Professional Documents

Culture Documents

Ijett V20P224

Uploaded by

GomishChawlaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ijett V20P224

Uploaded by

GomishChawlaCopyright:

Available Formats

International Journal of Engineering Trends and Technology (IJETT) Volume 20 Number 3 Feb 2015

Design & Manufacturing of All Terrain Vehicle (ATV)- Selection,

Modification , Static Dynamic Analysis

*2

of ATV

#3

Vehicle

Upendra S. Gupta ,Sumit Chandak ,Devashish Dixit

1

Reader SVITS Indore

2

Reader SVITS Indore

Abstract- This paper provides in-detail description of the design maneuver. Design is done and carried out linear static analysis

considerations, static & dynamic analysis and mathematical and Dynamic analysis for the frame.

data involved in the design of a ATV Vehicle. The focus has been

laid on the simplicity of design, high performance, easy II Design Methodologies

maintenance and safety at very reasonable prices.The design

and development comprises of material selection, chassis and A. Roll cage Configuration, Design & Material

frame design, cross section determination, determining strength One of the key design decisions of our frame that greatly Increases

requirements of roll cage, stress analysis and simulationsto test the safety, reliability and performance in any automobile design is

the ATV against failure .During the entire design process, material selection. To ensure that the optimal material is chosen,

consumer interest through innovative, inexpensive, and effective extensive research was carried out and compared with materials from

methods was always the primary goal. Most of the components multiple categories. The Objectives of Roll cage design, Since safety

have been chosen keeping in mind the easy availability and of driver is paramount to us, the roll cage is required to have adequate

reliability. factor of safety even in worst case scenarios To have greater torsional

According to recognition of customers need we are going to stiffness to ensure lesser deflection under dynamic loading and

design a vehicle which is ergonomic, aerodynamic, highly enhanced physical object.

engineered and easily manufactured. Hence it makes the

vehicle more efficient. Our vehicle can navigate through almost Material Yield Outer Thickness carbon

all terrain, which ultimately is the objective behind the making strength diameter percentage

of any all-terrain vehicles. We began the task of designing by ST 52.3 460 1.25 2 mm 18.899%

conducting extensive research of each main component of the (with Mpa

vehicle.

seam)

Keywords: Roll cage, material, finite element analysis, strength,

Power train; Final-drive, Rack and Pinion, Suspension, Table 1: Material Properties of ST52.3

Brakes,

B. Steering System

I. INTRODUCTION

The quality of the steering system and geometry also dictates the

The objective of the study is to design and develop the roll cage for All performance of the ATV. We prefer rack and pinion steering

- Terrain Vehicle. Material for the roll cage is selected based on over other steering systems due to Its low cost, Simple

strength, cost and availability. The roll cage is designed to incorporate construction & Immediate response

all the automotive sub-systems. A software model is prepared in Solid

works software. Later the design is tested against all modes of failure by

conducting various simulations and stress analysis with the aid of Ansys

Software(14). Based on the result obtained from these tests the design is

modified accordingly. After successfully designing the roll cage, it is

ready for fabricated. The vehicle is required to have a combination

frame and roll cage consisting of steel members. As weight is critical in

a vehicle powered by a small engine, a balance must be found between

the strength and weight of the design. To best optimize this balance the

use of solid modeling and finite element analysis (FEA) software is

extremely useful in addition to conventional analysis. There are many

ATVs in the market, but they are not manufactured in India. These

ATVs are assembled here. So we are giving a cost effective design of

Fig1:Adams Steering System

an All Terrain Vehicle Frame. Since the chassis is the main part of an

automotive, it should be strong and light weight. Thus, the chassis

design becomes very important. Typical capabilities on basis of which

these vehicles are judged are hill climbing, pulling, acceleration and

maneuverability on land as well as shallow waters. This is aimed to

design the frame of an ATV which is of minimum possible weight and

show that the design is safe, rugged and easy to

ISSN: 2231-5381 http://www.ijettjournal.org Page 131

International Journal of Engineering Trends and Technology (IJETT) Volume 20 Number 3 Feb 2015

Steering System

Steering Adams steering Inside ideal steer angle=(wheel base/turning

mechanism radius-track/2)=25.46

inner angle 39.8 Ackerman =( inside steer angle outside steer angle)

outer angle 25.46 deg = (37.33-24.82 )= 12.51 degree

Ideal Ackerman = inside ideal steer angle outside ideal

Radius turning- 2.55 m steer angle =(39.80-25.46) =14.34 deg

% Ackerman = 100 *(ackerman/ideal ackerman)

inner angle actual 37.33 deg

% Ackerman=87.23%

outer angle actual- 24.82 deg

steering Ratio- 18.53:1

Percentage 87.23 per

Ackerman

Length of tie rod 48.259 "

rack 22"

Tie rods ends- 13.12"

steering Arm 3.48"

length

king to king pin- 50.98"

Ackerman angle- 23.01 deg Fig2: Graph of Steering Geometry

Included Angle 9 deg

Table2: Technical Specification of steering System

C. Design criteria of Adams steering model

The objective of steering system is to provide max directional control

of the vehicle and provide easy manoeuvrability of the vehicle in all

type of terrains with appreciable safety and minimum effort. Typical

target for a quad vehicle designer is to try and achieve the least

turning radius so that the given feature aids while manoeuvring in

narrow tracks, also important for such a vehicle for drivers effort is

minimum. We researched and compared multiple steering systems. Fig3: Graph Scrub Radius v/s Wheel Travel

We need a steering system that would be easy to maintain, provide

easy operation, excellent feedback, cost efficient and compatible to

drivers ergonomics.

(i)Steering Geometry Steering Angle and Ratio

3.2 turns lock to lock which implies that steering wheel

can turn 1.6*360=576 degree on one side.

By the deflection of 576 degree of steering to left Length

of steering arm d =8.841cm.

cos (left wheel steer angle)=(2d2-x2)/2d2=37.33

Cos (right wheel steer angle)=24.82

Left wheel steer angle = 37.33 degree

Right wheel steer angle = 24.82 degree.

Difference b/w left wheel steer angle & right wheel

steer angle = 37.33-24.82 = 12.51degree. Fig4: Graph optimum Kinematic analysis of adams steering Model

Steering ratio= 576/35.075= 18.53

D. Suspension System

(ii) Turning radius

2 2 2 (1/2) The overall purpose of a suspension system is to absorb impacts

R=(a +l cot d)

Cotd=(cot (in)+cot(out))/2=((39.80+25.46)/2)=32.63 from coarse irregularities such as bumps and distribute that force

R=2.55 mt

with least amount of discomfort to the driver. We completed this

objective by doing extensive research on the front and rear

(iii) Percentage Ackermann

suspension arms geometry to help reduce as much body roll as

Outside ideal steer angle=(wheel possible. Proper camber and caster angles were provided to the

base/turning radius+track/2)=39.80 front wheels. The shocks will be set to provide the proper

ISSN: 2231-5381 http://www.ijettjournal.org Page 132

International Journal of Engineering Trends and Technology (IJETT) Volume 20 Number 3 Feb 2015

dampening and spring coefficients to provide a smooth and iteration was found non-disturbing centre changes so

well performing ride. Double A Wishbone was selected for its

simple design and ability to provide a good travel. satisfactory bump steer.

Motion Ratio Front 0.86

Motion Ratio Gear 0.6

Front Spring Constant 12.86N/mm

Rear Spring Constant 39.6/mm

Camber -1

Caster 3.6

Toe 0

Sprung mass 185

Unsprung Mass 90

Wheel Travel Front Left 6

Wheel Travel Front Right 6

Wheel Travel Rear Left 5 Fig5: Bump steer of suspension system

Wheel Travel Rear Right 5

F. Driveline System

Table3: Technical Specification of suspension system During the design the aim was to achieve a driveline which

allows the maximum torque in the first gear while a top speed of

E. Design Criteria of Suspension System 60 km/h in the top gear.In the choice of CVT or Manual

(i)Determination of spring rates gearbox we chose a manual gearbox according to the

suggestions of driver as well as the research about its

A frequency range of 100 to 125 (for the sprung mass) was advantages.We followed the design methodology that the power

used to obtain the testing range of2.197kg/mm and 3.793kg/mm available at the output shaft of the engine must be transmitted to

for spring rates.125 mm was elected due to large chunk of the wheels at an appropriate ratio. We calculated the static

wheel travel so that driver do not feel any discomfort. friction force on the tyres due to road and calculated the first

gear ratio to rotate the tyre from a stand still position.In the

f 1 = 1/ 2 {(ks*kt)/( ks*kt)/ ms} design we first assumed the tire size engine specifications and

the loss factor. The data is as follows

(ii)Spring Design Consideration

Wheel diameter = 24 inches

Helical Close Coiled springs were selected.

Circumference = 1.914 m.

Material of wire = ASTM A228 Modulus of Rigidity

(G) = 79.24 GPa Loss factor = 12%

Diameter of coil (D) = 91.59mm and 76.352mm Engine power = 8.8 Hp at 3600 RPM

Parameters selected for spring wire No. of Turns was Engine = 305 cc, 10 hp at 3800 rpm

now calculated from the following formula:

4 3

K= (G*d )/ 8*n*D

No of Active Turns for front spring = 8 and for rear = 8

Equivalent air suspension system is used. Gear Speed Engine Drive Axle of driveline

(km/h) shaft (RPM) (RPM)

Spring Wire Diameter(d) Total Length 1 12 3400 104.49

Front 10mm 368.3mm 2 21 3400 183.246

Rear 10mm 508mm 3 28 3400 287.95

Table4: Technical Specification of Helical closed coil springs

4 43 3400 437.95

(ii)Bump Steer

The pivot point of the tie rod affects bump steer so that the steering Reverse 7 3400 61.08

is unaffected by bump steer. We geometrically kept the

instantaneous centre of arm and tie rod coinciding with each other. Table5: speed of drive shaft on different gears

The velocity ratio and motion ratio of tie rod ends and a arm ends

were kept almost equal. The mounting point of tie rod at wheel

below the central axis end tie rod end at wheel below the central axis

and tie rod end at the chassis was kept above the central axis. This by

ISSN: 2231-5381 http://www.ijettjournal.org Page 133

International Journal of Engineering Trends and Technology (IJETT) Volume 20 Number 3 Feb 2015

Gear Gear ratio

First 32.53

Second 18.55

Third 11.80

Fourth 7.76 Fig6: Disc brake & Drum Brake

Reverse 55.66

Table6: Final driveline data including differential

In order to reduce the vibrations produced by the engine and the

driveline we are using anti vibration mountings of neoprene rubber.

G. Design consideration of Brakes

The purpose of the braking system is to increase the safety and

maneuverability of the vehicle. In order to achieve maximum

performance from the braking system, the brakes have been designed

to lock up all four wheels at the same time. It is desired from a quad

bike that it should have effective braking capability to negotiate rigid

terrains. We are using disc brakes rather than drum brakes because Fig7: Comparison of disc brake & drum brake with respect to stopping

More cooling air volume, time ,Heat generation & Braking Torque.

Generated heat is less than drum brakes.

Braking torque is less. From the graph given by NASA when the driver is in

normal condition the pedal force applied by him is 250N.

The brakes are composed of the disc of outer diameter of

220mm and inner diameter 160mm and 3mm thickness.

Brakes calliper are of floating type of with double piston

as these are more economical, lighter in weight and also

require fewer parts than fixed calliper.

The total weight of the vehicle along with 60 kg driver

was estimated to be 350kg.

The weight distribution for the car was estimated to

be approximately 40:60 from front to rear.

Static weight front Wf =140N

Static weight rear Wr =210N

Static load distribution

f =0.4 and r =0.6

Relative centre of gravity height X=h/wb=0.3

Where h is height of centre of gravity wb is wheel base

Dynamic Condition:

Front Dynamic axle load,((1- f)+X.a)M=283.5kg

Fig8: graph given by NASA

Rear Dynamic axle load,((1- r)-X.a)M=66.5kg (Where

a is deceleration (0.7gunits) * *

Pedal ratio =P*A /250= 5.75:1 (where A =area of master

Braking force rear on each tyre ylinder)Average deceleration by considering response time, aave

B.Fr=(Wr/2)*a*g=721.035 N = v/((v/a)+0.3g) = 0.623

(where v is maximum speed i.e. 60km/h)

torque T=B.Fr*R=219.77N-m (where R= radius of tyre) Stopping distance =v2/(2*g*

Disc effective radius re=(220+160)/4=95mm aave)=22.73m Stopping time

=v/a*g=2.727 sec. Power=17832.98W

Clamp load C=T/(re*f*n)= 3855.614N (where n

=2,no. of friction faces) H. Driver Ergonomics

System pressure P=C/A= 2.84MPa (A=area of piston)

For the purpose of driver comfort/ergonomics an assembly was

imported to CATIA software. This assembly included the roll cage

of the car, seat, steering system and the driver. The driver was placed

in order to mimic the actual situation during the race.

ISSN: 2231-5381 http://www.ijettjournal.org Page 134

International Journal of Engineering Trends and Technology (IJETT) Volume 20 Number 3 Feb 2015

Using CATIA:

Proper pedal positioning is ensured for easy operation

of pedals by driver.

Posture of driver is examined by using human builders

ergonomics module of Catia.

The left hand reach envelop and right hand reach envelop

as well as vision of the driver was examined by the

Catia ergonomics analysis.

Proper safety distance as mentioned in the rule book

was also taken into consideration.

We have used 95% male human builder for the above

Fig12: Left hand reach of Vehicle

driver ergonomics analysis.

III Results & Discussion of Static & Dynamic

Analysis of ATV Vehicle

The Finite Element Analysis (FEA)of the vehicle was done

using ANSYS. The stress analysis was done under worst case

scenarios and maximum forces were applied in the analysis.

Adequate factor of safety were ensured for all the components

under these worst case conditions.

The FEA of Rollcage and suspension components

was done using ANSYS Workbench 14. The analysis for

rollcage included front impact, rear impact, side impact,

Fig9: Safe Distance of Vehicle rollover, front bump, rear bump and torsion. For all the analysis

the weight of the vehicle is taken tobe350kg.

Technical Front Side Rear

Parameter impact Impact Impact

Velocity 50 40 40

( Km/h)

Time of 0.2 0.3 0.2

impact (s)

Force (kN) 24.305 12.96 19.44

In terms of 7.09 3.78 5.66

Gs

Fig10: Vision of Vehicle Table 7: Analysis of Roll Cage by using ANSYS

Technic Front Side Rear Front Torsion Roll over

al impa Impa Impa Bump

Parame ct ct ct

ter

Max. 159.4 189.6 132.9 353.2 242.73 319.53

Eqvt. 6 6 6 5

Stress

(Mpa)

Max. 1.06 8.57 1.13 13.01 9.6 15.9

Deform

at

Member

(mm)

Factor 3.01 2.53 3.6 1.04 1.97 1.5

of safety

Fig11: Right hand reach of Vehicle

Table 8: Impact Assessment Data by using Ansys Software12

ISSN: 2231-5381 http://www.ijettjournal.org Page 135

International Journal of Engineering Trends and Technology (IJETT) Volume 20 Number 3 Feb 2015

Fig13: Finite element analysis of Front Impact Fig17: Finite element analysis of Front Bump

Fig14: Finite element analysis of Rear Impact

Fig18: Finite element analysis of Rear Bump

Fig15: Finite element analysis of Side Impact

Fig19: Finite element analysis of Torsion

(i)Analysis of suspension pickup points & Clamps:

The Suspension pickup points and the clamps are the main parts that

connect the unsprung mass with the roll cage. Hence in the rough

terrains they are an important area to look and check for any

possibility of failure. FEA of both was done to ensure the same. 3g

bump forces were taken while analysing both.

Fig16: Finite element analysis of Roll over

ISSN: 2231-5381 http://www.ijettjournal.org Page 136

International Journal of Engineering Trends and Technology (IJETT) Volume 20 Number 3 Feb 2015

Fig20: Finite element analysis of suspension pickup points & Clamps

Fig23: graph of lca Force v/s wheel Movement

(ii)Analysis of knuckle

The Knuckle undergoes various direct, shear and thrust forces during

the plying of vehicle. And since we have manufactured a custom

design, it becomes more necessary to ensure its safety. FEA of the

knuckle was done taking in account the brake calliper clamp load of

3929.8 N, bearing force of 1000 N and 3g bump forces during the

run.

Fig24: graph of steering wheel Torque v/s Steering wheel angle

(iii)Dynamic Analysis on MSC Adams for front

suspension system

The Spring Constant for Rear suspension was selected as

2.197kg/mm.The initial Camber Angle was kept -1 deg. The

Kingpin Angle was kept +9 deg. The Rear suspension

Fig21: Finite element analysis of knuckle

system then undergoes a dynamic test where it encounters a

(ii)Dynamic Analysis on MSC Adams bump of 100mm

The Dynamic Analysis of the suspension system of the vehicle was

done on MSc Adams. Separate Analysis for Front and Rear

Suspension Systems were done.The Spring Constant for the front

suspension was Kept 2.197 kg/mm. The initial Caster Angle was

kept +3.6 deg. The initial Camber was kept -1.0 degree. A Dynamic

Analysis where this Front Suspension system undergoes a bump of

100mm was conducted and the Resulting Graphs. Various

suspension parameters were

Fig25:Front Suspension System

(iv)Dynamic Analysis on MSC Adams for rear suspension

The Spring Constant for Rear suspension was selected as

3.793kg/mm. The initial parameters were kept Camber Angle

0 deg, Kingpin Angle 0 deg and caster Angle 0 deg. The

Rear suspension system then undergoes a dynamic test where

it encounters a bump of 100mm.

Fig22: dynamic analysis of suspension systen

ISSN: 2231-5381 http://www.ijettjournal.org Page 137

International Journal of Engineering Trends and Technology (IJETT) Volume 20 Number 3 Feb 2015

IV CONCLUSION

The objective of designing a single-passenger off-road race

vehicle with high safety and low production costs seems to be

accomplished. The design is first conceptualized based on

personal experiences and intuition. Engineering principles

and design processes are then used to verify and create a

vehicle with optimal performance, safety, manufacturability,

and ergonomics. The design process included using Solid

Works, CATIA and ANSYS software packages to model,

Fig26: Rear Suspension System

simulate, and assist in the analysis of the completed vehicle.

After initial testing it will be seen that our design should

(iv)Dynamic Analysis on MSC Adams for safety factor, improve the design and durability of all the systems on the

travel, deflection & Motion Ratio car and make any necessary changes up until the leaves for

For travel of 8 inch simple kinematic and dynamic analysis is used the competition. The power-train used in the design offers easy

Travel for front spring= 5.16 inch,Travel for rear spring=3 inch operation and maintenance. Multiple unique design features provide

easy adjustability that give the owner more control over the vehicle.

(v)Dynamic Analysis on MSC Adams for A Arms Further, software analysis shows us that the vehicle can take frontal

impacts of up to 159.46 Mpa and side impacts of up to 189.66 Mpa.

For A arms loads are calculated using Adams and four bar linkage This clearly reaffirms the vehicles ability to withstand extreme

method and analysis is performed in ansys software (14) to optimise conditions.

its hard points and motion ratio.

V REFERENCES

[1] John C. Dixon; Suspension analysis and computation geometry;

ISBN: 978-0-470-51021-6; October 2009

[2] Thomas D. Gillespie; Fundamental of Vehicle Dynamics; ISBN: 978-1-

56091-199-9; February 1992.

[3] Zhanwang, Y., and Zongyu, C., Dynamic Response Analysis of

Minicar Changan Star 6350, Proceedings of 2nd MSC worldwide

automotive conference, MSC, 2000

http://www.mscsoftware.com/support/library/conf/auto00/p02200.pdf

[4] Kim, H. S., Hwang, Y. S., Yoon, H. S., Dynamic Stress Analysis of a Bus

Systems, Proceedings of 2nd MSC worldwide automotive conference, MSC,

2000. http://www.mscsoftware.com/support/library/conf/auto00/p03200.pdf

Fig27: Dynamic Analysis of A Arms [5] Fermer, M., McInally, G., Sandin, G., Fatigue Life Analysis of Volvo S80

Bi-fuel, Proceedings of 1st MSC worldwide automotive conference,

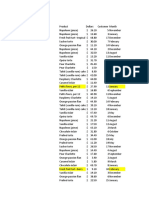

(vi)Technical Specification of ATV Vehicle MSC, 1999

http://www.mscsoftware.com/support/library/conf/auto99/p00499.pdf

Engine Drive Manual Four Speed [6] Johansson, I., and Gustavsson, M., FE-based Vehicle Analysis of Heavy

Suspension Double Wishbone Trucks Part I Proceedings of 2nd MSC worldwide automotive conference,

MSC, 2000 www.mscsoftware.com/support/library/conf/auto00/p01200.pdf

Wheels Brakes Disc Brakes [7] Oijer, F., FE-based Vehicle Analysis of Heavy Trucks Part II,

Steering ratio 18.5. : 1 Proceedings of 2nd MSC worldwide automotive conference, MSC,

2000www.mscsoftware.com/support/library/conf/auto00/p01100.pdf

Maximum Rack Travel 3 [8] Parnell, T., White, C., and Day, S., Finite Element Simulation of

1800 Rollover for Heavy Truck Vehicles, ASCE Engineering mechanics

Wheels 24 x 8 = 12 conference, Baltimore, 1999. http://citeseer.ist.psu.edu/407030.html

Speed 58 Km/ H [9] Chiba, S., Aoyama K., Yanabu, K., Tachibana, H., Matsuda, K., Uchikura,

M., Fatigue Strength Prediction of Truck Cab by CAE , Journal of

Acceleration Mitsubishi Motors TechnicalReview, Vol.15, 2003, pp. 54-60.

Stopping Distance 22.73 M http://sciencelinks.jp/j-east/article/200310/000020031003A0250701.php

[10] Lee, D. C., Choi, H. S., Han, C. S., Design of Automotive Body

Deceleration 0.7 gm Structure Using Multicriteria Optimization , Journal of Structural and

Gradeability - Multidisciplinary Optimization, Vol. 32, 2006, pp. 161-167.

http://www.springerlink.com/content/y70812k267632r47/

Emission - [11] Jin-yi-min, Analysis and Evaluation of Minivan Body Structure ,

Proceedings of 2nd MSC worldwide automotive conference, MSC, 2000.

Ground Clearance 12 http://www.mscsoftware.com/support/library/conf/auto00/p00500.pdf

Turning Radius 2.5 M [12] Lee, J. N., Nikravesh, P. E., Steady State Analysis of

Multibody Systems with Reference to Vehicle Dynamics , Journal of

Fuel consumption 10 m/ l Nonlinear Dynamics, Vol. 5, 1994, pp. 181- 192.

http://www.springerlink.com/content/jwu5842568731t84/

ISSN: 2231-5381 http://www.ijettjournal.org Page 138

You might also like

- ActionverbsDocument2 pagesActionverbsapi-241737054No ratings yet

- Business Model Canvas PosterDocument1 pageBusiness Model Canvas PostersunnyNo ratings yet

- Annual Report 2017 2018Document368 pagesAnnual Report 2017 2018kamlesh100% (1)

- Create A Leading Global Online Food Delivery Player: June 2020Document31 pagesCreate A Leading Global Online Food Delivery Player: June 2020GomishChawlaNo ratings yet

- The Value Proposition Canvas 1 PDFDocument1 pageThe Value Proposition Canvas 1 PDFGomishChawlaNo ratings yet

- Building Bar ChartsDocument2 pagesBuilding Bar ChartsGomishChawlaNo ratings yet

- FIN 350 - Business Finance Homework 3 Fall 2014 SolutionsDocument6 pagesFIN 350 - Business Finance Homework 3 Fall 2014 SolutionsGomishChawlaNo ratings yet

- Leading Global Online Food Delivery PlayerDocument11 pagesLeading Global Online Food Delivery PlayerGomishChawlaNo ratings yet

- Task3 Week4Document1 pageTask3 Week4GomishChawlaNo ratings yet

- Task3 Week4Document1 pageTask3 Week4GomishChawlaNo ratings yet

- Task3 Week4Document1 pageTask3 Week4GomishChawlaNo ratings yet

- Custom Pivot Table StylesDocument118 pagesCustom Pivot Table StylesGomishChawlaNo ratings yet

- Task1 Week3 - 1Document2 pagesTask1 Week3 - 1MajidNo ratings yet

- Task1 Week3 - 1Document2 pagesTask1 Week3 - 1MajidNo ratings yet

- The Challenge: A Recent Study of The Computer Science: Advanced Placement Test Found That in 11 StatesDocument1 pageThe Challenge: A Recent Study of The Computer Science: Advanced Placement Test Found That in 11 StatesGomishChawlaNo ratings yet

- The Solution To This Problem Is Computed Tomography (CT)Document3 pagesThe Solution To This Problem Is Computed Tomography (CT)GomishChawlaNo ratings yet

- Task1 Week1Document1 pageTask1 Week1GomishChawlaNo ratings yet

- Fire Safety & PreventionDocument13 pagesFire Safety & PreventionUdoy PaulNo ratings yet

- Task1 Week2Document1 pageTask1 Week2GomishChawlaNo ratings yet

- Task1 Week1Document1 pageTask1 Week1GomishChawlaNo ratings yet

- NVIDIA P40 Supported ServersDocument13 pagesNVIDIA P40 Supported ServersGomishChawlaNo ratings yet

- Task1 Week3 - 1Document2 pagesTask1 Week3 - 1MajidNo ratings yet

- Task1 Week3 - 1Document2 pagesTask1 Week3 - 1MajidNo ratings yet

- ACMA-Presentation Press-Conference 2020Document16 pagesACMA-Presentation Press-Conference 2020KarthikMeenakshiSundaramNo ratings yet

- PivottabletempDocument32 pagesPivottabletempGomishChawlaNo ratings yet

- Topic - Contemporary As It Discusses About Students: Taking The Exam OnlineDocument2 pagesTopic - Contemporary As It Discusses About Students: Taking The Exam OnlineGomishChawlaNo ratings yet

- LogsDocument1 pageLogsGomishChawlaNo ratings yet

- $10000 For 5 Years 10% 1/r 10 6.209213 Formula For PV PV $37,907.87 PV Function $37,907.87 1/r (1+r)Document1 page$10000 For 5 Years 10% 1/r 10 6.209213 Formula For PV PV $37,907.87 PV Function $37,907.87 1/r (1+r)GomishChawlaNo ratings yet

- Charts Resizing-MovingDocument5 pagesCharts Resizing-MovingGomishChawlaNo ratings yet

- Charts FormattingDocument5 pagesCharts FormattingGomishChawlaNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Unit 1 Metro LogyDocument9 pagesUnit 1 Metro LogyMuthuvel M100% (1)

- Module ADocument2 pagesModule AMaddula SaibhushanamNo ratings yet

- Lec 2 Integrated Logistics Support - Fin - 1Document61 pagesLec 2 Integrated Logistics Support - Fin - 1Gürkan Özbil100% (1)

- Manual AV110X PDF Engines CoolantDocument8 pagesManual AV110X PDF Engines CoolantBrad BerberNo ratings yet

- 047-Testing of Electrical Protection PDFDocument13 pages047-Testing of Electrical Protection PDFVikrant Deshmukh0% (1)

- Business Processes MappingDocument32 pagesBusiness Processes MappingLavinia100% (1)

- ASQ Actualtests CQE v2015-03-26 by Miguel 160qDocument48 pagesASQ Actualtests CQE v2015-03-26 by Miguel 160qMazin Alahmadi100% (2)

- Quality ControlDocument19 pagesQuality ControlNorazilah Mohamed PaidNo ratings yet

- Unit - 3 Software DesignDocument60 pagesUnit - 3 Software DesignIshwariyaNo ratings yet

- BV H5003GBDocument99 pagesBV H5003GBTuanTranNo ratings yet

- Vdocument - in - Chapter 2 Basic Concepts of Structural Reliability TheoryDocument46 pagesVdocument - in - Chapter 2 Basic Concepts of Structural Reliability TheoryChristian RuizNo ratings yet

- Ultrastar SATA Series: HighlightsDocument2 pagesUltrastar SATA Series: HighlightslelaNo ratings yet

- Grasberg Block Cave Mine Cave Planning and UndercutDocument12 pagesGrasberg Block Cave Mine Cave Planning and Undercutalvaroaac4No ratings yet

- E6000 Curly CableDocument5 pagesE6000 Curly Cableritafa6209No ratings yet

- Computers in Industry: Gonca Tuncel, Gu Lgu N AlpanDocument10 pagesComputers in Industry: Gonca Tuncel, Gu Lgu N AlpanJUAN ALEJANDRO TASCÓN RUEDANo ratings yet

- The Role of Organizational Factors PDFDocument19 pagesThe Role of Organizational Factors PDFkarpanaiNo ratings yet

- SE:FY14 ReportDocument280 pagesSE:FY14 Reportbring it onNo ratings yet

- Modicon M241 Logic Controller: System Functions and Variables Plcsystem Library GuideDocument116 pagesModicon M241 Logic Controller: System Functions and Variables Plcsystem Library GuideVitan DanutNo ratings yet

- Raspberry Pi and Arduino Based Automated Irrigation SystemDocument40 pagesRaspberry Pi and Arduino Based Automated Irrigation SystemDileep VaraprasadNo ratings yet

- Essential Spare Parts EngDocument24 pagesEssential Spare Parts EngAprilmind StateNo ratings yet

- Standar Standar Standar Standar Standard EN 50 dEN50 dEN50 dEN50 D EN 50155 155 155 155 155Document3 pagesStandar Standar Standar Standar Standard EN 50 dEN50 dEN50 dEN50 D EN 50155 155 155 155 155telkom182No ratings yet

- SPA Training Module Handout Continuous Sampling 6JUN2019Document46 pagesSPA Training Module Handout Continuous Sampling 6JUN2019Geovanni calderonNo ratings yet

- Chapter 6 PPT NewDocument17 pagesChapter 6 PPT NewNadhila NurmalasariNo ratings yet

- Reliability Centered Maintenance (RCM) ProgramDocument8 pagesReliability Centered Maintenance (RCM) ProgramWily Fitra Dermawan100% (1)

- Electronic InterlockingDocument148 pagesElectronic InterlockingSanjeev Kumar73% (15)

- SJ-20130509142153-001-ZXSDR R8863 (HV1.0) Product Description - 573602Document35 pagesSJ-20130509142153-001-ZXSDR R8863 (HV1.0) Product Description - 573602Nouvric Int100% (1)

- Critical Components For Maintenance Outage Scheduling Considering Weather Conditions and Common Mode Outages in Reconfigurable Distribution SystemsDocument10 pagesCritical Components For Maintenance Outage Scheduling Considering Weather Conditions and Common Mode Outages in Reconfigurable Distribution SystemsXupisgoleNo ratings yet

- 1002 PDFDocument6 pages1002 PDFali.jahayaNo ratings yet

- FMEA2002Document22 pagesFMEA2002deleep6132No ratings yet

- MINDRA DC-7 Service ManualDocument224 pagesMINDRA DC-7 Service ManualArturo Jimenez Terrero100% (1)