Professional Documents

Culture Documents

Chapter 1

Uploaded by

Kaleem UllahCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Chapter 1

Uploaded by

Kaleem UllahCopyright:

Available Formats

EQUIPMENT IN WELL CONTROL

If the equipment does not work

properly, well control will not be

possible

2004 PetroSkills LLC, All Rights Reserved

Equipment

Erosion of steel is one of the

biggest problems in well control

2004 PetroSkills LLC, All Rights Reserved

Equipment

High velocity

gas and solids

will cut steel

2004 PetroSkills LLC, All Rights Reserved

Equipment

A spool on a capping stack eroded

out past the ring gasket in just a few

hours

2004 PetroSkills LLC, All Rights Reserved

Equipment

Erosion in

a choke

manifold

2004 PetroSkills LLC, All Rights Reserved

Equipment

Erosion of a

mud cross

below the

blowout

preventers

2004 PetroSkills LLC, All Rights Reserved

Equipment

Erosion of a

blowout

preventer after a

blowout

2004 PetroSkills LLC, All Rights Reserved

Equipment

The choke line should be straight

and no threaded connections

2004 PetroSkills LLC, All Rights Reserved

Equipment

If turns are required, they should be

targeted turns

2004 PetroSkills LLC, All Rights Reserved

Equipment

Do you see a

problem with

this choke line?

2004 PetroSkills LLC, All Rights Reserved

Equipment

Minimum choke

manifold

2004 PetroSkills LLC, All Rights Reserved

Equipment

Choke manifold

with extra flow

paths

2004 PetroSkills LLC, All Rights Reserved

Equipment

One of the first

drilling chokes

Production

chokes will not

last as a choke

in a drilling

situation

2004 PetroSkills LLC, All Rights Reserved

Equipment

Example of

a drilling

choke

Drilling

chokes are

designed to

handle drill

solids

2004 PetroSkills LLC, All Rights Reserved

Equipment

Drilling choke with stem and seat

2004 PetroSkills LLC, All Rights Reserved

Equipment

Positive chokes should not be

included in a choke manifold

The pressure cannot be adjusted

with a positive choke

2004 PetroSkills LLC, All Rights Reserved

Equipment

The panic line should go straight

to the pit with no turns

Since flow is at a high rate and

low pressure, erosion will be

severe

2004 PetroSkills LLC, All Rights Reserved

Equipment

The downstream part of the choke

manifold is prone to washout

2004 PetroSkills LLC, All Rights Reserved

Equipment

Headers are

designed to

allow flow to the

separator or

mud pits

2004 PetroSkills LLC, All Rights Reserved

Equipment

This is a better

option for the

header

2004 PetroSkills LLC, All Rights Reserved

Equipment

The connections

to the separator

are as important

as the separator

A washout

upstream of the

separator shuts

down the

operation

2004 PetroSkills LLC, All Rights Reserved

Equipment

Inadequate

offshore

separator

2004 PetroSkills LLC, All Rights Reserved

Equipment

Inadequate land

separator

2004 PetroSkills LLC, All Rights Reserved

Equipment

The separator

should be a

minimum 4 foot

diameter with

minimum 4

lines to the

separator

2004 PetroSkills LLC, All Rights Reserved

Equipment

In some

operations, a

much larger

mud gas

separator may

be required

2004 PetroSkills LLC, All Rights Reserved

Equipment

A mud gas

separator with a

liquid level

control valve is

best

2004 PetroSkills LLC, All Rights Reserved

Equipment

Typical kill line

2004 PetroSkills LLC, All Rights Reserved

Equipment

A stabbing valve

should be

readily available

on the rig floor

Need a

crossover for

the drill collars

2004 PetroSkills LLC, All Rights Reserved

Equipment

Also need to

know the

minimum inside

diameter of the

stabbing valve

(ball and not pin

conection)

Measure it!

2004 PetroSkills LLC, All Rights Reserved

You might also like

- Wave Propagation in Drilling, Well Logging and Reservoir ApplicationsFrom EverandWave Propagation in Drilling, Well Logging and Reservoir ApplicationsNo ratings yet

- 10 2118@195057-MSDocument14 pages10 2118@195057-MSAlexandra Guamann MendozaNo ratings yet

- How The Latest Oil Capping Attempt Will WorkDocument1 pageHow The Latest Oil Capping Attempt Will WorkThe State NewspaperNo ratings yet

- Wireless Well Completions ScandOil December 2017Document3 pagesWireless Well Completions ScandOil December 2017RaamNo ratings yet

- Basin Research - 2020 - Howlett - Turbidites Topography and Tectonics Evolution of Submarine Channel Lobe Systems in TheDocument35 pagesBasin Research - 2020 - Howlett - Turbidites Topography and Tectonics Evolution of Submarine Channel Lobe Systems in TheamacuroNo ratings yet

- 4D Seismic Case StudyDocument14 pages4D Seismic Case Studytheoneandonly1No ratings yet

- Spe 21696 MSDocument9 pagesSpe 21696 MSAleks ProañoNo ratings yet

- Why Drill in Fluids'Document15 pagesWhy Drill in Fluids'mareba55No ratings yet

- Producing The ReservoirDocument35 pagesProducing The ReservoirSergeyNo ratings yet

- Wireline Tractor TechnologyDocument1 pageWireline Tractor TechnologyVedant Singh RaghavNo ratings yet

- Patent WO2013126388A1 - Early Kick Detection in An Oil and Gas Well - Google PatentsDocument10 pagesPatent WO2013126388A1 - Early Kick Detection in An Oil and Gas Well - Google PatentsshadyghanemNo ratings yet

- Energy Conversion TableDocument4 pagesEnergy Conversion Tableaecsuresh35No ratings yet

- Development of A Network and Gas Lift Allocation Model For Production Optimization in The Ras Budran FieldDocument14 pagesDevelopment of A Network and Gas Lift Allocation Model For Production Optimization in The Ras Budran FieldTaiwo Adenike BashorunNo ratings yet

- Going Beyond Exploration: HeadlinesDocument18 pagesGoing Beyond Exploration: HeadlinesibidaboNo ratings yet

- Project Execution and Operation of The World's First FDPSO - AzuriteDocument23 pagesProject Execution and Operation of The World's First FDPSO - AzuritejrladduNo ratings yet

- Akpo LeafletDocument4 pagesAkpo LeafletMusa MohammedNo ratings yet

- Fluid Saturation: 2. Archie's Parameter Determination Techniques 2.1. Core Sample PreparationDocument9 pagesFluid Saturation: 2. Archie's Parameter Determination Techniques 2.1. Core Sample PreparationHelan TatarNo ratings yet

- GEO ExPro V15i2Document68 pagesGEO ExPro V15i2Ezzadin N BabanNo ratings yet

- PGE 361 Lecture 11 Fluid Saturation 2 Lab Measurements (Compatibility Mode)Document16 pagesPGE 361 Lecture 11 Fluid Saturation 2 Lab Measurements (Compatibility Mode)Salar waliNo ratings yet

- Geosteer01 - Intro and BasicsDocument33 pagesGeosteer01 - Intro and Basicsibrahim askarNo ratings yet

- 231 PDFDocument20 pages231 PDFhawar abdul-khaliqNo ratings yet

- Permanent Dowhole GuageDocument14 pagesPermanent Dowhole Guagemrjohnston37No ratings yet

- Building The Dynamic Reservoir Model 2Document80 pagesBuilding The Dynamic Reservoir Model 2egv2000No ratings yet

- The Capping Stack System: Key FactsDocument2 pagesThe Capping Stack System: Key FactsРоман ЖуковNo ratings yet

- JPT 2017 AgostoDocument88 pagesJPT 2017 Agostoabraham dominguezNo ratings yet

- AC ResistivityDocument6 pagesAC ResistivityJulio TedescoNo ratings yet

- Ontrak SpecsDocument2 pagesOntrak SpecstheislandboyNo ratings yet

- Drilling FluidsDocument20 pagesDrilling Fluidsdekra abdo100% (1)

- Recommend Frequency of Well Integrity MonitoringDocument1 pageRecommend Frequency of Well Integrity MonitoringalizareiforoushNo ratings yet

- W2V12 - Reservoir Simulation - Handout PDFDocument8 pagesW2V12 - Reservoir Simulation - Handout PDFtita_luphbie100% (1)

- Sesi - 04 - Seismic Acquisition - GeneralDocument86 pagesSesi - 04 - Seismic Acquisition - GeneralRidho IrsyadNo ratings yet

- Drilling OperationsDocument72 pagesDrilling OperationsBudede Samuel100% (1)

- Mismatches As Well Top Attributes Attributes: Schlumberger PublicDocument12 pagesMismatches As Well Top Attributes Attributes: Schlumberger PublicWilliam AmpomahNo ratings yet

- Cement RetainerDocument2 pagesCement RetainerahmedNo ratings yet

- Lab 2-Determination of Formation Water Resistivity Using Fluid CompositionDocument9 pagesLab 2-Determination of Formation Water Resistivity Using Fluid CompositionSunny BbaNo ratings yet

- Seminar For Reserves EstimatorsDocument47 pagesSeminar For Reserves EstimatorsGustavo EspinozaNo ratings yet

- Use of The Dual-Activity Drillship As A Field Development ToolDocument15 pagesUse of The Dual-Activity Drillship As A Field Development ToolTee Shi FengNo ratings yet

- PLT-presntation - PDFDocument60 pagesPLT-presntation - PDFEdi Agurto CarrascoNo ratings yet

- 03 Testing & Drilling IntroductionDocument40 pages03 Testing & Drilling Introductionمنتظر علي الموسوي100% (1)

- WellPlan ReportDocument34 pagesWellPlan ReportElmar CahangirovNo ratings yet

- OTC 6041 Gravel Pack in Offshore Wells: by A.N. de Sa, A.F.C. Tavares, and L.C. Do Carmo Marques, Petrobras SADocument10 pagesOTC 6041 Gravel Pack in Offshore Wells: by A.N. de Sa, A.F.C. Tavares, and L.C. Do Carmo Marques, Petrobras SAStephanMarquesNo ratings yet

- Wellhead HeightDocument2 pagesWellhead HeightPranjal PatilNo ratings yet

- Capping & Containment: Global Industry Response Group RecommendationsDocument0 pagesCapping & Containment: Global Industry Response Group RecommendationsMEUBRONo ratings yet

- Liquid PermeabilityDocument8 pagesLiquid PermeabilityYung MindsNo ratings yet

- IAM - Lunch & Learn (Brian)Document15 pagesIAM - Lunch & Learn (Brian)ashraff09No ratings yet

- 10 - Clean Up A WellDocument28 pages10 - Clean Up A WellAmin AminNo ratings yet

- SPE 00039328 AutotrackDocument8 pagesSPE 00039328 AutotrackdiegoilNo ratings yet

- Introduction To Coiled Tubing: Module 00 - Day OneDocument7 pagesIntroduction To Coiled Tubing: Module 00 - Day OneFauzan Rahman HaqNo ratings yet

- Basic Understanding of Oil Well Casing and TubingDocument21 pagesBasic Understanding of Oil Well Casing and TubingmanibabuNo ratings yet

- 2-New Completion Technology4Document7 pages2-New Completion Technology4klibiNo ratings yet

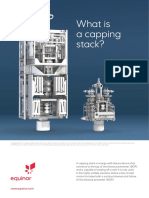

- Equinor Capping StackDocument5 pagesEquinor Capping StackHumisar Alprialdus SinagaNo ratings yet

- Offshore DrillingDocument22 pagesOffshore DrillingTarun Agarwal100% (1)

- Reeve Up or Change Out A Winch Line (Tugger Line) : Cormorant Alpha Drilling Operations GuideDocument5 pagesReeve Up or Change Out A Winch Line (Tugger Line) : Cormorant Alpha Drilling Operations GuidealiNo ratings yet

- PerforationsDocument0 pagesPerforationsSikander MushtaqNo ratings yet

- Rig Equipment (Ok)Document25 pagesRig Equipment (Ok)Mahmoud Ahmed Ali AbdelrazikNo ratings yet

- 1 ResistivityDocument25 pages1 ResistivitygasmigasmiNo ratings yet

- Subsea Well Plug and Abandon Intervention Using A Coiled Tubing Conveyed Inflatable Packer A Case Study KopyaDocument7 pagesSubsea Well Plug and Abandon Intervention Using A Coiled Tubing Conveyed Inflatable Packer A Case Study KopyaErdal AYDINNo ratings yet

- Hydrocarbon Fluid Inclusions in Petroliferous BasinsFrom EverandHydrocarbon Fluid Inclusions in Petroliferous BasinsNo ratings yet

- Kelly Hose PDFDocument2 pagesKelly Hose PDFKaleem UllahNo ratings yet

- High Pressure Lines PDFDocument3 pagesHigh Pressure Lines PDFKaleem UllahNo ratings yet

- Kelly Cocks PDFDocument2 pagesKelly Cocks PDFKaleem UllahNo ratings yet

- Intermediate Inspection Criteria, Well Control Equipment: Equipment Group: Shooting NippleDocument2 pagesIntermediate Inspection Criteria, Well Control Equipment: Equipment Group: Shooting NippleKaleem UllahNo ratings yet

- Mud Pump - High Pressure Lines PDFDocument7 pagesMud Pump - High Pressure Lines PDFKaleem UllahNo ratings yet

- HP Hoses PDFDocument2 pagesHP Hoses PDFKaleem UllahNo ratings yet

- Intermediate Well Control Equipment Inspection Criteria: Equipment Group: Mud / Gas SeparatorDocument2 pagesIntermediate Well Control Equipment Inspection Criteria: Equipment Group: Mud / Gas SeparatorKaleem Ullah0% (1)

- Pakinstan Glycol PresentationDocument19 pagesPakinstan Glycol PresentationKaleem UllahNo ratings yet

- Fuid End PDFDocument2 pagesFuid End PDFKaleem UllahNo ratings yet

- Intermediate Well Control Equipment Inspection Criteria: Equipment Group: Choke Line Coflexip Type HoseDocument2 pagesIntermediate Well Control Equipment Inspection Criteria: Equipment Group: Choke Line Coflexip Type HoseKaleem UllahNo ratings yet

- Adapters and Drilling SpoolsDocument2 pagesAdapters and Drilling SpoolsKaleem UllahNo ratings yet

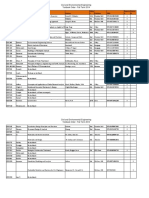

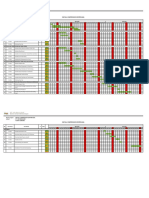

- Daily Tool Pusher ChecklistDocument2 pagesDaily Tool Pusher ChecklistKaleem UllahNo ratings yet

- Drilling Fluid Systems: © 2004 Baker Hughes Incorporated All Rights ReservedDocument33 pagesDrilling Fluid Systems: © 2004 Baker Hughes Incorporated All Rights ReservedKaleem UllahNo ratings yet

- Pakistan Oil-Based Fluids PresentationDocument42 pagesPakistan Oil-Based Fluids PresentationKaleem UllahNo ratings yet

- Red Baron General CatalogDocument40 pagesRed Baron General CatalogKaleem Ullah100% (1)

- Driller Module: Sedco Forex Modular Training ProgramDocument2 pagesDriller Module: Sedco Forex Modular Training ProgramKaleem UllahNo ratings yet

- Fishing ToolDocument17 pagesFishing ToolKaleem UllahNo ratings yet

- Driller Module Workbook 4 Sedco Forex Modular Training ProgramDocument3 pagesDriller Module Workbook 4 Sedco Forex Modular Training ProgramKaleem UllahNo ratings yet

- Surface Well Control Exercise No. 11 - Equipment - GeneralDocument27 pagesSurface Well Control Exercise No. 11 - Equipment - GeneralKaleem UllahNo ratings yet

- Driller Module Workbook 5 Sedco Forex Modular Training ProgramDocument3 pagesDriller Module Workbook 5 Sedco Forex Modular Training ProgramKaleem UllahNo ratings yet

- PDC - Terminology and MechanicsDocument17 pagesPDC - Terminology and MechanicsKaleem UllahNo ratings yet

- Surface Well Control Exercise No. 10 - Equipment - Revised January 2012 - Welltrain Logo PDFDocument14 pagesSurface Well Control Exercise No. 10 - Equipment - Revised January 2012 - Welltrain Logo PDFKaleem UllahNo ratings yet

- Driller Workbook3Document4 pagesDriller Workbook3Kaleem UllahNo ratings yet

- F Chapter 6 Annular SpaceDocument55 pagesF Chapter 6 Annular SpaceAbdul-alim BhnsawyNo ratings yet

- Experiment 2Document2 pagesExperiment 2Ir Fik TNo ratings yet

- Incremental Launch Method For Steel Truss Bridge ErectionDocument11 pagesIncremental Launch Method For Steel Truss Bridge ErectionaapennsylvaniaNo ratings yet

- Deck Slab Concreting - Aug 2011Document11 pagesDeck Slab Concreting - Aug 2011AlsonChinNo ratings yet

- The Ritz-Carlton MEP April 18Document86 pagesThe Ritz-Carlton MEP April 18yiuloi997023No ratings yet

- Flare Boom Engineering - Failure - DrillSafeDocument11 pagesFlare Boom Engineering - Failure - DrillSafeAndrey RogozhaNo ratings yet

- Poster PresentationDocument102 pagesPoster PresentationGhale KajiNo ratings yet

- Intro To Sprayed ConcreteDocument36 pagesIntro To Sprayed ConcreteLaura AmorimNo ratings yet

- Fresh and Mechanical Properties of Basalt Fiber Reinforced ConcreteDocument7 pagesFresh and Mechanical Properties of Basalt Fiber Reinforced ConcreteОлег ШибекоNo ratings yet

- 2R SquatDocument11 pages2R SquatInsan Ahammad100% (1)

- Fatigue AnalysisDocument8 pagesFatigue Analysisaap1No ratings yet

- FM Mod4@Azdocuments - inDocument17 pagesFM Mod4@Azdocuments - inVivek Thakur Sujanian100% (1)

- 05.aslan500 Datasheet PDFDocument1 page05.aslan500 Datasheet PDFnandinipriyatNo ratings yet

- 2.9 Shell Momentum Balance and Velocity Profile in Laminar Flow 2.9A IntroductionDocument6 pages2.9 Shell Momentum Balance and Velocity Profile in Laminar Flow 2.9A IntroductionElijah GoreNo ratings yet

- Los Angeles Abrasion Test On Aggregates - Values For Pavements and RoadsDocument4 pagesLos Angeles Abrasion Test On Aggregates - Values For Pavements and RoadsCarlo Dela CruzNo ratings yet

- Fall 2014 Textbook Fall 2014Document2 pagesFall 2014 Textbook Fall 2014Tabish IslamNo ratings yet

- PUNCH TechPaper Foynes Port West JettyDocument14 pagesPUNCH TechPaper Foynes Port West JettyermvvNo ratings yet

- Crystalline Waterproofing TechnologyDocument8 pagesCrystalline Waterproofing TechnologyKiran Kumar JhaNo ratings yet

- Knauf GifafloorDocument4 pagesKnauf GifafloorRichard Aldeen VerzosaNo ratings yet

- ME2113-1 Lab Report DEFLECTION AND BENDING STRESSES IN BEAMSDocument8 pagesME2113-1 Lab Report DEFLECTION AND BENDING STRESSES IN BEAMSsteven mcqueen67% (15)

- Components of Road Structure and Method of ConstructionDocument14 pagesComponents of Road Structure and Method of ConstructionM iqbal100% (1)

- 5 Over 2 Podium Design WoodWorks Part 2Document4 pages5 Over 2 Podium Design WoodWorks Part 2albertoxinaNo ratings yet

- 1 Stress & StrainsDocument55 pages1 Stress & StrainsTechnautsNo ratings yet

- QUANTUTY FOR COMMUNITY BRIDGE 0+000 To 15+360Document9 pagesQUANTUTY FOR COMMUNITY BRIDGE 0+000 To 15+360Abera Mamo JaletaNo ratings yet

- Specific Gravity and Weight Per Cum of Construction MaterialsDocument2 pagesSpecific Gravity and Weight Per Cum of Construction Materialsatul_kulkarni83% (6)

- What Is CLSVOFDocument15 pagesWhat Is CLSVOFjimgogreatNo ratings yet

- Schedule Install Compressor CentrifugalDocument2 pagesSchedule Install Compressor CentrifugalredharereNo ratings yet

- Properties of Philippine Woods LoadsDocument2 pagesProperties of Philippine Woods LoadsJoshua VicenteNo ratings yet

- Assignment 7Document4 pagesAssignment 7mahakNo ratings yet

- Ferrocement Construction Technology and Its Applications PDFDocument20 pagesFerrocement Construction Technology and Its Applications PDFPranavaDart0% (1)