d n e s s . Both t h e s e t e n d e n c i e s a r e

Th e t r a n s i t i o n t e m p e r a t u r e s f r o m F i g . 3 a r e plotted q u a l i t a t i v e l y c o n s i s t e n t with the e m b r i t t l e m e n t e q u a -

vs the m a t r i x h a r d n e s s in F i g . 7. It can be s e e n that tion of T a k a y a m a e l a l . 3z It should be noted that the

the i s o c h r o n a l c u r v e s have a v a r i e t y of s l o p e s b e c a u s e slow e m b r i t t l e m e n t o b s e r v e d in the high h a r d n e s s

of the slow k i n e t i c s at the high h a r d n e s s l e v e l . F o r s a m p l e s o c c u r s in a l l g r a i n s i z e s .

e x a m p l e , the 100 h c u r v e shows a d i s t i n c t c o n c a v e -

d o w n w a r d n e s s , which is c o n t r a r y to the b e h a v i o r of E f f e c t of V a r i a t i o n in Mo Content of the S t e e l

P doped N i - C r s t e e l s . 24 T h e l a t t e r d a t a w e r e plotted

at constant l e v e l s of i n t e r g r a n u l a r s e g r e g a t i o n , r a t h e r Since the w o r k by P o w e r s , s'6 it has b e e n known that

than c o n s t a n t aging t i m e s ; the p r e s e n t i s o e h r o n a l Mo ad d i t i o n s of m o r e than 0 3 wt pct do m o r e h a r m

c u r v e s at s h o r t aging t i m e s do not r e p r e s e n t i s o a d - than good. Th e r e s u l t s of Charpy t e s t s by Wada and

s o r p t i o n co n d i t i o n s , as is c l e a r f r o m F i g . 6. T h e H a g e l 7 on a s e r i e s of 2.25 Cr s t e e l s a r e shown in

c u r v e s tend to s t r a i g h t e n out at l o n g e r aging t i m e s , F i g . 9. E a c h s t e e l had to be t e m p e r e d d i f f e r e n t l y to

because isoadsorption conditions are ultimately provide a constant as-tempered tensile strength, be-

reached. c a u s e of the v a r y i n g Mo content. 7 T h e i r r e s u l t s c l e a r l y

S i m i l a r e x p e r i m e n t s w e r e done on the 0.02 P s t e e l , show a m i n i m u m in F A T T a r o u n d 0.5 to 0.7 pct Mo.

which was found to exhibit v i r t u a l l y the s a m e g e n e r a l Th e d a t a in F i g . 10 show that the m a t r i x h a r d n e s s is

e m b r i t t l e m e n t c h a r a c t e r i s t i c s a s the 0.04 P s t e e l , a l - e s s e n t i a l l y c o n s t a n t above 0.6 pct Mo. T h e r e f o r e , it

though the t r a n s i t i o n t e m p e r a t u r e s w e r e a l w a y s l o w e r is a p p a r e n t that the high Mo e f f e c t is not due to h a r d -

than t h o s e of the 0.04 P s t e e l , a s would be e x p e c t e d . ness changes.*

T h e v a r i a t i o n of t r a n s i t i o n t e m p e r a t u r e with p r i o r *Notethat the maximumhardness differencebetween 0.5 and 1.3 pct Mom

a u s t e n i t e g r a i n s i z e was e x a m i n e d f o r the 0.04 P and Fig. 10 ]s 17 DPHunits. From the data m Fig. 7 this wouldproduce at most a

0.02 P s t e e l s , a s shown in F i g . 8. T h e g r a i n s i z e e f - 10 ~ increasem transition temperature, as opposed to the 70 ~ differenceindi-

f e c t i s m o r e p r o n o u n c e d in the 0.04 P s t e e l , which is cated m Fig. 9.

c o n s i s t e n t with the r e s u l t s of Capus. 3~ A l s o , t h e r e is Th e r e s u l t s of X - r a y a n a l y s e s of c a r b i d e p a r t i c l e s

a t e n d e n c y for the g r a i n s i z e e f f e c t to be g r e a t e r at extracted electrolytically from their specimens are

2 8 2 - V O L U M E I1A, FEBRUARY 1980 METALLURGICALTRANSACTIONS A

I I I I I p

I o UNEMBRITTL~'D I I I I I/~ I I

8 0 , e-, 9 STEP-COOLED

| j ~

z

o

I.--

or"

L.I-

M7 C3

I'--

b_ _

40 - / -

t ~ e

LtJ /-

r ~__ o o ~ ~ n,- __ @/@ m

I l 1 ~ 0 I i 0 I i <I

~,)

M2 C

0 02 04 0.6 08 I0 12 14

TOTAL Mo CONTENT (wt %) o I I I I I I

0,4 0,8 1,2

Fig. 9-Fracture appearance transitmn temperatures (FATT) of 2 88 Cr

steels with varying total Mo content in both the quenched-and-tem- TOTAL Mo CONTENT(wt%)

pered and step-cooled conditions. 7 Fig. l l-Types of carbide present m the step-cooled 288Cr steels with

varying total Mo content.

g i v e n in F i g . 11. It can be s e e n that the i n c r e a s e d

e m b r i t t l e m e n t at > 0.7 pct Mo is a c c o m p a n i e d by M2C d i s s o l v e d C r c o n c e n t r a t i o n i n c r e a s e s a s M7C3 is r e -

p r e c i p i t a t i o n ! T h i s is the r e s u l t of the l o n g e r t e m p e r - placed by M2C (Fig. 11). The p r e s e n c e of the m i n i m u m

ing t i m e s applied to the high Mo s t e e l s which showed in the d i s s o l v e d Cr content c o r r e s p o n d s to the m i n i -

a high r e s i s t a n c e to softening; the p r o l o n g e d t e m p e r - m u m in the t r a n s i t i o n t e m p e r a t u r e .

ing allowed M~C p r e c i p i t a t i o n to o c c u r . F i g u r e 11 Our i n t e r p r e t a t i o n of the Wada and Hagel r e s u l t s

shows that the f r a c t i o n of M2C i n c r e a s e d as the total a r e , t h e r e f o r e , as follows: A s the Mo content is r a i s e d

Mo content i n c r e a s e d . At the s a m e t i m e , the f r a c t i o n

of M7C3 d e c r e a s e d , due to the fixed C content. Since , i i i 9 o U OF PENN '

MTCs is a Cr r i c h c a r b i d e , the d e c r e a s e of MTCa would x OUTSIDE LAB

r e s u l t in m o r e Cr in solution, t h e r e b y p e r m i t t i n g

08

more Cr-P cosegregation.

The r e s u l t s of the a n a l y s e s of the e x t r a c t f r o m the

f e r r i t e m a t r i x for Mo a r e p r e s e n t e d in F i g . 12. T h r e e

s e p a r a t e a n a l y s e s a r e shown; two out of the t h r e e i n -

0

06 S --f:-

Ld

dicate that the c o n c e n t r a t i o n of d i s s o l v e d Mo i n c r e a s e s >~ o4

s t e a d i l y to a s a t u r a t i o n l e v e l at a total Mo content of 0

/.o//"

~ 0.7 pct. As the Mo content is i n c r e a s e d beyond 0.7

pct, it a l l goes to f o r m m o r e c a r b i d e . F o r the two

c u r v e s which show s a t u r a t i o n beyond 0.7 pct Mo, the

l e v e l of one c u r v e c o r r e s p o n d s to 75 pct of the other,

i m p l y i n g that the e r r o r between t h e m is s y s t e m a t i c .

0 02 04 06 0.8 I0 12 14

A s i m p l e c a l c u l a t i o n shows that the higher l e v e l of

Mo is m o r e p l a u s i b l e . * E v e n the t h i r d a n a l y s i s shows TOTAL Mo CONTENT (wt%)

* F o r the 1.3 Mo steel, the calculated values of the dissolved Cr and Mo are

Fig. 12-Concentration of Mo in the ferrite phase for the step-cooled

1.67 and 0.75 pct respectively. 2% Cr steels with varying total Mo content.

I I r I

a m a r k e d change in slope at ~ 0.7 pet total Mo and is

thus r o u g h l y c o n s i s t e n t with the other two. The r e s u l t s

of the a n a l y s e s of the Cr c o n c e n t r a t i o n in solution in 2.0

the f e r r i t e a r e given in Fig. 13. It is c l e a r that the

O~ / x~

o 1 6 ~ Cr/ x~ x

I I I I I I I

260 ^~x I

0

-- I00

"r- ,3 ~.2

13,. 240 -- 98 123

LLI Mo

03 -- 96 m > 0.8

U.I _J

i..iJ Z

220

z

(:3

n,"

-- 94

a

a:

I

o~~ 0.4 ~"~ ......

-r" - 92

200

l I 1 I I I 0 i i t i

0.2 0 4 0.6 0 8 1.0 1.2 14 0 04 08 12 I6

TOTAL Mo CONTENT (wt % ) TOTAL Mo CONTENT (wt %)

Fig. 10-Hardness of the step-cooled 2 88Cr steels with varying total Fig. 13-Concentrations of Mo and Cr in the ferrite phase for the step

Mo content. cooled 288Cr steels with varying total Mo content,

METALLURGICAL TRANSACTIONS A VOLUME l l A , FEBRUARY 1980-283

I i i I i i i i s i s t e n t with the above r e a s o n i n g , a s shown in F i g . 14.

The Plzo PHR shows a m i n i m u m v a l u e when the t o t a l

Mo content is a r o u n d 0.5 to 0.7 p c t . The o n e - t o - o n e

,,12 c o r r e s p o n d e n c e b e t w e e n the Cr~29 and Plz0 P H R s i s

(a)

c o n s i s t e n t with the c o s e g r e g a t i o n p h e n o m e n o n . T h e

MO186 PHR is found to i n c r e a s e m o n o t o n i c a l l y , r e -

f l e c t i n g the i n c r e a s e d bulk c o n c e n t r a t i o n ; the Mo p e a k

o

is p r e s u m a b l y due to Mo c a r b i d e s , d i s s o l v e d Mo, and

s e g r e g a t e d Mo.

I--

The following can be c o n c l u d e d f r o m t h e s e r e s u l t s :

T h e P induced t e m p e r e m b r i t t l e m e n t s u s c e p t i b i l i t y of

(b)

.~-$4 C r - M o s t e e l s d e p e n d s on the c o n c e n t r a t i o n s of Mo and

Cr d i s s o l v e d in the f e r t i l e m a t r i x . T h e s e , in t u r n ,

v:~ 2 a r e d e t e r m i n e d by the b u l k c o n c e n t r a t i o n s of Cr and

w

13_ ~ Mo and by the p r e c i p i t a t i o n of c a r b i d e s . T h e d o m i n a n t

r o l e of Mo is to s c a v e n g e P and thus to inhibit s e g r e -

gation, while that of C r is to e n h a n c e P s e g r e g a t i o n .

(c)

~4

(.9

E f f e c t of T i n

2 T i n is a v e r y p o w e r f u l e m b r i t t l e r in the N i - C r

t ; I i I

s t e e l s 33 due to the s t r o n g N i - S n c o s e g r e g a t i o n . How-

0 02 0.4 0.6 08 I0 1~2 14 e v e r , the Sn induced e m b r i t t l e m e n t in N i - C r s t e e l s

s e e m s to be s u p p r e s s e d b y Mo, p e r h a p s b y the s a m e

TOTAL M0 CONTENT(wt%) m e c h a n i s m a s for P . F o r e x a m p l e , W a d a 34 showed

Fig. 1 4 - A u g e r p e a k h e i g h t ratios from - 1 0 0 ~ fracture surfaces of that the t r a n s i t i o n t e m p e r a t u r e shift (A0) a f t e r s t e p

the step-cooled 2 8 8 Cr steels w i t h varying t o t a l Mo c o n t e n t : (a)

cooling for a m a r t e n s i t i c 3.5 N i - l . 7 C r - 0 . 1 V s t e e l

Pl2o/FeTo3, (b) Mots6/FeTo3, (c) Crs29/Fe~o 3 .

(with 0.25 C and 0.02 Sn) can be r e d u c e d f r o m ~ 250

f r o m z e r o , the d i s s o l v e d Mo c o n c e n t r a t i o n i n c r e a s e s to 50~ by the a d d i t i o n of 0.5 Mo.* T h i s i s a v e r y

and P is s c a v e n g e d . Although the i n c r e a s e d t e m p e r - *The specimens had the hardness level o f R c 35 and a grain size of ASTM

ing t i m e c a u s e s M7C3 to be f o r m e d at the e x p e n s e of No. 7.

M~C, the d o m i n a n t effect i s M o - P s c a v e n g i n g , and the p o w e r f u l d e m o n s t r a t i o n of the Mo effect, p a r t i c u l a r l y

e m b r i t t l e m e n t s u s c e p t i b i l i t y d e c r e a s e s . When the Mo in the p r e s e n c e of Ni which can enhance the d r i v i n g

content i s r a i s e d beyond 0.7 pct, M2C r e p l a c e s MTCs, f o r c e for Sn s e g r e g a t i o n e n o r m o u s l y . A s i m i l a r r e -

i n c r e a s i n g the d i s s o l v e d Cr content and the e m b r i t t l e - s u l t was r e p o r t e d by Schulz ~5 f o r a 3.5 N i - l . 7 Cr

m e n t s u s c e p t i b i l i t y again r i s e s due to the c o s e g r e g a - steel.

l i o n of C r and P . The s a m e heat t r e a t m e n t s a s u s e d for the P doped

The A u g e r a n a l y s e s of the above s a m p l e s a r e c o n - s t e e l s w e r e e m p l o y e d for the 0.02 and 0.04 Sn s t e e l s .

Sn -DOPED STEELS, FINE G S

LOW HARDNESS INTERMEDIATE HARDNESS HIGH HARDNESS

- 25 I [ I -25 / ] I I -25 I I I

n 9 004 % 9 004% 9 004%

[] 002% r-t 0 0 ; ' %

w

t- -50 - -50 [ ] 002%

-50 t

z

o

I-- -75 -75

Z Q

<[

13

-JOO= - - 9 lJ-----

-I00 t -IOOL

[]

Fig. 1 5 - V a r i a t i o n w i t h aging time

o f the 4 ft-lb (5.4 J) t r a n s i t i o n tO -125 I [ I -125 ~ [ I I -125 I I ]

t e m p e r a t u r e and hardness of the 0 I 2 3 0 I 2 3 o I 2 3

fine grained 0.02 and 0.04 Sn

steels at three hardness levels, 320 I I I 320 - - I f 320 I I I

aged at 520~ W

rl

t~

v

280 280 - - 2801

(,9

bJ 240 240 ~B- - 240

Z

t3

IZ

200 k.....~. .~ _

2O0 - 200 --

160 I I L ~600 I I [ 160 I I I

I 2 3 2 I 3 t 2 3

AGEING TIME AT 5 2 0 ~ (103h)

284-VOLUME I 1 A , F E B R U A R Y 1980 METALLURGICAL TRANSACTIONS A

The v a r i a t i o n of the t r a n s i t i o n t e m p e r a t u r e and m a t r i x

IVIOI a IVIO

h a r d n e s s at the fine g r a i n s i z e a r e given in F i g . 15.

F o r both s t e e l s A0 i s found to be v e r y s m a l l , with at

m o s t v e r y s l i g h t e m b r i t t l e m e n t in the f i r s t 50 h and -X~o) + ( X zp

aCrV~ Cr- X BC r '\ [2]

a f t e r that a s t e a d y s t a t e . M e t a l l o g r a p h i c e x a m i n a t i o n

of the a s - q u e n c h e d 0.04 Sn s t e e l by use of the s p e c i a l o _ X~ B

p i c r i c a c i d e t c h a n t which a t t a c k s P e n r i c h e d g r a i n Z~GMo = AGMo 2 a F e M o ( M o - X M o )

b o u n d a r i e s r e v e a l e d s o m e p e n r i c h m e n t in the g r a i n

b o u n d a r i e s . T h i s m a y account for the minute e m b r i t - ,

+ aMop(X P

r _ X~) + Or'

MoCr

( X q~

Cr - X c r )

B [3]

t l e m e n t which did o c c u r .

T h e X - r a y a n a l y s e s of the a s - t e m p e r e d H, I, and L

Sn doped s p e c i m e n s showed that the t y p e s of c a r b i d e AGCr = AG~r _ 2aFeCr(X~r _ XcrB )

present were:

H : M3C + ~Crp(Xp

' ~ - Xp) + aMoCr(XMo-- XMo) [4]

I: MzC + MTCa

L : M2C + MTCa T h e c o e f f i c i e n t s ~ij g i v e the net e n e r g y g a i n f r o m

f o r m i n g ij a t o m p a i r s at the e x p e n s e of ii and jj p a i r s ,

which i s the s a m e a s in the P s t e e l s . T h i s i s u n d e r - and the a ' c o e f f i c i e n t s give the e n e r g y gain when two

s t a n d a b l e b e c a u s e the p r e s e n c e of r e s i d u a l P o r 0.02 of t h r e e s o l u t e e l e m e n t s p a i r - u p at the e x p e n s e of the

to 0.04 Sn should not change s i g n i f i c a n t l y the c a r b i d e o t h e r two p o s s i b l e u n l i k e - a t o m p a i r i n g s . F o r e x a m p l e ,

p r e c i p i t a t i o n k i n e t i c s o r the c o n c e n t r a t i o n of Mo in OtFe p is p r o p o r t i o n a l to EFe p -- 1 / 2 ( E F e F e + c p p )

s o l u t i o n . T h e r e f o r e , the amount of Mo in s o l u t i o n for w h e r e ei] is the e n e r g y a s s o c i a t e d with the bond of an

the a g e d I o r L s p e c i m e n s would be ~ 0.4 p c t . Yet, ij a t o m p a i r , and O~MoP = a M o P - (OtFe P + O~FeMo).

t h e r e i s no e m b r i t t l e m e n t . In t h i s " q u a s i - c h e m i c a l " m o d e l the i n t e r n a l e n e r g y

Hence we can conclude that, in the a b s e n c e of Ni, of the s o l i d s o l u t i o n is a p p r o x i m a t e d by the s u m of

0.4 pct Mo in s o l u t i o n i s s u f f i c i e n t to s c a v e n g e 0.04 the e n e r g i e s of the n e a r e s t - n e i g h b o r b o n d s . B e c a u s e

pct Sn. We cannot s a y which f a c t o r i s m o r e i m p o r t a n t : of this s i m p l i f i c a t i o n , one cannot t a k e the m o d e l too

the a b s e n c e of Ni o r the M o - S n s c a v e n g i n g e f f e c t . l i t e r a l l y and e x p e c t to c a l c u l a t e a c c u r a t e l y X ~ (T)

using a and ~ ' v a l u e s o b t a i n e d f r o m h e a t s of f o r m a -

DISCUSSION

tion of p u r e c o m p o u n d s , o r s o m e o t h e r e m p i r i c a l

C o m p a r e d with the r e l a t i v e l y s i m p l e N i C r s t e e l s on m e t h o d . H o w e v e r , the r e g u l a r s o l u t i o n m o d e l i s of

which m o s t of the s y s t e m a t i c s t u d i e s of t e m p e r e m - g r e a t v a l u e for c o n c e p t u a l p u r p o s e s and for c o m p a r -

b r i t t l e m e n t have b e e n c a r r i e d out, C r M o s t e e l s ing the i n t e r a c t i v e e f f e c t s of v a r i o u s e l e m e n t s , a s

c l e a r l y offer a h i g h e r l e v e l of c o m p l e x i t y . F r o m the w i l l be s e e n h e r e .

p r e s e n t study, a s w e l l a s o t h e r r e l a t e d work, ~ it a p - F r o m Eq. [1] it can be s e e n that the m o s t i~paportant

p e a r s that P i s the only one of the c o m m o n i m p u r i t i e s q u a n t i t i e s f o r the d e t e r m i n a t i o n of X ~ a r e X ~ and

which p r o d u c e s a s i g n i f i c a n t a m o u n t of e m b r i t t l e m e n t . AGp. Since P is r e a s o n a b l y s u r f a c e - a c t i v e in F e ,

Although t h i s in i t s e l f s i m p l i f i e s the p r o b l e m , the AG~ is s i g n i f i c a n t (Eq. [2]), but we a l s o e x p e c t s u b -

c o m p l e x i t i e s a r i s e f r o m the e f f e c t s of v a r i a t i o n of s t a n t i a l c o n t r i b u t i o n s to AG,p f r o m the t e r m s in Eq.

the d i s s o l v e d Mo o r C r l e v e l s (due to c a r b i d e r e a c - [2] containing a M o P and a C r P . P a s t work29,~~ 39

t i o n s ) on the t e n d e n c y for s e g r e g a t i o n of P . T h e s e has i n d i c a t e d a s t r o n g a t t r a c t i v e i n t e r a c t i o n b e t w e e n

v a r i a t i o n s depend on the t h e r m a l h i s t o r y of the s t e e l C r and P and a v e r y s t r o n g a t t r a c t i o n b e t w e e n Mo

d u r i n g both heat t r e a t m e n t and s u b s e q u e n t e x p o s u r e

to aging(e.g., o p e r a t i n g ) t e m p e r a t u r e s . I I I I I

The t e r n a r y r e g u l a r solution m o d e l of G u t t m a n n ~

v

IAGED520~

c a n be g e n e r a l i z e d to p r o v i d e a f r a m e w o r k with which

to r a t i o n a l i z e the b e h a v i o r of 2.25 C r - 1 Mo s t e e l in a o 25

I--

q u a l i t a t i v e way. The e q u i l i b r i u m c o n c e n t r a t i o n of any rr i

p a r t i c u l a r solute in an i n t e r f a c e (which is t r e a t e d a s

a s e p a r a t e phase ~) i s given b y : 3v -r"

20-

AGI Iz.I

X B exp "RT -r 15-

x, : [11 <

1 + j =n-~ XB (exp R-T-AG~ 1) W

r, I0-

j=l

I

ir

0b,-

w h e r e B r e f e r s to the bulk s o l i d s o l u t i o n which c o n -

tains components. Since C d o e s not e n t e r d i r e c t l y I.L

into the i n t e r g r a n u l a r s e g r e g a t i o n in the p r e s e n t c a s e , 0

(xJ

we can t r e a t P doped CrMo s t e e l a s a f o u r component m- I I I I I 1

s y s t e m . Using the r e g u l a r solution m o d e l we can a p - 0.2 0 4 0.6 0.8 1.0

p r o x i m a t e the i m p o r t a n t AG i t e r m s a s follows:38*

DISSOLVED Mo(wt%)

*These come from a straightforward extension of Guttmann's ternary regular

Fig. 1 6 - I n t e r g r a n u l a r c o n c e n t r a t i o n of P at 5 2 0 ~ {.in t e r m s o f the

solution model to a quaternary solution; the detailed derivation3~ can be supplied

Pl2o PHR) as a f u n c h o n of the Mo c o n c e n t r a t i o n in solution for the

upon request to the authors.

0.04 P steel at several hardness levels.

METALLURGICAL TRANSACTIONS A VOLUME l l A , F E B R U A R Y 1 9 8 0 - 2 8 5

I I I I I I I I I I

o

50 O p

<[

rr

I : m

9 9

oom

9

9

<9 oO 9 9 9 Fig. 17-Relationship between

bJ 9"::. ",)r the intergranular concentrations

I

Y

<[

20 0-

;#-<...." at 520~ (a) of P and Mo and

(b) of P and Cr.

&O& 9 9

W

n

o0~ 9 9

0

9

b_

I0- 0

0

0

o4 AA

n

,,j,

%

I I I I I l I I I I

0 2 4 6 8 0 2 4 6 8 I0 12

Mo186/FeTo 3 PH R (%) Cr529/Fe705 PHR (%)

(a) (b)

and P. The positive ~ ' t e r m s would produce c o s e g r e - et al 4~ and has r e c e n t l y been d e m o n s t r a t e d conclusively

gation of Mo + P and Cr + P; hence, the t h r e e (X/~ by the f r e e - s u r f a c e s e g r e g a t i o n study of G r a h a m and

--X B) would a l l i n c r e a s e and there would be mutual Yen. 41 More r e c e n t work by DiDio and G r a h a m 42 has

e n h ~ c e m e n t of s e g r e g a t i o n of P by Mo and Cr. T h e r e - d e m o n s t r a t e d the P scavenging effect of Mo by use of

fore, unless X~ were somehow d e c r e a s e d , an i n c r e a s e the s a m e technique.

in bulk concentration of Cr or Mo would be expected to If it is a s s u m e d that the Mo + P scavenging effect

produce enhanced P s e g r e g a t i o n . is the r e s u l t of the formation of Mo3P and that Mo3P

The p r e s e n t r e s u l t s indicate that i n c r e a s e s in Cr do and Fe3P can f o r m a continuous, isomorphous solid

enhance P s e g r e g a t i o n , but that i n c r e a s e s in Mo con- solution, then Guttmann's 43 adaptation of H i l l e r t ' s 44

tent r e t a r d it. The l a t t e r can be seen in F i g . 16 where r e g u l a r solution a n a l y s i s of c a r b i d e s o l u b i l i t i e s can

data from s e v e r a l conditions of t h e r m a l h i s t o r y a r e be used to e s t i m a t e the X~ v a l u e s at v a r i o u s l e v e l s of

c o l l e c t e d and it is shown that the s e g r e g a t e d P l e v e l X ~ o . The e x p r e s s i o n for X~ f r o m such an a n a l y s i s is

d e c r e a s e s as the Mo concentration in the f e r r i t e in- given by :

c r e a s e s . This can only happen if Mo acts as a s c a v e n -

exp(4.97 - 4490/T) [5]

g e r of P and l o w e r s the mobile P concentration so

X~

much that the ,large LxGp is m o r e than offset by the 1 + [exp 5 5 3 6 / T - - 1]Xffr 3

reduction in X ~ . The c l a s s i c example of this b e h a v i o r

in s t e e l s is, of c o u r s e , the Mn + S r e a c t i o n . B

Since the Mo does not scavenge all of the P, one If we take the m e a s u r e d v a l u e s of XMo for the v a r i o u s

would expect to see some c o s e g r e g a t i o n of Mo and Cr a s - t e m p e r e d conditions and calculate X~, we can plot

with the r e m a i n i n g P. This is supported by Fig. 17 these on c a l c u l a t e d c u r v e s of X~ and XB at v a r i o u s

IYlO

which shows that both the Cr and Mo Anger peak t e m p e r a t u r e s (usingEq. [5]) as shown ifi F i g . 19. It

heights i n c r e a s e with the P peak height. Since n e i t h e r can be seen that this calculation is consistent with

Cr nor Mo a r e surface active in Fe to any a p p r e c i a b l e the e x p e r i m e n t a l r e s u l t s ; X~ in the H condition

extent, this behavior indicates c o s e g r e g a t i o n . It is not is r e d u c e d significantly below the bulk concen-

p o s s i b l e to say how much Mo and Cr have c o s e g r e - t r a t i o n in the alloy. (This a n a l y s i s gives only a p p r o x i -

gated, b e c a u s e p a r t of the signal f r o m the i n t e r g r a n u - mations because of the v a r i o u s s i m p l i f i c a t i o n s made.)

l a r f a c e t s came f r o m g r a i n boundary c a r b i d e s . The a s - t e m p e r e d values of X~ obtained above can

The i n t e r p r e t a t i o n of the effects of Cr and Mo is be i n s e r t e d into Eq. [1] and e s t i m a t e s of the other

aided by the m e t a l l o g r a p h i c r e s u l t s of Kaneko et a139 p a r a m e t e r s can be made to calculate X~ for the e a r l y

on the effects of v a r i o u s alloy e l e m e n t s on the solu- stage of segregation at 520~ When this was done, ~8

b i l i t y of P in F e , r e p r o d u c e d in F i g . 18. They have the range of X~ v a l u e s for the t h r e e h a r d n e s s condi-

shown that Mo i n t e r a c t s much more strongly with P tions was found to be 0.54 to 0.57, which is obviously

in Fe than does Cr. T h e i r r e s u l t s a r e consistent with too s m a l l to explain the d i f f e r e n c e s found here in the

the p r e c i p i t a t i o n of some kind of Mo phosphide. It e m b r i t t l e m e n t behavior

~k (see F i g . 4(a)). In addition,

should be noted that Nb, Ti, and Zr should be even a calculation of X ~ vs t e m p e r a t u r e indicated that the

more potent P s c a v e n g e r s than Mo. The scavenging steep t e m p e r a t u r e dependence of X~p would occur above

of P by Ti was indicated by e a r l i e r work of Ohtani 800~ However, in the p r e s e n t r e s u l t s this o c c u r s b e -

2 8 6 - V O L U M E 11A, FEBRUARY 1980 METALLURGICAL TRANSACTIONS A

I / T xlO-* t h i s was found in the effect of T i in a low C N i C r s t e e l

10.07 8 9 I0 II 12 doped with Sb. ~ The s t e e l was c o m p a r e d with and

a I I ~ ' f

8.0 without a T i addition and in the f o r m e r it was found

6,0 1 that some T i had c o s e g r e g a t e d with the Sb, d i s p l a c i n g

~ ~. ~-Fe-P Binary system s o m e of the Ni which n o r m a l l y c o s e g r e g a t e s with Sb.

4,0

F u r t h e r m o r e , the i n c r e a s e in t r a n s i t i o n t e m p e r a t u r e

for a given a m o u n t of s e g r e g a t e d Sb was c o n s i d e r a b l y

~I 2.0

t5 s m a l l e r in the s t e e l c o n t a i n i n g the s e g r e g a t e d T i .

08 C l e a r l y , the s u b s t i t u t i o n of T i for Ni in the g r a i n

.s I,O 06

0.8

b o u n d a r y made the Sb m u c h l e s s e m b r i t t l i n g .

04 An analogous effect of Mo on P has b e e n r e p o r t e d

= 0.6

o

by D u m o u l i n and G u t t m a u n47 b a s e d on a study of CrMo

,= 0.4 s t e e l s of c o m p o s i t i o n s d i f f e r e n t f r o m the ones studied

u)

0.2

o h e r e . Since t h i s would be a n a d d i t i o n a l b e n e f i c i a l ef-

0.2 Q_ fect of Mo to go along with the s c a v e n g i n g effect found

h e r e , we a t t e m p t e d to d e t e r m i n e whether or not it oc-

0,1 c u r r e d in our s t e e l s . The data f r o m the Wada and

~, 0.08 ,_~ , N j ~---~"'_, 0,04 Hagel s p e c i m e n s a r e s u m m a r i z e d in F i g . 20, and it

:.: 0.06 can be s e e n that the change in t r a n s i t i o n t e m p e r a t u r e

~ 0,04

_\ ,- p e r unit P s e g r e g a t i o n is not influenced by the c o n -

o ~r ~Nb ~\ \ " 0,02 c e n t r a t i o n of d i s s o l v e d Mo. We do not have data for

s e g r e g a t e d Mo b e c a u s e of the p r o b l e m of s e p a r a t i n g

0.02

I100 I000 900 800 700 600 500 the A u g e r s i g n a l f r o m s e g r e g a t e d Mo f r o m that due

Temperature (%) to i n t e r g r a n u i a r c a r b i d e s . However, s i n c e the d i s -

(a) solved Mo r e m a i n s e s s e n t i a l l y c o n s t a n t in the r a n g e

of t o t a l Mo b e t w e e n 0.7 and 1.3 pet, and s i n c e the s e g -

r e g a t e d P l e v e l in this r a n g e i n c r e a s e s , one would e x -

pect that the s e g r e g a t e d Mo c o n c e n t r a t i o n would not

fall to z e r o in this r a n g e . Yet the P potency h e r e a p -

p e a r s to be the s a m e a s in the Mo f r e e s t e e l . Since

the p r e s e n c e of c o s e g r e g a t e d C r m a y d i s t o r t this p i c -

t u r e c o n s i d e r a b l y , we can only say at p r e s e n t that we

' ' ' 1,o have yet to find e v i d e n c e to support a n effect of Mo on

the potency of P . However, on p h y s i c a l g r o u n d s ~ such

a n effect could be a n t i c i p a t e d .

F i n a l l y , the effect of p r i o r heat t r e a t m e n t on s u b -

s e q u e n t t e m p e r e m b r i t t l e m e n t can be d e m o n s t r a t e d

-oz_ , k ' ' ' ' A

o

Alloying

Element (wt %)

(b) z iO-i L

n

Fig. 18-Results of Kaneko e t al, 39 showingeffects of various alloying

elements on the solubility of P in e-Fe: (a) as a functmn of tempera-

ture for 1 pct alloying addition and (b) at 1000~

0-2

tween 400 and 600~ which, of c o u r s e , a l l s t u d i e s of _n I - c-

t e m p e r e m b r i t t l e m e n t show. It a p p e a r s that t h e r e is

d

n e e d for b e t t e r t h e r m o d y n a m i c data for the r e l e v a n t o

s o l u t e s in F e b a s e d a l l o y s b e f o r e we can b e g i n to be

q u a n t i t a t i v e in c a l c u l a t i o n s of e q u i l i b r i u m s e g r e g a t i o n a io -3

W

l e v e l s . F u r t h e r m o r e , the p r e s e n t a n a l y s i s a s s u m e s <~ 520-C

that F e , P, and Mo a r e s u b s t i t u t i o n a l ; that is, that .-I

they c o m p e t e for a fixed n u m b e r of g r a i n b o u n d a r y s

_1

s i t e s . T h i s m a y not be the e a s e , and a m o r e e l a b o r a t e < I I I L

model may be called for .45 0 0.25 0.5 0.75 1.0 25

W h e n e v e r one finds e o s e g r e g a t i o n of a m e t a l l o i d DISSOLVED M o ( w t % )

and a m e t a n i e alloy e l e m e n t in a s t e e l t h e r e is the

Fig. 19-Calculated solid solubdity of P m a Fe-Mo-P alloy at the

p o s s i b i l i t y that the e m b r i t t l i n g potency of the m e t a l - tempering and aging temperatures used for the P steel, as a function

loid e l e m e n t will be a l t e r e d . A d r a m a t i c e x a m p l e of of the No concentration in the ferrite.

METALLURGICALTRANSACTIONSA VOLUME llA, FEBRUARY 1980-287

I I if the 1a activity is high enough, r e m o v a l of Mo f r o m

solution by c a r b i d e f o r m a t i o n can offset a v e r y l a r g e

softening effect.

o.. I00 It should be noted that a p p a r e n t l y anomalous effects

~0~0/

/ 0 " - ' - ' 0 -

of h a r d n e s s on the kinetics and d e g r e e of t e m p e r e m -

b r i t t l e m e n t of other Mo containing s t e e l s , n a m e l y

-r 0

12. NiCrMoV and CrMoV r o t o r s t e e l s , have been o b s e r v e d

0

b e f o r e . 48,49 These effects a r e g e n e r a l l y consistent

f~

with the p r e s e n t r e s u l t s , and t h e r e f o r e we b e l i e v e that

u_ I0 they can be i n t e r p r e t e d b e s t not in t e r m s of h a r d n e s s

rE, --0

--r __ or m i c r o s t r u c t u r e alone, but by a l s o taking into account

the concentrations of Mo and Cr in the f e r r i f e ~hase.

This point was a l s o alluded to by Viswanathaa. 8

0

SUMMARY

It has been shown that t e m p e r e m b r i t t l e m e n t of

CrMo s t e e l s by P can be influenced significantly by

0 O..."~'G 0 O ~

the concentrations of Mo and Cr in solution in the f e r -

j r i t e phase and that these concentrations change as a

t~ 0.5 r e s u l t of the f o r m a t i o n of v a r i o u s c a r b i d e s and thus

u.J

they depend on the t h e r m a l h i s t o r y of this s t e e l . Tin

o~

at concentrations up to 0.04 pet was found not to e m -

I I b r i t t l e an otherwise pure 2.25 C r - 1 Mo s t e e l . It was

0.6 1.2 a l s o shown that, although scavenging of P continues

to i n c r e a s e at concentrations of dissolved Mo of at

TOTAL Mo CONTENT ( w t % ) l e a s t 1 pet, i n c r e a s e s in total Mo content above 0.7

Fig. 20-Transition temperature, P~2o/FeT03 PHR, transition tempera-

ture shift per umt intergranular P concentratmn, and Mo concentratmn pet a r e actually l e s s d e s i r a b l e under n o r m a l conditions

m ferrite as a function of the total Mo content for 2 88 Cr steels. of heat t r e a t m e n t , b e c a u s e at higher total Mo contents

by an e x p e r i m e n t c a r r i e d out with s a m p l e s of the

9 0.o4 P

s t e e l s doped with 0.02 and 0.04 pet P and with 0.04

pet Sn. Since Sn is innocuous in this s t e e l , the Sn 9 0,02 P

9 0 04 Sn

doped s t e e l can be c o n s i d e r e d equivalent to an undoped n- ,~o , JI I I , ,

heat with the r e s i d u a l 0.002 pet P.* The s a m p l e s were

b.l

l.- 0 ~ ~

*However, it is not unhkely that the presence of the Sn would raise the

acUvity of this P, assumingSn to act hke Si (See Part II).

z

a u s t e n i t i z e d for 2 h at 1170~ t e m p e r e d for v a r i o u s n,-

-50

I.-

t i m e s at 650~ and e m b r i t t l e d by the common s t e p -

cooling t r e a t m e n t 29 As seen in F i g . 21(b), a l l t h r e e

s t e e l s softened with time at 650~ this in i t s e l f should -I00 I L I ,

lead to a reduction in t r a n s i t i o n t e m p e r a t u r e , a s is

found for the 0.02 P and the 0.04 Sn s a m p l e s . However, 350 (b) l 1 I I ,

A

the 0.04 P s a m p l e exhibits a maximum in e m b r i t t l e -

ment s u s c e p t i b i l i t y for a t e m p e r i n g t i m e of 10 h at

300

650~ According to the Baker and Nutting data

(Fig. 1) the 10 h t e m p e r i n g introduces the maximum - _-

amount of M2C, and the c a r b i d e is r e p l a c e d by M7C3 250

with f u r t h e r t e m p e r i n g . X - r a y a n a l y s i s of the above

s a m p l e s showed that the types of c a r b i d e p r e s e n t

were: I I I I

Tempering Time Carbide Type

rr

20 min MsC

"I-

Q.

20 t

1 h MsC

I0 h M2C + MvC~

IO

20 h M2C + M7C3 MOSTLY

O

CLEAVAGE

I

Thus, in the s t e e l containing 0.04 P the e m b r i t t l e m e n t t~ ia"

" "I I I I

in the s a m p l e t e m p e r e d for 10 H is g r e a t e r than the 0 I0 20

e m b r i t t l e m e n t in the h a r d e r (20 min and 1 h) s a m p l e s

TEMPERING TIME AT 6 5 0 * C ( h )

because of the r e m o v a l of Mo f r o m its P scavenging

Fig. 21-Variation with tempering time of the 4 ft-lb (5.4 J) transition

r o l e due to M2C f o r m a t i o n . T e m p e r i n g for 20 h p r o - temperature, hardness, and P12o/FeTo3 Auger peak height ratio from

duces even f u r t h e r softening, which finally s u c c e e d s - 1 0 0 ~ fracture surface of the step-cooled 0.04 P, 0.02 P, and 0.04

in reducing the e m b r i t t l e m e n t level somewhat. Thus, Sn steels.

288-VOLUME 11A, FEBRUARY 1980 METALLURGICAL TRANSACTIONS A

the dissolved Mo content remains constant and the dis- 10. M. L. Wayman, P. Dumoulin, and M. Guttraann" Can. Metall. Quart., 1978,

solved Cr content increases. vol. 18, p. 632.

I I. B. J. Schulz and C. J. McMahon, Jr.. ASTM STP 499, p. 104, 1972.

These results have a number of implications which

12. G. A. Dreyer, D. C. Austen, and W. D. Smith: Met. Progr., 1964, vol. 86, p.

should be recognized by users of steels containing Mo. ]16.

First, studies of temper embrittlement which do not 13. B. S. Lement, B. L. Averbach, and M. Cohen: Trans. ASM, 1954, vol. 46,

take account of the variations in dissolved Mo (and p. 851.

Cr) due to variations in thermal history are liable to 14. W. Koch and H. Sundermann: J. Iron SteelInst.. 1958, vol. 190, p. 373.

15. R. W. Gurry, J. Christakso, and C. D. Stricker: Trans. ASM, 1957, vol. 50,

be misinterpreted. Secondly, if steels containing 1

p. 105.

pct Mo are to be used in situations where temper em- 16. K. W. Andrews and H. Hughes: ASTM STP 393, p. 3, 1966.

brittlement is possible, then the heat treatment (and 17. D. J. Dyson and K. W. Andrews" J. Iron SteeIInst., 1969, vol. 207, p. 208.

perhaps the carbon content) should be altered so as 18. T. M. F. Ronald and C. Bodsworth: J. Iron SteelInst., 1965, vol. 203, p. 252.

to prevent formation of M2C at the expense of M7C3. 19. D. J. Dyson and K. W. Andrews: Z Iron SteelInst., 1964, vol. 202, p. 325.

20. R. Stockdale and R. Binns: Private communication, Climax Molybdenum Co.,

Finally, efforts should be made to improve the r e s i s - Ann Arbor, Mich., 1977.

tance of this class of steels to temper embrittlement 21. ASTM Standards: ChemicalAnalysls of Metals; Sampling and Analysis of

by basic changes in the alloy content and heat treat- MetalBearing Ores, Part 32, ASTM, Phila., PA, 1969.

ment. The guiding principle should be to maximize 22. R. G. Baker and J. Nutting: J. Iron Steellnst., 1959, vol. 192, p. 257.

the concentration of dissolved Mo (or other effective 23. J. Yu and C. J. McMahon, Jr.: Met. Tran~ A, 1980, vol. 11A, p. 291.

24. R. A. Mulford, C. J. McMahon, Jr., D. P. Pope, and H. C. Feng: Met. Trans. A,

P scavengers, such as Nb) and to avoid precipitation

1976, vol. 7A, p. I 183.

of Mo in carbides. Since Cr enhances P segregation 25. R. Bmscato: Weld. J., 1970, vol. 49, p. 148.

and is not an effective P scavenger (at least at the 26. J. Watanabe, Y. Shindo, Y. Murakami, T. Adachi, and S. Ajiki: Presented at

concentrations examined here), increases in Cr should 29th ASME Meeting, 1974.

be made with caution. 27. J. E. Bridge, Jr., G. N. Maniar, and T. U. Phillips: Met. Trans., 1971, vol. 2,

p. 2209.

28. H. Morikawa, H. Komatsu, and M. Tanino: J. Electron Mtcrosc., 1973, vol. 22,

ACKNOWLEDGMENTS p. 99.

29. J. R. Low, Jr., D. F. Stein, A. M. Turkalo, and R. P. Laforce: Trans. TMS-AIME,

This paper is based on work supported by the 1968, vol. 242, p. 14.

National Science Foundation, MRL PrOgram, under 30. C. J. McMahon, Jr.: ASTM STP 407, p. 127, 1968.

Grant No. DMR76-80994. In its initial phase support 31. J. M. Capus: J. Iron Steellnst., 1962, vol. 200, p. 922.

32. S. Takayama, T. Ogura, S. C. Fu, and C. J. McMahon, Jr.: Unpublished re-

was also received from the Commonwealth of Penn- search, Univ. of Penn., Phila., PA, 1979.

sylvania Science and Engineering Foundation. We are 33. A. K. Cianelli, H. C. Feng, A. H. Ucisik, andC. J. McMahon, Jr.: Met. Trans.A,

particularly grateful to Drs. T. Wada and W. C. Hagel 1977, voL 8A, p. 1059.

of the Climax Molybdenum Co. for providing us with 34. T. Wada: Unpublished research, Climax Molybdenum Co., Ann Arbor, MI,

specimens from their research and for helpful dis- 1972_

35. B. J. Schulz: Ph.D. Thesis, Univ. of Pennsylvania, Phila., PA, 1973.

cussions. R. Stockdale, D. Schumacher, and R. Binns 36. J. Murza and C. J. McMahon, Jr.: Unpublished research, Univ. of Pennsylvania,

of the Climax Molybdenum Co. performed the chemical Phila., PA, 1979.

analysis of the electrolytes for Cr and Fe and some 37. M. Guttmann: Surf. Sci., 1975, vol. 53, p. 213.

of the analyses for Mo. At Pennsylvania Christine 38. J. Yu: Ph.D. Thesis, University of Pennsylvania, Phila., PA, 1979.

39. H. Kaneko, T. Nishizawa, T. Tamaki, and A. Tanifuji: J. Jpn Inst. Met., 1965,

McMahon carried out some of the Mo analyses and

voL 29, p. 166.

the centrifuge separations. M s s r s . Shin-Cheng Fu and 40. H. Ohtani, H. C. Feng, and C. J. McMahon, Jr.: Met. Tran~, 1974, vol. 5, p.

H. Katz were of great assistance with the Auger and 516.

X - r a y analyses, respectively. 41. W. R. Graham and A. C. Yen: Met. Tran~ A, 1978, vol. 9A, p. 1461.

42. R. DiDio and W. R. Graham: Unpublished research, Univ. of Penn., Phila.,

PA, 1979.

REFERENCES 43. M. Guttmann: Met. Sct., 1976, vol. 10, p. 337.

44. M. Hillert: Phase Transformations, p. 181, ASM, Metals Park, OH, 1970.

1. R. H. Greaves and J. A. Jones: J. Iron Steel Inst., 1925, vol. 111, p. 231. 45. M. Guttmann and D. McLean: InterfacialSegregation, p. 261, ASM, Metals

2. H. Jolivet and G. Vidal: Rev. Met., 1944, vol. 41, p. 378. Park, OH, 1978.

3. G. Vidal: Rev. Met., 1945, vol. 42, p. 149. 46. H. Ohtani, H. C. Feng, and C. J. McMahon, Jr.: Met. Trans. A, 1976, vol. 7A,

4. C. J. McMahon, Jr., A. K. Cianelli, and H. C. Feng: Met. Tran~ A, 1977, vol. p. 1123.

8A, p. 1055. 47. Ph. Dumoulin, M. Foucault, M. Palmier, M. Wayman, M. Biscondi, and M.

5. A. E. Powers:Trans.ASM, 1956, vol. 48, p. 149. Guttmann: Mem. Sci. Rev. Met., 1979, vol. 76, p. 187.

6. A. E. Powers: s Iron Steellnst., 1957, vo[ 186, p. 323. 48. IL Viswanathan: Int. Symposium on Optimization of Processing, Properties

7. T. Wada and W. C. Hagel: Met. Trans. A, 1976, vol. 7A, p. 1419. and Service Performance Through Microstructural Control (MICON), Westing-

8. P. L Gruzin and V. V. Minal Fiz. Met. Metalloved., 1964, vol. 17, p. 62. house R & D Center Rept~ 78-102-GRABO-P1, Houston, April, 1978.

9. M. P. Scab: ActaMet., 1977, vol. 25, p. 345. 49. IL Viswanathan and A. Joshi: Met. Trans. A, I975, vol. 6A, p. 2289.

METALLURGICAL TRANSACTIONS A V O L U M E I1A, F E B R U A R Y 1 9 8 0 - 2 8 9

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)