Professional Documents

Culture Documents

Abstract Final Year Project

Uploaded by

Unni CyriacCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Abstract Final Year Project

Uploaded by

Unni CyriacCopyright:

Available Formats

Summary of your final year project

Project Title: Design of Cam Mechanism

Objective: Objective of the project is to numerically generate a cam profile to control motion of swing

gripper of sheet feed offset printing machine SOM125. This project was a part of the increasing the

capacity of machine

Project done for: Hindustan machine tools limited (HMT), Kerala India , HMT is one of the top

manufacturers of Sheetfed Offset Printing Machine from India.

Background information: As part of continuous development, HMT decided to improve the capacity

of their Sheetfed Offset Printing SOM125 . They chartered a project for this development. As part of

final year project, myself with other 3 colleague involved in this project. Our assignment was to

develop a cam system which can overcome the speed limitation of existing spring loaded cam system.

Our assigned task was an integral part of the total project.

Project Description

Existing CAM mechanism which drives the swing gripper use springs to keep the contact of the swing

gripper roller with cam profile. When the speed of the cam rotation increases, spring fails to keep the

swing gripper roller in contact with the cam profile. This was a major bottle neck for increasing the

speed of the machine. Task was to develop new system to overcome above mentioned difficulty.

Old system

New system is proposed as part of the project, where the follower motion was controlled by counter cam

instead of spring .Thus the one of the constraints to increase the speed of the machine can be overcame. .

A program was developed in 'C' programming language for numerically generating

cam profile for CNC machining

New system

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Bra ADCO TFDocument2 pagesBra ADCO TFUnni CyriacNo ratings yet

- AdweaDocument12 pagesAdweaUnni Cyriac100% (1)

- 2009 10 Formstückkatalog EDocument127 pages2009 10 Formstückkatalog EUnni CyriacNo ratings yet

- Final Submittal For Butterfly Valve - Dairy Farm Revised 20-8-2017Document95 pagesFinal Submittal For Butterfly Valve - Dairy Farm Revised 20-8-2017Unni CyriacNo ratings yet

- Spare Parts List - Cost Per SiteDocument1 pageSpare Parts List - Cost Per SiteUnni CyriacNo ratings yet

- DS Datasheet ERHARD Needle Valves enDocument8 pagesDS Datasheet ERHARD Needle Valves enEnrike GutierrezNo ratings yet

- Attachment - 3 Model Input ListingDocument25 pagesAttachment - 3 Model Input ListingUnni CyriacNo ratings yet

- Low Lit Book FNL LRDocument92 pagesLow Lit Book FNL LRraja_18No ratings yet

- Notes:: Shop DrawingDocument1 pageNotes:: Shop DrawingUnni CyriacNo ratings yet

- Attachment - 6 Out Put HydrotestDocument18 pagesAttachment - 6 Out Put HydrotestUnni CyriacNo ratings yet

- Stress Analysis CommentsDocument1 pageStress Analysis CommentsUnni CyriacNo ratings yet

- InvoiceDocument1 pageInvoiceUnni CyriacNo ratings yet

- King City WQTDocument4 pagesKing City WQTUnni CyriacNo ratings yet

- Attachment - 4 Model Input Listing Hydro Test PDFDocument11 pagesAttachment - 4 Model Input Listing Hydro Test PDFUnni CyriacNo ratings yet

- N2664 W M MS 06 An 2465 R1 Hydrotesting of AG PipingDocument9 pagesN2664 W M MS 06 An 2465 R1 Hydrotesting of AG PipingUnni CyriacNo ratings yet

- Final Submittal For Butterfly Valve - Dairy Farm Revised 20-8-2017Document95 pagesFinal Submittal For Butterfly Valve - Dairy Farm Revised 20-8-2017Unni CyriacNo ratings yet

- Control Valve Data SheetDocument1 pageControl Valve Data SheetUnni CyriacNo ratings yet

- 2014 Abu Dhabi Guideline - Air Quality Monitoring Handbook For Quality Manual-1-FINAL V - New Format Pages NumberedDocument60 pages2014 Abu Dhabi Guideline - Air Quality Monitoring Handbook For Quality Manual-1-FINAL V - New Format Pages NumberedUnni CyriacNo ratings yet

- Hydraulic Report Lifting Station R0Document12 pagesHydraulic Report Lifting Station R0Unni CyriacNo ratings yet

- FA Specification ComplianceDocument8 pagesFA Specification ComplianceUnni CyriacNo ratings yet

- TDR 01 R1Document2 pagesTDR 01 R1Unni CyriacNo ratings yet

- Understanding API 1169-Part 40 CFR 112 P PDFDocument82 pagesUnderstanding API 1169-Part 40 CFR 112 P PDFUnni Cyriac100% (1)

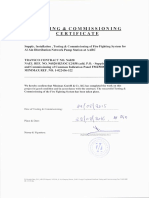

- Testing and Commissioning CertificateDocument1 pageTesting and Commissioning CertificateUnni Cyriac100% (1)

- Polythylene Pipes and Fittings For Pressurised Water-2016Document48 pagesPolythylene Pipes and Fittings For Pressurised Water-2016Unni CyriacNo ratings yet

- IEng and CEng Guidance Notes PDFDocument26 pagesIEng and CEng Guidance Notes PDFUnni CyriacNo ratings yet

- 1169 BOK Apr-Dec-2017 Final-011117 PDFDocument9 pages1169 BOK Apr-Dec-2017 Final-011117 PDFUnni CyriacNo ratings yet

- 1169 BOK Apr-Dec-2017 Final-011117 PDFDocument9 pages1169 BOK Apr-Dec-2017 Final-011117 PDFUnni CyriacNo ratings yet

- 1169 BOK Apr-Dec-2017 Final-011117Document9 pages1169 BOK Apr-Dec-2017 Final-011117Unni CyriacNo ratings yet

- Cutting Location at ShobaisiDocument1 pageCutting Location at ShobaisiUnni CyriacNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)