Professional Documents

Culture Documents

Static Calculation Example

Uploaded by

Sung Woong MoonCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Static Calculation Example

Uploaded by

Sung Woong MoonCopyright:

Available Formats

Appendix D.2.

4 Example 2 - Static Pressure Reduction Required to Bring a Fan System Back Into Its Motors Nameplate Rating

at Design

Static Flow Loss Calculation

Pressure

Duct System Static Pressure Calculation

Assume 11'6 floor to floor except 13' for 7th floor

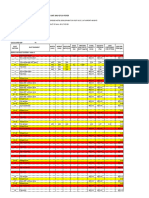

System - ACU-4

ITEM DESCRIPTION FLOW SECTION DUCT DUCT DUCT DUCT VEL. LOSS CAT. FRIC. SECTION PERCENT RUNNING TOTAL REMARKS MISC. CALCULATIONS

RATE LENGTH HTH. WTH. DIA. VEL. PRESS. COEFF. LOSS RATE OR OF Clean filtersDirty filters Calculation 1 Calculation 2 Calculation 3 Calculation 4

cfm Feet In. In. In. Fpm In.w.c Co In.w.c. In.w.c ITEM TOTAL In.w.c. In.w.c.

per LOSS

100 ft. in.w.c

0 Outdoors 0.00 0.00

1 Intakc louver 13,680 #DIV/0! #DIV/0! N/A 0.15 N/A #VALUE! #VALUE! #VALUE! #VALUE! Assumption/allowance Blade angle = 0.00 blade lengths/Duct perimeter = 1.96

2 O.A. Damper 13,680 20.00 72.00 1,368 0.1167 0.52 N/A N/A #VALUE! #VALUE! #VALUE! #VALUE!

3 O.A. Duct 13,680 52 20.00 72.00 1,368 0.1167 N/A N/A 0.05 #VALUE! #VALUE! #VALUE! #VALUE!

4 Mixing Plenum 13,680 #DIV/0! #DIV/0! N/A 0.20 N/A #VALUE! #VALUE! #VALUE! #VALUE! Assumption/allowance

5 Filters 13,680 #DIV/0! #DIV/0! N/A 0.90 N/A #VALUE! #VALUE! #VALUE! #VALUE! Roll filters, loss based on fully loaded Farr 30/30 rating

6 Cooling coil (wet) 13,680 #DIV/0! #DIV/0! N/A 0.71 N/A #VALUE! #VALUE! #VALUE! #VALUE! Based on the value from the ACU-1 shop drawing, assume similar

7 Reheat coil 13,680 #DIV/0! #DIV/0! N/A 0.42 N/A #VALUE! #VALUE! #VALUE! #VALUE! selection

Based on the value from the ACU-1 shop drawing, assume similar

8 Fan casing 13,680 #DIV/0! #DIV/0! N/A 0.20 N/A #VALUE! #VALUE! #VALUE! #VALUE! selection

Assumption/allowance

9 System effect - fan discharge 13,680 27.00 33.00 2,211 0.3047 1.00 N/A N/A #VALUE! #VALUE! #VALUE! #VALUE! Assume that you loose 1 velocity head

10 Y branch, 60, with conversion to round 13,680 27.00 33.00 2,211 0.3047 0.21 NA NA #VALUE! #VALUE! #VALUE! #VALUE! Based on ASHRAE SR5-17 Branch flow/Total flow = 0.36 Branch area/Total area = 0.23

11 16" round duct 4,970 2 16.00 3,560 0.7899 NA NA 0.95 #VALUE! #VALUE! #VALUE! #VALUE!

12 Radiused 90 round elbow 4,970 16.00 3,560 0.7899 0.15 N/A N/A #VALUE! #VALUE! #VALUE! #VALUE!

13 16" round duct 4,970 2 16.00 3,560 0.7899 NA NA 0.95 #VALUE! #VALUE! #VALUE! #VALUE!

14 Fire damper 4,970 16.00 3,560 0.7899 0.19 NA NA #VALUE! #VALUE! #VALUE! #VALUE!

15 16" round duct 4,970 2 16.00 3,560 0.7899 NA NA 0.95 #VALUE! #VALUE! #VALUE! #VALUE!

16 Radiused 90 round elbow 4,970 16.00 3,560 0.7899 0.15 N/A N/A #VALUE! #VALUE! #VALUE! #VALUE!

17 Sound attenutator 4,970 16.00 3,560 0.7899 0.81 NA NA #VALUE! #VALUE! #VALUE! #VALUE! Could be as low as Co = .27

18 16" round duct 4,970 4 16.00 3,560 0.7899 NA NA 0.95 #VALUE! #VALUE! #VALUE! #VALUE!

19 Radiused 45 round elbow 4,970 16.00 3,560 0.7899 0.07 NA NA #VALUE! #VALUE! #VALUE! #VALUE!

20 16" round duct 4,970 14 16.00 3,560 0.7899 NA NA 0.95 #VALUE! #VALUE! #VALUE! #VALUE!

21 Offset down 4,970 16.00 3,560 0.7899 0.25 N/A N/A #VALUE! #VALUE! #VALUE! #VALUE!

22 16" round duct 4,970 5 16.00 3,560 0.7899 NA NA 0.95 #VALUE! #VALUE! #VALUE! #VALUE!

23 Y branch, flow through run 4,970 16.00 3,560 0.7899 0.13 NA NA #VALUE! #VALUE! #VALUE! #VALUE! Through flow/Total flow 0.70 Through area/Incoming area = 1.00

24 Conical reducer with branch, flow 3,500 16.00 2,507 0.3917 0.13 NA NA #VALUE! #VALUE! #VALUE! #VALUE! Through flow/Total flow 0.46 Through area/Incoming area = 0.39

25 through

10" roundrun

duct 1,600 12 10.00 2,934 0.5365 NA NA 0.73 #VALUE! #VALUE! #VALUE! #VALUE!

26 Radiused 45 round elbow 1,600 10.00 2,934 0.5365 0.07 NA NA #VALUE! #VALUE! #VALUE! #VALUE!

27 10" round duct 1,600 2 10.00 2,934 0.5365 NA NA 0.73 #VALUE! #VALUE! #VALUE! #VALUE!

28 Radiused 90 round elbow 1,600 10.00 2,934 0.5365 0.15 N/A N/A #VALUE! #VALUE! #VALUE! #VALUE!

29 10" round duct 1,600 14 10.00 2,934 0.5365 NA NA 0.73 #VALUE! #VALUE! #VALUE! #VALUE!

30 7th floor connection, flow through run 1,600 10.00 2,934 0.5365 0.14 NA NA #VALUE! #VALUE! #VALUE! #VALUE! Through flow/Total flow 0.85 Through area/Incoming area = 1.00

31 10" round duct 1,360 12 10.00 2,494 0.3876 NA NA 0.60 #VALUE! #VALUE! #VALUE! #VALUE!

32 6th floor connection, flow through run 1,360 10.00 2,494 0.3876 0.13 NA NA #VALUE! #VALUE! #VALUE! #VALUE! Through flow/Total flow 0.81 Through area/Incoming area = 0.81

33 9" round duct 1,100 6 9.00 2,490 0.3865 NA NA 0.80 #VALUE! #VALUE! #VALUE! #VALUE!

34 Offset 1,100 9.00 2,490 0.3865 0.25 N/A N/A #VALUE! #VALUE! #VALUE! #VALUE!

35 9" round duct 1,100 6 9.00 2,490 0.3865 NA NA 0.80 #VALUE! #VALUE! #VALUE! #VALUE!

36 5th floor connection, flow through run 1,100 9.00 2,490 0.3865 0.13 N/A N/A #VALUE! #VALUE! #VALUE! #VALUE! Through flow/Total flow 1.00 Through area/Incoming area = 1.00

37 9" round duct 840 12 9.00 1,901 0.2254 N/A N/A 0.55 #VALUE! #VALUE! #VALUE! #VALUE!

38 4th floor connection, flow through run 840 9.00 1,901 0.2254 0.13 N/A N/A #VALUE! #VALUE! #VALUE! #VALUE! Through flow/Total flow 0.69 Through area/Incoming area = 1.00

39 9" round duct 580 6 9.00 1,313 0.1075 N/A N/A 0.30 #VALUE! #VALUE! #VALUE! #VALUE!

40 Offset 580 9.00 1,313 0.1075 0.25 N/A N/A #VALUE! #VALUE! #VALUE! #VALUE!

41 9" round duct 580 6 9.00 1,313 0.1075 N/A N/A 0.30 #VALUE! #VALUE! #VALUE! #VALUE!

42 3rd floor connection, flow through run 580 9.00 1,313 0.1075 0.14 N/A N/A #VALUE! #VALUE! #VALUE! #VALUE! Through flow/Total flow 0.55 Through area/Incoming area = 0.60

43 7" round duct 320 3 7.00 1,197 0.0894 N/A N/A 0.32 #VALUE! #VALUE! #VALUE! #VALUE!

44 Radiused 90 round elbow 320 7.00 1,197 0.0894 0.15 N/A N/A #VALUE! #VALUE! #VALUE! #VALUE!

45 7" round duct 320 2 7.00 1,197 0.0894 N/A N/A 0.32 #VALUE! #VALUE! #VALUE! #VALUE!

46 Radiused 90 round elbow 320 7.00 1,197 0.0894 0.15 N/A N/A #VALUE! #VALUE! #VALUE! #VALUE!

47 Close fitting interation 320 7.00 1,197 0.0894 N/A N/A N/A #VALUE! #VALUE! #VALUE! #VALUE! AMCA stance between/Duct diameter = 3.43

48 7" round duct 320 8 7.00 1,197 0.0894 N/A N/A 0.32 #VALUE! #VALUE! #VALUE! #VALUE!

49 Radiused 90 round elbow 320 7.00 1,197 0.0894 0.15 N/A N/A #VALUE! #VALUE! #VALUE! #VALUE!

48 7" round duct 320 3 7.00 1,197 0.0894 N/A N/A 0.32 #VALUE! #VALUE! #VALUE! #VALUE!

49 7" flex duct 320 1 7.00 1,197 0.0894 N/A N/A 0.64 #VALUE! #VALUE! #VALUE! #VALUE!

50 Air valve 320 4.00 4.00 2,880 0.5171 N/A N/A N/A 0.43 #VALUE! #VALUE! #VALUE! Difference between velocity pressures

51 Plenum loss 320 4.00 4.00 2,880 0.5171 1.00 N/A N/A #VALUE! #VALUE! #VALUE! #VALUE! Assumed air valve size, assume loss of all velocity pressure

52 Grill loss 320 4.00 16.00 720 0.0323 1.00 N/A N/A #VALUE! #VALUE! #VALUE! #VALUE! Assume discharge over 4 - 4" square grilles

53 #DIV/0! #DIV/0! N/A N/A N/A #VALUE!

54 #DIV/0! #DIV/0! N/A N/A N/A #VALUE!

55 #DIV/0! #DIV/0! N/A N/A N/A #VALUE!

TOTAL #VALUE!

TOTAL with lower loss attenuator #VALUE!

Formulas used

Velocity = 4005 x (Velocity Pressure)1/2

quivalent length for system effect calcs, outlet velocity over 2,500 fpm = Velocity x (Duct area 1/2)/10,600

Estimated static requirement for the window terminal unit - 4" damper = ### in.w.c.

Estimated static requiement for a unit with a 5" damper (see below) = 0.55 in.w.c.

System total with this unit = ###

System total with this unit and a lower loss attenuator = ###

Page 1 of 3 of sheet Static Pressure Calculation of file 353056259.xls

Printed on 04/27/2017 at 08:23:15

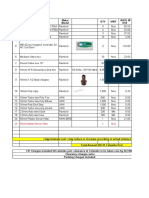

Appendix D.2.4 Example 2 - Static Pressure Reduction Required to Bring a Fan System Back Into Its Motors Nameplate Rating

at Design

Static Flow Loss Calculation

Pressure

Duct System Static Pressure Calculation

Assume 11'6 floor to floor except 13' for 7th floor

System - ACU-4

ITEM DESCRIPTION FLOW SECTION DUCT DUCT DUCT DUCT VEL. LOSS CAT. FRIC. SECTION REMARKS MISC. CALCULATIONS

RATE LENGTH HTH. WTH. DIA. VEL. PRESS. COEFF. LOSS RATE OR Calculation 1 Calculation 2 Calculation 3 Calculation 4

cfm Feet In. In. In. Fpm In.w.c Co In.w.c. In.w.c ITEM

per LOSS

100 ft. in.w.c

1 7" flex duct 320 1 7.00 1,197 0.0894 #VALUE!

1 Air valve 320 5.00 5.00 1,843 0.2118 0.12 Difference between velocity pressures

2 Plenum loss 320 5.00 5.00 1,843 0.2118 1.00 0.21 Assumed air valve size, assume loss of all velocity pressure

3 Grill loss 320 5.00 5.00 1,843 0.2118 1.00 0.21 Assume discharge over 4 - 4" square grilles

timated static requiement for a unit with a 6" round damper (see below) = 0.41 in.w.c.

System total with this unit = ###

System total with this unit and a lower loss attenuator = ###

ITEM DESCRIPTION FLOW SECTION DUCT DUCT DUCT DUCT VEL. LOSS CAT. FRIC. SECTION REMARKS MISC. CALCULATIONS

RATE LENGTH HTH. WTH. DIA. VEL. PRESS. COEFF. LOSS RATE OR Calculation 1 Calculation 2 Calculation 3 Calculation 4

cfm Feet In. In. In. Fpm In.w.c Co In.w.c. In.w.c ITEM

per LOSS

100 ft. in.w.c

1 7" flex duct 320 1 7.00 1,197 0.0894 #VALUE!

1 Air valve 320 6.00 1,630 0.1656 0.08 Difference between velocity pressures

2 Plenum loss 320 6.00 1,630 0.1656 1.00 0.17 Assumed air valve size, assume loss of all velocity pressure

3 Grill loss 320 6.00 1,630 0.1656 1.00 0.17 Assume discharge over 4 - 4" square grilles

Page 2 of 3 of sheet Static Pressure Calculation of file 353056259.xls

Printed on 04/27/2017 at 08:23:15

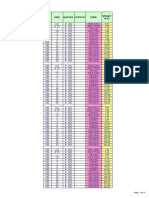

D u c t S ta tic P r e s s u r e , In c h e s w .c .

0.00

0.50

1.00

O u t d o o rs

In t a k c lo u ve r

O .A . D am pe r

O .A . D u c t

M ix in g P le n u m

F ilt e rs

C o o lin g c o il (w e t )

R e h e a t c o il

F a n c a s in g

S y s t e m e ffe c t - fa n d is c h a rg e

Y b ra n c h , 6 0 , w it h c o n ve rs io n t o ro u n d

1 6 " ro u n d d u c t

R a d iu s e d 9 0 ro u n d e lb o w

1 6 " ro u n d d u c t

F ire d a m p e r

1 6 " ro u n d d u c t

R a d iu s e d 9 0 ro u n d e lb o w

S ou nd atte nutator

1 6 " ro u n d d u c t

R a d iu s e d 4 5 ro u n d e lb o w

1 6 " ro u n d d u c t

O ffs e t d o w n

1 6 " ro u n d d u c t

Y b ra n c h , flo w t h ro u g h ru n

C o n ic a l re d u c e r w it h b ra n c h , flo w t h ro u g h ru n

1 0 " ro u n d d u c t

R a d iu s e d 4 5 ro u n d e lb o w

1 0 " ro u n d d u c t

R a d iu s e d 9 0 ro u n d e lb o w

1 0 " ro u n d d u c t

Location

7 t h flo o r c o n n e c t io n , flo w t h ro u g h ru n

1 0 " ro u n d d u c t

6 t h flo o r c o n n e c t io n , flo w t h ro u g h ru n

9 " ro u n d d u c t

O ffs e t

9 " ro u n d d u c t

5 t h flo o r c o n n e c t io n , flo w t h ro u g h ru n

9 " ro u n d d u c t

AHU4 Pressure Gradient Diagram

4 t h flo o r c o n n e c t io n , flo w t h ro u g h ru n

9 " ro u n d d u c t

O ffs e t

9 " ro u n d d u c t

3 rd flo o r c o n n e c t io n , flo w t h ro u g h ru n

7 " ro u n d d u c t

R a d iu s e d 9 0 ro u n d e lb o w

7 " ro u n d d u c t

R a d iu s e d 9 0 ro u n d e lb o w

C lo s e fit t in g in t e ra t io n

7 " ro u n d d u c t

R a d iu s e d 9 0 ro u n d e lb o w

7 " ro u n d d u c t

7 " fle x d u c t

A ir va lve

P le n u m lo s s

G rill lo s s

You might also like

- AHU-GF-14-FOYERDocument7 pagesAHU-GF-14-FOYERKaran GnaniNo ratings yet

- General Data: Piping Sizing and Pressure DropDocument7 pagesGeneral Data: Piping Sizing and Pressure DropSilvano CiminiNo ratings yet

- Asd6 Asd18lDocument1 pageAsd6 Asd18lsinggih prasetiyoNo ratings yet

- Space 2001Document43 pagesSpace 2001Nguyen Duc CuongNo ratings yet

- General Spec Sheets of All InstrumentsDocument32 pagesGeneral Spec Sheets of All InstrumentsArslan NisarNo ratings yet

- Metering Class Current Transformer: Features 600V Class SpecificationsDocument1 pageMetering Class Current Transformer: Features 600V Class SpecificationsDavid RojasNo ratings yet

- Rainbird Irrigation System Parts List and QuoteDocument2 pagesRainbird Irrigation System Parts List and QuoteMilinda DiasNo ratings yet

- EST2718Document1 pageEST2718subin sujathanNo ratings yet

- Fan Static Head Calculation SheetDocument1 pageFan Static Head Calculation SheetAqil KhanNo ratings yet

- T-100 A/B MBR Condensate Receiving Tank: InputDocument1 pageT-100 A/B MBR Condensate Receiving Tank: InputZULFIKAR AZANNo ratings yet

- Hyperco Product CatalogDocument20 pagesHyperco Product CatalogRicardo Rangel PosadasNo ratings yet

- Optimizing air distribution along a clinker coolerDocument2 pagesOptimizing air distribution along a clinker coolerrupesh soniNo ratings yet

- 09-12-18-24 Solar DC Air Conditioner SpecificationDocument1 page09-12-18-24 Solar DC Air Conditioner SpecificationRiyadh MirzaNo ratings yet

- Bunker Nord MaruDocument1 pageBunker Nord MaruEdgar Quintero VillanuevaNo ratings yet

- Ducted Blower System (A5DB-H/A5MC-H) Ducted Blower System (A5DB-H/A5MC-H)Document1 pageDucted Blower System (A5DB-H/A5MC-H) Ducted Blower System (A5DB-H/A5MC-H)Azrul AzimNo ratings yet

- Yamuna Tanker Pool (A)Document17 pagesYamuna Tanker Pool (A)Bunty JeeNo ratings yet

- Manual de Instalação Samsung FJM Duto SlimDocument16 pagesManual de Instalação Samsung FJM Duto SlimRobson FreitasNo ratings yet

- Pipe Configuration: Nodes TotalsDocument3 pagesPipe Configuration: Nodes TotalsJohn ANo ratings yet

- PIPE NO Input Data Sheet for Water Transmission PipesDocument10 pagesPIPE NO Input Data Sheet for Water Transmission PipesRajesh GangwalNo ratings yet

- 3.5 Cores 300 sqmm Al Arm cable capacity calculation tableDocument11 pages3.5 Cores 300 sqmm Al Arm cable capacity calculation tableNajma ShaikhNo ratings yet

- Carga Termica P.B. y P.A. AireproyDocument2 pagesCarga Termica P.B. y P.A. AireproyEduardo MustielesNo ratings yet

- Ducts Pressure Losses Board: Project: SITE: Al Madinah Duct Name: Serving: (MT) General DataDocument1 pageDucts Pressure Losses Board: Project: SITE: Al Madinah Duct Name: Serving: (MT) General DataahmedNo ratings yet

- Room Checksums: by Gulf Consult 1St-Extra Bedroom Heating Coil Peak CLG Space Peak Cooling Coil Peak TemperaturesDocument50 pagesRoom Checksums: by Gulf Consult 1St-Extra Bedroom Heating Coil Peak CLG Space Peak Cooling Coil Peak TemperaturesSajidNo ratings yet

- FJ SM Asy9 12 LSBCW PDFDocument16 pagesFJ SM Asy9 12 LSBCW PDFMihaela CaciumarciucNo ratings yet

- Century StarDocument121 pagesCentury StarHoài ThanhNo ratings yet

- T60 - SimulatorDocument5 pagesT60 - Simulatorshanthikumaravel0% (1)

- Satistical Process Control Study: Data Collections:-Sample D2 A2 D4Document1 pageSatistical Process Control Study: Data Collections:-Sample D2 A2 D4cqi9nNo ratings yet

- Pressure Drop CalcDocument24 pagesPressure Drop CalcKorcan ÜnalNo ratings yet

- MVWFWDocument1 pageMVWFWparthasutradharNo ratings yet

- Bulova 1979 CasePartsSupplement1Document75 pagesBulova 1979 CasePartsSupplement1Martin ReevesNo ratings yet

- AFT Fathom Model Analysis of 15W40 Oil PipelineDocument9 pagesAFT Fathom Model Analysis of 15W40 Oil Pipelineruben estebanNo ratings yet

- K321-05041 A2 - Electrical Load AnalysisDocument4 pagesK321-05041 A2 - Electrical Load AnalysisJerome EugeneNo ratings yet

- 1St-Stage By-Pass Plug: 1338777layout-L80 2400 1500 Davis-Lynch 1338777layoutDocument4 pages1St-Stage By-Pass Plug: 1338777layout-L80 2400 1500 Davis-Lynch 1338777layoutZPECNo ratings yet

- BBS-028-ZONE-01 & 02 DiaphragmDocument5 pagesBBS-028-ZONE-01 & 02 DiaphragmMuhammad Abubakar SheikhNo ratings yet

- Friction Factor and Equivalent Length ConclusionsDocument2 pagesFriction Factor and Equivalent Length ConclusionsYonatan AdiNo ratings yet

- 22-270-T-C01-01 - Site TanksDocument17 pages22-270-T-C01-01 - Site Tankshgag selimNo ratings yet

- Two (2) Storey Residential Unit: PB-PB - Existing PB-1 PB - PB - PBDocument1 pageTwo (2) Storey Residential Unit: PB-PB - Existing PB-1 PB - PB - PBSarah MartinNo ratings yet

- Supplemental Procurement Plan for 3rd Quarter 2017Document35 pagesSupplemental Procurement Plan for 3rd Quarter 2017Imperial ArnelNo ratings yet

- Constant Velocity Duct DesignDocument5 pagesConstant Velocity Duct DesignJojolasNo ratings yet

- r44 Pricelist 2022Document136 pagesr44 Pricelist 2022Mant y Log UAPNNo ratings yet

- Hiwall Single Split Type Specifications: RAS-10S3KHS-V RAS-13S3KHS-V RAS-18S3KHS-V RAS-24S3KHS-VDocument1 pageHiwall Single Split Type Specifications: RAS-10S3KHS-V RAS-13S3KHS-V RAS-18S3KHS-V RAS-24S3KHS-VKhánh Nguyễn MinhNo ratings yet

- Usha Ceiling Fan: Helnnty N NDocument1 pageUsha Ceiling Fan: Helnnty N NBABU LAL CHOUDHARYNo ratings yet

- Building Phase 2 Floor Apply To All Room Corridor Equip. No. FCU-L4-C-01 ZoneDocument8 pagesBuilding Phase 2 Floor Apply To All Room Corridor Equip. No. FCU-L4-C-01 ZonebaparisNo ratings yet

- Vol 10 INSTALLATION & OPERATING MANUAL (IOM) 50 MMBTU - BOOK No 10Document78 pagesVol 10 INSTALLATION & OPERATING MANUAL (IOM) 50 MMBTU - BOOK No 10Akhosh KrishnaNo ratings yet

- Pre-Stowage Plan-Maputo 01 23 02 2022Document1 pagePre-Stowage Plan-Maputo 01 23 02 2022Zb ZbNo ratings yet

- Flange Leakage v1.0Document5 pagesFlange Leakage v1.0SENTHILNo ratings yet

- ServicePartsPricelist Jan2013 USDDocument414 pagesServicePartsPricelist Jan2013 USDConstantin Precup100% (1)

- In Process - HT55 PinDocument1 pageIn Process - HT55 PinGulfeng SafetyNo ratings yet

- Compact Orifice Flow Meter: Features & BenefitsDocument2 pagesCompact Orifice Flow Meter: Features & Benefitshaisam sarwarNo ratings yet

- ME Exhaust Valve History AUG 2021Document1 pageME Exhaust Valve History AUG 2021AkshayKumarNo ratings yet

- 4a Test ReportDocument23 pages4a Test ReportSiva NandhamNo ratings yet

- Heat Load Cal Conf RMDocument1 pageHeat Load Cal Conf RMBiswajit DeyNo ratings yet

- ArchDocument4 pagesArchCarlos Torres OliverosNo ratings yet

- Birin Khola Hydrology - TentativeDocument5 pagesBirin Khola Hydrology - TentativeVishwa Prakash AmatyaNo ratings yet

- Metrado de IsDocument25 pagesMetrado de IsPablo TorresNo ratings yet

- Robinson Helicopter Company R44 Spare Parts Price ListDocument124 pagesRobinson Helicopter Company R44 Spare Parts Price ListTony GarrisonNo ratings yet

- Provisional Survey ReportDocument11 pagesProvisional Survey ReportFrianata ZrNo ratings yet

- Pump CalcDocument1 pagePump CalcMoch WildanNo ratings yet

- AA SelecionadoDocument3 pagesAA SelecionadoJosé Luis ColmenarezNo ratings yet

- HD Q-PAC 적용 폐수 처리장의 Biotrickling Filter 설계 지원 예 - H2S 제거, Thiobacillus 또는 Acidithiobacillus균류의 미생물 사용Document3 pagesHD Q-PAC 적용 폐수 처리장의 Biotrickling Filter 설계 지원 예 - H2S 제거, Thiobacillus 또는 Acidithiobacillus균류의 미생물 사용Sung Woong MoonNo ratings yet

- Pressure Drop Across Q-PAC: Liquid LoadingDocument5 pagesPressure Drop Across Q-PAC: Liquid LoadingSung Woong MoonNo ratings yet

- TS 112 Process and Instrument DiagramsDocument27 pagesTS 112 Process and Instrument DiagramsGeetha_jagadish30100% (1)

- William Ganns Square of NineDocument12 pagesWilliam Ganns Square of NineAntonio Carlos Belfort50% (2)

- 7S Ejector Venturi Scrubbers BrochureDocument14 pages7S Ejector Venturi Scrubbers BrochureGM EdgardNo ratings yet

- FRP Duct PDFDocument33 pagesFRP Duct PDFSung Woong MoonNo ratings yet

- FRP Pipe Engineering GuideDocument44 pagesFRP Pipe Engineering GuideA.Subin DasNo ratings yet

- Chapter 9 Part 2 HWM 2nd Ed Solutions PDFDocument22 pagesChapter 9 Part 2 HWM 2nd Ed Solutions PDFSung Woong Moon100% (1)

- AgitatorDocument6 pagesAgitatorSung Woong MoonNo ratings yet

- RJ 2000 Scrubber system for 1000kg (견적의뢰용) PDFDocument47 pagesRJ 2000 Scrubber system for 1000kg (견적의뢰용) PDFSung Woong MoonNo ratings yet

- In-Process Modifications and Pretreatment Upgrading Meat PackinsDocument100 pagesIn-Process Modifications and Pretreatment Upgrading Meat Packinsashutosh_21jNo ratings yet

- A Hand Book For The Mechanical Designer Ventilation Duct FanDocument107 pagesA Hand Book For The Mechanical Designer Ventilation Duct Fanrawneeh100% (6)

- FlotationDocument22 pagesFlotationjollyjummy58520% (1)

- BETE 110metric Catalog PDFDocument128 pagesBETE 110metric Catalog PDFSung Woong MoonNo ratings yet

- Fibreglass Tank PDFDocument56 pagesFibreglass Tank PDFdadan yupi andika100% (1)

- Info RASCHIG JAEGER Tripacks Hacketten 600Document26 pagesInfo RASCHIG JAEGER Tripacks Hacketten 600Sung Woong MoonNo ratings yet

- Chapter 10. 10.1. 10.2. 10.3.Document59 pagesChapter 10. 10.1. 10.2. 10.3.OmarhersanNo ratings yet

- Chapter 9 Part 2 HWM 2nd Ed SolutionsDocument10 pagesChapter 9 Part 2 HWM 2nd Ed SolutionsSung Woong MoonNo ratings yet

- Make Entries in Yellow Blanks Only Bold Entries Are Formulas... Do Not ChangeDocument1 pageMake Entries in Yellow Blanks Only Bold Entries Are Formulas... Do Not ChangeSung Woong MoonNo ratings yet

- Design of Water TankDocument26 pagesDesign of Water Tankspthebuilder91% (11)

- TP40 15 SedimentationDocument14 pagesTP40 15 Sedimentationtony_mardiantoNo ratings yet

- Activated Sludge System 11Document48 pagesActivated Sludge System 11Sung Woong MoonNo ratings yet

- Loading ConditionsDocument19 pagesLoading ConditionsAdamGemayelNo ratings yet

- Chapter 9 Part 2 HWM 2nd Ed Solutions PDFDocument22 pagesChapter 9 Part 2 HWM 2nd Ed Solutions PDFSung Woong Moon100% (1)

- Me Prodsheet Dh-2100Document2 pagesMe Prodsheet Dh-2100Sung Woong MoonNo ratings yet

- Dowex Ion Exchanger Resin LADocument93 pagesDowex Ion Exchanger Resin LASung Woong MoonNo ratings yet

- Poppele Thesis Njit Etd1958 001Document115 pagesPoppele Thesis Njit Etd1958 001c_pythonNo ratings yet

- FRP DesignDocument17 pagesFRP DesignRUSTSHIELD IndonesiaNo ratings yet

- Static Calculation ExampleDocument3 pagesStatic Calculation ExampleSung Woong MoonNo ratings yet

- Loading ConditionsDocument19 pagesLoading ConditionsAdamGemayelNo ratings yet

- Air Conditioner Service Manual Models LV-C3621CL/HL/AL LV-D4821CL/HL/AL LV-D6021CL/HL/ALDocument43 pagesAir Conditioner Service Manual Models LV-C3621CL/HL/AL LV-D4821CL/HL/AL LV-D6021CL/HL/ALCesar Calderon GrNo ratings yet

- Material Data Sheet: Urban@plastum - CZ WWW - Plastum.czDocument1 pageMaterial Data Sheet: Urban@plastum - CZ WWW - Plastum.czDavis GNo ratings yet

- Concept of Heat Pump and RefrigeratorDocument8 pagesConcept of Heat Pump and RefrigeratorNamesh KorkeNo ratings yet

- David Resume Maintenance August 2010Document2 pagesDavid Resume Maintenance August 2010David SimkovskyNo ratings yet

- Lesson 1. Patterns and Numbers in NatureDocument4 pagesLesson 1. Patterns and Numbers in NatureDylan HenryNo ratings yet

- Unit 2 ThermodynamicsDocument62 pagesUnit 2 Thermodynamicsgolukumar10723No ratings yet

- Steelmaking Nozzle Wear AnalysisDocument15 pagesSteelmaking Nozzle Wear Analysiswillian limaNo ratings yet

- Fury Electric Spec SheetDocument1 pageFury Electric Spec Sheetardiansyahsave23No ratings yet

- A Novel Active Free Piston Stirling EngineDocument16 pagesA Novel Active Free Piston Stirling Engineel TorquesNo ratings yet

- Wired Contoller: User'S ManualDocument28 pagesWired Contoller: User'S ManualHelgon ArbiriNo ratings yet

- Aj034ncj5ch AzDocument1 pageAj034ncj5ch AzShirley BarreraNo ratings yet

- Precalentadores PDFDocument52 pagesPrecalentadores PDFlcsandovalr989No ratings yet

- Asphalt Testing EquipmentDocument104 pagesAsphalt Testing EquipmentCooper TechnologyNo ratings yet

- Toshiba Rotary Compressor Tech SpecsDocument1 pageToshiba Rotary Compressor Tech Specscalvin.bloodaxe447880% (5)

- ANSI AHRI Standard 1360 I-P 2013 With Addendum 1 PDFDocument15 pagesANSI AHRI Standard 1360 I-P 2013 With Addendum 1 PDFdimaomarNo ratings yet

- Smile: Checklist For Site Sop Required ElementsDocument2 pagesSmile: Checklist For Site Sop Required ElementsS ONo ratings yet

- V. Babu (Author) - Fundamentals of Engineering Thermodynamics-CRC Press (2019)Document440 pagesV. Babu (Author) - Fundamentals of Engineering Thermodynamics-CRC Press (2019)Sushanth ShenoyNo ratings yet

- 1EM Energy Recovery Ventilator (ERV) PDFDocument34 pages1EM Energy Recovery Ventilator (ERV) PDFElvis FariasNo ratings yet

- PAF Physics Online Test 1-6-1Document22 pagesPAF Physics Online Test 1-6-1think outside The box100% (2)

- IB Physics 2 Summer Refresh WorkDocument25 pagesIB Physics 2 Summer Refresh WorkJeffNo ratings yet

- Agard Ag 54Document148 pagesAgard Ag 54AeroenggNo ratings yet

- AHU Systems UGDocument52 pagesAHU Systems UGSalimYousufNo ratings yet

- ISOCode ListDocument135 pagesISOCode ListRashid MalikNo ratings yet

- Pressure Switch (Refrigerant Pressure Cutoff)Document2 pagesPressure Switch (Refrigerant Pressure Cutoff)allan lariosaNo ratings yet

- Thermosyphon Oil CoolingDocument22 pagesThermosyphon Oil CoolingRenato MendesNo ratings yet

- RAC Lect1-2Document39 pagesRAC Lect1-2Musab LatifNo ratings yet

- Remote Cooling System DesignDocument30 pagesRemote Cooling System DesignarifNo ratings yet

- Unit 2 Different Modes of Heat Transfer: StructureDocument36 pagesUnit 2 Different Modes of Heat Transfer: StructureAman GodaraNo ratings yet

- Temp Conversion WorksheetDocument1 pageTemp Conversion WorksheetEJ DelimaNo ratings yet

- Ahlm PhET Gas Laws StudentDocument3 pagesAhlm PhET Gas Laws StudentMIKHAEL ANGELO CAPITONNo ratings yet