Professional Documents

Culture Documents

Cam

Uploaded by

Sheikh AzizCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cam

Uploaded by

Sheikh AzizCopyright:

Available Formats

DYNACAM HELP FILE Copyright 2010 Robert L.

Norton

PRESSURE ANGLERADIAL CAMTRANSLATING ROLLER FOLLOWER

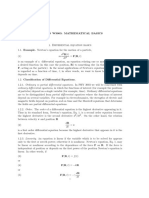

The pressure angle is defined as shown in Figure 7-2 that depicts a radial or disk cam with a

translating roller follower. Force can only be transmitted from cam to follower or vice versa

along the common normal or axis of transmission which is perpendicular to the axis of slip,

or common tangent as shown in Figure 7-2. The pressure angle is the angle between the

direction of motion (velocity) of the follower and the direction of the axis of transmission.*

When = 0, all the transmitted force goes into motion of the follower and none into slip ve-

locity. When becomes 90 there will be no motion of the follower. As a rule of thumb, we

would like the pressure angle to be between zero and about 30 for translating followers to

avoid excessive side load on the sliding follower. If the follower is oscillating on a pivoted

arm, a pressure angle up to about 35 is acceptable. Values of greater than these can in-

crease the follower sliding or pivot friction to undesirable levels and may tend to jam a trans-

lating follower in its guides.

F

Pressure Vfollower

angle

d

R1 Transmission

angle

R1

R2 b

Common normal

(axis of transmission) R2

a

Common tangent Roller follower

(axis of slip)

N sin

Cam

N cos N Normal force

cam

FIGURE 7-2

Cam pressure angle and forces in a radial cam with offset translating roller follower

Excerpted from Norton, R. L., Cam Design and Manufacturing Handbook 2ed, Industrial Press, New York, 1

Copyright 2009. All rights reserved. For more information on this topic see the complete book.

You might also like

- Handling and Storage of Flammable MaterialsDocument13 pagesHandling and Storage of Flammable MaterialsSheikh AzizNo ratings yet

- Handling and Storage of Flammable Materials PDFDocument20 pagesHandling and Storage of Flammable Materials PDFSheikh AzizNo ratings yet

- Asrar E Khudi by Allama Muhammad Iqbal PDFDocument87 pagesAsrar E Khudi by Allama Muhammad Iqbal PDFSheikh AzizNo ratings yet

- PM Wbs Guide PDFDocument56 pagesPM Wbs Guide PDFAbdul100% (2)

- Bal-e-Jibril-071 Ki Haq Se Farishton Ne Iqbal Ki GhamaziDocument1 pageBal-e-Jibril-071 Ki Haq Se Farishton Ne Iqbal Ki GhamaziSheikh AzizNo ratings yet

- Multidisciplinary Projects For Second YeDocument5 pagesMultidisciplinary Projects For Second YeSheikh AzizNo ratings yet

- Multidisciplinary Projects For Second YeDocument5 pagesMultidisciplinary Projects For Second YeSheikh AzizNo ratings yet

- Allama Iqbal Aur Hum BookDocument128 pagesAllama Iqbal Aur Hum BookSheikh AzizNo ratings yet

- Allama Iqbal Aur Hum Book PDFDocument128 pagesAllama Iqbal Aur Hum Book PDFSheikh AzizNo ratings yet

- PM Wbs Guide PDFDocument56 pagesPM Wbs Guide PDFAbdul100% (2)

- PM Wbs Guide PDFDocument56 pagesPM Wbs Guide PDFAbdul100% (2)

- Differential Equation BasicsDocument4 pagesDifferential Equation BasicsSheikh AzizNo ratings yet

- OpsMan Course Handbook PUBLICDocument57 pagesOpsMan Course Handbook PUBLICSheikh AzizNo ratings yet

- Rahman BabaDocument155 pagesRahman BabaSheikh AzizNo ratings yet

- Solution of The Diffusion Equation: Introduction and Problem DefinitionDocument37 pagesSolution of The Diffusion Equation: Introduction and Problem DefinitionPratyushAgarwalNo ratings yet

- Approx Method Draw Involute Tooth Rev2Document23 pagesApprox Method Draw Involute Tooth Rev2Sheikh AzizNo ratings yet

- Methods of Producing Low Temperatures: LessonDocument14 pagesMethods of Producing Low Temperatures: Lessoncaptainhass100% (1)

- Asrar E Khudi by Allama Muhammad Iqbal PDFDocument87 pagesAsrar E Khudi by Allama Muhammad Iqbal PDFSheikh AzizNo ratings yet

- Nptel - Ac.in Courses IIT-MADRAS Applied Thermodynamics Module 4 6 AsdcDocument4 pagesNptel - Ac.in Courses IIT-MADRAS Applied Thermodynamics Module 4 6 AsdcSanjeev PrakashNo ratings yet

- Book 6th EditionDocument991 pagesBook 6th EditionSheikh AzizNo ratings yet

- Quality Control Solutions Manual Dale H. Besterfield 9eDocument20 pagesQuality Control Solutions Manual Dale H. Besterfield 9eAubrey Alvarez55% (11)

- Solution Statics Meriam 6th Chapter02 For PrintDocument25 pagesSolution Statics Meriam 6th Chapter02 For PrintRone César FonsecaNo ratings yet

- Gazette 5th Pec 2017 KasurDocument192 pagesGazette 5th Pec 2017 KasurSheikh AzizNo ratings yet

- Lewis Gun Mechanism Made Easy PDFDocument20 pagesLewis Gun Mechanism Made Easy PDFSheikh AzizNo ratings yet

- Pro - ENGINEER Wildfire 5.0 - Tutorial and Multimedia CD (Book, 2009) (WorldCatDocument3 pagesPro - ENGINEER Wildfire 5.0 - Tutorial and Multimedia CD (Book, 2009) (WorldCatSheikh AzizNo ratings yet

- Machinist Course - Metal Properties, Characteristics, Uses, and CodesDocument98 pagesMachinist Course - Metal Properties, Characteristics, Uses, and Codesmerlinson1100% (5)

- Bolt, Nut, Screw, and Washer Manufacturing ReportDocument40 pagesBolt, Nut, Screw, and Washer Manufacturing ReportLemi Chala BeyeneNo ratings yet

- Metals and Their Properties - Physical and ChemicalDocument5 pagesMetals and Their Properties - Physical and Chemicalcourtz911No ratings yet

- Approx Method Draw Involute ToothDocument10 pagesApprox Method Draw Involute ToothAustin BruceNo ratings yet

- 7 - Diesel - Cycle PDFDocument5 pages7 - Diesel - Cycle PDFLalith KrishnanNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- 8 - Unit 4-PP Economics-Prob IDocument10 pages8 - Unit 4-PP Economics-Prob IMohammad Ibrahim KhaleelNo ratings yet

- Bang Nhiet Dung Cua Hoi NuocDocument3 pagesBang Nhiet Dung Cua Hoi NuocNgoc AyucontrolNo ratings yet

- Water Content of The Kawah Kamojang Geothermal ReservoirDocument10 pagesWater Content of The Kawah Kamojang Geothermal ReservoirAswar Abu KhawlahNo ratings yet

- Commissioning Checklist 2Document5 pagesCommissioning Checklist 2Gaurav TaydeNo ratings yet

- Basic Energy Meters (EMS-Series)Document3 pagesBasic Energy Meters (EMS-Series)Jaskaran SinghNo ratings yet

- Tapping Volcanic Energy for Human UseDocument8 pagesTapping Volcanic Energy for Human UseKadita Mage100% (1)

- Starting induction motors efficientlyDocument25 pagesStarting induction motors efficientlyMonika VaitulionytėNo ratings yet

- Shielding PDFDocument49 pagesShielding PDFgilbertomjcNo ratings yet

- Protective RelaysDocument13 pagesProtective RelaysTanvir ShakilNo ratings yet

- Thermal Chemistry Calorimeter Problem AnswersDocument3 pagesThermal Chemistry Calorimeter Problem AnswersrkvermNo ratings yet

- Insulation Monitoring Relay: CM-IWM.11Document11 pagesInsulation Monitoring Relay: CM-IWM.11F Diaz BarreraNo ratings yet

- IGBT Module Selection and ApplicationDocument7 pagesIGBT Module Selection and Applicationvdsantos74No ratings yet

- ME8391 IQ 03 - by LearnEngineering - inDocument24 pagesME8391 IQ 03 - by LearnEngineering - inelabalajiNo ratings yet

- Assignment 3Document3 pagesAssignment 3daffy duckNo ratings yet

- 3 Winding Transformer Impedance Calculation in IEC Short Circuit StudyDocument4 pages3 Winding Transformer Impedance Calculation in IEC Short Circuit StudydrboudNo ratings yet

- ME 8792 PPE Unit - 1Document142 pagesME 8792 PPE Unit - 1UdamanNo ratings yet

- Calculate LT Cable Size and Voltage DropDocument13 pagesCalculate LT Cable Size and Voltage DropsulaimanNo ratings yet

- Modeling and Simulation of Lithium-Ion Battery ConsideringDocument7 pagesModeling and Simulation of Lithium-Ion Battery ConsideringCarlos Morales ZamoraNo ratings yet

- EEE 1105 011 Comparison of The Effects of Phase To Ground FaultsDocument7 pagesEEE 1105 011 Comparison of The Effects of Phase To Ground FaultsFAKEIDS421No ratings yet

- Crush and RestitutionDocument77 pagesCrush and RestitutionFabiano CardosoNo ratings yet

- 04 Nonideal Transformer PDFDocument20 pages04 Nonideal Transformer PDFchacher100% (1)

- SPM Physics Wave Oscillation Damping ResonanceDocument4 pagesSPM Physics Wave Oscillation Damping ResonanceIVAN TIONG WEI JUN MoeNo ratings yet

- Science 6.5Document6 pagesScience 6.5Nestlee ArnaizNo ratings yet

- COOLER MASTER - RS-850-AFBA-G1 - 850W - ECOS 3494 - ReportDocument1 pageCOOLER MASTER - RS-850-AFBA-G1 - 850W - ECOS 3494 - ReportSat.Narkoba Polres EndeNo ratings yet

- Anly Controller: Multi Function Digital Voltage RelayDocument3 pagesAnly Controller: Multi Function Digital Voltage RelayHannan RizqiNo ratings yet

- Mitsubishi ElectricDocument140 pagesMitsubishi ElectricNguyễn Bùi ĐạtNo ratings yet

- Phyc 2121 Week 11 20Document89 pagesPhyc 2121 Week 11 20ElloNo ratings yet

- Concentration of Cane Sugar Syrup in An EvaporatorDocument8 pagesConcentration of Cane Sugar Syrup in An EvaporatorJohn Fritz FestejoNo ratings yet

- Hydrometer Calibration by Hydrostatic Weighing With Automated Liquid Surface PositioningDocument15 pagesHydrometer Calibration by Hydrostatic Weighing With Automated Liquid Surface PositioningSebastián MorgadoNo ratings yet

- Name: Maturan, Renz Myko B. Date: November 28, 2022 Subject & Section: EE 330 AC/DC Machineries - CDocument7 pagesName: Maturan, Renz Myko B. Date: November 28, 2022 Subject & Section: EE 330 AC/DC Machineries - CRenz MykoNo ratings yet