Professional Documents

Culture Documents

An Eco-Friendly Tanning System For Leather Manufacture

Uploaded by

Ashraf Rios Khater0 ratings0% found this document useful (0 votes)

31 views8 pagesP2220

Original Title

p220

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentP2220

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

31 views8 pagesAn Eco-Friendly Tanning System For Leather Manufacture

Uploaded by

Ashraf Rios KhaterP2220

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 8

AN ECO-FRIENDLY TANNING SYSTEM FOR LEATHER MANUFACTURE

M.Nirenjana*, T.N. Archana*, Anubhav Malhotra*, Swarna V Kanth#, B Madhan#, J. Raghava

Rao#, Balachandran Unni Nair#, S. Sadulla#, T Ramasami#

* - Department of Leather Technology, Allagappa College of Technology, Anna University, Chennai - 25

#-

Central Leather Research institute, Adyar, Chennai-20

E-mail: nirenltit21@yahoo.co.in

Key words: Alginic acid, crosslinking, collagen

Abstract

Polysaccharides are abundant in nature and are profuse, non-toxic, biodegradable natural polymers

possessing high degree of functionalization. However to fulfil the demand for tailored application profiles,

native biopolymers are often modified. Alginic acid is one such polysaccharide that has been modified and

widely used in food ,phamaceutical, and medical industries. Alginic acid has been modified to dialdehyde

alginic acid and used as a tanning agent for the stabilization of collagen. Shrinkage temperature

measurements, collagenase activity, scanning electron microscopy, infrared spectroscopy and differential

scanning colorimetry techniques have been investigated.

1.Introduction most commercial tanning practices, as they result

in leathers for different end uses with good

Leather is one of the unique material which physical and organoleptic properties. In recent

posses characteristics like breathability, times because of the ecological concerns the

viscoelasticity which arises from the naturally leather industry is looking for an alternative

woven fibrous skin matrix. These characteristics tanning system. It faces serious disadvantages

of leather is well suited in several applications. due to the constraint of its discharge norms of

In leather processing the natural material skin is 2ppm[12]. The currently practiced chrome

being stabilized against degradation. The unit tanning procedures results in only 60-65% of the

process involved in the stabilization of skin into chromium being offered to the leather and a

leather is called tanning. There are various substantial amount of chrome is discharged into

chemical agents used for tanning. Currently the the effluent [13]. As of now there is no safe

tanning industry is dominated by the use of method of disposal method available for the

chromium salts. chrome effluent or the chrome tanned leather

products, which is a major concern. Hence

Hides and skins predominantly contain collagen, researchers throughout the world are looking for

the most abundant protein in animals. There are alternative tanning systems, which would result

19 different types of collagen [1], of which type I in leathers with good hydrothermal stability,

collagen is the main component of skin, tendon, strength characteristics, organoleptic properties

bone and other tissues. This protein is present as and very importantly eco-friendly. A cleaner and

chains wound in triple helical form [2], which sustainable tanning agent/system that can result

are organized into fibrils of great strength and in leather with good functional properties is the

stability [3]. The structure of collagen is current need of the tanning industry.

stabilized by inter- and intra-chain hydrogen

bonds [4] and by water mediated hydrogen Biomaterials, biodegradable polymers are

bonds [5,6]. important biomaterials, which are abundant in

occurrence possessing a high degree of

In olden days collagen stabilization was brought functionalisation. Alginic acid is one such

about by plant polyphenols, through multiple material, which has already established its

hydrogen bonds [7,8]. Some of the oligomers of applications in food, pharmaceutical, and

chromium were known to interact with collagen medical industries (Kennedy, Griffith, Atkins,

[9,10], bringing about irreversible matrix 1984; Mc Neely and Pettitt, 1973). Molecular

changes, thus imparting higher stability [11]. The design of these materials plays an important role

networks formed between collagen and tanning in determining their suitability in such

agents are covalent bonds, complex bonds applications. Alginic acid is a linear, binary

Coulombic forces, H-bonds and hydrophobic copolymer of 1,4-linked -L-guluronic acid and

interactions depending on the tanning system. -D-mannuronic acid [14], usually isolated from

Chrome tanning is a primary tanning system in a brown algae but is also present in some species

of bacteria [15,16]. Along the polymer chain the cheapest raw material with large number of

two residues are arranged in an irregular aldehyde groups in a single molecule.

blockwise pattern [17-19]. There are three types

of blocks: homopolymeric sequence of This paper presents the studies on the feasibility

mannurronate (MM blocks) and guluronate of using dialdehyde alginic acid as a tanning

residues (GG blocks) and a region where the two agent for stabilization of collagen.

residues alternate (MG blocks). The relative

proportions of these block types are affected by 2. Materials and Methods

several factors [20-22] such as the botanical 2.1. Materials

source, plant maturity, collection site and Type IA collagenase was obtained from SIGMA

seasonal variations. ALDRICH, U.S. The Alginic acid and other

In solution, alginates behave like flexible coils chemicals used for the process were obtained

[24]. However on interaction with metal ions, from S.D fine chemicals.

they form ordered structure as evidenced by their

X-ray diffraction patterns [25]. Attempts have 2.2. Methods

been made to covalently crosslink sodium 2.2.1.Periodate oxidation of alginic acid

alginate with gelatin and athylenediamine using 20 g Alginic acid and calculated amount of

water-soluble carbodiimide. Recently it is sodim metaperiodate were dispersed in 100ml of

reported that although higher molecular weight distilled water and stirred in the dark

alginate is non-biodegradable, its dialdehyde magnetically at 25C for 6 hrs to obtain

derivative is biodegradable [26]. Alginic acid is dialdehyde Alginic acid of different degree of

the only polysaccharide, which naturally oxidation. The degree of oxidation was followed

contains carboxyl groups in each constituent by determining the concentration of periodate

residue, and possesses various abilities for left unconsumed by iodometry after 6 hrs [31],

functional materials. To fulfill the demand for and the degree of oxidation was found to be

tailored end use applications the native 98%.

biopolymers are often need to be modified.

Tanning with aldehydes is known to mankind for 2.2.2 Fourier transform infrared (FT-IR)

a very long time and aldehydes such as spectra

formaldehyde, glyoxal and glutaraldehyde have FT-IR spectra of Alginic acid and dialdehyde

been used for stabilization of skin[27-30]. In the Alginic acid were acquired on a Impact 400 FT-

present study alginic acid is converted to IR instrument using a potassium bromide (KBr)

dialdehyde alginic acid and the crosslinking disc containing 1% finely ground sample.

ability of this modified biopolymer is studied.

2.2.3 Differential scanning calorimetry(DSC)

studies

Thermal properties of Alginic acid and

dialdehyde Alginic acid were analyzed using

Dupont 2910 Differential Scanning Colorimeter.

All measurements in the instrument were

conducted under a nitrogen atmosphere. The

samples were scanned at 5C/min . The

temperature at the midpoint of the change in

slope of the DSC change was taken as the

Structural formula of alginic acid [23] structural change in Alginic acid to dialdehyde

Alginic acid with respect to thermal heat.

Dialdehyde alginic acid has been proved to be

biodegradable and toxologically accepted 2.2.4 Pretreatment of collagen

chemical [26]. Hence dialdehyde alginic acid has Collagen matrix of goat skin has been used for

the dual advantage of being a tanning material crosslinking experiments. The raw skin has been

and the leather products after usage will not have converted to acidified collagen (pickled pelt) at

disposal problems, as they can be made pH 3.0 after adopting a sequence of

biodegradable under certain conditions. In this operations/processes that is conventionally

context, the dialdehyde starch has immense carried out in the pretanning operation during

potential to be used as a tanning agent in leather leather manufacture [32].

processing as it is abundant and one of the

2.2.5 Crosslinking of collagen with dialdehyde form of hydroxyproline from insoluble collagen

alginic acid [38]. Aliquots of 750 l of supernatant of

Ten gram portions of acidified collagen matrix samples collected at different time interval were

have been brought to a pH of 8 by treating the withdrawn after centrifuging at 10,000 rpm for

collagen with 8% sodium chloride and 80% 10 min. The collagenase hydrolysate was

water in a bottle shaker at 8 rpm for 30 minutes hydrolyzed in sealed hydrolysis tubes with 6 N

at room temperature, 2% sodium formate as 10% HCl for 16 hrs. The hydrolysates were

solution has been added and the shaker has been evaporated to dryness in a porcelain dish over a

run for 30 minutes and then 3% sodium water bath to remove excess acid. The residue

bicarbonate as 10% solution was added in 3 free of acid was made up to a known volume and

feeds of 10 minutes in the running shaker. the percentage (%) of hydroxyproline was

Dialdehyde alginic acid at concentration of 10% determined using the method of Woessner [39].

has been used for crosslinking treatment to the This method of determining hydroxyproline

marked bottle shaker containing collagen matrix involves the oxidation of hydroxyproline to

at pH 8 and was run for 24 hours at 300C. At the pyrrole-2-carboxylic acid, which complexes with

end of the crosslinking period, the waste solution p-dimethylaminobenzaldehyde exhibiting

was collected and the uptake of dialdehyde maximum absorbance at 557 nm.

alginic acid was calculated. The crosslinked Hydroxyproline = (concentration in g/weight of

collagen samples were thoroughly washed and sample) x dilution factor. Soluble collagen =

aged for 24 hours. Hydrothermal stability and Hydroxyproline 7.4. % Collagen degradation =

Scanning Electron Microscopy experiments were (Weight of soluble collagen/Initial collagenous

carried out. The samples were further taken for weight) x 100. (Initial collagenous weight has

collagenase activity. been adjusted after taking into account the

amount of Dialdehyde alginic acid fixed)

2.2.6 Determination of hydrothermal stability

The temperature at which the collagenous fiber 2.2.8 Scanning Electron microscopic (SEM)

shrinks to one third of its original length is noted studies

as the shrinkage temperature of the fibre. The Dialdehyde alginic acid crosslinked sample

measurement of the shrinkage temperature were cut from the official sampling position [40]

determines the thermal stability of collagenous after the treatment process. The sample were

matrices. The shrinkage temperature is also fixed by soaking them with buffered formalin for

termed as hydrothermal stability as the 18 h. Samples were then dehydrated gradually

measurement is carried out in the presence of using acetone and methanol as per standard

water. The hydrothermal stability of native and procedure [41]. Samples were then cut into

dialdehyde alginic acid treated collagen was specimens with uniform thickness. The

measured using a Theis shrinkage meter by the specimens were then coated with gold using a

standard method [37]. JEOL JFC-1100E ion-sputtering device. A JEOL

JSM-5300 scanning electron microscope was

2.2.7 Collagenase Hydrolysis of the stabilized used for the analysis. The micrographs for the

collagen cross section were obtained by operating the

The enzymatic degradation of collagen adjusted SEM at an accelerating voltage of 20 kV with

to pH 7.0(native) and collagen stabilized with different lower and higher magnification levels.

dialdehyde alginic acid by collagenase was

analyzed by estimating the amount of 3. Results & Discussions

hydroxyproline released in the solution after

hydrolysis. The native and stabilized collagen There are two hydroxyls attached to carbons at

was treated with bacterial collagenase (Type IA) 2,3 position and one carboxyl in 6 position in

from Clostridium histolyticum. Collagenase each dehydrated glucose unit. There are many

treatment was carried out in 0.04 M CaCl2 reactive groups available in the alginic acid

solution buffered at pH 7.2 with 0.05 M tris HCl. molecule that can react with different chemical

The collagen: enzyme ratio was maintained at reagents. Periodate oxidation of alginic acid

40:1. The samples were incubated at a selectively cleaves the C2-C3 bond between the

temperature of 37oC. Samples were collected at two adjacent hydroxyl groups and the 1,2--diol

different time interval upto 96 hrs and stored in group in glucose is converted into a dialdehyde.

freezer. The cleavage of native and stabilized The advantage of periodic acid lies in the

collagen was monitored by the release of soluble specificity of its oxidation. It forms aldehydes

within the polysaccharide molecule but it does acid reduces, which again is an indication of the

not continue the oxidation of the polymers to low oxidation of alginic acid to alginic dialdehyde.

molecular weight water-soluble forms. The

extent of oxidation can be readily controlled, and

a complete range of aldehyde derivatives of a

starch is made available as the oxidation level

varies between 0 and 100%. At 100% oxidation

hydroxyl groups of each glucose residue in the

Alginic acid is converted to its corresponding

dialdehyde structure; at 50% oxidation half of

the glucose residues of the alginic acid are

converted.

3.1 Structural properties of alginic acid and

dialdehyde alginic acid

The FT-IR spectrum of alginic acidis shown in b

Fig. 1a. In the fingerprint region of the spectrum

of alginic acid three characteristic peaks appear

between 937 and 1111 cm-1; these peaks are

attributed to C-O bond stretching. The band at

948 cm-1 is assigned to 14 linkage. The peak

at 1038 cm-1 is characteristic of the

anhydroglucose ring O-C stretch. The peaks at

808 cm-1 and 787 cm-1 can be assigned to

mannuronic and guluronic acids. The band at

815 cm-1 is due to the polyguluronate structure

and the band at 880 presents the characteristic -

mannuronic residues. Another characteristic peak Fig. 1. FT-IT of a) Alginic acid and b) Alginic

occurs at 1630 cm-1, which could be a feature of acid dialdehyde

tightly bound water present in starch. The

spectrum also displays absorption peak at 1743 3.2 Thermal properties of alginic acid and

cm-1corresponding to the stretching band of the dialdehyde alginic acid

free carboxyl anions. An extremely broad band The thermal stability of the alginic acid and

due to the hydrogen bonded hydroxyl group (O- alginic acid dialdehyde were studied using DSC.

H) appears at 3403 cm-1 that is attributed to the The exothermal and the endothermal changes of

complex vibrational stretches associated with Alginic acid and oxidized alginic acid at the

free inter and intra molecular bound hydroxyl increase of constant temperature of 5oC were

groups which make up the gross structure of measured by DSC. Fig. 2a shows the results of

Alginic acid. The sharp band at 2926 cm-1 is native alginic acid. The peak at 124.18 C is due

characteristic of the C-H stretches associated to the thermal transition of Alginic acid. The

with the ring methane hydrogen atoms. DSC of the dialdehyde alginic acid shown in Fig.

2b indicates a peak at 135.53C, which is due to

Comparison of the spectrum of alginic acid with the thermal transition of introduction of

alginic acid dialdehyde (Fig. 1b) clearly indicates dialdehyde functionality. The DSC curve of

the deviations around 1600 1700 cm1, which dialdehyde alginic acid and Alginic acid indicate

could be due to the introduction of additional different thermal degradation characteristics

carbonyl stretching (C=O) of aldehydic between the native and the oxidized Alginic acid.

functional group. The occurrence of sharp band The dialdehyde alginic acid appears to be more

at 2926 cm-1 in the spectrum is associated with stable since the inception of degradation is at

the C-H stretching with the dialdehyde alginic higher temperature. This greater thermal

acid substituents. The strong band at 3404 cm-1 stability of the dialdehyde alginic acid molecule

(hydroxyl groups) of dialdehyde alginic acidis of may be due to the introduction of aldehyde

decreased intensity as the oxidation of alginic functionality by lowering the amount of

acid to dialdehyde alginic acid reduces the hydroxyl groups after oxidation of Alginic acid

number of hydroxyl groups as compare to alginic molecules. Thus the thermal stability is increased

as a large proportion of aldehyde functionality been established that a maximum offer of 10% of

prevails in the large Alginic acid molecule. aldehydes is sufficient for the stabilization of

a collagen. Hence the treatment of dialdehyde

alginic acid with collagen had been carried out at

10% offer, pH 8 for a period of 24 hrs. The

aldehydic functionality in the dialdehyde alginic

acid can covalently bind with amino groups of

the collagen and the hydroxyl groups of the

dialdehyde alginic acid can involve in hydrogen

bonding interaction with the functional groups

available in collagen matrix.

3.4 Hydrothermal stability of the stabilized

collagen

The shrinkage temperatures measured for the

acidified(pickled) skin and the dialdehyde alginic

b acid treated skin are given in Table 1. The

shrinkage temperature for the acidified collagen

fibres has been found to be 560C. Shrinkage

temperature is the temperature at which the skin

(collagen) matrix shrinks to one third of its

original length. The temperature at which the

shrinkage of collagen matrix occurs is highly

specific and occurs due to destabilization of the

protein. It is also termed as hydrothermal

stability. The hydrothermal stability of native

skin is around 600C, which is higher compared to

Fig. 2. DSC of a) Alginic acid and b) Alginic the acidified skin, because acidification alters the

acid dialdehyde IEP of the protein and the electrostatic

interaction due to salt bridges within the collagen

3.3 Interaction of collagen with dialdehyde matrix is comparatively stronger at IEP and

alginic acid hence the matrix can offer higher resistance to

The aldehydes are known to interact with the shrinking. The long-range ionic interactions and

amino groups of the protein [46]. The amino other non-covalent interactions are the cause for

groups are generally protonated at lower pH and ordering of the collagen molecules the fibre

hence aldehyde interaction with proteins is matrix. Hence the basic forces, which are

preferable at pHs above iso electric point (IEP) responsible for the high denaturation temperature

of the protein. The IEP of acid pretreated (alkali of this protein, could be attributed to such long-

followed by acid) collagen is 4.7 and above this range interactions. Any further increase in the

pH collagen will remain negatively charged and ordering of the collagen will also increase the

amino sites are available for the interaction of stability of the matrix against hydrothermal

aldehydes. Earlier studies indicate pH 8 is stress. Increase in resistance against

conducive for the interaction of aldehydes with hydrothermal stress is one of the important

collagen [43]. Also, periodate oxy starch, like aspects in the stabilization of collagen matrix. It

periodate oxycellulose, has been shown [44,45] is found that treatment of collagen with

to be extremely sensitive to degradation by dialdehyde alginic acid has resulted in increase

alkali, by virtue of the presence of dialdehyde of the hydrothermal stability of the collage

groups. Hydrolysis may take place either at the matrix considerably. As seen from the Table 1,

1,4-bonds or at the C2-O bonds, giving the hydrothermal stability of the collagen matrix

depolymerized and decomposition products, treated with dialdehyde alginic acid is found to

which may take part in the reaction in the be 800C, which is 240C more than is observed for

alkaline range [46]. Hence reaction pH 8 can acidified collagen. The interaction of dialdehyde

also favor such hydrolysis process which can alginic acid with collagen has further increased

result in the reduction of molecular weight and the long range ordering of collagen, which in

size and can favor the penetration of dialdehyde turn is responsible for the increase in the

alginic acid into the collagen matrix. It has also hydrothermal stability of the collagen matrix.

treated with alginic acid dialdehyde exhibited

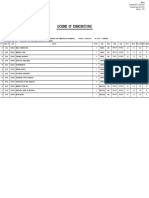

Table 1: Hydrothermal stability of acidified and only 40% degradation. The interaction of

dialdehyde alginic acid treated goat skin dialdehyde alginic acid with collagen has

brought in changes in the active sites of collagen

Process Shrinkage because of which collagenase is not able to

temperature(C) express it activity of breaking down the

Acidified skin 56 collagenous matrix.

Dialdehyde alginic 80

acid treated skin Table2: % Collagen degradation (based on

release of hydroxy proline) from native and

alginic acid dialdehyde treated collagen after 72

3.5 Enzymatic Stability of dialdehyde alginic hrs of collagenase hydrolysis

acid treated Collagen:

Collagen is resistant to all enzymes except % Collagen

collagenase. Triple helical structure of the Degradation

collagen renders stability against degradation to

several proteinases other than collagenases [47]. Native Collagen 98

The stability of the dialdehyde alginic acid Collagen treated with 40

treated collagen matrix against enzymatic alginic acid dialdehyde

degradation has been studied by analyzing the

rate of hydrolysis of collagen on treatment with 3.6 Scanning Electron microscopic (SEM)

bacterial collagenase. Bacterial collagenase analysis of the native and stabilized collagen:

preferentially cleaves X-Gly (X is most Evaluation of opening up of fiber bundles by

frequently a neutral amino acid) bond of the - implicit approach was done using Scanning

Gly-Pro-X-Gly-Pro-X- sequence in the non polar Electron Microscope. Scanning electron

regions of the collagen molecule [48]. Bacterial micrographs of collagen matrix stabilized using

collagenases from Clostridium histolyticum the polyaldehyde showing the cross section at a

cleave collagen at multiple sites [49], whereas, magnification of x 600 is given in Fig. 3. The

mammalian collagenases from human-fibroblast SEM micrograph of dialdehyde alginic acid

cleave collagen only at a single site (leu-Ileu) treated collagen fibres as seen from Fig. 3

breaking it into a 3/4th and 1/4th fragment [50]. appears to be coated. The coating could be due to

Hence a treated collagen matrix exhibiting the presence of dialdehyde alginic acid around

stability against the activity of bacterial the collageanous fibres. Normally sample from

collagenase can exhibit high resistance to acidified collagen displays a very fine opening

degradation by any class of enzymes. Collagen up of fiber bundles because in pretreatment of

matrix treated with dialdehyde alginic acid has collagen with alkali followed by acid treatment,

been subjected to hydrolysis by collagenase and fiber opening is developed as an osmotic-driven

the resulting hydrolysates have been analyzed for splitting of fiber bundles and the hydrostatic

hydroxyproline released into solution. The pressure built inside the matrix keeps the fibers

hydroxyproline content is a direct measure of the apart from each other.

amount of collagen solubilised. The amount of

hydroxyproline released in the supernatant for

the native and dialdehyde alginic acid treated

collagen matrix samples subjected to collagenase

treatment for a period of 72 hrs is given in Table

2. From the table it is observed that skin treated

with alginic acid dialdehyde offers resistance to

degradation by collagenase. The stabilization

effect of the collagen fibers treated with

dialdehyde alginic acid, where marked decrease

in the degradation is observed as against the

untreated collagenous matrix. Native collagen

matrix has undergone extensive hydrolysis with

the treatment of collagenase. The native collagen Fig. 3. Scanning electron micrograph of the cross

exhibited 98% hydrolysis of collagen in the section (600X) alginic acid dialdehyde treated

above time period whereas collagen matrix collagen fibres

13. Chandrasekaran, B., Raghava Rao, J., Nair,

4. Conclusion B.C.U. and Ramasami, T. 1999, Journal of

Scientific Industrial Research, 58, 1-10.

The presented work clearly indicates that the 14. F.G.Fischer ,H.Dorfel, Z.Phys. Chem., 301

biopolymer alginic acid in oxidized form as (1955) 186.

dialdehyde alginic acid can be used in the 15. P.A.J.Gorin, J.F.T.Spencer, Can.J.Chem.,

stabilization of another biopolymer collagen. The (1966) 993.

treatment of collagen matrix with dialdehyde 16. A.Linker,R.S.Jones , J.Biol.Chem, 241 (1966)

alginic acid has improved the thermal and 3845.

enzymatic stability of collagen. Substantial 17. A.Haug,B.Larsen,O.Smidsrod,ActaChem.Scand,

increase in hydrothermal stability is observed on 21(1967)691.

treatment with dialdehyde alginic acid . The18. B.Larsen,O,Smidsrod,T.Painter, A.Haug, Acta

dialdehyde alginic acid treatment renders Chem.Scand,24(1970)726.

collagenous matrix resistant to enzymatic 19. A.Haug,B.Larsen,O.Smidsrod,Carbo.Res.,32,197

hydrolysis. The stability against heat and 4,217.

enzymatic hydrolysis are the main aspects to be20. J.W.A.McLee,L.Kavalieris,D.J.Brasch,M.T.Bro

considered for the permanent stabilization of wn,L.D.Melton,J.Appl.Phycology,4(1992)357.

collagen which is achieved in the process called 21. P.Gacesa,Carbo.Polym.,8,1988,161.

tanning. The dialdehyde alginic acid, a modified 22. O.Smidsrod,Carbo.Res.,13,1970,359.

polymer of alginic acid appears to be an 23. Phillips, Wedlock and Williams: Gums and

effective alternative material that can be used in Stabilizers for the Food Industry 5 (1990) by

the process of stabilization of collagen. permission of Oxford University Press.

24. O.Smidsrod,A.Haug,Acta Chem.Scand., 22,

5.References 1968, 797.

25. C.Sterling,Biochem.Biophys.Acta,26,1957,186.

1. Procop.D.J, Kivirikko.K.I; Molecular Biology,26. Bouhadir.K.H.,Lee.K.Y.,Alsberg.E.,Damm.K.L,

Diseases and potentials for therapy. Annu. Rev. Anderson.K.W.,Moony.D.J,Degradation of

Biochem.;1995,64,403-34. partially oxidized alginate and its potential

2. Ramachandran, G.N., Kartha G. 1955, Nature, application for tissue

174, 269. engineering.Biotechnol.Prog.,2001,17: 945-50.

3. Nimmi, H. E., Boca Raton, F. L. 1998, Collagen,27. Gustavson, K. H.; The Chemistry of tanning

CRC, 1. Process, Academic Presas, N.Y. p 244, 1956

4. Rich, A., Crick F. 1955, Nature, 176, 915. 28. Krysztof Bienkiewicz,; Physical Chemistry of

5. Ramachandran, G. N., Chandrasekaran, 1968, R. Leather Making, Robert E. Hrieger Publishing

Biopolymers, 6, 1648. Company, INC. Malabar, Florida, p. 374, 1983

6. Ramachandran, G. N., Sasisekaran, V. 1965,29. E. M. Filachione, M. L. Fein, E. H. Harris, F.

Biochem biophys Acta., 70, 11. P. Luvisi, A. H. Korn, W. Windus, J. Naghski.;

7. Tu, S.T., Lollar, R. M. 1950, Journal of Journal of American Leather Chemists

American Leather Chemists Association, 45, Association, 54, 668, 1959.

324. 30. George M. Sleichter, Robert M. Lollar;

8. Shuttleworth, S.G. 1952, Journal of American Journal of American Leather Chemists

Leather Chemists Association, 47, 603. Association, 49, 414, 1954.

9. Gayatri, R., Rajaram, A., Rajaram, R., 31. Guthrie RD. Periodate Oxidation. In: Whistler

Govindaraju, K., Rao, J. R., Nair, B.U., RL, WolframML, editors. Methods in

Ramasami, T. 1997, Proceedings of Indian carbohydrate chemistry. New York:Academic

Academy of Sciences (Chemical Sciences) 109, Press; 1953. p. 43247.

145. 32. Thorstensen, T. C. Practical Leather

10. Rao, J.R., Gayatri, R., Rajaram, R., Nair, B.U., Technology, 4th ed., 1993, Krieger Publishing

Ramasami, T. 1999, Biophys Biochem Acta, Co.: Malabar, FL.

1472, 595. 33. C.S. Wise and C. L. Mehltretter, 1958,

11. Santappa, M., Ramasami. T., Kedlaya, K. J. Analytical Chemistry, 30, 174-175.

1982, Journal of Scientific Industrial Research, 34. Nayudamma, Y., Thomas Joseph, K., Bose, S.

41, 616. M., 1961, Journal of American Leather Chemists

12. Standards for discharge of industrial effluents: Association, 56, 548.

Indian standards industrial effluents: Bureau of 35. Lenore S. Clesceri, Arnold E. Greenberg and

Indian Standards, 1985, IS-2490. Rhod IUC, Determination of Volatile matter,

Journal of Society of Leather Technologists and 45. Filachione, E. M., Clarke, I. D., Harris, E. H.,

Chemists, 7, 277, 2002. Fee, J., Witnauer, L. P., Naghski, J., and Boyd, J.

36. Es Trussell, Standards methods for the N.; Journal of American Leather Chemists

examination of water and waste water, 17th ed., Association, 52, 200, 1957.

American Public Health Association, 46. Krysztof Bienkiewicz,; Physical Chemistry of

Washington D. C, part 4500, 4-147 to 4-148, Leather Making, Robert, 1983, E. Hrieger

1989. Publishing Company, INC. Malabar, Florida, p.

37. Brodsky, R., Nutting G. C.; Journal of American 374 -378,

Leather Chemists Association, 44, 831, 1949. 47. Seifter S. and Harper E. (1971), The

38. Ryan J.N., and Woessner J. F., 1971, Biochem. collagenases, In: The enzymes, Boyer P.D., ed.,

Biophys. Res. Comm., 44, 144-149. Vol. II, Academic Press, New York, pp.649-697.

39. Woessner J.F., 1961, Arch. Biochem. Biophys., 48. Galardy R.E. and Grobelny D. (1983),

93, 440-447. Inhibition of collagenase from Clostridium

40. Echlin, P. In: Scanning Electron Microscopy; histolyticum by phosphoric and phosphonic

Heywood, V. H., Ed.; Academic Press: London, amides, Biochemistry, Vol. 22, pp.4556-4561.

1971; Vol. 4, p 307. 49. French M.F., Bhown A. and Van Wart, H.E.

41. Official methods of analysis; Society of Leather (1992), Identification of Clostridium

Technology and Chemistry: Herts, U.K., 1965. histolyticum collagenase hyperreactive sites in

42. Thiebaud,S.,Aburt,J.,Alric.,Borredon,E., type I, type II and type III collagens: Lack of

Bikiaris, D., Prinos,J., & Pnayiotou, C. J. 1977, correlation with local triple helical stability, J.

Journal of Applied polymer Prot. Chem., Vol. 11, pp.83-97.

Science,65,705 721. 50. Gomez D.E., Alonso D.F., Yoshiji H. and

43. Launer, H. F., Tomimatsu, Y. 1961, Journal of Thorgeirsson U.P. (1997), Tissue inhibitors of

organic Chemistry, 26, 541. metalloproteinases: Structure, regulation and

44. Meara, D., Richards, G. N. 1958, Journal of biological functions Eur. J. Cell Biol., Vol. 74,

American Chemists Society, 1204, 4508. pp.111-122.

You might also like

- Becoming An Effective Tutor - 3 Things You Need To KnowDocument1 pageBecoming An Effective Tutor - 3 Things You Need To KnowAshraf Rios KhaterNo ratings yet

- Five Most Sought-Out Type of TutorsDocument1 pageFive Most Sought-Out Type of TutorsAshraf Rios KhaterNo ratings yet

- Hiring Tutors 101 What To Look ForDocument1 pageHiring Tutors 101 What To Look ForAshraf Rios KhaterNo ratings yet

- Opening The Gateway To The Egypt-The Gift of The Nile-Through HurghadaDocument3 pagesOpening The Gateway To The Egypt-The Gift of The Nile-Through HurghadaAshraf Rios KhaterNo ratings yet

- Article 30 - 4 Organizational Strategies For Increasing Your Business ProductivityDocument2 pagesArticle 30 - 4 Organizational Strategies For Increasing Your Business ProductivityAshraf Rios KhaterNo ratings yet

- How To Handle Difficult Clients - Should I Work With ThemDocument1 pageHow To Handle Difficult Clients - Should I Work With ThemAshraf Rios KhaterNo ratings yet

- Importance of Having A Contract For Tutoring ServicesDocument1 pageImportance of Having A Contract For Tutoring ServicesAshraf Rios KhaterNo ratings yet

- Why Is Tutoring Important in The 21st CenturyDocument1 pageWhy Is Tutoring Important in The 21st CenturyAshraf Rios KhaterNo ratings yet

- The Benefits of Tutoring at A Centralized LocationDocument1 pageThe Benefits of Tutoring at A Centralized LocationAshraf Rios KhaterNo ratings yet

- Tackling Math Subjects - Tutoring Tips To ConsiderDocument1 pageTackling Math Subjects - Tutoring Tips To ConsiderAshraf Rios KhaterNo ratings yet

- Electromagnetic EnergyDocument2 pagesElectromagnetic EnergyAshraf Rios KhaterNo ratings yet

- Role of Beta-Alanine Supplementation On Muscle SummaryDocument1 pageRole of Beta-Alanine Supplementation On Muscle SummaryAshraf Rios KhaterNo ratings yet

- Problem Set 4. Energy BalancesDocument4 pagesProblem Set 4. Energy BalancesAshraf Rios KhaterNo ratings yet

- Norick 30B 24continueDocument6 pagesNorick 30B 24continueAshraf Rios KhaterNo ratings yet

- Article 28 - Single Mother Help - How To Deal With FinancesDocument2 pagesArticle 28 - Single Mother Help - How To Deal With FinancesAshraf Rios KhaterNo ratings yet

- 05 Periodic Table (4, D)Document7 pages05 Periodic Table (4, D)Ashraf Rios KhaterNo ratings yet

- Calculating Molecular WeightsDocument3 pagesCalculating Molecular WeightsAshraf Rios KhaterNo ratings yet

- Characterizing PolymersDocument23 pagesCharacterizing PolymersAshraf Rios KhaterNo ratings yet

- Children in Poverty StoryDocument3 pagesChildren in Poverty StoryAshraf Rios KhaterNo ratings yet

- Impromptu!Document1 pageImpromptu!Ashraf Rios KhaterNo ratings yet

- Policies and Standards for the BSCHE program (April 23, 2008Document15 pagesPolicies and Standards for the BSCHE program (April 23, 2008Ashraf Rios KhaterNo ratings yet

- 2 LipidDocument48 pages2 LipidAshraf Rios KhaterNo ratings yet

- Growing Your Local Section's Outreach To Area High Schools: American Chemical SocietyDocument35 pagesGrowing Your Local Section's Outreach To Area High Schools: American Chemical SocietyAshraf Rios KhaterNo ratings yet

- 2355 Big M SupplementDocument1 page2355 Big M SupplementAshraf Rios KhaterNo ratings yet

- 08 - Separable Differential Equations PDFDocument4 pages08 - Separable Differential Equations PDFAshraf Rios KhaterNo ratings yet

- 4 3885 96Document5 pages4 3885 96Onesiforus Onie'dhimas AsmaraNo ratings yet

- Career Research Paper Name: - Overall GradeDocument2 pagesCareer Research Paper Name: - Overall GradeAshraf Rios KhaterNo ratings yet

- VBEE WQI Data EXAMPLEDocument4 pagesVBEE WQI Data EXAMPLEAshraf Rios KhaterNo ratings yet

- Calculation and Definition of Particle SphericityDocument1 pageCalculation and Definition of Particle SphericityJay CruzatNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5784)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- We Are Intechopen, The World'S Leading Publisher of Open Access Books Built by Scientists, For ScientistsDocument17 pagesWe Are Intechopen, The World'S Leading Publisher of Open Access Books Built by Scientists, For ScientistsTami TomNo ratings yet

- Comparison of SEM, TEM, STEM and AFM techniquesDocument2 pagesComparison of SEM, TEM, STEM and AFM techniquesTehreem Fatima0% (1)

- Chapter TEMDocument28 pagesChapter TEMMaaz ZafarNo ratings yet

- 028 Ece 8 SemDocument243 pages028 Ece 8 SemDheeraj SinghNo ratings yet

- Use of Biomass For A Development of Nanocellulose-Based Biodegradable Flexible Thin Film Thermoelectric MaterialDocument7 pagesUse of Biomass For A Development of Nanocellulose-Based Biodegradable Flexible Thin Film Thermoelectric MaterialLaura Juliana DuitamaNo ratings yet

- General Practice in Failure Analysis PDFDocument12 pagesGeneral Practice in Failure Analysis PDFAhmed AymanNo ratings yet

- Photocatalytic Degradation of LDPEDocument10 pagesPhotocatalytic Degradation of LDPErubikaNo ratings yet

- Reduce Mill Scale to Sponge Iron Powder Using CokeDocument9 pagesReduce Mill Scale to Sponge Iron Powder Using CokeLevent öncelNo ratings yet

- SOP - SEM - Nova 230Document20 pagesSOP - SEM - Nova 230Cindy WANGNo ratings yet

- BTech EEE 3rd Sem Exam SchemeDocument176 pagesBTech EEE 3rd Sem Exam SchemeShivam SharmaNo ratings yet

- Development of Graphitic Carbon NitrideDocument64 pagesDevelopment of Graphitic Carbon NitrideKoorosh IraniNo ratings yet

- Various Posters DFMDocument5 pagesVarious Posters DFMmanvik joshiNo ratings yet

- Electron MicrosDocument43 pagesElectron Microssmurali_sNo ratings yet

- Sinthesis Review PDFDocument9 pagesSinthesis Review PDFWilly MarimonNo ratings yet

- The Use of Nanoclay in Preparation of Epoxy Anticorrosive CoatingsDocument10 pagesThe Use of Nanoclay in Preparation of Epoxy Anticorrosive Coatingsbelgacem hafidaNo ratings yet

- Physical and Photo-Electrochemical Properties of Mgfe2O4 Prepared by Sol Gel Route: Application To The Photodegradation of Methylene BlueDocument9 pagesPhysical and Photo-Electrochemical Properties of Mgfe2O4 Prepared by Sol Gel Route: Application To The Photodegradation of Methylene BlueSamah SamahNo ratings yet

- Measurement: Anandraj Joseph, Girish M. JoshiDocument5 pagesMeasurement: Anandraj Joseph, Girish M. Joshiapi-3852712No ratings yet

- Coir Fibre Reinforcement and Application in Polymer Composites: A ReviewDocument14 pagesCoir Fibre Reinforcement and Application in Polymer Composites: A ReviewAshokan Keloth100% (1)

- Uttarakhand Technical University: DehradunDocument11 pagesUttarakhand Technical University: DehradunsandyNo ratings yet

- LC Supplies PDFDocument148 pagesLC Supplies PDFAlberto CampinasNo ratings yet

- Old Wine in New Bottle PDFDocument12 pagesOld Wine in New Bottle PDFMariaNo ratings yet

- Sem Edx Peak Id MistakesDocument11 pagesSem Edx Peak Id MistakesTeo Chen HoneNo ratings yet

- Morphological Study of Magnesium Hydroxide Nanoparticles Precipitated in Dilute Aqueous SolutionDocument10 pagesMorphological Study of Magnesium Hydroxide Nanoparticles Precipitated in Dilute Aqueous SolutionChemical Ferdi IzzecsonNo ratings yet

- Failure Analysis Introduction for Metallurgical EngineersDocument21 pagesFailure Analysis Introduction for Metallurgical EngineersFelipe Novais100% (1)

- Assignment 2 ProcessMineralogyDocument8 pagesAssignment 2 ProcessMineralogyinung84No ratings yet

- Analytical Services - Diya Lab Mumbai (Pharma Field)Document1 pageAnalytical Services - Diya Lab Mumbai (Pharma Field)Diyalabs Mumbai100% (1)

- 12 4 2019 Sublimable PDFDocument15 pages12 4 2019 Sublimable PDFhamada SadekNo ratings yet

- BiotechnologyDocument2 pagesBiotechnologyLyka Mae Gemino TestaNo ratings yet

- Characterisation of Milk Proteins in Confectionery ProductsDocument12 pagesCharacterisation of Milk Proteins in Confectionery ProductsMizanur RahmanNo ratings yet