Professional Documents

Culture Documents

Wem 50

Uploaded by

Adisak AumpiemOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Wem 50

Uploaded by

Adisak AumpiemCopyright:

Available Formats

50 Using This Manual

Abstract

This section tells you how this manual is organized. Abstracts of each section are

included along with a list of other Company manuals. Figure 50-1 is a Quick Refer-

ence Guide that highlights key areas of the manual. A Cross Reference Chart

(Figure 50-2) relates the manual to others with complementary information. The

index at the end of the manual will also help you find particular topics.

Chevron Corporation 50-1 January 1997

50 Using This Manual Welding Manual

Scope and Application

The Welding Manual has been written for Company personnel who are responsible

for selecting and applying welding specifications and for inspecting welding opera-

tions. It is directed both to entry-level personnel and nonspecialists regardless of

experience. This manual should not be used as a substitute for sound engineering

judgment.

Company personnel who write or review welding procedures should be familiar

with the applicable Codes, Chevron specifications and the recommendations

provided in this manual.

The intent is to provide practical, useful information based on Company experi-

ence. Therefore, forms have been included in the front of the manual for your

convenience in suggesting changes. Your input and experience are important for

improving subsequent printings and keeping this manual up-to-date.

Organization

The colored tabs in the manual will help you find information quickly. In summary:

White tabs are for table of contents, introduction, appendices, PC disks, index,

and general purpose topics.

Blue tabs denote Engineering Guidelines.

Gray tabs are used for Specifications and related forms. (There are none in this

manual.)

Red tab marks a place for you to keep documents developed by your organiza-

tion.

Engineering GuidelinesAbstracts

The following are abstracts of each section of this manual.

Section 100This section describes the welding processes commonly used for

Company applications, along with the advantages, disadvantages, and typical appli-

cations for each. It discusses joint design and describes the various types of joints

and welds. Weld metal composition is covered, including proper storage and

handling of welding electrodes. The section describes preheating, with reasons for

preheating and methods used. There is a detailed discussion of postweld heat treat-

ment (PWHT) purposes and methods. In addition, oxygen and arc cutting of metals

is covered.

Section 200This section describes the development of a welding procedure speci-

fication, the qualification of that specification, and the qualification of the welder

using that specification. It focuses on the ASME Boiler and Pressure Vessel Code,

Section IX, because this code is most frequently used for qualifying weld proce-

dures and welders (except for pipelines, offshore structures and shipbuilding).

January 1997 50-2 Chevron Corporation

Welding Manual 50 Using This Manual

Section 300This section covers basic welding and heat treatment considerations

for commonly used alloys including dissimilar metal combinations, overlay, and

corrosion resistance linings. It reviews safe welding and cutting practices and

covers general welding troubleshooting. It also covers hot tap welding, and repair-

welding without PWHT.

Section 400This section identifies and characterizes the hazards unique to

welding and cutting. Precautions are described and reference is made to the avail-

able guidelines.

Section 500This section discusses ways to assure the quality of a welding job.

The first half the section describes nondestructive test methods and guides the

reader on which methods to choose for a particular application. The second half of

the section, covering welding inspection, is also available in pocket size as the

Company's Guide to Welding Inspection.

Section 600This section discusses welding and related topics applicable to

offshore structures. Process equipment fabrication for platform modules is not

covered here since it is the same as for onshore facilities.

Section 700This section covers field installation of socket weld casing heads. It

discusses preheat and welding, as well as the postheat necessary to obtain crack-

free welds without postweld heat treatment (PWHT). The section gives detailed

procedures for welding casing heads and covers qualification of weld procedures

and welders.

Appendices

Appendix A contains data sheets for most of the alloys encountered in the petro-

leum and chemical industry.

Appendix B is an index of Chevron-qualified welding procedures, listed in order by

Chevron's WPS number.

Appendix C also is an index of Chevron-qualified welding procedures, but listed in

order by base metals and process.

Appendix D contains samples of ASME standard forms.

Appendix E contains the AWS Standard Welding Symbol Chart.

Appendix F contains a table showing equivalents of various hardness scales.

Other Company Manuals

The text sometimes refers to documents in other Company manuals. These docu-

ments carry the prefix of that manual. The prefixes are defined here:

Prefix Company Manual

CIV Civil and Structural

Chevron Corporation 50-3 January 1997

50 Using This Manual Welding Manual

CMP Compressor

COM Coatings

CPM Corrosion Prevention

DRI Driver

ELC Electrical

EXH Heat Exchanger and Cooling Tower

FFM Fluid Flow

FPM Fire Protection Manual

HTR Fired Heater and Waste Heat Recovery

ICM Instrumentation and Control

IRM Insulation and Refractory

MAC General Machinery

NCM Noise Control

PIM Piping

PMP Pump

PPL Pipeline

PVM Pressure Vessel

TAM Tank

UTL Utilities

WEM Welding

Fig. 50-1 Quick Reference Guide

Task Welding Manual Sections

Learn Background Information About

Welding Fundamentals 100

Welding Qualifications 200

Welding Procedures 300, Appendices B & C

Safety 400

Special Applications 600, 700

Materials

Alloy Data Appendix A

Weld Metal 130

Forms Appendix D, Appendix E

January 1997 50-4 Chevron Corporation

Welding Manual 50 Using This Manual

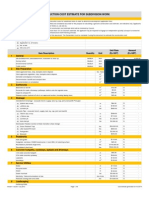

Fig. 50-2 Manuals Cross Reference Chart (1 of 2)

WEM PIM PPL FFM COM CPM IRM ICM

Coatings

External X X X

Insulation X X

Internal X X

Selection Chart X X

Weight X

Components

API 5L Line Pipe X

ASTM A106 Pipe X

Instruments X

Valves and Fittings X X X

Computer Programs X X

Construction

Cathodic Protection X

Coating X X X

Inspection X X X X

Offshore Methods X X X X X

Safety X X X

Spooling X

Testing X X X

Welding X X X

Design

Hot Oil X X X

Metering X

Pipeline X

Piping Layout X

Plant Piping X

SCADA X

Weld Procedure X

Materials

Properties X X

Selection X X X X

Expansion X X

Hot Tapping X X X

Inspection and Testing X X X X X

Installation X

Crossings X

Chevron Corporation 50-5 January 1997

50 Using This Manual Welding Manual

Fig. 50-2 Manuals Cross Reference Chart (2 of 2)

WEM PIM PPL FFM COM CPM IRM ICM

Pipeline X

Plant Piping X

Pipe Cleaning X X X

Pulsation Control X

Specifications (Company)

C.S. Piping X

Cement-Lined Pipe X

Cleaning Piping X

External FBE Coating X

Induction Bending X

Internal Coating X

Insulation X

Line Pipe X

Pressure Testing of Plant Piping X

Radiography X X

Sour Line Pipe X

Specifications (Industry)

ANSI/ASME B31.3 X X

ANSI/ASME B31.4 X

ANSI/ASME B31.5 X

API 1104 X

API 1107 X

API 1111 X

API 10E X

API 14E X

API 2510 X

ASME Section IX X

Surveying X

Troubleshooting X

Vibration X

Welding X X

January 1997 50-6 Chevron Corporation

You might also like

- PVM 50Document6 pagesPVM 50abdelillahNo ratings yet

- Com 50Document7 pagesCom 50lingoalvaNo ratings yet

- cmp50 Using This ManualDocument6 pagescmp50 Using This ManualPitipong SunkhongNo ratings yet

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- Mid-Year Edition: New Publications InsideDocument44 pagesMid-Year Edition: New Publications InsideLuis Angel OlivaresNo ratings yet

- 1 RWMA - Resistance-Welding-Literature-1Document3 pages1 RWMA - Resistance-Welding-Literature-1dneprmtNo ratings yet

- Tank Manual 50 Using This ManualDocument4 pagesTank Manual 50 Using This ManualmilecsaNo ratings yet

- Welding Documentation (BBX 10504) : C1: IntroductionDocument20 pagesWelding Documentation (BBX 10504) : C1: IntroductionAhnaf Fadhlur Rahman Bin Awang HanibNo ratings yet

- International Welding Codes and StandardsDocument17 pagesInternational Welding Codes and StandardsDominic Apollo RoblesNo ratings yet

- Ces ManualsDocument8 pagesCes Manualslosmoscasbr-1No ratings yet

- Exh 50Document8 pagesExh 50RogerNo ratings yet

- Aws Publications Catalog: Summer 2010Document20 pagesAws Publications Catalog: Summer 2010saeedahmad901No ratings yet

- Damage Mechanisms Fixed Equipment in Refining IndustryDocument13 pagesDamage Mechanisms Fixed Equipment in Refining IndustryMansoor Ali100% (3)

- PPL100 General InformationDocument5 pagesPPL100 General InformationAnonymous PkeI8e84RsNo ratings yet

- ME591 - Part - 4Document17 pagesME591 - Part - 4manal.saber92No ratings yet

- Tam 50Document5 pagesTam 50Efrain TiradoNo ratings yet

- IIAR ProcedimientodeSoldadura PDFDocument12 pagesIIAR ProcedimientodeSoldadura PDFmelator100% (3)

- Commonly Used Welding CodesDocument21 pagesCommonly Used Welding CodesgregkilatonNo ratings yet

- Gas Welding PDFDocument42 pagesGas Welding PDFManickamEllampoorananNo ratings yet

- Aws Publications Catalog American Welding SocietyDocument20 pagesAws Publications Catalog American Welding SocietyChirag Anand0% (1)

- Pip Resp003v-2004Document48 pagesPip Resp003v-2004zufriateguiNo ratings yet

- Asme Sec Ix - Short NotesDocument29 pagesAsme Sec Ix - Short NotesRavindra S. Jivani100% (2)

- 5 - Module 5Document47 pages5 - Module 5Ahmed Shaban Kotb100% (1)

- Automotive Steel Design ManualDocument22 pagesAutomotive Steel Design ManualftmrlNo ratings yet

- SAES-W-014 - Old SpecDocument12 pagesSAES-W-014 - Old SpecMichael TayactacNo ratings yet

- Documents Covering Welding Inspection and QualificationDocument28 pagesDocuments Covering Welding Inspection and QualificationMohamed El SayadNo ratings yet

- ASME Codes and Standards - A Summary - Welding & NDTDocument15 pagesASME Codes and Standards - A Summary - Welding & NDTTin Aung KyiNo ratings yet

- New Heat ExchangerDocument12 pagesNew Heat ExchangerMosaddek100% (1)

- Api1104 1-1Document17 pagesApi1104 1-1abidahad311No ratings yet

- Assignment 1 - Brief - Unit 13 - LA 062016 No ComDocument4 pagesAssignment 1 - Brief - Unit 13 - LA 062016 No ComIsaiahNo ratings yet

- Boon Asme Ix NotesDocument31 pagesBoon Asme Ix NotesPRAVEENNo ratings yet

- Wem Pu 6089 A PDFDocument74 pagesWem Pu 6089 A PDFolalekanNo ratings yet

- Exh 100Document3 pagesExh 100RogerNo ratings yet

- Welding, Cutting & Allied Processes and Arc Welding Power Sources (Welding Machines)Document56 pagesWelding, Cutting & Allied Processes and Arc Welding Power Sources (Welding Machines)Prashant Kumar mishraNo ratings yet

- Welding Codes and How They're UsedDocument5 pagesWelding Codes and How They're UsedPasquale CutriNo ratings yet

- Electrod 5Document3 pagesElectrod 5RAMESH PANDARINo ratings yet

- ASM005.002 Topical Guide # 6-WeldingDocument13 pagesASM005.002 Topical Guide # 6-WeldingArnab GoswamiNo ratings yet

- Legal Statement Year 2006 ReleaseDocument9 pagesLegal Statement Year 2006 ReleaseWawan Mazid SupriatnaNo ratings yet

- 50 Using This Manual: Chevron Corporation 50-1 January 1997Document8 pages50 Using This Manual: Chevron Corporation 50-1 January 1997Anonymous j5XYgIuNo ratings yet

- Fabrication, Welding and Inspection Basics For Maintenance EngineersDocument3 pagesFabrication, Welding and Inspection Basics For Maintenance Engineersகோகுல் இராNo ratings yet

- Title: Minimum Requirements On Welding From Supplier and Sub-SupplierDocument10 pagesTitle: Minimum Requirements On Welding From Supplier and Sub-SupplierDeepak DasNo ratings yet

- SGN09 - Weld Design, Welding and Non-Destructive Testing ConsiderationsDocument8 pagesSGN09 - Weld Design, Welding and Non-Destructive Testing ConsiderationsMircea PavelNo ratings yet

- Asme Sec Ix - Short NotesDocument20 pagesAsme Sec Ix - Short NotesParvee K NakwalNo ratings yet

- General Guide - Codes and StandardsDocument4 pagesGeneral Guide - Codes and StandardsmanuyemNo ratings yet

- International Organization For Standardization IsoDocument4 pagesInternational Organization For Standardization Isoammarashraf91No ratings yet

- Welding Procedure Guide - 2008 CDocument122 pagesWelding Procedure Guide - 2008 CEduardo CastilloNo ratings yet

- Asme Sec Ix - Short Notes ReferenceDocument29 pagesAsme Sec Ix - Short Notes Referencekart_rl0% (1)

- Best Welding Practices (Pernis) : Doel / ScopeDocument91 pagesBest Welding Practices (Pernis) : Doel / Scopechompink6900100% (1)

- Tech Paper Fcaw IIDocument13 pagesTech Paper Fcaw IIAsad Bin Ala QatariNo ratings yet

- Quality Index For Friction Stir Welds in 7050 Aluminum PlatesDocument10 pagesQuality Index For Friction Stir Welds in 7050 Aluminum PlatesGabriel AguirreNo ratings yet

- Aws CatalogDocument43 pagesAws CatalogDesmond Chin100% (1)

- Saes W 015 PDFDocument13 pagesSaes W 015 PDFMohamed SolimanNo ratings yet

- WpsDocument14 pagesWpsstanley100% (1)

- Fundamentals of HVOF Spray For Reconditioning ComponentsDocument49 pagesFundamentals of HVOF Spray For Reconditioning ComponentsEdgard Molina100% (1)

- Welding in Pipelines - PV - StructureDocument6 pagesWelding in Pipelines - PV - StructureanshumanNo ratings yet

- Shell and Tube Heat Exchanger Specification SheetDocument18 pagesShell and Tube Heat Exchanger Specification SheetAkram DriraNo ratings yet

- 3050 Using This Manual: Chevron Corporation 3050-1 August 1999Document8 pages3050 Using This Manual: Chevron Corporation 3050-1 August 1999milecsa100% (1)

- ELT-05-ET-TS-0003 - Specification For Welding Consumable For 9% Ni Steel - R0Document12 pagesELT-05-ET-TS-0003 - Specification For Welding Consumable For 9% Ni Steel - R0jorgekarlosprNo ratings yet

- 9 NiDocument7 pages9 NiAdisak AumpiemNo ratings yet

- Arcelormittal 9 Percent NickelDocument5 pagesArcelormittal 9 Percent NickelAdisak AumpiemNo ratings yet

- Risk Oxidation ChartDocument1 pageRisk Oxidation ChartAdisak AumpiemNo ratings yet

- QS Assessment Checklist - PEDDocument8 pagesQS Assessment Checklist - PEDAdisak AumpiemNo ratings yet

- Plates - S420G2 M PDFDocument2 pagesPlates - S420G2 M PDFAdisak AumpiemNo ratings yet

- Welding Consumables: Insert Lot and Sertificate in Aibel Standard ToolsDocument7 pagesWelding Consumables: Insert Lot and Sertificate in Aibel Standard ToolsAdisak AumpiemNo ratings yet

- Plates - S420G2 MDocument2 pagesPlates - S420G2 MAdisak AumpiemNo ratings yet

- P-Numbers Base Metal (Typical or Example)Document2 pagesP-Numbers Base Metal (Typical or Example)Adisak AumpiemNo ratings yet

- SteelTubeHandbook February2012Document120 pagesSteelTubeHandbook February2012Adisak AumpiemNo ratings yet

- Acceptance Criteria To TR1826Document1 pageAcceptance Criteria To TR1826Adisak Aumpiem0% (1)

- Olympus Probe Catalog PDFDocument52 pagesOlympus Probe Catalog PDFcutefrenzy100% (4)

- AISC - Inspection of Welded and Bolted JointsDocument26 pagesAISC - Inspection of Welded and Bolted JointsAdisak AumpiemNo ratings yet

- The Procedure Handbook of Arc Welding (Twelfth Edition)Document742 pagesThe Procedure Handbook of Arc Welding (Twelfth Edition)Adisak Aumpiem100% (1)

- Architecture Santo Tomas SyllabusDocument3 pagesArchitecture Santo Tomas SyllabusrichellerojNo ratings yet

- StratosDocument4 pagesStratosCelith Rossy Inga PeñaNo ratings yet

- BS en Iso 14692-3-2017Document46 pagesBS en Iso 14692-3-2017SRIDHAR BABU KONADANo ratings yet

- FlowCon DPCV BrochureDocument4 pagesFlowCon DPCV BrochureDenon EvonNo ratings yet

- PracticalDocument94 pagesPracticalAshiqueHussainNo ratings yet

- Circular Concrete TanksDocument55 pagesCircular Concrete Tanksenvirojspl75% (4)

- The Philippines, Occupational Safety and Health Standards: RULE 1140 ExplosivesDocument15 pagesThe Philippines, Occupational Safety and Health Standards: RULE 1140 ExplosivesRuby Arnz PagaranNo ratings yet

- Dimensions of Steel Beams Type IPE and INP European StandardDocument4 pagesDimensions of Steel Beams Type IPE and INP European StandardfarithNo ratings yet

- Multi Stage Centrifugal PumpDocument72 pagesMulti Stage Centrifugal PumpTg Tarro100% (7)

- MOS For Construction of Bridge - 042 Updated at PIC-I-T - 7062Document27 pagesMOS For Construction of Bridge - 042 Updated at PIC-I-T - 7062Najmul QamarNo ratings yet

- Air Vee BendingDocument4 pagesAir Vee Bendinganil chejaraNo ratings yet

- 20 THDocument2 pages20 THdohamateNo ratings yet

- Construction Cost Estimator For Subdivision WorkDocument6 pagesConstruction Cost Estimator For Subdivision WorkRonaldRayLachica100% (8)

- 22년식NMAX125.o 1fsno45dn1l1ni6g1qo71jos14vq8Document63 pages22년식NMAX125.o 1fsno45dn1l1ni6g1qo71jos14vq8Jae Man YouNo ratings yet

- PC 406 2Document133 pagesPC 406 2JacksonNo ratings yet

- Static and Cyclic Properties of Clay Subgrade Stabilised With Rice Husk Ash and Portland Slag CementDocument12 pagesStatic and Cyclic Properties of Clay Subgrade Stabilised With Rice Husk Ash and Portland Slag CementAndrea RinconNo ratings yet

- Acoustics Required in A Recording StudioDocument19 pagesAcoustics Required in A Recording StudioRiyaNo ratings yet

- InfraCo Review 2007Document63 pagesInfraCo Review 2007m_edas4262No ratings yet

- Method Statement For Road Surfacing in Existing IrrigigationDocument14 pagesMethod Statement For Road Surfacing in Existing IrrigigationCamille TolentinoNo ratings yet

- Gigant Specification TablesDocument1 pageGigant Specification Tablesđức cường trầnNo ratings yet

- MDB Lesson 4 Poisson's Ratio-Biaxial and Triaxial DeformationsDocument12 pagesMDB Lesson 4 Poisson's Ratio-Biaxial and Triaxial DeformationsChan MirandaNo ratings yet

- Job Advert - ServicemanDocument2 pagesJob Advert - ServicemanJoseph buluguNo ratings yet

- Toilet & Bath at Bedroom: Medicine Cabinet Counter Top Lavatory Installation Siphon Jet Water ClosetDocument1 pageToilet & Bath at Bedroom: Medicine Cabinet Counter Top Lavatory Installation Siphon Jet Water ClosetStephen Mark Garcellano DalisayNo ratings yet

- Union 18k Split With ImageDocument3 pagesUnion 18k Split With Imageubaldoferns9357No ratings yet

- Beton DrucrciDocument7 pagesBeton DrucrciCedrick TchoundaNo ratings yet

- West-Araya Extended AbstractDocument4 pagesWest-Araya Extended AbstractJoe ColomboNo ratings yet

- Product Guide Fiber Reinforced Polymer (GFRP) Bars For Concrete ReinforcementDocument9 pagesProduct Guide Fiber Reinforced Polymer (GFRP) Bars For Concrete ReinforcementBayram Aygun100% (1)

- High-Workability Concrete High-Workability ConcreteDocument43 pagesHigh-Workability Concrete High-Workability ConcreteF Azam Khan AyonNo ratings yet

- Obe Reports Hec - Report Section OutlineDocument2 pagesObe Reports Hec - Report Section OutlineDanish EjazNo ratings yet

- Elements of Soil Mechanics, 8th Edition Example 5.3Document6 pagesElements of Soil Mechanics, 8th Edition Example 5.3Mirna KristiyantoNo ratings yet