Professional Documents

Culture Documents

Mix Design Forms

Uploaded by

Tk SubhashCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mix Design Forms

Uploaded by

Tk SubhashCopyright:

Available Formats

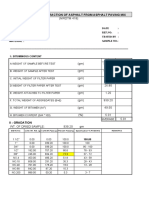

ODOT CONTRACTOR MIX DESIGN SUMMARY

PROJECT MIX CLASS

CONTRACT NO. LEVEL (2,3,4)

MIX PRODUCER PROJECT MANAGER

CMDT CMDT JMF MIX ID NO.

BID ITEM #

AGGREGATE & OTHER CONSTITUENTS (RAP, BL. SAND, LIME, ETC.)

STOCKPILE SIZES

SOURCE NUMBER

STOCKPILE PERCENTAGE (Psp)

Bulk Specific Gravity (Gsb)

Apparent Specific Gravity (Gsa)

Design developed with "dryback" Gmm (Y/N)? JOB MIX FORMULA

Aggregate Gradation CA & FA

Blend

MIXTURE AT DESIGN ASPHALT CONTENT Sieve Ratios

Maximum Specific Gravity (Gmm) 3/4" (19 mm)

Gyratory Bulk Gravity (Gmb) 1/2" (12.5 mm) CA

Combined Aggregate (Gsb) 3/8" (9.5 mm)

Effective Specific Gravity (Gse) 1/4" (6.3 mm)

Combined Apparent Gravity (Gsa) No. 4 (4.75 mm) FA

Absorbed Asphalt, % (Pba) No. 8 (2.36 mm)

Effective Asphalt Content, % (Pbe) No. 16 (1.18 mm)

P200 / Pbe Ratio No. 30 (0.60 mm)

Air Voids, % (Va) No. 50 (0.30 mm)

VMA, % No. 100 (0.150 mm)

VFA, % No. 200 (0.075 mm)

Tensile Strength Ratio (TSR) FA Average

TSR Compaction Blows FA Std Dev.

VIR Asphalt content, % (Pb)

APA Rut depth - mm RAP AC, % (Pbr)

Gmb Sample Weight @ JMF Virgin Binder Repl, %

Number of Gyrations Antistrip, %

Draindown % (open graded) Agg. Treatment, %

Date Asphalt Brand

Asphalt Grade

CMDT Signature

Mixing temp. range

CMDT Card # Placement temp. range

Asphalt SpGr (Gb) 77 F

COMMENTS: BLEND CHOSEN? Asphalt SpGr (Gb) 60 F

REASON? :

HMAC Mix Design Forms 1-2012

HMAC Mix Design Forms 1-2012

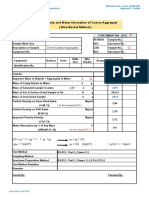

AASHTO T-85: Specific Gravity and Absorption of Coarse Aggregate

Size Average Average Average Average

Source

A) Mass of Dry Sample

B) Mass of SSD Sample

C) Mass of Sample Immersed

Bulk Specific Gravity (Gsb)

Bulk Specific Gravity (SSD)

Apparent Specific Gravity (Gsa)

Absorption (%)

AASHTO T-84: Specific Gravity and Absorption of Fine Aggregate

Size Average Average Average Average

Source

S) Mass of SSD Sample

B) Mass of Pyc. + Water

C) Mass of Pyc.+H2O+Sample

Mass of Dry Sample + Pan

Mass of Pan

A) Mass of Dry Sample

Bulk Specific Gravity (Gsb)

Bulk Specific Gravity (SSD)

Apparent Specific Gravity (Gsa)

Absorption (%)

Combined Specific Gravity

Size

Split Sieve

Percent Passing Split Sieve

Bulk Specific Gravity (Gsb)

Bulk Specific Gravity (SSD)

Apparent Specific Gravity (Gsa)

Absorption (%)

Comments:

Certified Technician and Card Number:

HMAC Mix Design Forms 1-2012

RAP WORKSHEET

Separated Size Gb@77F

AASHTO T-209: Theoretical Maximum Specific Gravity

Sample 1 2 3

Mass of Dry RAP (Rhot)

Mass of Added Binder (Bindernew)

Pb-new

Mass of Coated Sample (C)

Actual Dry Mass Uncoated Sample (A)

Actual Mass of Added Binder (C-A)

Mass @ SSD

Pycnometer + Water

Pycnometer + Water + Mix

RAP Gmm SSD

Asphalt Content of RAP

Sample 1 2 3 4 5

Basket Tare

Mass of RAP + Basket

Mass of Agg and Basket

Mass Initial, Mi

Mass Final, Mf

%I = [(Mi - Mf)/Mi]x100 Average

Corrected Pb, Cf = 0.50

RAP Gse

AASHTO T-85: Specific Gravity and Absorption of Coarse Aggregate

Size Average

Source

A) Mass of Dry Sample Combined Specific Gravity

B) Mass of SSD Sample T-84 & T-85

C) Mass of Sample Immersed Size

Bulk Specific Gravity (Gsb) Split Sieve

Bulk Specific Gravity (SSD) Percent Passing Split Sieve

Apparent Specific Gravity (Gsa) Burnt Bulk Specific Gravity (Gsb)

Absorption (%) Burnt Bulk Specific Gravity (SSD)

Burnt Apparent Specific Gravity

AASHTO T-84: Specific Gravity and Absorption of Fine Aggregate Absorption (%)

Size Average Combined RAP Specific Gravity

Source ODOT TM-319

S) Mass of SSD Sample RAP Gsb

B) Mass of Pyc. + Water RAP Gsa

C) Mass of Pyc.+H2O+Sample

Mass of Dry Sample + Pan

Mass of Pan

A) Mass of Dry Sample

Bulk Specific Gravity (Gsb)

Bulk Specific Gravity (SSD)

Apparent Specific Gravity (Gsa)

Absorption (%)

Certified Technician and Card Number:

HMAC Mix Design Forms 1-2012

RAP Gradation

SAMPLE 1 SAMPLE 2

Sieve Mass Initial Dry Mass Sieve Mass Initial Dry Mass

% Retained % Pass % Retained % Pass

Size Retained Dry Washed Mass Size Retained Dry Washed Mass

1" Mass After Sieve 1" Mass After Sieve

3/4" Sieve Loss 3/4" Sieve Loss

1/2" 1/2"

3/8" 3/8"

1/4" 1/4"

#4 #4

#8 #8

#16 #16

#30 #30

#50 #50

#100 #100

#200 #200

Pan Pan

SAMPLE 3 SAMPLE 4

Sieve Mass Initial Dry Mass Sieve Mass Initial Dry Mass

% Retained % Pass % Retained % Pass

Size Retained Dry Washed Mass Size Retained Dry Washed Mass

1" Mass After Sieve 1" Mass After Sieve

3/4" Sieve Loss 3/4" Sieve Loss

1/2" 1/2"

3/8" 3/8"

1/4" 1/4"

#4 #4

#8 #8

#16 #16

#30 #30

#50 #50

#100 #100

#200 #200

Pan Pan

SAMPLE 5 Average

Sieve Mass Initial Dry Mass

% Retained % Pass Sieve Size % Pass

Size Retained Dry Washed Mass

1" Mass After Sieve 1"

3/4" Sieve Loss 3/4"

1/2" 1/2"

3/8" 3/8"

1/4" 1/4"

#4 #4

#8 #8

#16 #16

#30 #30

#50 #50

#100 #100

#200 #200

Pan Pan

Certified Technician and Card Number:

HMAC Mix Design Forms 1-2012

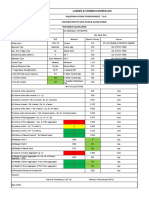

AGGREGATE STOCKPILE QLs

Aggregate

Upper Control

Lower Control

Source

Point

Point

Gsb

Sieve Size

25.0 1"

19.0 3/4"

12.5 1/2"

9.5 3/8"

6.35 1/4"

4.75 #4

2.36 #8

1.18 #16

0.600 #30

0.300 #50

0.150 #100

0.075 #200

HMAC Mix Design Forms 1-2012

Stage 1 Trial Blends

Dust Pull

Aggregate

Coarse

Percent

Blend

Sieve Size

25.0 1"

19.0 3/4"

12.5 1/2"

9.5 3/8"

6.35 1/4"

4.75 #4

2.36 #8

1.18 #16

0.600 #30

0.300 #50

0.150 #100

0.075 #200

Gsb Gsa

Dust Pull

Aggregate

Percent Medium

Blend

Sieve Size

25.0 1"

19.0 3/4"

12.5 1/2"

9.5 3/8"

6.35 1/4"

4.75 #4

2.36 #8

1.18 #16

0.600 #30

0.300 #50

0.150 #100

0.075 #200

Gsb Gsa

Dust Pull

Aggregate

Percent Fine Blend

Sieve Size

25.0 1"

19.0 3/4"

12.5 1/2"

9.5 3/8"

6.35 1/4"

4.75 #4

2.36 #8

1.18 #16

0.600 #30

0.300 #50

0.150 #100

0.075 #200

HMAC Mix Design Forms 1-2012

Gsb Gsa

HMAC Mix Design Forms 1-2012

STAGE 1: Analysis of Compacted Paving Mixture (Preliminary Trial)

Mixing Temp, F Stockpile Specific Gravity Coarse Medium Fine

Compaction Temp, F

Design Gyrations

Percent AC in RAP Asphalt

1. Bulk Specific Gravity (Gmb), Compacted Mix

2. SSD Maximum Specific Gravity (Gmm) Total Mixture

3. Bulk Specific Gravity (Gsb), Total Aggregate

4. Effective Specific Gravity (Gse), Total Aggregate

5. Apparent Specific Gravity (Gsa), Total Aggregate

6. Air Voids (Va), %

7. Voids in Mineral Aggregate (VMA)

8. Voids Filled with Asphalt (VFA), %

9. Effective Asphalt Content (Pbe), %

10. Absorbed Asphalt (Pba) % By Weight, Total Aggregate

11. Virgin Binder Replacement, % By Weight, Total Binder

12. P200 (Actual)

13. P200/Pbe Ratio

Compacted Bulk Specific Gravity (Gmb)

Coarse Medium Fine

Specimen 1 2 1 2 1 2

Final Height Volumetrics Normalized to 4.0% Air Voids (SSD Gmm)

A. Mass in Air Blend Coarse Medium Fine JMF Criteria

C. Weight in Water Pb

B. Mass SSD Va

D. Immersed Volume VMA

E. Geometric Volume VFA

F. Imm/Geom. Ratio Pbe

Gma - Gmb %VirginRepl

Gma (A/A-C) P200/Pbe

Gmb [(A/B)-C]

Gmb Average

Maximum Specific Gravity (Gmm)

Blend Coarse Medium Fine

Pycnometer+Lid+Mix

Pycnometer+Lid

Mass of Dry Sample

Mass of SSD Sample

Pycnometer+Lid+Water

Pycnometer+Lid+Water+Mix

Gmm

SSD Gmm

Certified Technician and Card Number:

HMAC Mix Design Forms 1-2012

JMF - BATCH VERIFICATION

Virgin % RAP %

SIEVE RAP COMBINED SIEVE

SIZE MASS 1 MASS 2 TOTAL MASS % RET % PASS % PASS % PASS TARGET TOLERANCE SIZE

1" 1"

3/4" 3/4"

1/2" 1/2"

3/8" 3/8"

1/4" 1/4"

#4 #4

#8 #8

#16 #16

#30 #30

#50 #50

#100 #100

#200 #200

PAN

TOTAL MASS (g)

INIT. DRY MASS (g) DRY WASHED MASS (g) SIEVE LOSS %

Certified Technician and Card Number:

HMAC Mix Design Forms 1-2012

STAGE 2 TESTING

AASHTO T-209: Theoretical Maximum Specific Gravity and Density of Bituminous Paving Mixtures

Percent Asphalt Content (Pb)

Pycnometer + Lid + Mix

Pycnometer + Lid

Mass of Dry Sample

Mass of SSD Sample

Pycnometer + Lid + Water

Pycnometer + Lid + Water + Mix

Uncorrected Maximum Specific Gravity (Gmm)

Uncorrected Effective Specific Gravity (Gse)

SSD Maximum Specific Gravity (SSD Gmm)

SSD Effective Specific Gravity (Gse)

Gse Difference

Average Gse

Back-Calculated Design Maximum Specific Gravity Determination

Pb Ps Gse Gb Gmm

AASHTO T 166/275: Bulk Specific Gravity of Compacted Hot Mix Asphalt (HMA)

Mixing Temp, F Gyration Level

Compaction Temp, F

Wt. in H2O SSD Mass Gmb Immersed to Gma Gma - Gmb

% AC Height Dry Mass Voids Geom. Ratio

Average

Average

Average

Average

Certified Technician and Card Number:

HMAC Mix Design Forms 1-2012

STAGE 2: Analysis of Compacted Paving Mixture (Superpave Method)

Stockpile Blend % Specific Gravity Mixing Temp, F

Compaction Temp, F

Design Gyrations

Air Voids Designed to, %

Dryback Rices / Gmm (YES / NO)

Optimum

Asphalt

Asphalt Cement Content

Percent AC in RAP Mix Composition, % By Weight of Total Mix, Pb

Pb Contributed by RAP

1. Bulk Specific Gravity (Gmb), Compacted Mix

2. Maximum Specific Gravity (Gmm) Total Mixture

3. Bulk Specific Gravity (Gsb), Total Aggregate

4. Effective Specific Gravity (Gse), Total Aggregate

5. Apparent Specific Gravity (Gsa), Total Aggregate

6. Air Voids (Va), %

7. Voids in Mineral Aggregate (VMA)

8. Voids Filled with Asphalt (VFA), %

9. Effective Asphalt Content (Pbe), %

10. Absorbed Asphalt (Pba) % By Weight, Total Aggregate

11. Virgin Binder Replacement, % By Weight Total Binder

12. P200 (Actual)

13. P200/Pbe Ratio

Aggregate Blend Dust Pull

Blend JMF

Sieve Size

Target Tolerance

25.0mm ( 1" )

19.0mm ( 3/4" )

12.5mm ( 1/2" )

9.5mm ( 3/8" )

6.35mm ( 1/4" )

4.75mm ( #4 )

2.36mm ( #8 )

1.18mm ( #16 )

0.600mm ( #30 )

0.300mm ( #50 )

0.150mm ( #100 )

0.075mm ( #200 )

HMAC Mix Design Forms 1-2012

STAGE 3 - TSR's

AASHTO T-283: Resistance of Compacted Bituminous Mixture to Moisture Induced Damage

Compaction Temp: Sample: %AC:

Blows / Gyrations: Gmm:

Sample Number 1 2 3 4 5 6 7 8

Diameter, in

Height, in

Weight in Air, g

SSD Weight, g

Weight in Water, g

Volume, cm3

Bulk Specific Gravity, Gmb Average

% Voids (7.0% +/- 0.5%)

Volume of Air Voids

Test Condition Wet (W) or Dry (D)

Wet Condition Average Voids: Dry Condition Average Voids:

Desired Wt. Gain

Target Saturation Weight

Weight After Saturation

Volume of Absorbed Water Average

% Saturation (70% - 80%)

P, Load for Dry Sample, lbs Average

Sdry = 2P/ (t x D x )

P', Load for Wet Sample, lbs Average

Swet = 2'P/ (t x D x )

Tensile Strength Ratio, % = (Swet/Sdry) x 100: Visual Stripping Rating 0-5:

0 = No Stripping

Comments: 5 = Significant Stripping

Certified Technician and Card Number:

HMAC Mix Design Forms 1-2012

You might also like

- Mix Design FormsDocument13 pagesMix Design FormsSashi KumarNo ratings yet

- Type III (PMB) - Plant Trial - 8-10-19Document3 pagesType III (PMB) - Plant Trial - 8-10-19Bader Al-AneziNo ratings yet

- Worksheet For Superpave Asphalt Concrete Mix Design Aashto R 35Document4 pagesWorksheet For Superpave Asphalt Concrete Mix Design Aashto R 35deenhanifah695No ratings yet

- Marshall Test WorksheetDocument5 pagesMarshall Test WorksheetMoslem AghapourNo ratings yet

- Lab Data Shit 5Document2 pagesLab Data Shit 5Farabi RNo ratings yet

- Asphalt MQC2Document30 pagesAsphalt MQC2Wosemy SoyNo ratings yet

- 12 Volumetric AnalysisDocument1 page12 Volumetric AnalysisjitendraNo ratings yet

- MarshallDocument1 pageMarshallaashish patidarNo ratings yet

- Kingdom of Saudi Arabia: Marshall Asphalt Mix Design DataDocument1 pageKingdom of Saudi Arabia: Marshall Asphalt Mix Design DataHamza AldaeefNo ratings yet

- Chara-e-Saleem Karwan Street No.04 Kabul City.: Construction Materials Testing LabDocument23 pagesChara-e-Saleem Karwan Street No.04 Kabul City.: Construction Materials Testing LabShafiqullah GowharyNo ratings yet

- Block-1D HMAC Mix Design - TN-II - 2024Document67 pagesBlock-1D HMAC Mix Design - TN-II - 2024abcheema112No ratings yet

- Contoh Form TRIAL COMPACTION ACBCDocument24 pagesContoh Form TRIAL COMPACTION ACBCC-pang MinorityNo ratings yet

- Wakaaladda Horumarinta Wadooyinka: Free Zone ProjectDocument7 pagesWakaaladda Horumarinta Wadooyinka: Free Zone ProjectsacsewNo ratings yet

- 25.00mm Class B Mix Design Submittal 2022 1622 - v13Document4 pages25.00mm Class B Mix Design Submittal 2022 1622 - v13Don PopinoNo ratings yet

- Clay Lump and Fariable Particle in AggDocument2 pagesClay Lump and Fariable Particle in AggNanang SuryanaNo ratings yet

- Comminution Ore TestingDocument35 pagesComminution Ore TestingHarrison Antonio Mira NiloNo ratings yet

- Adobe Scan 04-May-2022Document25 pagesAdobe Scan 04-May-2022Stupidity TalksNo ratings yet

- Marshall Test: Specimen NumberDocument1 pageMarshall Test: Specimen NumberTALHA SHAHIDNo ratings yet

- For GSB GR V & WMMDocument16 pagesFor GSB GR V & WMMSasanka SekharNo ratings yet

- Four Laning of Cholopuram - Thanjavur From KM 116.440 To KM 164.275 Section of Nh-45C in The State of Tamilnadu NHDP Phase-Iv On Hybrid Annuity ModeDocument2 pagesFour Laning of Cholopuram - Thanjavur From KM 116.440 To KM 164.275 Section of Nh-45C in The State of Tamilnadu NHDP Phase-Iv On Hybrid Annuity ModeJ Marees Kumar ThangarathinamNo ratings yet

- Manufacturer and DesignationDocument3 pagesManufacturer and DesignationEmma DNo ratings yet

- (MRDTM 418) : Quantitative Extraction of Asphalt From Asphalt Paving MixDocument7 pages(MRDTM 418) : Quantitative Extraction of Asphalt From Asphalt Paving MixBelal AlmokdadNo ratings yet

- (MRDTM 418) : Quantitative Extraction of Asphalt From Asphalt Paving MixDocument7 pages(MRDTM 418) : Quantitative Extraction of Asphalt From Asphalt Paving Mixsara tahaNo ratings yet

- Unit Weight and Specific Gravity W/S E: Forms Example 12345 Super Concrete Ready Mix Sean Parker 123Document2 pagesUnit Weight and Specific Gravity W/S E: Forms Example 12345 Super Concrete Ready Mix Sean Parker 123HanafiahHamzahNo ratings yet

- Ds - TECHDRAIN GTG 30.6 - enDocument1 pageDs - TECHDRAIN GTG 30.6 - enThameem SharaafNo ratings yet

- Labratory TESTING FORMSDocument71 pagesLabratory TESTING FORMSMesfin Derbew100% (1)

- Costing SheetDocument2 pagesCosting SheetazadNo ratings yet

- Sancone SalinanDocument2 pagesSancone SalinanAnwarNo ratings yet

- Bitumen Content TestingDocument9 pagesBitumen Content TestingjaffnaNo ratings yet

- Formate 111Document3 pagesFormate 111aashish patidarNo ratings yet

- Stirling: Project Masaka RoadsDocument7 pagesStirling: Project Masaka RoadsRonald WaiswaNo ratings yet

- Marshal Density, Stabilty and Flow of DBM / BCDocument3 pagesMarshal Density, Stabilty and Flow of DBM / BCanshuman prasadNo ratings yet

- Group 2 Agg Density - DataDocument4 pagesGroup 2 Agg Density - DataHind AwadNo ratings yet

- Drilling Data SheetDocument4 pagesDrilling Data SheetmghareebNo ratings yet

- Bolted Flange Thickness CalculationDocument6 pagesBolted Flange Thickness Calculationshazan0% (1)

- Sample Report Design MixDocument6 pagesSample Report Design MixShuvro ChakravortyNo ratings yet

- Table1. The Deposition Parameters of The As Prepared FilmsDocument3 pagesTable1. The Deposition Parameters of The As Prepared FilmsNader HemayaNo ratings yet

- JMF Density Void Analysis PDFDocument231 pagesJMF Density Void Analysis PDFujjawaldaharwalNo ratings yet

- Computation of Properties of Asphalt Mixtures (Bs. 598) : Remarks Test ResultsDocument1 pageComputation of Properties of Asphalt Mixtures (Bs. 598) : Remarks Test ResultsMathias OnosemuodeNo ratings yet

- Khurmala Field Field Department Drilling Deve. Oil Wells Project TU LocationDocument9 pagesKhurmala Field Field Department Drilling Deve. Oil Wells Project TU Locationahmed1adnan-10No ratings yet

- Proposed Concrete Design Mix by FilFirstDocument19 pagesProposed Concrete Design Mix by FilFirstjaymarNo ratings yet

- Summary of CAMCE Trial MixDocument1 pageSummary of CAMCE Trial MixNadira PervinNo ratings yet

- Heater Treater Design: Company Information: Project InformationDocument1 pageHeater Treater Design: Company Information: Project InformationAnonymous bHh1L1No ratings yet

- Input DataDocument1 pageInput DataForood Torabian IsfahaniNo ratings yet

- Thorplas Bearings: Engineering ManualDocument32 pagesThorplas Bearings: Engineering ManualNuM NaNo ratings yet

- M5 With Fly AshDocument3 pagesM5 With Fly AshBagish Upadhyay UpadhyayNo ratings yet

- Ds - INTERDRAIN GM & GMG 27.6 - enDocument1 pageDs - INTERDRAIN GM & GMG 27.6 - enThameem SharaafNo ratings yet

- Bitumen (Mar1) PDFDocument1 pageBitumen (Mar1) PDFvenkateswara rao PothinaNo ratings yet

- Ds - INTERDRAIN GM & GMG 25.6 - enDocument1 pageDs - INTERDRAIN GM & GMG 25.6 - enThameem SharaafNo ratings yet

- Sr. No. Particulars Value Unit of Measuremen T: MSGL-3KL-R002B/CDocument3 pagesSr. No. Particulars Value Unit of Measuremen T: MSGL-3KL-R002B/CBhaumik BhuvaNo ratings yet

- 3kl R 002ADocument3 pages3kl R 002ABhaumik BhuvaNo ratings yet

- HMA Classroom Slide PresentationDocument129 pagesHMA Classroom Slide PresentationManuel VidalNo ratings yet

- Pemintaan SumitomoDocument3 pagesPemintaan Sumitomoaptria wariskiNo ratings yet

- Marshall FormateDocument2 pagesMarshall Formateabhishek negiNo ratings yet

- LAM. B Soil Loboratory TestDocument29 pagesLAM. B Soil Loboratory TestAlex SudrajatNo ratings yet

- M15 With Fly Ash 12-10-22Document3 pagesM15 With Fly Ash 12-10-22Bagish Upadhyay UpadhyayNo ratings yet

- 2 - Log and Core Analysis 2016 PDFDocument40 pages2 - Log and Core Analysis 2016 PDFFarzaneh Sedighi100% (1)

- DGR#21 K-461 (KDS-28) Wi-07Document262 pagesDGR#21 K-461 (KDS-28) Wi-07AhmedNo ratings yet

- 2015 Corelok IncDis SMA - DPDocument5 pages2015 Corelok IncDis SMA - DPDilhara WickramaarachchiNo ratings yet

- HINCOL Rapid Setting Modified Emulsion (Bond Coat) A4 (Web)Document2 pagesHINCOL Rapid Setting Modified Emulsion (Bond Coat) A4 (Web)Tk SubhashNo ratings yet

- RoadBond QuickDocument2 pagesRoadBond QuickTk SubhashNo ratings yet

- HINCOL Bitumen Primer-2 (Web)Document2 pagesHINCOL Bitumen Primer-2 (Web)Tk SubhashNo ratings yet

- 2005 Quantifying The Effects of PMADocument18 pages2005 Quantifying The Effects of PMATk SubhashNo ratings yet

- Tender DocDocument258 pagesTender DocTk SubhashNo ratings yet

- ZycoBond 2018 1.0Document1 pageZycoBond 2018 1.0Tk SubhashNo ratings yet

- R Zycotherm-Flyer ENG 2018 1.0Document2 pagesR Zycotherm-Flyer ENG 2018 1.0Tk SubhashNo ratings yet

- Evaluation of Gilsonite Modified Asphalt Mixtures PDFDocument9 pagesEvaluation of Gilsonite Modified Asphalt Mixtures PDFTk SubhashNo ratings yet

- Hincol Application HandbookDocument86 pagesHincol Application HandbookTk Subhash0% (1)

- IRC-SP-76-2008 Guidelines of Thin and Ultra Thin White Toping PDFDocument56 pagesIRC-SP-76-2008 Guidelines of Thin and Ultra Thin White Toping PDFTk Subhash100% (1)

- IRC 047.1972 Builtup SPray GroutDocument12 pagesIRC 047.1972 Builtup SPray GroutTk SubhashNo ratings yet

- ASPHALT CUTBACK MC30, 70, 250, 500, 800, 3000: Safety Data SheetDocument11 pagesASPHALT CUTBACK MC30, 70, 250, 500, 800, 3000: Safety Data SheetTk SubhashNo ratings yet

- Fog Seal Guidelines: S C D TDocument22 pagesFog Seal Guidelines: S C D TTk SubhashNo ratings yet

- Tack Coat Best PracticesDocument17 pagesTack Coat Best PracticesTk SubhashNo ratings yet

- Profile HincolDocument19 pagesProfile HincolTk SubhashNo ratings yet