Professional Documents

Culture Documents

Daily Report-012 (Su Jinlong)

Uploaded by

sujinlong0 ratings0% found this document useful (0 votes)

21 views5 pagesOriginal Title

Daily Report-012(Su Jinlong).doc

Copyright

© © All Rights Reserved

Available Formats

DOC, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

21 views5 pagesDaily Report-012 (Su Jinlong)

Uploaded by

sujinlongCopyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

You are on page 1of 5

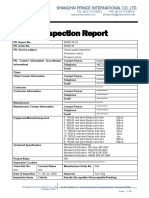

Daily Report

www.GQIS.co.uk

Project: Hinkley Jetty Design

Customer: Edgen Murray

Finalisation

Sub-Vendor: Zhejiang Chankong Steel

Vendor: ESC Group

Pipe CO.,LTD

Sub-Vendor Address: Tianning, Jiashan,

Vendor Address: Putuo, Shanghai,China

Zhejiang

Vendor Reference: Sub-Vendor Reference:

GQIS Assignment No: Customer Reference:

Purchase Order No: 3568 Report No: 012

8PM 3rd, September

Date of Visit:

-8AM 4th,September,2016

MATERIAL INSPECTED THIS VISIT

Item No. Quantity Description Tag No., Batch No., Serial No., Cast,

Heat No.

167111925 1 Raw coil material inspection Detail data refer to below

table.

SUMMARY / AREAS OF CONCERN

GUI-036-00 (Revision 0) Flash Report Dated: 22nd March 2016

Daily Report

www.GQIS.com

Customer: Edgen Murray Purchase Order 3568

No.:

1. SMMARY / AREAS OF CONCERN:

1.1 Raw coil material inspection

As per ITP step 09(Incoming raw material quality control and assurance-Raw material inspection, including

material identification, appearance and dimension inspection), GQIS inspector carride out inpection for raw

coil material, the detail inspection scope as below table, all inspection data found in conformity with ITP &

specification and traceability, the surface hasnt found any indication of damage. The result is satisfactory.

Serial No. Material Size Heat No. Delivering Specification

Grade Condition

167111925 S355J2 25X1500 16103257A Hot Rolled EN 10025-2 2004: S355J2

1.2 Witness hydrostatic testing for flexible hose

As per ITP step 16(Grout pipe hydro test), GQIS inspector witness hydrostatic testing for flexible hose;

Before testing, GQIS inspector reviewed flexible hoses certificates, verified the drawing and specification

requirement, checked calibration certificate for hydrostatic testing equipment and valid time and confirmed

that are satisfactory. Not any indication of leakage was found during test, test duration 15 seconds and testing

pressure was 18 Bar, which in line with the drawing and specification.

1.3 Review SSAW end product inspection record

As per ITP step 09(Incoming raw material quality control and assurance-Raw material inspection), GQIS

inspector reviewed factory original data of SSAW end product inspection record, randomly spot inspection

product and result in conformity with original record, confirm the factory inspection record is real and

reliable, the inspection scope and result in line with the drawing and specification.

1.4 Inspection ancillary dimension and assembly dimension with pile 3568-C06-058

As per ITP step 15(Production and installation of ancillary), GQIS inspector carried out visual and dimension

inspection for ancillary dimension and assembly dimension with pile 3568- C06-058 according to the drawing

and specification, not found any dimension out of tolerence and the result is satisfactory.

1.5 On manufacturing progress reference to attachment document: 3568 Production Summary-04.

Picture

Raw coil material inspection

007 (Revision 0) Daily Report Dated: 29nd August 2016

Daily Report

www.GQIS.com

Customer: Edgen Murray Purchase Order 3568

No.:

1.3 Witness hydrostatic testing for flexible hose

Review SSAW end product inspection record

007 (Revision 0) Daily Report Dated: 29nd August 2016

Daily Report

www.GQIS.com

Customer: Edgen Murray Purchase Order 3568

No.:

Witness MT and found indication at three location

Inspection ancillary dimension

Inspection ancillary dimension

007 (Revision 0) Daily Report Dated: 29nd August 2016

Daily Report

www.GQIS.com

Customer: Edgen Murray Purchase Order 3568

No.:

Inspection ancillary assembly dimension of pile 3568-C06-058

Inspection ancillary assembly dimension of pile 3568-C06-058

Accepted Yes Non-Compliant No

Technical Specialist: Su Jinlong Operations Coordinator:

Date: 8PM 3rd, September -8AM Date:

4th,September,2016

007 (Revision 0) Daily Report Dated: 29nd August 2016

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Masters Guide To Enclosed Space EntryDocument60 pagesA Masters Guide To Enclosed Space EntryHongKi AN100% (1)

- Magnetic Flux LeakageDocument2 pagesMagnetic Flux LeakagesujinlongNo ratings yet

- API 572 2009CNDocument160 pagesAPI 572 2009CNsujinlongNo ratings yet

- Magnetic Flux Leakage TechnologyDocument12 pagesMagnetic Flux Leakage TechnologyAwais TariqNo ratings yet

- API 653 Inspection ModuleDocument348 pagesAPI 653 Inspection ModulesujinlongNo ratings yet

- Additional Tank RCFA LogDocument2 pagesAdditional Tank RCFA LogsujinlongNo ratings yet

- FSF1 RCFA LogDocument3 pagesFSF1 RCFA LogsujinlongNo ratings yet

- Asme 36.10MDocument26 pagesAsme 36.10MAlberto darian100% (1)

- Pressure VesselDocument40 pagesPressure VesselPrt00789% (18)

- A Masters Guide To Ships Piping 2 ND EditionDocument42 pagesA Masters Guide To Ships Piping 2 ND EditionMoe LattNo ratings yet

- CPF2 RCFA LogDocument6 pagesCPF2 RCFA LogsujinlongNo ratings yet

- Root Cause Failure Analysis Report (Rcfa) - LogDocument3 pagesRoot Cause Failure Analysis Report (Rcfa) - LogsujinlongNo ratings yet

- Pressure Vessel PDFDocument40 pagesPressure Vessel PDFsujinlongNo ratings yet

- Inspection Report PDFDocument29 pagesInspection Report PDFsujinlongNo ratings yet

- High Pressure VesselsDocument26 pagesHigh Pressure VesselsAnonymous pMVR77x1No ratings yet

- Sample Inspection Report of ExchangerDocument22 pagesSample Inspection Report of Exchangerrtrajan_mech5408100% (4)

- Inspection - : Flash ReportDocument3 pagesInspection - : Flash ReportsujinlongNo ratings yet

- Basic Pressure Vessel ConceptsDocument25 pagesBasic Pressure Vessel ConceptsVimin Prakash90% (10)

- Piper Inspection Report PDFDocument5 pagesPiper Inspection Report PDFsujinlong100% (4)

- ML063040307 Response To Request For Additional Information Regarding Report of in Service Inspection of Steam Generator Tubes Cycle 14 PDFDocument6 pagesML063040307 Response To Request For Additional Information Regarding Report of in Service Inspection of Steam Generator Tubes Cycle 14 PDFsujinlongNo ratings yet

- LNG Standard Inspection Report PDFDocument21 pagesLNG Standard Inspection Report PDFsujinlongNo ratings yet

- Flash Report-2016-2-20Document3 pagesFlash Report-2016-2-20sujinlongNo ratings yet

- Flash Report-2016-2-21Document3 pagesFlash Report-2016-2-21sujinlongNo ratings yet

- ML073610391 Response To Request For Additional Information Regarding Report of in Service Inspection of Steam Generator Tubes Cycle 14 PDFDocument7 pagesML073610391 Response To Request For Additional Information Regarding Report of in Service Inspection of Steam Generator Tubes Cycle 14 PDFsujinlongNo ratings yet

- IRIS Boiler Tubes Inspection ReportDocument347 pagesIRIS Boiler Tubes Inspection ReportsujinlongNo ratings yet

- Flash Report-2016-2-26Document3 pagesFlash Report-2016-2-26sujinlongNo ratings yet

- Flash Report-2016-2-17Document3 pagesFlash Report-2016-2-17sujinlongNo ratings yet

- Flash Report-2016-2-16Document3 pagesFlash Report-2016-2-16sujinlongNo ratings yet

- Flash Report-2016-2-21Document3 pagesFlash Report-2016-2-21sujinlongNo ratings yet

- Flash Report-2016-2-26Document3 pagesFlash Report-2016-2-26sujinlongNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- 00-10-001 - F - Nov.2000Document0 pages00-10-001 - F - Nov.2000Levi MurdokNo ratings yet

- GAIL Gas Limited: Tender Document For Procurement of Pe Pipes (1 Year Arc)Document219 pagesGAIL Gas Limited: Tender Document For Procurement of Pe Pipes (1 Year Arc)BGL NAGARNo ratings yet

- Bidding Document, NCB.24-078-079Document84 pagesBidding Document, NCB.24-078-079Shivshankar SinghNo ratings yet

- SRSExample WebappDocument31 pagesSRSExample WebappSuresh RamanujamNo ratings yet

- Crimping Tools SpecificationDocument30 pagesCrimping Tools SpecificationjenishjsNo ratings yet

- 23 Samss 071Document30 pages23 Samss 071nadeem shaikhNo ratings yet

- WI-INSP-01 R2 Work Instruction-Pressure Vessel InspDocument8 pagesWI-INSP-01 R2 Work Instruction-Pressure Vessel InspRakesh Mishra100% (1)

- J. Kemp Ellington, Michael T. Brannick, and Edward L. LevineDocument1 pageJ. Kemp Ellington, Michael T. Brannick, and Edward L. LevineA TUNo ratings yet

- SA MCVS R - VERSION 4 (DATED Aug 2018)Document85 pagesSA MCVS R - VERSION 4 (DATED Aug 2018)Alex LisichenkoNo ratings yet

- CCTV Method Statement Final Rev-01 PDFDocument33 pagesCCTV Method Statement Final Rev-01 PDFabdul wasay100% (1)

- Final Guidelines of DILRMPDocument260 pagesFinal Guidelines of DILRMPrkekkarNo ratings yet

- ISO 9001-2015 GuidelinesDocument5 pagesISO 9001-2015 Guidelinessuresh kumarNo ratings yet

- Global Claims in Practice - September 2012Document23 pagesGlobal Claims in Practice - September 2012gimasaviNo ratings yet

- Sigma7 Rotary Servomotor Product ManualDocument215 pagesSigma7 Rotary Servomotor Product ManualTrí ChốtNo ratings yet

- Itp (Inspection Test Plan) Rudi eDocument58 pagesItp (Inspection Test Plan) Rudi eRudi EriantoNo ratings yet

- Specifications for Earthwork Formation RVNLDocument32 pagesSpecifications for Earthwork Formation RVNLkartick adhikaryNo ratings yet

- YKP External Coating SpecificationDocument34 pagesYKP External Coating SpecificationAnonymous jLVLP4w3m100% (2)

- PAES 233: Multicrop Washer-Peeler StandardDocument16 pagesPAES 233: Multicrop Washer-Peeler StandardFaroukNo ratings yet

- Astm b108-Aluminium-Alloy Permanent Mold CastingsDocument18 pagesAstm b108-Aluminium-Alloy Permanent Mold CastingsEldennisNo ratings yet

- Smart DCR User ManualDocument39 pagesSmart DCR User ManualImran MulaniNo ratings yet

- Process ValidationDocument30 pagesProcess ValidationprakashNo ratings yet

- Section 17 - Metal Works (Cont'D) : The Arab Architects Sec 17/2 Qatar University New Research ComplexDocument26 pagesSection 17 - Metal Works (Cont'D) : The Arab Architects Sec 17/2 Qatar University New Research ComplexNATHANNo ratings yet

- Aashto Catalog PDFDocument23 pagesAashto Catalog PDFamrNo ratings yet

- Tender Documents For Gas Seperation Dehydration Etc by Oil PDFDocument71 pagesTender Documents For Gas Seperation Dehydration Etc by Oil PDFuss1957No ratings yet

- Astm A227Document4 pagesAstm A227Adolfo Luis Avila MurciaNo ratings yet

- Ts 16949 Proc Forms MatrixDocument1 pageTs 16949 Proc Forms MatrixRob WillestoneNo ratings yet

- Itb-Keoc-2012-014 - Annex II BoqDocument384 pagesItb-Keoc-2012-014 - Annex II Boqelsabet gezahegnNo ratings yet

- Contrato Trafigura Imopetro 01.18 - 02.07.2018 VF 1 PDFDocument91 pagesContrato Trafigura Imopetro 01.18 - 02.07.2018 VF 1 PDFUtsav Agarwal100% (1)

- Codan Industrial Hose CatalogueDocument218 pagesCodan Industrial Hose CatalogueYadiNo ratings yet

- E20 CVL Work OrderDocument151 pagesE20 CVL Work OrderEr. TK SahuNo ratings yet