Professional Documents

Culture Documents

High Precision X-Ray Fluorescence Analysis (XRF) by Reconstitution Technique

Uploaded by

Anonymous FW5PVUpOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

High Precision X-Ray Fluorescence Analysis (XRF) by Reconstitution Technique

Uploaded by

Anonymous FW5PVUpCopyright:

Available Formats

Chapter 1: Inorganic Analysis Reference procedure

High Precision X-Ray Fluorescence Analysis (XRF)

by Reconstitution Technique

Key words

Elemental analysis, reconstitution, precision analysis, synthetic calibration, XRF analysis

Quantities and items tested

Amounts of elements as major and minor constituents (atomic number 12 (magnesium), excluding the noble

gases and halogens) in solid materials such as metals, oxides and silicates e.g. metal alloys, ores, soils, minerals,

cements, building materials

Testing range Uncertainty of results

Mass fractions of elements from 0.1 g/kg to 800 g/kg from 5 % to 0.1 %

Fields of application

Certification of reference materials; precision analysis; e.g. of high-grade inorganic materials such as refractory

metals or special metal alloys

Methodology and instrumentation

The method of reconstitution is based on the use of synthetic calibration samples. Because of the definite

manufacturing process it is possible to use the same sample preparation procedure for both the analysis sample

and for the calibration samples, too.

The basic principle of the reconstitution is based on a pre-analysis of the analysis sample and bracketing

calibration samples an iterative assimilation of the composition of the calibration samples and the analysis

sample itself. The calibration range is therefore always adjusted to the individual case.

By the iterative adjustment of the composition of the calibration samples and the analysis sample matrix effects

and a deviation from the linear calibration function are avoidable in most cases. The trueness of the method is

controlled by the iterative principle itself.

Because of the advantages of the sample preparation procedure and the high precision XRF-analysis is the ideal

method for realizing the reconstitution principle. The method is basically usable for all analytical methods which

allow an isoformation of calibration and analysis sample, especially all methods based on solutions.

If XRF-analysis is applied the preparation of the calibration samples and the measuring sample of the material to

be investigated is realized by the fusion technique using lithium or sodium tetraborate.

Qualification and quality assurance

A high reliability of the analytical results by using the reconstitution technique is attained by the direct control of

accuracy using the iterative adjustment of calibration and analysis samples resulting in an extensive avoidance of

matrix effects.

If a reconstitution analysis is performed by XRF a number of advantages are contributing to a minimization and a

high reliability of the measuring uncertainty:

Repeated measurements with identical samples

Long range time stability of the signals

Calculable uncertainty contributions by sample preparation procedures

Optimal control of trueness

Elimination of matrix effects and optimization of calibration

Contact: Dr. Markus Ostermann Phone: +49 30 8104 1143

E-mail: markus.ostermann@bam.de Fax: +49 30 8104 1147

Division I.4: Process Analytical Technology back to Catalogue of Reference

Procedures

Date: June 2010 1(2) 104en.pdf

Reference procedure Chapter 1: Inorganic Analysis

Further information

Basic principle of the reconstitution technique

In contrast to the conventional analytical mode (calibration for the realization of a correlation between

measuring values and amounts) the contents of elements by using the synthetic mode of reconstitution can

only be accepted as free of interferences and therefore as true, if an identity of analysis sample and the

reference sample is obtained in a sufficient way:

The composition of an unknown analysis sample is determined by synthesis of calibration samples which lead

to equal signals compared to the analysis sample.

The composition of the calibration samples is varied in an iterative way to a point where the difference among the

signals of all samples is no longer significant.

Iterative assimilation of the composition of calibration samples towards the analysis sample

Only pure substances of exactly defined stoichiometry and of well-known grade of impurities are used to prepare

the synthetic calibration samples.

Oxides, carbonates or other compounds of the relevant elements which can be produced in a suitable way with a

high grade of purity are used for this purpose. Also pure elements can be used.

The analysis sample as well as the synthetic mixtures for the calibration samples are prepared as glass fusions

(lithium or sodium tetraborate) to obtain homogeneous samples for the XRF measurements.

While preparing the borate fusions reproducible operating conditions (temperature program) have to be maintained

in order to get an optimum comparability between the calibrations samples and the analysis sample.

1150C

700C 850C

decomposition

warming up cooling down

+ 4.5 g

oxidation

Lithiumtetraborate

(Sodiumnitrate)

20C

ca. 70 30 15 15 time in minutes

Temperature program for the fusion of borate glass samples for XRF analysis

Applications

Analysis of Si-, Ca- und Al-containing alloys Analysis of copper, bronze, brass and white

alloy

Analysis of ferrous alloys and nickel alloys

Analysis of ferrochromium

Analysis of natural and technical oxides

Analysis of refractory materials (e.g. tungsten,

Analysis of cements and building materials

tantalum, niobium)

Literature

Gotthard Staats und Siegfried Noack,

Qualittssicherung in der Analytik; Die Rekonstitution Eine Methode zur Optimierung der Richtigkeit von

Analysen

Verlag Stahleisen GmbH, Dsseldorf 1996 ISBN 3-514-00581-8

Date: June 2010 2(2) 104en.pdf

You might also like

- 281 283 PMR Oct11Document3 pages281 283 PMR Oct11kulihat_hijauNo ratings yet

- PotassiumDocument5 pagesPotassiumAhmed IsmailNo ratings yet

- Session 3 - Efficiency Element ICPDocument54 pagesSession 3 - Efficiency Element ICPHasanuddin NurdinNo ratings yet

- Application Battery Impurities 5110 Icp Oes 5991 9508en Us AgilentDocument5 pagesApplication Battery Impurities 5110 Icp Oes 5991 9508en Us AgilentxxxNo ratings yet

- NewItem 110 HzincineratorDocument158 pagesNewItem 110 HzincineratorchiragNo ratings yet

- E1409 13Document7 pagesE1409 13senthilNo ratings yet

- Environmental Test EquipmentsDocument17 pagesEnvironmental Test EquipmentsJayu DarjiNo ratings yet

- Niton Apollo Stainless SteelDocument2 pagesNiton Apollo Stainless Steelcelestino biasottoNo ratings yet

- Determination of Trace Impurities in High Purity Tellurium (7N Pure) Using ICP-MS and Transversely Heated Electrothermal AASDocument5 pagesDetermination of Trace Impurities in High Purity Tellurium (7N Pure) Using ICP-MS and Transversely Heated Electrothermal AASNarayan BhatNo ratings yet

- What Is Analytical Chemistry?: Seeks ImprovedDocument52 pagesWhat Is Analytical Chemistry?: Seeks ImprovedFiqran Ratu WaraNo ratings yet

- Atomic Absorption SpectrosDocument21 pagesAtomic Absorption SpectrosTho AnhNo ratings yet

- Automated Analyser For Monitoring The Contents of Hydrocarbons in Gas Emitted From Exploratory Bore-Holes in The Gas and Oil IndustryDocument7 pagesAutomated Analyser For Monitoring The Contents of Hydrocarbons in Gas Emitted From Exploratory Bore-Holes in The Gas and Oil Industrymelo2007No ratings yet

- TOM Unit VDocument25 pagesTOM Unit VShajin SNo ratings yet

- Articulo para DiscusionDocument10 pagesArticulo para DiscusionMAILETH CAROLINA ANILLO ARRIETANo ratings yet

- Analysis of Pure Copper - A Comparison of Analytical MethodsDocument12 pagesAnalysis of Pure Copper - A Comparison of Analytical Methodsban bekasNo ratings yet

- Thermal and Mechanical Analysis Alan Murphy: CNMR - Athlone Institute of TechnologyDocument34 pagesThermal and Mechanical Analysis Alan Murphy: CNMR - Athlone Institute of TechnologyKaushik SenguptaNo ratings yet

- TC Forensic, Australia - Masters Degree ThesisDocument4 pagesTC Forensic, Australia - Masters Degree Thesisecordova1No ratings yet

- Metals Ebook 202011 WebDocument13 pagesMetals Ebook 202011 WebRioZuNo ratings yet

- Certificate of Analysis: National Institute of Standards and TechnologyDocument5 pagesCertificate of Analysis: National Institute of Standards and TechnologyJohn GiannakopoulosNo ratings yet

- ASNT Nivel III ExaminationDocument6 pagesASNT Nivel III ExaminationjomsedNo ratings yet

- Chemical Fingerprinting For Critical Material Constituents: December 2003 Process Control Focus Group ToolboxDocument31 pagesChemical Fingerprinting For Critical Material Constituents: December 2003 Process Control Focus Group ToolboxPazhanisamy MurugaianNo ratings yet

- Applications of Zeeman Graphite Furnace Atomic Absorption Spectrometry in the Chemical Laboratory and in ToxicologyFrom EverandApplications of Zeeman Graphite Furnace Atomic Absorption Spectrometry in the Chemical Laboratory and in ToxicologyC. MinoiaNo ratings yet

- Automatizacion Del Laboratorio Pa F.A-TesisDocument295 pagesAutomatizacion Del Laboratorio Pa F.A-TesisAnonymous FfIxH2o9No ratings yet

- XLT Mining App NotesDocument4 pagesXLT Mining App NotesKarthigeyan SukumarNo ratings yet

- PB y As Perkin Elmer PDFDocument5 pagesPB y As Perkin Elmer PDFChipo ChipNo ratings yet

- 98 PB IRs JAASDocument5 pages98 PB IRs JAASmanudemNo ratings yet

- App PinaacletoxicmetalsedibleoilsDocument4 pagesApp PinaacletoxicmetalsedibleoilsA Lutfi FuadiNo ratings yet

- Application of High Temperature X-Ray Diffraction As A Tool For Material Characterisation and Product OptimisationDocument13 pagesApplication of High Temperature X-Ray Diffraction As A Tool For Material Characterisation and Product OptimisationQudratAQKhanNo ratings yet

- CHEMISTRY 3080 4.0 Instrumental Methods of Chemical AnalysisDocument15 pagesCHEMISTRY 3080 4.0 Instrumental Methods of Chemical AnalysisFatma MaharaniNo ratings yet

- INAA Application For Trace Element Determination IDocument8 pagesINAA Application For Trace Element Determination IbcfNo ratings yet

- Stannum: Jurnal Sains Dan Terapan Kimia: Website: Doi: 10.33019/jstk.v3i2.2338Document8 pagesStannum: Jurnal Sains Dan Terapan Kimia: Website: Doi: 10.33019/jstk.v3i2.2338Danish AyeshaNo ratings yet

- Analytical ChemistryDocument79 pagesAnalytical ChemistryDipeshBardoliaNo ratings yet

- Thermal Characterization of Polymers - Thermoplastics, Thermoplastic Elastomers, Elastomers and ThermosetsDocument36 pagesThermal Characterization of Polymers - Thermoplastics, Thermoplastic Elastomers, Elastomers and ThermosetsNETZSCH - Leading Thermal AnalysisNo ratings yet

- Brochure TGA enDocument12 pagesBrochure TGA enStancu BranNo ratings yet

- Validation Plan FormatDocument8 pagesValidation Plan FormatNora BuanNo ratings yet

- Building A Comprehensive Reference Tandem MS Library of Peptides, Glycans and Glycopeptides For Therapeutic AntibodiesDocument36 pagesBuilding A Comprehensive Reference Tandem MS Library of Peptides, Glycans and Glycopeptides For Therapeutic AntibodiesМаратNo ratings yet

- Bouchard 2014Document6 pagesBouchard 2014Linda Alejandra PerezNo ratings yet

- Determination of Mercury in Soil Samples: Utilizing Direct Mercury Analysis in As Little As 6 Minutes Per SampleDocument3 pagesDetermination of Mercury in Soil Samples: Utilizing Direct Mercury Analysis in As Little As 6 Minutes Per SampleJorge Sierra PaezNo ratings yet

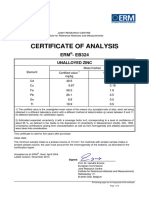

- Certificate of Analysis: ERM - EB324Document3 pagesCertificate of Analysis: ERM - EB324Sidneide Ferreira SantosNo ratings yet

- A 751Document7 pagesA 751Senthilkumar DharmarajNo ratings yet

- Romatographic Methods of Analysis: Section: 5 Gas Chromatography (GC)Document19 pagesRomatographic Methods of Analysis: Section: 5 Gas Chromatography (GC)ahmed hagagNo ratings yet

- Technology: Thermal and Mechanical Analysis Alan MurphyDocument34 pagesTechnology: Thermal and Mechanical Analysis Alan MurphyMukul AzadNo ratings yet

- Jurnal XRFDocument5 pagesJurnal XRFNabila Qurrota AiniNo ratings yet

- CHEMISTRY 3080 4.0 Instrumental Methods of Chemical AnalysisDocument49 pagesCHEMISTRY 3080 4.0 Instrumental Methods of Chemical AnalysisFatma MokhtarNo ratings yet

- Analysis of Residual Elements in Steel Pipe With The Thermo Scientific Niton XL3t 900 GOLDD SeriesDocument2 pagesAnalysis of Residual Elements in Steel Pipe With The Thermo Scientific Niton XL3t 900 GOLDD SeriesMarioNo ratings yet

- Hydra-C Application Note #1047Document2 pagesHydra-C Application Note #1047pravin kondeNo ratings yet

- Limestone Whitepaper PDFDocument5 pagesLimestone Whitepaper PDFras110477No ratings yet

- Trace Metal Content Analysis in Carbon Black: Standard Test Method ForDocument4 pagesTrace Metal Content Analysis in Carbon Black: Standard Test Method ForSdferwste SrqreNo ratings yet

- Archeological SDocument10 pagesArcheological SLuís Carlos Leva BorduchiNo ratings yet

- Parametric Optimization of Selective Laser Melting For Forming Ti6Al4V Samples by Taguchi MethodDocument7 pagesParametric Optimization of Selective Laser Melting For Forming Ti6Al4V Samples by Taguchi MethodHa Linh PhanNo ratings yet

- Total Nitrogen in Petroleum Products and Inorganic Materials by An Automated Micro-Dumas Nitrogen AnalyzerDocument10 pagesTotal Nitrogen in Petroleum Products and Inorganic Materials by An Automated Micro-Dumas Nitrogen AnalyzerGuisela Carbajal RomeroNo ratings yet

- 5.sensors 20 05992 v2Document16 pages5.sensors 20 05992 v2ARSALAN AHMADNo ratings yet

- D 5885 PDFDocument5 pagesD 5885 PDFsud1313100% (2)

- Materials Analysis Icp Aes PDFDocument4 pagesMaterials Analysis Icp Aes PDFFirdha Aulia Noor FadilahNo ratings yet

- Catalyst CharacterizationDocument5 pagesCatalyst CharacterizationghenisNo ratings yet

- Industrial Production of Iron OreDocument19 pagesIndustrial Production of Iron OreChandrakumar87No ratings yet

- Prospekt Vtocc 2013 en Web 1Document16 pagesProspekt Vtocc 2013 en Web 1SutarnoNo ratings yet

- Brochure Elementrac ONH Hydrogen in Steel enDocument6 pagesBrochure Elementrac ONH Hydrogen in Steel enStancu BranNo ratings yet

- Loubser - Combining (2008) XRD FOR MINE PDFDocument11 pagesLoubser - Combining (2008) XRD FOR MINE PDFWill NinaNo ratings yet

- PokjDocument13 pagesPokjAnonymous FW5PVUpNo ratings yet

- Environmental Impacts of Synthetic Based Drilling Fluids: OCS Study MMS 2000-064Document132 pagesEnvironmental Impacts of Synthetic Based Drilling Fluids: OCS Study MMS 2000-064shuvo134No ratings yet

- 74 File Cat29 en Num0 PDFDocument1 page74 File Cat29 en Num0 PDFAnonymous FW5PVUpNo ratings yet

- BIPP.08.1-01.Customer Complaint Registration BooksDocument2 pagesBIPP.08.1-01.Customer Complaint Registration BooksAnonymous FW5PVUpNo ratings yet

- 2 - SK HandaDocument27 pages2 - SK HandachakrabortyPNo ratings yet

- Keywords Fresh Liver, One-Drop Method, Teflon Bomb, Trace Metals, Inductively Coupled Plasma Atomic Emission SpectrometryDocument2 pagesKeywords Fresh Liver, One-Drop Method, Teflon Bomb, Trace Metals, Inductively Coupled Plasma Atomic Emission SpectrometryAnonymous FW5PVUpNo ratings yet

- 74 File Cat29 en Num0Document3 pages74 File Cat29 en Num0Anonymous FW5PVUpNo ratings yet

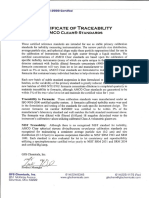

- AMCO Clear Certificate of Traceability-SignedDocument2 pagesAMCO Clear Certificate of Traceability-SignedAnonymous FW5PVUpNo ratings yet

- YyyjiDocument18 pagesYyyjiAnonymous FW5PVUpNo ratings yet

- Some Aspects of Sample Preparation For Determining Trace Elements by Atomic Emission and Mass SpectrometryDocument6 pagesSome Aspects of Sample Preparation For Determining Trace Elements by Atomic Emission and Mass SpectrometryAnonymous FW5PVUpNo ratings yet

- Determination of Cadmium, Lead, Iron, Nickel and Chromium in Selected Food Matrices by Plasma Spectrometric TechniquesDocument6 pagesDetermination of Cadmium, Lead, Iron, Nickel and Chromium in Selected Food Matrices by Plasma Spectrometric TechniquesAnonymous FW5PVUpNo ratings yet

- Yyyji PDFDocument9 pagesYyyji PDFAnonymous FW5PVUpNo ratings yet

- 1 549 07083Document11 pages1 549 07083navneetkaur77No ratings yet

- Zasd PDFDocument3 pagesZasd PDFAnonymous FW5PVUpNo ratings yet

- 5990 8767en PDFDocument72 pages5990 8767en PDFAnonymous FW5PVUpNo ratings yet

- ZasdDocument13 pagesZasdAnonymous FW5PVUpNo ratings yet

- 2 Ftir2000Document3 pages2 Ftir2000Anonymous FW5PVUpNo ratings yet

- 5990 8767enDocument5 pages5990 8767enAnonymous FW5PVUpNo ratings yet

- Waste Analysis Plan Analytical MethodDocument1 pageWaste Analysis Plan Analytical MethodAnonymous FW5PVUpNo ratings yet

- Sdarticle pdfEGTRDocument1 pageSdarticle pdfEGTRAnonymous FW5PVUpNo ratings yet

- Spectraa 240Document58 pagesSpectraa 240JESUS ABAD100% (1)

- Internal Audit Report 2014Document3 pagesInternal Audit Report 2014Anonymous FW5PVUpNo ratings yet

- 5990 8767en PDFDocument72 pages5990 8767en PDFAnonymous FW5PVUpNo ratings yet

- LPI Organization Chart ISO 9001Document8 pagesLPI Organization Chart ISO 9001Anonymous FW5PVUpNo ratings yet

- Analytical Chemistry Laboratories PDFDocument9 pagesAnalytical Chemistry Laboratories PDFAnonymous FW5PVUpNo ratings yet

- 90 1008 01 PDFDocument6 pages90 1008 01 PDFEmad EmadNo ratings yet

- 0157 OPTIMA8000 Libya PDFDocument6 pages0157 OPTIMA8000 Libya PDFEmad EmadNo ratings yet

- Waste Analysis Plan Analytical Method PDFDocument9 pagesWaste Analysis Plan Analytical Method PDFAnonymous FW5PVUpNo ratings yet

- 44-74110APP ElementalAnalysisofSoilsDocument4 pages44-74110APP ElementalAnalysisofSoilsAnonymous FW5PVUpNo ratings yet

- Dielectric PropertiesDocument10 pagesDielectric PropertiesMuhammad Lutfi Almer HasanNo ratings yet

- BG1005 - 2010 - Part II - HW#1Document4 pagesBG1005 - 2010 - Part II - HW#1blueworld_918094No ratings yet

- Separating Mixtures Particulate NatureDocument5 pagesSeparating Mixtures Particulate NatureStruggl1ngNo ratings yet

- Characteristics of Dough and Bread As Affected by The Incorporation of Sweet Potato Paste in The FormulationDocument10 pagesCharacteristics of Dough and Bread As Affected by The Incorporation of Sweet Potato Paste in The FormulationDanaNo ratings yet

- Murphy's Law PDFDocument4 pagesMurphy's Law PDFMarcelo Catalan LopezNo ratings yet

- Continuum Electromechanics Cem - 811Document637 pagesContinuum Electromechanics Cem - 811kgrhoads100% (1)

- Guide To The Construction Installation Operation and Maintenance of Air ReceiversDocument34 pagesGuide To The Construction Installation Operation and Maintenance of Air Receiversjosh100% (1)

- Recommended Practices ON Static Electricity: OISD-110 OISD - 110 (Rev.1)Document35 pagesRecommended Practices ON Static Electricity: OISD-110 OISD - 110 (Rev.1)manuppm100% (1)

- Tanker Cargo CalculationsDocument5 pagesTanker Cargo Calculationsutkarshgahtori83% (6)

- PG 91Document1 pagePG 91Shahruzi MahadzirNo ratings yet

- Calculate The Mole ConceptDocument1 pageCalculate The Mole ConceptRajiv Shankar SinhaNo ratings yet

- Chemical SafetyDocument28 pagesChemical SafetyYves CaraangNo ratings yet

- 5 Mass TransferDocument85 pages5 Mass TransfergeorgiadisgNo ratings yet

- Chemical Equilibrium Worksheet 2 AnsDocument3 pagesChemical Equilibrium Worksheet 2 AnsYing LiangNo ratings yet

- Juba Form Two ExamDocument8 pagesJuba Form Two ExamHossam Abdalla SalehNo ratings yet

- S K HazraDocument6 pagesS K HazraRicky MenonNo ratings yet

- What Are Inorganic CompoundsDocument1 pageWhat Are Inorganic CompoundsSherryl V MorenoNo ratings yet

- Diploma Thomas UehlingerDocument75 pagesDiploma Thomas UehlingerTienTranNo ratings yet

- Want To Be A DoctorDocument17 pagesWant To Be A DoctormadhavNo ratings yet

- 1995 Review - Aqueous Tape Casting of Ceramic PowdersDocument12 pages1995 Review - Aqueous Tape Casting of Ceramic PowdersFreudensteinitzNo ratings yet

- Fuel Oil I&C Conceptual Basic Design: I.P.D.C. Project: Shirvan Gas Turbine Power Plant (Bop2 Portion)Document14 pagesFuel Oil I&C Conceptual Basic Design: I.P.D.C. Project: Shirvan Gas Turbine Power Plant (Bop2 Portion)Ehsan PourangNo ratings yet

- CHENG 211 Assignment 1 s2 17 18Document5 pagesCHENG 211 Assignment 1 s2 17 18Hayat YusufNo ratings yet

- Introductory Experiment: Calibration of Volumetric GlasswareDocument4 pagesIntroductory Experiment: Calibration of Volumetric GlasswareOcampo AmyNo ratings yet

- As 4873.1-2005 Recommended Practice For Inductively Coupled Plasma-Mass Spectrometry (ICP-MS) Principles andDocument8 pagesAs 4873.1-2005 Recommended Practice For Inductively Coupled Plasma-Mass Spectrometry (ICP-MS) Principles andSAI Global - APACNo ratings yet

- AGARD - Blading Design For Axial Turbomachines PDFDocument213 pagesAGARD - Blading Design For Axial Turbomachines PDFRadek Wasilewski100% (1)

- P 04A Tutorial 3 2010Document1 pageP 04A Tutorial 3 2010jonnoyjohnsonNo ratings yet

- HPLC For Carbohydrate Analysis: October 2014Document21 pagesHPLC For Carbohydrate Analysis: October 2014Julia Zahra ArdiantiNo ratings yet

- Van't HoffDocument6 pagesVan't HoffKrisna PamungkasNo ratings yet

- MOA of BarbituratesDocument3 pagesMOA of BarbituratesReymart FernandezNo ratings yet

- Astm 578Document5 pagesAstm 578ASWANTH T S100% (1)