Professional Documents

Culture Documents

Assignment

Uploaded by

Ajwad HaziqCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Assignment

Uploaded by

Ajwad HaziqCopyright:

Available Formats

Assignment Management and Professional Ethics (BNJ 30502) (Date line: 18

December 2016)

1. What is technovation? Explain the process of technovation. (10 marks)

Technovation also known as technical innovation means developing new

ideas, products, services, and processes which exploit technology. It may be

driven by a new technology (How can we use this?) or by needs (What

technology might we apply to improve this?). The process of technovation is

firstly, it tries to manage broad market uncertainties with tools such as

market analyses and business plans and by prioritizing the ideas and plans

that are most likely to be successful. Second, this process attempts to

manage technological uncertainties during the conversion phase, in which

the company can utilize tools such as concurrent engineering, project

management techniques, consultants, universities, and technological centers

to aid development and to mitigate uncertainties. The final stage, which is

defined by launch, diffusion or sales (depending on the author), is not well

developed in the literature.

(http://www.answers.com/Q/What_is_the_meaning_of_technovation?#slide=7)

(http://sistemas-producao.net/lgi/wp-content/uploads/2015/11/Inovation-

process.pdf)

2. Differentiate the term inventions and Innovation. Give simple example of

each term. (20 marks)

Invention can be defined as the creation of a product or introduction of a

process for the first time. Innovation on the other hand, occurs if someone

improves on or makes a significant contribution to an existing product,

process or service. Example of invention when someone created a computer

and innovation is when a company comes up with a creative new product

such as a new tablet computer.

(http://www.yourdictionary.com/innovation#IBBO5fgddSLiBri9.99)

(http://www.yourdictionary.com/invention#ty136CUg8lTJqcRR.99)

(http://mediashift.org/2012/03/the-difference-between-invention-and-

innovation086/)

3. Explain the term world class manufacturing? (10 marks)

World class manufacturing is a collection of concepts, which set standard for

production and manufacturing for another organization to follow. World class

manufacturers tend to implement best practices and also invent new

practices as to stay above the rest in the manufacturing sector. The main

parameters which determine world-class manufacturers are quality, cost

effective, flexibility and innovation. There are three main principles, which

drive world-class manufacturing. Firstly, Implementation of just in time and

lean management leads to reduction in wastage thereby reduction in cost.

Secondly, Implementation of total quality management leads to reduction of

defects and encourages zero tolerance towards defects. Lastly,

Implementation of total preventive maintenance leads to any stoppage of

production through mechanical failure.

(http://www.managementstudyguide.com/world-class-manufacturing.htm)

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Honey Comb Is Delicious.Document6 pagesHoney Comb Is Delicious.Ajwad HaziqNo ratings yet

- 3.2 Finite Element Modelling and Simulation in Metal FormingDocument1 page3.2 Finite Element Modelling and Simulation in Metal FormingAjwad HaziqNo ratings yet

- Intro:: DefinitionDocument2 pagesIntro:: DefinitionAjwad HaziqNo ratings yet

- Autobody Advanced OutlineDocument1 pageAutobody Advanced OutlineAjwad HaziqNo ratings yet

- Autobody Advanced OutlineDocument1 pageAutobody Advanced OutlineAjwad HaziqNo ratings yet

- Methodology Practice 2Document2 pagesMethodology Practice 2Ajwad HaziqNo ratings yet

- 4Document29 pages4Ajwad HaziqNo ratings yet

- Malaysian Energy Demand and Emissions From The Transportation SectorDocument7 pagesMalaysian Energy Demand and Emissions From The Transportation SectorAjwad HaziqNo ratings yet

- Methodology Practice 2Document2 pagesMethodology Practice 2Ajwad HaziqNo ratings yet

- Inspect and Replace Drive Axle Wheel StudsDocument3 pagesInspect and Replace Drive Axle Wheel StudsAjwad HaziqNo ratings yet

- 3.2 Finite Element Modelling and Simulation in Metal FormingDocument1 page3.2 Finite Element Modelling and Simulation in Metal FormingAjwad HaziqNo ratings yet

- 3.2 Finite Element Modelling and Simulation in Metal FormingDocument1 page3.2 Finite Element Modelling and Simulation in Metal FormingAjwad HaziqNo ratings yet

- Conclusion NDocument1 pageConclusion NAjwad HaziqNo ratings yet

- Group SS3 N SS4Document2 pagesGroup SS3 N SS4Ajwad HaziqNo ratings yet

- Foc 1Document4 pagesFoc 1Ajwad HaziqNo ratings yet

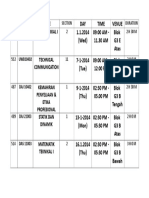

- Jadual Exam FinalDocument1 pageJadual Exam FinalAjwad HaziqNo ratings yet

- TutoDocument2 pagesTutoAjwad HaziqNo ratings yet

- 3.2 Finite Element Modelling and Simulation in Metal FormingDocument2 pages3.2 Finite Element Modelling and Simulation in Metal FormingAjwad HaziqNo ratings yet

- Methodology Practice 2Document2 pagesMethodology Practice 2Ajwad HaziqNo ratings yet

- Foc 1Document4 pagesFoc 1Ajwad HaziqNo ratings yet

- Faculty of Engineering Technology Department of Mechanical Engineering Technology Practice ReportDocument1 pageFaculty of Engineering Technology Department of Mechanical Engineering Technology Practice ReportAjwad HaziqNo ratings yet

- Edition, Prentice: ReferenceDocument1 pageEdition, Prentice: ReferenceAjwad HaziqNo ratings yet

- AyamDocument1 pageAyamAjwad HaziqNo ratings yet

- Transformer: Electrical System (Skaa 2032) Tutorial 2Document3 pagesTransformer: Electrical System (Skaa 2032) Tutorial 2rowmanNo ratings yet

- References Lab Elek. 3Document1 pageReferences Lab Elek. 3Ajwad HaziqNo ratings yet

- AyamDocument1 pageAyamAjwad HaziqNo ratings yet

- Balancing of Rotating MassesDocument13 pagesBalancing of Rotating MassesAjwad HaziqNo ratings yet

- Defensive Driving Course ProposalDocument1 pageDefensive Driving Course ProposalAjwad Haziq100% (1)

- 193 Sample-Chapter PDFDocument82 pages193 Sample-Chapter PDFAjwad Haziq100% (1)

- Nabil AhDocument6 pagesNabil AhAjwad HaziqNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- New Mobility Concepts: Myth or Emerging Reality?: April 2014Document10 pagesNew Mobility Concepts: Myth or Emerging Reality?: April 2014pacotao123No ratings yet

- Porter DiamondDocument3 pagesPorter DiamondS Rahman Ove80% (5)

- Project Overview - LAAR Grad 2023Document12 pagesProject Overview - LAAR Grad 2023Nancy NashaatNo ratings yet

- Catalogue Eurotruss 2016 PDFDocument312 pagesCatalogue Eurotruss 2016 PDFtobeNo ratings yet

- Temporal Dimension Summary ArnavDocument7 pagesTemporal Dimension Summary Arnavarnav saikia67% (3)

- Technopreneurship PrelimDocument9 pagesTechnopreneurship PrelimAs ReNo ratings yet

- Organizational Context To Change - AppleDocument10 pagesOrganizational Context To Change - AppleArmughan BukhariNo ratings yet

- Development of Fintech inDocument10 pagesDevelopment of Fintech inkonosubaNo ratings yet

- IMD MBA 2015 Class ProfileDocument16 pagesIMD MBA 2015 Class ProfileHoya ChiangNo ratings yet

- Assignment4c (Ranjit Singh) Air Canada StrategiesDocument5 pagesAssignment4c (Ranjit Singh) Air Canada Strategiesਟੀਮ ਹਰਿਆਲੀ ਚੂੜਲ ਕਲਾਂNo ratings yet

- IT01Document2 pagesIT01Zelop DrewNo ratings yet

- Internal and External FactorsDocument23 pagesInternal and External FactorsKomang GalihNo ratings yet

- Generating Leaders GE StyleDocument6 pagesGenerating Leaders GE StyleiloveyouphuongvyNo ratings yet

- Entrepreneurship: First SemesterDocument100 pagesEntrepreneurship: First SemesterHenrie G Cabajes100% (2)

- David Vogel Article Ecosystem Advantage How To Harness T PDFDocument23 pagesDavid Vogel Article Ecosystem Advantage How To Harness T PDFGaneshKommaNo ratings yet

- Headquarters-Subsidiary Relationships in MNCS: Fifty Years of Evolving ResearchDocument9 pagesHeadquarters-Subsidiary Relationships in MNCS: Fifty Years of Evolving ResearchAssal NassabNo ratings yet

- PTC 2019 BrochureDocument24 pagesPTC 2019 BrochurePhD to Consulting ConferenceNo ratings yet

- UTA 012 - Course OutlineDocument3 pagesUTA 012 - Course OutlineNaman BansalNo ratings yet

- Analysis of China's 13th Five-Year PlanDocument5 pagesAnalysis of China's 13th Five-Year PlanAPCO WorldwideNo ratings yet

- China's Online Gaming - Group Presentation - 09!05!2011 - Strategy Creators - BangaloreDocument22 pagesChina's Online Gaming - Group Presentation - 09!05!2011 - Strategy Creators - Bangaloreupalr100% (1)

- Aditidaryan WiproDocument19 pagesAditidaryan WiproAditi DaryanNo ratings yet

- H 17 CscoursetextDocument305 pagesH 17 CscoursetextyousefNo ratings yet

- University Manual 4 1 2022Document149 pagesUniversity Manual 4 1 2022Punit RonadNo ratings yet

- BMA608 New Product Failure - Essay: Submitted byDocument9 pagesBMA608 New Product Failure - Essay: Submitted byshama mahzabeenNo ratings yet

- Green Cities ReportDocument45 pagesGreen Cities ReportDaisy50% (2)

- Kaizen Workshop As An Important Element of ContinuDocument7 pagesKaizen Workshop As An Important Element of ContinuIvica KorenNo ratings yet

- First 100 Days As A CIODocument36 pagesFirst 100 Days As A CIOMarius Iulian Rosu100% (9)

- AgriculturaDocument275 pagesAgriculturaHelton SilvaNo ratings yet

- Starbucks Company's International Business StrategyDocument3 pagesStarbucks Company's International Business StrategyDickson100% (1)

- Are Nanoweapons Paving The Road To Human ExtinctionDocument13 pagesAre Nanoweapons Paving The Road To Human ExtinctionAris YsaisNo ratings yet