Professional Documents

Culture Documents

Apply Solubility Theory For Process Improvements

Uploaded by

kumar_chemicalOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Apply Solubility Theory For Process Improvements

Uploaded by

kumar_chemicalCopyright:

Available Formats

Reactions and Separations

Apply Solubility

Theory for Process

Improvements

For solid compounds that dissolve in solvents

Michael J. Gentilcore

Tyco Healthcare but do not ionize, the thermodynamics of

solubility can provide valuable predictions

and insights.

ANY CHEMICAL PROCESSES DEPEND on The activity of a solid in solution is described by

M the solubility of solids in liquid solvents to de-

fine key process steps. Some common examples

include crystallization to isolate a product at good yields,

the following thermodynamic relationship (3):

d ln ans HnF

= (3)

recrystallization to remove impurities, reaction where a dT RT 2

solid reactant must be dissolved in order to participate in

a chemical conversion, and filtration where a dissolved This relationship is similar to the Clausius-Clapey-

product solution is filtered from a solid catalyst. Solubili- ron equation for vapor pressure of a pure liquid:

ty is often a major determinant of the economic effec-

d ln p 0 H V

tiveness of a particular process step. = ( 4)

Typically, solubility data are provided as experimental dT RT 2

data summarized in tabular or graphical form, and they

are often extremely limited in scope. Solubility theory Substituting Eq. 1 into Eq. 3 and integrating, assum-

can easily be applied to many compounds that do not ing that the heat of fusion is constant from the melting

ionize or dissociate to provide and predict solubility over point temperature (Tm) to any other temperature (T), the

a wide range of conditions. This article reviews the ba- equation for the solubility of solids in solution is (3):

sics of solubility theory and discusses how to apply solu-

bility theory to process improvement. HnF 1 1

ln n x n = (5)

R T Tm

Solubility theory of non-electrolytes

The activity of a component in a solution is a multi-

ple of its mole fraction (3): Equation 5 is applicable to compounds that do not

ionize or dissociate in solution and where the solid phase

an = nxn (1) is pure. It cannot be used for electrolytes like salts, or-

ganic acids and amines. Derivations are available for

The multiple is called the activity coefficient. This cases where the heat of fusion is not assumed to be con-

is the same activity coefficient used to correct Raoults stant (3). Systems where the solid phase is not pure are

law for predicting partial pressure above a solution: those where the solvent has a true solubility in the solid

phase as opposed to where the solvent is simply en-

pn = nxn pn0 (2) trapped or otherwise unremoved as free solvent that con-

taminates the solids. For extreme pressure changes (more

38 CEP March 2004 www.cepmagazine.org

the scope of this article. Many of these methods require

Nomenclature computer subroutines to fit experimental data, and there-

fore are somewhat cumbersome when used for solubility

a = activity of a component in solution, dimensionless problems. Thus, this article will present only the van Laar

A = van Laar correlation parameter, cal/gmol correlation for simple two-component systems, which con-

B = van Laar correlation parameter, cal/gmol sists of the following two equations (1):

H = molal enthalpy, kcal/gmol

2

MW = molecular weight, g/gmol

A x1

p = partial pressure of component above solution, mmHg RT ln 1 = A1 + ( 9)

p0 = vapor pressure of pure liquid, mmHg B x2

R = universal gas constant = 1.987 cal/gmol/K 2

B x2

S = molal entropy, cal/gmol/K RT ln 2 = B1 + (10)

T = temperature, K A x1

V = molal volume, cm3/gmol

x = mole fraction of a component in solution, dimensionless By a few mathematical transforms, the van Laar corre-

X, Y = simplifying terms for van Laar correlation lation is especially useful in correlating solubility data

Greek Letters using linear regression. Equation 9 can be rearranged to:

= activity coefficient, dimensionless

1 A x1 1

= density, g/cm3

= + (11)

Subscripts RT ln 1 B x2 A

m = melting point

n = nth component Defining the following two mathematical transforms:

1 = first component

x1

2 = second component X= (12)

Superscripts x2

F = fusion, i.e., melting 1

L = liquid Y= (13)

S = solid

RT ln 1

V = vaporization

0 = standard state, pure liquid gives the equation:

A 1

than 100 atm), the change in solubility and melting points

Y= X+ (14)

B A

with pressure cannot be ignored. Derivations are available

for the change in solubility with pressure (3). Equation 14 is in the form of y = mx + b. A plot of trans-

The entropy of fusion is given by the equation (2): formed experimental data (Y vs. X) will be linear with inter-

cept 1/A0.5 and slope (A0.5)/B. If only a single solubility data

HF = TmSF (6) point exists, the van Laar equation can be reduced to a one-

parameter form by assuming the following relationship (1):

Substituting Eq. 6 into Eq. 5 give the following equiva-

A V1L

lent equation for solubility (1): = (15)

B V2L

S Eq.

F

Tmm6 into

1 Eq. 5 gives the following equiv-

F

ln Substituting

nn x nn =

nn

(7)

alent equation R for solubility

T (1): For the solid component, the molal volume of the pure

liquid melt is the proper volume to estimate i.e., not the

Finally, for ideal solutions, the activity coefficient is set specific gravity of the solid or the bulk density of the

to unity to give the ideal solubility equation (2): solid. The one-parameter simplification works best for

non-polar solvents and solutes (1). It is not reliable for

SnF Tm

ln x n = 1 (8) polar components.

R T

Examples

Activity coefficient correlations The following examples illustrate the general use of

Numerous methods to calculate an activity coefficient these equations.

are available (e.g., the Margules, Wilson, NRTL, UNI- Example 1 ideal solubility estimate. What is the ideal

QUAC and UNIFAC methods), but these are beyond the solubility at 25C of a compound that melts at 58C with a

CEP March 2004 www.cepmagazine.org 39

Reactions and Separations

heat of fusion of 8.1 kcal/gmol? Solution: Tm = 273 + 58 = using the goal seek feature in a spreadsheet or writing a

331 K and SF = (8.1/331)(1,000) = 24.5 cal/gmol/K. Solve user-defined function. Notice how the solubility has dra-

Eq. 8 for x: x = exp{(24.5/1.987)[331/(25 + 273) 1]} = matically increased for this compound (from 0.05 mole

0.255 mole fraction. Comment: The ideal solubility is inde- fraction at 25C to 0.33 mole fraction at 40C) as it ap-

pendent of the solvent. The solvents molecular weight will proached its melting point of 58C.

change the solubility on a weight-percent basis, but not the

mole fraction. Physical properties

Example 2 activity coefficient estimate. For the com- Only two physical properties are required to employ

pound in the first example, the observed solubility at 25C solubility theory, heat of fusion and melting point. Thermal

is 0.05 mole fraction. What is the activity coefficient? So- analysis systems that perform differential scanning

lution: a = 0.255 and x = 0.05. Solve Eq. 1 for : = calorimetry (DSC) and thermogravimetric analysis (TGA)

0.255/0.05 = 5.1. Comment: Activity coefficients are de- easily measure these properties if they are not otherwise

pendent on real data. The solvent was not stated in this ex- available in standard references.

ample, but the calculated activity coefficient is unique to DSC/TGA testing is quite common in research and pro-

that solvent in combination with the solid compound. cess development as part of the initial safety testing

Example 3 one-parameter van Laar correlation. For screening of new compounds. Typically, the focus of these

the compound in the previous examples, the solvent is tests is to assess thermal stability risks for compounds by

CCl4 (MW = 154 g/gmol, = 1.58 g/cm3). The solid is quantifying decomposition temperatures, mass changes on

nonpolar (MW = 218 g/gmol). The density of the liquid decomposition, heat of the decomposition reactions, and

from the solid upon melting is 0.90 g/cm3. What are the decomposition reaction kinetics.

van Laar parameters for the solvent and for the solid? With the predominant focus on collecting safety data, heat

Solution: Assign component 1 to be the solid and compo- of fusion and melting points may be observed but not report-

nent 2 to be the solvent. V1 = 218/0.90 = 242.2 cm3/gmol ed. If they are reported, their value in predicting solubility

and V2 = 154/1.58 = 97.5 cm3/gmol. Per Eq. 15, A/B = and guiding process development is often overlooked.

242.2/97.5 = 2.484. RTln1= (1.987)(25 + 273)[ln 5.1] = Some good advice ask specifically for these proper-

964.7 cal/gmol. x1 = 0.05 and x2 = 1 0.05 = 0.95. Solve ties when DSC/TGA work is performed.

Eq. 9 for A: A = (964.7)(1 + 2.484[0.05/0.95])2 = 1,233.4.

B = A/(A/B) = 1,233.4/2.484 = 496.5. Thus, A = 1,233.4 Application of theory

cal/gmol and B = 496.5 cal/gmol. Comment: The same pa- As can be seen in the examples, a very minimal amount

rameters are used for both the solid and the solvent. In this of data (the melting point, the heat of fusion and a single

example, Eq. 9 is used for the solid and Eq. 10 for the sol- solubility data point) can quickly be used to predict the en-

vent. The assignment of component 1 and 2 is arbitrary. If tire solubility curve. When available, additional data points

more than one data point is available, obtain the van Laar showing temperature dependence will increase confidence

parameters by plotting 1/(RTln1)0.5 vs. x1/x2. in the estimated solubility curve.

Example 4 partial pressure estimate. At 25C, the A solubility curve could be used to estimate yield losses

vapor pressure of CCl4 is 114 mmHg. What is the vapor for material balance for a process with a crystallization/fil-

pressure of a CCl4 solution at 25C (298 K) saturated with tration step. The ratio of the solubility of an impurity to

the solid in the previous examples? Solution: First, find 2 the solubility of a product could be used to define the best

using Eq. 10: 2 = exp {[496.5/(1.987 298)][1 + crystallization temperatures and solvent amounts. A solu-

(496.5/1,233.4)(0.95/0.05)]2} = 1.011. Then, Eq. 2 gives p2 bility curve could also be used to define minimum purge

= (1.011)(0.95)(114) = 109.5 mm Hg. Comment: Note that amounts of impurities required in a recycle process.

solubility data have been used to estimate a vapor-liquid When optimizing solvent charges and crystallization

equilibrium quantity. Activity coefficients from solubility temperatures for a process, fresh solvents should not be ar-

data can be used to estimate any property based on solution bitrarily added to a process to prevent slurry concentra-

theory such as boiling points or osmotic pressures (3). tions from becoming too thick. The amounts of solvents

Example 5 solubility estimate. What is the solubility added to a process should be based on what is needed to

of the compound in the previous examples at 40C (313 K) control impurities based on solubility. Process mother

in CCl4? Solution: The following trial-and-error procedure liquors can be recycled as diluents (rather than fresh sol-

is used: guess x1, calculate 1 by Eq. 9, calculate x11 and vents) to control the slurry concentration.

compare it to the value of x11 calculated from Eq. 7. If x1 Solubility theory could be used to evaluate operating con-

= 0.33, then x2 = 1 0.33 = 0.67, and 1 = ditions for process improvement potential that are not easily

exp{[1,233.4/(1.987 313)][1 + (2.484)(0.33/0.67)]2} = explored by a bench chemist (e.g., at elevated pressures and

1.49; x11 = (0.33)(1.49) = 0.49; by Eq. 7, x11 = temperatures), prior to committing to an expensive research

exp{[24.5/1.987][331/313 1]} = 0.49. Comment: Com- program. Higher solubility at elevated temperatures might be

mon ways to deal with trial-and-error calculations include taken advantage of for several reasons, including:

40 CEP March 2004 www.cepmagazine.org

higher payloads for a reaction where the product is kept Process improvement example:

in solution and filtered away from other solids such as het- Eliminating reaction solvent

erogeneous catalyst, solid absorbents, or byproduct salts A process dissolves a solid S in a solvent and then re-

faster reaction kinetics, especially for reactions where acts it with a liquid L to create a product P according

the solids are predominantly out of solution to the following stoichiometry: S + 8L P. P has a melt-

reduced energy costs, solvent costs and waste disposal ing point of 180C and a heat of fusion of 4 cal/gmol. L

costs, which can be achieved by processing with reduced has a normal boiling point of 110C. What is the best-case

amounts of solvent present; this is especially true if the sol- usage of L if the reaction is conducted only in L at atmo-

vent must be subsequently evaporated or distilled, or a reac- spheric reflux conditions and the reaction must finish as a

tion byproduct must be stripped to complete the reaction uniform solution of P in L? For simplicity, ignore any

elimination of reaction solvent by conducting the re- boiling point elevations.

action of a solid with no solvent in a small excess of a liq- Answer: The ideal solubility mole fraction of P at

uid reactant. 110C is 0.445. The amount of L needed over stoichio-

Solubility may also be used to estimate vapor/liquid metric requirements is (1 0.445)/0.445 = 1.25 moles

equilibrium or other properties predicted from solution L/mole of P. The best-case usage is then 8 + 1.25 = 9.25

theory such as osmotic pressure. moles of L per mole of P, or 15% over theory. This usage

could be compared to that of the current process, the raw

Process improvement example: material cost for the usage of original process solvent,

Crystallization temperature and the operating costs for any solvent recovery steps for

A process crystallizes a product from a solvent. The the original solvent.

final crystallization temperature is less than 10C to mini-

mize the yield loss from solubility. The process is run very Final thoughts

dilute to keep an impurity from co-crystallizing. The phys- Process simulation software has made extensive in-

ical property information for the system is presented in vestment in solution theory, especially for non-elec-

Table 1. Do you agree the cold temperatures and extra sol- trolytes, for prediction of vapor/liquid equilibrium. An

vent are the proper approach? activity coefficient prediction based on structure (UNI-

Answer: The solubility of the impurity will increase FAC) is a common feature in such software. However,

faster with temperature than the solubility of the product, the extension of activity coefficient to the solubility of

as illustrated by the ideal solubilities shown in Table 2. non-electrolytes has often been overlooked in process

Increasing the crystallization temperature from 10C simulation software. CEP

to 25C and cutting the amount of solvent in the pro-

cess by one-half to two-thirds is the directionally cor-

rect approach to improving the process. The combined MICHAEL J. GENTILCORE is an engineering consultant at Tyco

Healthcare Mallinckrodt (675 McDonnell Blvd., Hazelwood, MO

change of warmer crystallization temperatures and half 63042; Phone: (314) 654-4031; Fax: (314) 654-7174; E-mail:

the solvent will result in no increased product losses mike.gentilcore@tycohealthcare.com). He has over 25 years of chemical

and an improved ability to keep impurities in solution. engineering experience in design, research and development, and

Estimating activity coefficients could further refine manufacturing, and he holds several patents. He received a BS in

chemical engineering from Clarkson Univ. and an MS in engineering

these estimates. management from the Univ. of MissouriRolla. He is a member of AIChE

and a licensed P.E. in Missouri.

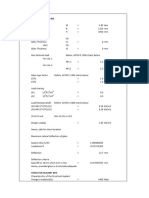

Table 1. Physical property data for

crystallization temperature example.

Product Impurity Literature Cited

Melting Point, C 150 165 1. Reid, R. C., et al., The Properties of Gases and Liquids, 4th

Heat of Fusion, cal/gmol-C 8 13 ed., McGraw-Hill, New York, NY (1987).

2. Castellan, G. W., Physical Chemistry, 2nd ed., Addison-

Wesley Publishing Co., Reading, MA (1971).

3. Hildebrand, J. H., and R. L. Scott, The Solubility of Non-

Table 2. Ideal solubilities for electrolytes, 3rd ed., Reinhold Publishing Co., New York, NY

crystallization temperature example.

(1950).

Product Impurity Website of Interest

10C 0.0091 0.00028 www.chemstations.net/documents/examples.htm Readers

who use CHEMCAD may find the information at the Predictive

20C 0.0185 0.00090

Crystallizer link on this site useful.

Increase in solubility 2.0 times 3.2 times3

CEP March 2004 www.cepmagazine.org 41

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 1-ADM-Aluminum Design Manual & SpecificationDocument83 pages1-ADM-Aluminum Design Manual & SpecificationAyham Aljawhary100% (2)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Heat Exchanger Student HandoutDocument39 pagesHeat Exchanger Student HandoutkotiNo ratings yet

- Single Shear Steel ConnectionDocument36 pagesSingle Shear Steel ConnectionNatalie WestNo ratings yet

- Equipment Costing: Chapter 22 (p558-597) CH EN 4253 Terry A. RingDocument20 pagesEquipment Costing: Chapter 22 (p558-597) CH EN 4253 Terry A. RingLívia AlmeidaNo ratings yet

- 3110336715Document580 pages3110336715kumar_chemicalNo ratings yet

- Urs Template ContentsDocument8 pagesUrs Template ContentsipatoffNo ratings yet

- Skin Friction and Pile DesignDocument7 pagesSkin Friction and Pile DesignNaveen RNo ratings yet

- Facade TreatmentDocument11 pagesFacade TreatmentfakemasterkgpNo ratings yet

- Analisis de Riesgo 2010MA-Online - QuintoDocument9 pagesAnalisis de Riesgo 2010MA-Online - QuintoSteven Correa MNo ratings yet

- Barry O Donovan Novartis (Compatibility Mode) PDFDocument13 pagesBarry O Donovan Novartis (Compatibility Mode) PDFkumar_chemicalNo ratings yet

- Glaxosmithkline Speeds Up Batch Release Time With Mes TechnologyDocument4 pagesGlaxosmithkline Speeds Up Batch Release Time With Mes Technologykumar_chemicalNo ratings yet

- 01 Brambilla CH 01Document28 pages01 Brambilla CH 01kumar_chemicalNo ratings yet

- Course Title Credits Th. Pr. Tr. Tu. Total Pre-Requisites: Course Role in Curriculum Catalogue DescriptionDocument2 pagesCourse Title Credits Th. Pr. Tr. Tu. Total Pre-Requisites: Course Role in Curriculum Catalogue Descriptionkumar_chemicalNo ratings yet

- Batch Process WhitePaperDocument9 pagesBatch Process WhitePaperImadudin AlaNo ratings yet

- Conceptual Production Plant DesignDocument22 pagesConceptual Production Plant Designkumar_chemicalNo ratings yet

- Laureates: Junior Prizes of The SCS Fall Meeting 2016: DitorialDocument2 pagesLaureates: Junior Prizes of The SCS Fall Meeting 2016: Ditorialkumar_chemicalNo ratings yet

- 13MA Rich PDFDocument9 pages13MA Rich PDFkumar_chemicalNo ratings yet

- Time-Cycle For DistillationDocument7 pagesTime-Cycle For Distillationkumar_chemicalNo ratings yet

- Rouge Pharmaceutical Water Steam SystemsDocument8 pagesRouge Pharmaceutical Water Steam Systemshareesh13hNo ratings yet

- Troup and Georgakis CPC08 2012 - FINAL-FinalDocument25 pagesTroup and Georgakis CPC08 2012 - FINAL-Finalkumar_chemicalNo ratings yet

- Travelling Expenses China-2016Document2 pagesTravelling Expenses China-2016kumar_chemicalNo ratings yet

- Wanbury Profile February 2006Document32 pagesWanbury Profile February 2006kumar_chemicalNo ratings yet

- Rouge Pharmaceutical Water Steam SystemsDocument8 pagesRouge Pharmaceutical Water Steam Systemshareesh13hNo ratings yet

- Vipul Doshi - Compliance Road MapDocument49 pagesVipul Doshi - Compliance Road Mapkumar_chemical100% (1)

- Rajiv Gandhi University of Health Sciences: ST NDDocument10 pagesRajiv Gandhi University of Health Sciences: ST NDkumar_chemicalNo ratings yet

- 4731Document2 pages4731kumar_chemicalNo ratings yet

- E111 0Document4 pagesE111 0kumar_chemicalNo ratings yet

- Publications in Brief: BooksDocument3 pagesPublications in Brief: Booksbhawanisr@gmail.comNo ratings yet

- How Operational Excellence Works - Process Optimization TechniquesDocument6 pagesHow Operational Excellence Works - Process Optimization Techniqueskumar_chemicalNo ratings yet

- 3.ITEC Shanghai 2007 Mothes Final 2007-4-17Document19 pages3.ITEC Shanghai 2007 Mothes Final 2007-4-17kumar_chemicalNo ratings yet

- 10 3303cet1648004Document7 pages10 3303cet1648004kumar_chemicalNo ratings yet

- 11ND Walsh PDFDocument7 pages11ND Walsh PDFAshok LenkaNo ratings yet

- Vessel VolumesDocument75 pagesVessel Volumeskumar_chemicalNo ratings yet

- How Operational Excellence Works - Process Optimization TechniquesDocument6 pagesHow Operational Excellence Works - Process Optimization Techniqueskumar_chemicalNo ratings yet

- Aspenone Production Management Execution PharmaceuticalsDocument4 pagesAspenone Production Management Execution Pharmaceuticalskumar_chemicalNo ratings yet

- Experiment No. 3: University of The East - Caloocan College of Engineering Civil Engineering DepartmentDocument6 pagesExperiment No. 3: University of The East - Caloocan College of Engineering Civil Engineering DepartmentJHONRUSSEL ANTONIONo ratings yet

- Unit - 5 Electric DipolesDocument9 pagesUnit - 5 Electric DipolesELMURNo ratings yet

- Bernoulli EquationDocument4 pagesBernoulli EquationShida Shidot100% (1)

- For K 0.156, Compression Steel Required.: Structures & Tall Buildings (CON4338) Data Page 1Document12 pagesFor K 0.156, Compression Steel Required.: Structures & Tall Buildings (CON4338) Data Page 1Ho JamesNo ratings yet

- C-SCP360H38B R410aDocument8 pagesC-SCP360H38B R410aRaúl RodríguezNo ratings yet

- HJT MBB Half-Cut Bifacial Dual-Glass Module Ska611HdgdcDocument2 pagesHJT MBB Half-Cut Bifacial Dual-Glass Module Ska611HdgdcMarko Maky ZivkovicNo ratings yet

- RS - Final 2023Document3 pagesRS - Final 2023Yousif Taha Al-badranNo ratings yet

- Electrochemistry: Redox Reactions and Galvanic Cells: Mr. Jeremiah G. Pedral Cs-DpsDocument28 pagesElectrochemistry: Redox Reactions and Galvanic Cells: Mr. Jeremiah G. Pedral Cs-DpsMickko O RadanNo ratings yet

- SPECTRALIS - Technical Data Sheet EnglishDocument4 pagesSPECTRALIS - Technical Data Sheet EnglishAna Laura López OrocioNo ratings yet

- Konten PDP Heat and SoundDocument3 pagesKonten PDP Heat and SoundhanismaNo ratings yet

- N3ational Certification Examination 2004Document8 pagesN3ational Certification Examination 2004Brahmananda TaraiNo ratings yet

- DPI General CatalogueWeb PDFDocument149 pagesDPI General CatalogueWeb PDFsunny_boy73No ratings yet

- PhysicalScience11 - Module3 - Intermolecular Forces STUDENTSDocument16 pagesPhysicalScience11 - Module3 - Intermolecular Forces STUDENTSMae repasoNo ratings yet

- Cam Analysis ManualDocument4 pagesCam Analysis ManualNishant B MayekarNo ratings yet

- Unit 43 Heat Pumps1Document92 pagesUnit 43 Heat Pumps1hvactrg1No ratings yet

- Structural Cals For UCWDocument11 pagesStructural Cals For UCWShubham SoniNo ratings yet

- Astm D788-16Document6 pagesAstm D788-16Gabriel Perez CruzNo ratings yet

- Edexcel A Level Chemistry Book 2 - OCRDocument268 pagesEdexcel A Level Chemistry Book 2 - OCREdcademiaNo ratings yet

- Cbjescco11 PDFDocument10 pagesCbjescco11 PDFneomatrix70No ratings yet

- 2 - Quantum InfoDocument24 pages2 - Quantum InfoSusie101No ratings yet

- Speed of Sound ExperimentDocument3 pagesSpeed of Sound Experimentapi-237866679No ratings yet

- CFD SyllabusDocument2 pagesCFD SyllabussumikannuNo ratings yet

- Line Data: Piping Isometric DrawingsDocument1 pageLine Data: Piping Isometric Drawingsksat85No ratings yet

- JEE Physics Test Series 1 PDFDocument21 pagesJEE Physics Test Series 1 PDFAkil kumarNo ratings yet

- Lecture Notes: Introduction To Condensed Matter TheoryDocument154 pagesLecture Notes: Introduction To Condensed Matter Theory谭志阳No ratings yet