Professional Documents

Culture Documents

US7850178B2

Uploaded by

marcgleb0 ratings0% found this document useful (0 votes)

4 views7 pagesAdjustable toe link

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentAdjustable toe link

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

4 views7 pagesUS7850178B2

Uploaded by

marcglebAdjustable toe link

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 7

(2)

6

sy

03)

wo

an

@

6s)

(60)

on

(2)

68)

656)

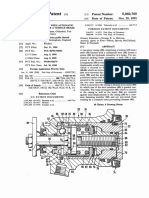

United States Patent

Fischer et al.

MOTOR VEHICLE ADJUSTABLE TO!

‘USOO7850178B2

1E LINK

Inventors: Markus Fischer, Aan Arbor, MI (US)

Erie Holmes, Aan Arhor, Mi

S)

Assignee: ZF Lemforder GmbH, Lemfoede (DE)

Notice: Subject to any disclaimer, the

patent is extended of adjusted under 35

USC. 154(b) by 107 days.

Appl. Now 12/828,282

Biled: Dee. 4, 2008

Prior Publication Data

US 2009101405061 Jun, 4, 2009

Related US.

Application Data

Provisional aplication No, 601992,176, fk

4.2007,

sssn0s2

01296

S506

S088

pre

7185356

7201500

20060127166

KR

KR

KR

KR

led on Dee.

m

me

me

alt

(10) Patent No.

4s) Date of Patent:

aig

Siem

‘199%

21997

22007

32007

‘42007

62006

US 7,850,178 B2

Dec. 14, 2010

Meee 298967

Mach ‘se

Nea font

waaes ‘oad

ier

Bie >see

apes ina

Hoc woe

PORPIGN PATENT DOCUMENTS

20020068591

2o0s00n1901

* cited by examiner

Primary Examiner

Assistant Examiner

(74) Attorney, Agent, or Firm—Gillord, Keass, Sprinkle

Anderson & Citkovsi, 2:C

Inc

B06 702 (2006.01)

us.cl, 280786.758

Fleld of Classification Search 28086.758, (5

2RO/9R.S1; 405/43, 44, 45, 46, 47.48, 74/57

74/586

‘ce pplication file for complete search history.

References Cited

USS. PATENT DOCUMENTS

396.800 A * 2/1970 Brernsk

120 103

20 i?

Ir

r197

n197

52002

42003

Panl N Dickson

Robert

A Coker

ABSTRACT

A toe link for the suspension system of a vehicle includes

‘means for adjusting the axial length of the we link while

preventing relative rotation of the extending ends of the toe

Tink,

79586

104

/

100

8 Claims, 3 Drawing Sheets

105

101

é,

110

|

Ft

aoa ‘222

_!

nt

U.S. Patent Dec. 14, 2010 Sheet 1 of 3 US 7,850,178 B2

U.S. Patent Dec. 14, 2010 Sheet 2 of 3 US 7,850,178 B2

U.S. Patent Dec. 14, 2010 Sheet 3 of 3 US 7,850,178 B2

oT)

100 212

US 7,850,178 B2

1

MOTOR VEHICLE ADJUSTABLE TOE LINK

(CROSS-REPERENCE TO RELATED

"APPLICATIONS,

‘This application claims the benefit of U.S. Provisional

Application Ser. No, 60992,176, lsd Dee. 4 2007, which is

Jinconporated herein by reference.

FIELD OF THE INVENTION

“The present invention relates to motor vehicle suspension

systems and more particularly to an improved toe link for

such systems which is capable of being longitudinally

adjusted.

BACKGROUND OF THE INVENTION

Suspensions of modern passenger cars have become rela.

tively complex in order to fulfil the safety and performance

‘demands required by customers. Ths eomplexity has led (0

multi-link rear suspension systems with contol aems and a

toe ink. The toe fink is typically longitudinally adjustable in

‘onde a allow forthe compensation within a given tolerance

‘during the final assembly of the suspension system,

Referring to FIG. 1, a prior art adjustable toe link 10 is

shown as having a frst rod 120 with a machined alignment

surface 315 anda second rod 130 with a machined alignment

sutface 328, These mschined aligned surfaces 315 and 328

‘are located within an adjuster 100 that permits axial move

ment of the machined alignment surfeews 318 and 328, and

thus the ods 120 and 130, rlativetoone another hy using the

‘extemal threads 122 and 132 of the rods 120 and 130 respec

tively in combination with intemal treads (aot shown) ofthe

‘adjuster 100, The extomal tress 122 canbe either et-hand,

threads or right-hand threads, with the extemal threads 132

being opposite to the extemal threads 122. Ia this manser,

rotation of the adjuster 100 causes the extension or contrac=

tion ofthe overall length ofa toe fink 10.

Inoperation, rotation of the adjuster 100 ina first direction

results in the serowing ofthe first od 120 and the second rod

130nto the adjuster thus shortening the length othe toe link

10. Inthe alterative, rotation of the adjuster 100 in an oppo-

site second direction rests in the unscrewing ofthe first rod

120d the second rod 130 rom the adjuster 100 causing the

‘we link 100 lengthen axially. The machined alignment sur-

faces 31S and 328 prevent relative rotation ofthe ist rod 120

‘andthe second rod 130 3 the adjuster 100 is rotated with one

‘ofthe rods 120 o¢ 130, In addition, the machined aignaseat

surfaces lessen the load on the distal ens ofthe frst ro 120

and the second rd 130 that attach tothe suspension system of

the motor vehicle wo resist rotation of the toe link. 1.

‘Afler the desired overall length ofthe toe link 10 has been

‘obtained by otating the adjuster 100 relative tothe first rod

4120 and the second red 130, a pair oF jamb nuts 110 can be

tightened against the adjuster 100 inorder to set the te link

ata desired fixed length In thismanncr, the toe link 10.can

be lengthened and shortened and subsequently fixed at 2

siven length. Although such a toe link adjuster 100 is useful,

the requirement of the machined alignment surfves M8 and

325 increases the complexity snd cost of adjustable toe links.

0

o

2

Therefore, an adjustable toe ink that ean provide adjustmes

to ts overall length while not requiring machined alignment

selaces would be desirable

‘SUMMARY OF THE INVENTION

‘The present invention discloses an adjustable toe ink fora

motor Vehicle As ste, the toe link has wily asa part of @

suspension sysiem or a vehicle

‘The adjustable te Tink disclosed herein includes a fest

threaded ro, a second threaded rod and an adjuster having a

srenerlly hollow eylindrical body witha first end anda see-

‘ond end. ‘The first en! ofthe adjuster hs internal threads

dimensioned to accept external thrwads on the frst threaded

ro and the second end has intemal threads dimensioned t0

‘accept external threads on the second threaded rod. A gener-

ally rigid inser is located between and atached to the end oF

the first threadod rod and the end of second thread ro

Located within the generally hollow eylindrical body of the

adjuster, the generally rigid insert is located between and

inserted at least partially into the end ofthe frst threaded rod

‘and the end ofthe second threxed cod. The generally rigid

insert is operable w prevent the fist threaded rod and the

second threaded rod from rotating relative to one another

‘when teadjustersrtated to lengthen or shorten the oe ink.

BRIEF DESCRIPTION OF THE DRAWINGS.

FIG. 1s Iongitudinal view partially in cross-section ofan

adjustable toe link ofthe prior at,

FIG, 2s view similar to FIG, 1 but illustrating a portion

ofan adjustable toe link ofthe present invention:

IG. 3isan exploded perspective view ofthe adjustabletoe

link shown in FIG. 2

FIG. 4 isan exploded perspective view imilarto FIG. 3but

ithistating another adjustable toe link ofthe present inven-

‘ion:

FIG, Sis an exploded perspective view similarto FIGS. 3

and but illustrating yet another preferred adjustable toe link

‘ofthe present invention:

FIG. 6 is an exploded perspective view of sill another

adjustable te link ofthe present invention

FIG. 7 is another exploded perspective view of another

adjustable toe Tink ofthe present invention

FIG, 8 is yet another exploded perspective view of yet

another adjustable toe fink of the present invention; and

FIG. 9 is a longitudinal cross sectional view of the pro

{ered adjustable toe ink shown in FIG. 8

DETAILED DESCRIPTION OF THE PREFERRED

EMBODIMENTS,

‘Turningnow toFIGS. 2and3, anembodiment of anadjust-

able te lnk is shown generally at reference numeral 20, The

toe lnk 20 includes first rod 210 and a second ol 220, The

fist rod 240 is provided with external threads 212 and a slot

211. The second rod 220 is provided with external heads 222

fand a slot 221

The te link 20 includes an adjuster 100, the adjuster 100,

having a generally hollow cylindrical body 104 with frst

end 101 ada second end 108, The frst end 101 has inter

‘threads 105 that are dimensioned such that the fist rod 210

‘with the externa threads 212 ean be serewed into the frstend

101 of the ajuster 100. | ikewise, the second end 103 of the

adjuster 100 has internal threads 108 that are dimensioned

such that the second rod 220 with the external threads 222 can

be sewed there into, In some instances, the external threads

US 7,850,178 B2

3

212 ofthe first rod 210 ae left-hand threads and the external

threads 222 ofthe second rod 220 are right-hand threads. la

the aliemative the fist rod 210 can have external right-hand

threads and the second rod 220 ean have extemal leftshand

threads,

Loctted within the generally hollow cylindrical bosly 104

‘ofthe adjuster 100 isa insert 300. As illustrated in FIG. 3, the

jnsert 300 is inthe form of fat spring 310, the spring 30

having a first end 311 and a second end 312. In berween the

first end 311 and the second end 312, the spring 310 is pro-

Vided with nonparallel sections 318 adjoined with crowns

‘314, The frst end 311 is dimensioned such that i fits atleast

Parially within the ot 211 of the first od 210. Likewise, the

Second end 312 is dimensioned such that atleast patil it

‘within the slot 221 of the second rod 220.

‘Upon assembly ofthe te link 20, the first od 210 and the

second rod 220 ate screwed into the adjuster 100 with the

inser 300 located within the hollow cylindrical body of the

juste between the first rod 210 and the second rod 220. ln

‘addition, due insert 300 as its frst end 311 inserted atleast

parially within the slot 211 andits second end 312 inserted at

Feast partially within the slot 21. It is appreciated that the

spring 310 pesmits axial movement of the ist ro 210 and the

second od 220 toward and away from each other long the toe

Fink 20 while preventing rotational movement of the frst rod

210 of second rod 220 when the auster 100 is rotated and

‘oneo the rods 210 oF 220 ished ina fixed rotational position.

In this manner, the insert 300 affords for adjustment of the

‘overall length of the toe link 20 while preventing rotation of

‘one of the rods when the other rod is held in fixed rotational

positon. Its appreciated that a distal end of the frst rod 210

‘and a distal end of the second rod 220 can be attached 10

different locations of motor vehicle suspension system,

Turning now to FIG. 4, another prefered embodiment of

the invention is shown generally at reference numer 30 as

including the spring 310 in combination witha firstinset 238

anda second insert 248, The toe link adjuster 30 hasa ist rod

230 with extemal threads 292 and a eavity 291 atthe end of

the od 230, Likewise, a second rod 240 has external threads

242 with a cavity 241 atthe end of the rod 240 facing the

‘cavity 231, The cavity 231 and the fist insert 235 are dimen-

‘honed such that he inser 235 fits at least partially within the

‘cavity 231 and yet does not rotate therein. In addition, the

‘cavity 241 and ihe second inser 245 are dimensioned such,

that the inser 245 can it atleast partially within the cavity

241 and not rotate therein, The frst inser 235 has a slot 236

‘andthe second insert 248 hasa slot 246, The slots 236:nd 246,

‘are gimensioned such thatthe firstend 311 ancl thesecondend,

$312of the spring 310 can fit at least paral therein, respec-

tively. Itis appreciated that the external threads 232 and the

‘extemal threads 242 work in a similar fashion with respect {0

the adjuster 100 as diselosed above with respect to FIGS. 2

‘and 3.

‘Upon assembly, tho first rod 230, with the first insert 235

inserted at last partially within the cavity 231, is threaded

into the frstend 101 ofthe adjuster 100. Likewise, the second

rod 240, with the second insert 248 inserted at least partially

‘within th cavity 241, is threaded int the second end 103 of

the adjuster 100, Located within the generally hollow cylin-

ical body of the adjuster 100 with the socond end 311 at

least partially inserted within the slot 296 of the firs isert

235 and the second end 312 at least partially inserted within

the slot 246 ofthe secon insert 245 ithe spring 310. Thusas

‘explained for the te link 20 above, the te link 30 permits

‘axial movement ofthe first rod 230 and the second rod 240

‘with respect to the adjuster 100 while preventing rotational

‘movement of the first rod 280 or the second rod 240 when one

0

o

4

‘ofthe rods is held ina fixed rotational position, Inthis manner

theadjuster 100 provides for adjustment ofthe overall legth

of the toe link 30 while the distal ends of the we link 30 are

held ina fixed rotational position relative to each other. The

spring 310 prevents relative rotation ofthe rods 230 and 240

‘hile the adjuster is being rotated to adjust the axial lnk of

the toe link 3.

Turing now to FIG, §, another embodiment is shown

generally a reference mimeral 40. The adjustable toe fink 40

Jncludes frst rod 250 with extemal threads 252 nd a cavity

251, Also included isa second rod 260 with extemal theads

262and cavity 261, A single invert 25S is included, theinsert

26S having first end 256 and a second end 287, The first end

256 is dimensioned such that it ean fit at east pata within

‘the eavity 251 and not rotate therein. The second end 257 is

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- KS Schadensbroschüre Englisch PDFDocument92 pagesKS Schadensbroschüre Englisch PDFmarcglebNo ratings yet

- VW 1.9L TDI Installation NoticeDocument4 pagesVW 1.9L TDI Installation Noticemarcgleb100% (1)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- ABS Inductiv Si HallDocument3 pagesABS Inductiv Si HallmarcglebNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- US9850967Document8 pagesUS9850967marcglebNo ratings yet

- US9874257Document8 pagesUS9874257marcglebNo ratings yet

- Thermal Behavior of Friction Clutch DiscDocument11 pagesThermal Behavior of Friction Clutch DiscmarcglebNo ratings yet

- Engineering Mechanics 2016: 22 International ConferenceDocument4 pagesEngineering Mechanics 2016: 22 International ConferencemarcglebNo ratings yet

- EP1469240A1Document12 pagesEP1469240A1marcglebNo ratings yet

- Effects of Variable Valve Lift On In-Cylinder Air MotionDocument18 pagesEffects of Variable Valve Lift On In-Cylinder Air MotionAnilNo ratings yet

- Manual Beurer - Tensiometru de Brat bm28Document16 pagesManual Beurer - Tensiometru de Brat bm28marcgleb100% (1)

- Patent Summary for Automatic Vehicle Brake ActuatorDocument12 pagesPatent Summary for Automatic Vehicle Brake ActuatormarcglebNo ratings yet

- Caliper Disc Brake Guide Retention MeansDocument12 pagesCaliper Disc Brake Guide Retention MeansmarcglebNo ratings yet

- Attestination: WoniniDocument22 pagesAttestination: WoninimarcglebNo ratings yet

- Kilic Clutch 2016Document7 pagesKilic Clutch 2016marcglebNo ratings yet

- Hydraulic Engine MountsDocument15 pagesHydraulic Engine MountsmarcglebNo ratings yet

- 39 00072 01 PI en Low P4Document7 pages39 00072 01 PI en Low P4marcglebNo ratings yet

- Stifness and Damping Characteristics of Rubber PDFDocument14 pagesStifness and Damping Characteristics of Rubber PDFmarcglebNo ratings yet

- Nonlinear Large Deformation Analysis of Rubber BumpersDocument13 pagesNonlinear Large Deformation Analysis of Rubber BumpersmarcglebNo ratings yet

- BR 0227Document26 pagesBR 0227ManicharanNo ratings yet

- Ada 501359Document51 pagesAda 501359marcglebNo ratings yet

- Clutch TS Guide 8 PDFDocument84 pagesClutch TS Guide 8 PDFmarcglebNo ratings yet

- ch07 PDFDocument17 pagesch07 PDFNarendra Reddy BhumaNo ratings yet

- MECANICA 2c tnr12 PDFDocument11 pagesMECANICA 2c tnr12 PDFMihaiCiupicNo ratings yet

- 09 OabdulahhDocument8 pages09 OabdulahhmarcglebNo ratings yet

- Fault Finding Guide WebDocument39 pagesFault Finding Guide Webmarcgleb100% (1)

- Engine Throtle FailureDocument2 pagesEngine Throtle FailuremarcglebNo ratings yet

- 41 46 1 PBDocument5 pages41 46 1 PBmarcglebNo ratings yet

- Canceling Oil Pan Active Powertrain NoiseDocument11 pagesCanceling Oil Pan Active Powertrain NoisemarcglebNo ratings yet

- 402-2 - SAF Warranty Handling Shock AbsorberDocument13 pages402-2 - SAF Warranty Handling Shock AbsorbermarcglebNo ratings yet