Professional Documents

Culture Documents

UK2121if 10048

Uploaded by

Joaquim ReisOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

UK2121if 10048

Uploaded by

Joaquim ReisCopyright:

Available Formats

Belzona 2121

FN10048 (D & A HI-COAT ELASTOMER)

INSTRUCTIONS FOR USE

1. TO ENSURE AN EFFECTIVE MOLECULAR Conditioner Touch Dry Max. Overcoating

WELD

Belzona 2911 30 min. 4 hours

a) SURFACE PREPARATION Belzona 2921 2 hours 8 hours

(i) Metallic Surfaces

Remove all loose surface contamination and degrease with Under no circumstances should application of Belzona

Belzona 9111 (Cleaner/Degreaser) or any other effective 2121 take place after the maximum overcoating time.

cleaner which does not leave a residue e.g. methyl ethyl

ketone (MEK). NOTE: Belzona 2911 has an 18 month shelf life from date of

manufacture when stored at 41 - 77F (5 - 25C) and must be

Grit blast to a minimum 3 mil (75 microns) profile. Where used before the stated use-by date.

blasting is not practical, thorough mechanical grinding may

be considered, except for applications involving tensile When using Belzona 2121 to overcoat a surface which has

loads, immersion and / or fluid flow. been treated with a Belzona 1000 Series product (except

Belzona 1221 (Super E-Metal)), the Belzona 1000 Series

(ii) Flexible Surfaces (e.g. rubbers) product must first be allowed to fully cure, the surface prepared

NOTE: Belzona 9111 can draw processing oils and waxes as outlined in section 1 (a) (i), and Belzona 2911 or Belzona

to the surface of some rubbers, particularly when new, 2921 applied as outlined in section 1 (b).

which then impairs adhesion of Belzona 2121. Test for this

on a small area. If, on rubbing with a rag moistened with Application of Belzona 2121 over Belzona 1221 can be

Belzona 9111, a greasy film appears, the surface should carried out up to 4 hours after the application of Belzona 1221

not be degreased, but simply abraded. without the need of any surface treatment other than removal of

contamination. When overcoating Belzona 1221 after this time,

Undercut fine edges with a sharp knife and scuff the surface the surface should be abraded, followed by conditioning as in

with a rotary wire brush or suitable roughing tool. Section 1(b).

Brush away loose contamination and degrease again with WHERE BELZONA 2121 SHOULD NOT ADHERE

Belzona 9111. Brush on Belzona 9411 (Release Agent) and allow to dry for

15 - 20 minutes before proceeding to step 2.

b) CONDITIONING

Immediately, apply a thin, even coat of Belzona 2911 2. COMBINING THE REACTIVE

(Elastomer QD Conditioner) or Belzona 2921 (Elastomer

GP Conditioner) onto the surface. A brush should be used COMPONENTS

as a stipple to ensure a practical coverage rate of 13 sq.ft.

(1.25 m) per unit, on steel and most metallic substrates. On Both Base and Solidifier components must remain sealed

well roughened rubber substrates this could be reduced by until the application stage.

as much as 50%.

a) Transfer the entire contents of both Base and Solidifier

The Belzona Conditioner must be touch dry before containers into the mixing bowl.

overcoating with Belzona 2121. This will depend on the

Belzona Conditioner selected, prevailing temperature, b) Immediately mix together for at least two minutes and use

relative humidity and substrate. At 68F (20C) and 50% all material within the times shown in the table below:-

relative humidity, the touch dry state will be achieved after

the times given when applied to a steel surface. These Temperature 41F 59F 77F 86F

(5C) (15C) (25C) (30C)

times may be extended when applied to rubber substrates.

Use all material within 25 min 20 min 10 min 6 min

VOLUME CAPACITY OF MIXED BELZONA 2121

27.95 cu.in. (458 cm) per 500g unit.

www.belzona.com Publication No. 45-03-11

3. APPLYING BELZONA 2121 4. COMPLETION OF THE MOLECULAR

REACTION

FOR BEST RESULTS

Do not apply when:-

Allow Belzona 2121 to solidify as below before subjecting it to

i) The temperature is below 41F (5C) or the relative humidity the conditions indicated:

is above 90%.

ii) Rain, snow, fog or mist is present. Movement or Full mechanical Immersion in

iii) There is moisture on the surface or is likely to be deposited use involving or thermal or chemicals

by subsequent condensation. no loading immersion loading

iv) The working environment is likely to be contaminated by 41F/ 5C 6 hours 3 days 5 days

oil/grease from adjacent equipment or smoke from 50F/10C 4 hours 2 days 3 days

kerosene heaters or tobacco smoking. 59F/15C 3 hours 2 days 3 days

68F/20C 2 hours 1 day 2 days

a)

Apply the Belzona 2121 to the conditioned surface with a 77F/25C 1 hours 1 day 2 days

86F/30C 1 hour 1 day 1 days

stiff bristled brush or the plastic applicator provided, to give

a coverage rate of 9.8 sq.ft. (0.91 m) at 20 mil (500

microns) thickness. 5. STORAGE

b) Apply a second coat of Belzona 2121 as above following Store in a dry environment between 41F (5C) and 77F (25C).

the overcoating instructions in Section 6.

Inadvertent storage of Belzona 2100 Base below 41F (5C)

NOTES: may result in partial solidification. If this occurs, the material can

1. DIFFERENTIATION BETWEEN LAYERS be restored to its normal form by resealing the container and

Belzona 2121 is available in red and black, to facilitate warming to between 104F (40C) and 122F (50C) for 3 hours

application and to prevent misses. In service the colour of the in a well ventilated, dry area.

applied product may change.

6. OVERCOATING

2. CLEANING

Mixing tools should be cleaned immediately after use with Application of subsequent layers of Belzona 2121 can be

Belzona 9111 or any other effective solvent e.g. MEK. carried out up to 3 days after the previous application without

Brushes, injection guns and other application tools should be need of any surface treatment other than removal of

cleaned using a suitable solvent such as Belzona 9121, MEK, contamination.

acetone or cellulose thinners.

Overcoating of aged or weathered Belzona 2121 is possible at

any time after initial application, provide that the surface

preparation techniques for flexible surfaces described in

Section 1 are employed.

HEALTH & SAFETY INFORMATION

Please read and make sure you understand the relevant Material Safety Data Sheets.

The technical data contained herein is based on the results of long term tests carried out in our laboratories and to the best of our knowledge is ISO 9001:2008

true and accurate on the date of publication. It is however subject to change without prior notice and the user should contact Belzona to verify Q 09335

the technical data is correct before specifying or ordering. No guarantee of accuracy is given or implied. We assume no responsibility for rates of ISO 14001:2004

coverage, performance or injury resulting from use. Liability, if any, is limited to the replacement of products. No other warranty or guarantee of EMS 509612

any kind is made by Belzona, express or implied, whether statutory, by operation of law or otherwise, including merchantability or fitness for a Manufactured under an ISO 9000

particular purpose. Registered Quality Management System

Nothing in the foregoing statement shall exclude or limit any liability of Belzona to the extent such liability cannot by law be excluded or limited.

Copyright 2011 Belzona International Limited. Belzona is a registered trademark. Belzona is a registered trademark

Belzona 2121 - Instructions for Use - (2) Printed in England Publication No. 45-03-11

You might also like

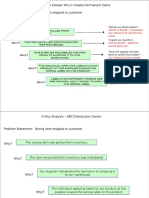

- 4 Steps To VSMDocument12 pages4 Steps To VSMJaqui MartinezNo ratings yet

- Acupuntura Aplicada A Patologias PDFDocument43 pagesAcupuntura Aplicada A Patologias PDF12ab34cd8969No ratings yet

- How To Implement Total Productive MaintenanceDocument44 pagesHow To Implement Total Productive MaintenanceJoaquim ReisNo ratings yet

- 5W Lean Maintenance PDFDocument1 page5W Lean Maintenance PDFJoaquim ReisNo ratings yet

- Belgian Pale Ale PDFDocument1 pageBelgian Pale Ale PDFJoaquim ReisNo ratings yet

- BP Business Plan Financial Tables Jun14Document7 pagesBP Business Plan Financial Tables Jun14ocalmaviliNo ratings yet

- Weibull Analysis ExcelDocument2 pagesWeibull Analysis ExcelJoaquim ReisNo ratings yet

- 02 - Heat ExchangersDocument88 pages02 - Heat ExchangersDana GuerreroNo ratings yet

- Dust Collection Technical HandbookDocument106 pagesDust Collection Technical HandbookcassindromeNo ratings yet

- Facts Concerning Dust Air PDFDocument18 pagesFacts Concerning Dust Air PDFJoaquim ReisNo ratings yet

- Black IPA PDFDocument1 pageBlack IPA PDFJoaquim ReisNo ratings yet

- Preview: 30 Shipping Container Homes (120 Page Ebook)Document120 pagesPreview: 30 Shipping Container Homes (120 Page Ebook)ElJay Arem100% (12)

- Reiki Master SecretsDocument96 pagesReiki Master SecretsJoaquim Reis100% (3)

- Facts Concerning Dust Air PDFDocument18 pagesFacts Concerning Dust Air PDFJoaquim ReisNo ratings yet

- 7 WastesDocument15 pages7 WastesJoaquim ReisNo ratings yet

- Dust Collection Technical HandbookDocument106 pagesDust Collection Technical HandbookcassindromeNo ratings yet

- 2 Reiki Master SecretsDocument95 pages2 Reiki Master SecretsJoão Pereira100% (41)

- ANOVA and experimental design analysis in agricultureDocument3 pagesANOVA and experimental design analysis in agricultureJoaquim ReisNo ratings yet

- Quik House BookletDocument14 pagesQuik House BookletnextSTL.com100% (1)

- How To Build A Shipping Container HouseDocument37 pagesHow To Build A Shipping Container Housegschiro93% (14)

- 2 Reiki Master SecretsDocument95 pages2 Reiki Master SecretsJoão Pereira100% (41)

- Build A Container Home Full PDF Book by Warren ThatcherDocument57 pagesBuild A Container Home Full PDF Book by Warren Thatcherwilbur_6979% (43)

- Anderson-Darling Normality Test CalculatorDocument6 pagesAnderson-Darling Normality Test Calculatordelmanto88No ratings yet

- KTH Conference Stockholm Keynote 21 October 2016 Final Greg WatsonDocument51 pagesKTH Conference Stockholm Keynote 21 October 2016 Final Greg WatsonJoaquim ReisNo ratings yet

- 5 WhyDocument4 pages5 WhyJoaquim ReisNo ratings yet

- 3Cs Principle Document Lean ModelDocument9 pages3Cs Principle Document Lean ModelJoaquim ReisNo ratings yet

- 3.2.3 Template - Project Schedule, V 1.0Document6 pages3.2.3 Template - Project Schedule, V 1.0k_jyothiNo ratings yet

- 2.01 Project Charter TemplateDocument5 pages2.01 Project Charter TemplateFrancisco HernandezNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5784)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- 2nd - Science-Second-Quarter-Week-1Document37 pages2nd - Science-Second-Quarter-Week-1Arlene AranzasoNo ratings yet

- Pre Test and Post TestDocument27 pagesPre Test and Post TestMATALANG GRACENo ratings yet

- Life Below WaterDocument10 pagesLife Below Watertrisha sobito0% (1)

- Collab#2 (Edited)Document14 pagesCollab#2 (Edited)Yani BatoctoyNo ratings yet

- KTS - Sarao.bakus Temple of Eternal FiireDocument176 pagesKTS - Sarao.bakus Temple of Eternal FiireK.T.S. SaraoNo ratings yet

- General Psychology - Unit 2Document23 pagesGeneral Psychology - Unit 2shivapriya ananthanarayananNo ratings yet

- ASSEMBLING COMPUTER: HOW TO BUILD A PCDocument48 pagesASSEMBLING COMPUTER: HOW TO BUILD A PCCeejaay PelinaNo ratings yet

- NNDC Planning Applications 4oct - 11 OctDocument4 pagesNNDC Planning Applications 4oct - 11 OctRichard SmithNo ratings yet

- Instrument To Be CalibratedDocument3 pagesInstrument To Be Calibratedsumit chauhanNo ratings yet

- Baby NamesDocument9 pagesBaby Namesppremamca_617705407No ratings yet

- Chapter 5 Coordinate GeometryDocument33 pagesChapter 5 Coordinate GeometryKalNo ratings yet

- Tiger 690 Conversion PDFDocument8 pagesTiger 690 Conversion PDFGerardo Esteban Lagos RojasNo ratings yet

- JMJ Marist Brothers Notre Dame of Marbel University Integrated Basic Education Department City of Koronadal, South CotabatoDocument13 pagesJMJ Marist Brothers Notre Dame of Marbel University Integrated Basic Education Department City of Koronadal, South CotabatoNestor Gerotape DiosanaNo ratings yet

- 3.1-T.C.Dies PDFDocument6 pages3.1-T.C.Dies PDFYahyaMoummouNo ratings yet

- Kathleen Langreo Notes FB (Feb6)Document27 pagesKathleen Langreo Notes FB (Feb6)Kaycee Ayo100% (4)

- Journal of Alloys and Compounds: Wei Li, Zhijun Xu, Ruiqing Chu, Peng Fu, Guozhong ZangDocument4 pagesJournal of Alloys and Compounds: Wei Li, Zhijun Xu, Ruiqing Chu, Peng Fu, Guozhong ZangSamah SamahNo ratings yet

- CIVL-365 Tutorial 8 SolutionDocument3 pagesCIVL-365 Tutorial 8 SolutionIvsNo ratings yet

- ABYIPDocument18 pagesABYIP千住 マリエルNo ratings yet

- Medication - Safety - v4 Last Update 2015Document81 pagesMedication - Safety - v4 Last Update 2015Retno PalupiNo ratings yet

- 2 History of OrthodonticsDocument11 pages2 History of OrthodonticsMeiz JaleelNo ratings yet

- Common Sense Mechanics 9Document9 pagesCommon Sense Mechanics 9Vikas VatsNo ratings yet

- Analytical Mechanics SolutionsDocument193 pagesAnalytical Mechanics SolutionsQuinton Boltin67% (9)

- Jurnal Risna YantiDocument14 pagesJurnal Risna YantiRisnayantiNo ratings yet

- BiodiversityDocument9 pagesBiodiversityVienica Dauz Mico Balbin100% (1)

- Procedure - AC Circuits and Signal Modulation - W20Document6 pagesProcedure - AC Circuits and Signal Modulation - W20ChocoNo ratings yet

- 3.1 From Algae To Terrestrial Plants-Student SheetDocument2 pages3.1 From Algae To Terrestrial Plants-Student Sheeteshaaljamal27No ratings yet

- Data Sheet ID FanDocument5 pagesData Sheet ID FanrudiawanNo ratings yet

- Hart Fuller Debate: Hart Fuller Debate Is One of The Most Interesting Academic Debates of All Times That Took Place inDocument1 pageHart Fuller Debate: Hart Fuller Debate Is One of The Most Interesting Academic Debates of All Times That Took Place inAmishaNo ratings yet

- PDPM Iiitdm Jabalpur: LASER Beam Machining AdvancementsDocument12 pagesPDPM Iiitdm Jabalpur: LASER Beam Machining AdvancementsDeva RajNo ratings yet

- PRN Maths Midterm QP Aug 18Document3 pagesPRN Maths Midterm QP Aug 18JanakChandPNo ratings yet