Professional Documents

Culture Documents

Ijet1 PDF

Uploaded by

Ri KoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ijet1 PDF

Uploaded by

Ri KoCopyright:

Available Formats

.K.P.Tyagi et al. / International Journal of Engineering and Technology Vol.

2 (6), 2010, 427-429

Effect of Gas Turbine Exhaust Temperature,

Stack Temperature and Ambient Temperature on

Overall Efficiency of Combine Cycle Power Plant

K.P.Tyagi #1, M.N.Khan *2

#,*

Department of Mechanical Engineering,

Krishna Institute of Engg. & Tech., Ghaziabad (India)

Corresponding Author: khanrkgit@rediffmail.com

AbstractThe gas turbine exhaust temperature, stack energy losses and long expected life are the important factors

temperature and ambient temperature play a very which make combine cycle power plants unique in

important role during the predication of the performance compression with other type of plants. Behbahani-nia et al. [1]

of combine cycle power plant. This paper covers studied the effect of gas pinch point and velocity on the

parametric analysis of effects of gas turbine exhaust components of the objective functions. Pash & Sanjeev [2]

temperature, stack temperature and ambient temperature presented a discussion about the parameters that influences the

on the overall efficiency of combine cycle power plant type of circulation and selection of heat recovery steam

keeping the gas turbine efficiency as well as steam turbine generator (HRSG). Ongiro [3] develops the numerical method

efficiency constant. The results shows that out of three to predict the performance of heat recovery steam generator

variables i.e. turbine exhaust temperature, stack (HRSG) for design and operations constrains. Ganapathy et al.

temperature and ambient temperature, the most [4] describe the features of heat recovery steam generator

dominating factor of increasing the overall efficiency of (HRSG) used in cheng cycle system, where a large quantity of

the combine cycle power plant is the stack temperature. steam is injected into the gas turbine to increase electrical

power output various authors [5-9] discussed factors affecting

Keywords: Gas Turbine, Steam Turbine, exhaust temperature, heat recovery steam generator (HRSG) design for achieving

stack temperature, ambient temperature, higher efficiency.

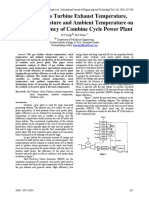

Combine cycle. Figure 2 shows the gas and steam conditions in the

boiler on temperature- enthalpy diagram. The enthalpy rise

Introduction between the feed water inlet and steam outlet must equal the

Combine cycle plant is used for large base-load enthalpy drop of the exhaust gasses in the heat recovery steam

generating stations. The ultimate aim is to reduce the cost of generator (HRSG). The pinch point and the terminal

power generation. In dual pressure steam cycle power plant, temperature differences cannot be less than 200 if the boiler is

higher efficiency can be obtained by increasing the average to be economical size.

temperature at which heat is transfer to steam. But the

additional complication would increase the cost of boiler and

steam turbine. The economical consideration of the various

power plants can be compared by the cost of electrical power

production, which depends upon the type and the quality of

fuel and to large extent to specific fuel consumption of the

power plant. The least expensive power plant is not necessary

most economical as its running cost may be high.

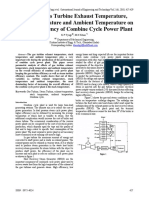

In gas turbine the maximum amount of energy not

converted to shaft power and is waste in exhaust gasses. The

exhaust gasses may be utilized in various ways, if it is wholly

used to produce steam generation in the waste heat boiler

recovery steam generator for steam turbine with the object to

produce shaft power, the efficiency of the plant can be

increase and such plant is refer as combine cycle power plant Figure 1

as shown in figure 1.

Heat Recovery Steam Generator (HRSG) are the

important component of combined cycle power plant used to

recover waste heat from the high temperature of the exhaust of

the gas turbines and generate steam. High efficiency, low

ISSN : 0975-4024 427

.K.P.Tyagi et al. / International Journal of Engineering and Technology Vol.2 (6), 2010, 427-429

Qst mg .C pg .T4 Ta

T4 Tstack

T4 Ta

Qst Q (1 gt )

T4 Tstack

i.e. (7)

T4 Ta

The overall efficiency is written as :

Wgt

W Wgt st .Qst

st

Q Q Q Q

Using equation (7), can be simplified as

Figure 2 gt st (1 gt )

T4 Tstack (8)

T4 Ta

Energy Balance of Gas and Steam in Combined Cycle

Effect of operating Temperature on Overall Efficiency of

The heat from the exhaust gasses from the gas Combined Cycle Power Plant

turbine should be sufficient to generate the steam and pressure This study i.e. the effect of turbine exhaust

in the waste heat recovery steam generator (HRSG). temperature, stack temperature and ambient temperature on

overall efficiency of combined cycle power plant is under the

The heat transferred from the exhaust gasses is: assumption of gas turbine efficiency and steam turbine

qex mg .C pg .T4 Tstack

efficiency are 36% and 32% respectively.

(1)

The heat absorbed or gain in the boiler Effect of Turbine Exhaust Temperature on overall

qex ms .h hw (2)

efficiency of combine cycle power plant for various values

of ambient Temperature at the particular value of Stack

Temperature

The super heat temperature is fixed by T4 and the terminal Equation (8) shows that the overall efficiency of the

temperature difference, and the enthalpy will depend on the combine cycle power plant is the function of turbine exhaust

pressure. The pinch point temperature Tp, is fixed by pinch temperature, stack temperature and ambient temperature but

point difference and the saturation temperature of the steam. from this equation it is difficult to say that for a particular

Therefore, heat balance between steam and exhaust gasses is value of Stack Temperature who the overall efficiency of the

ms h h f mg .C pg .T4 T p (3)

combine cycle power plant varies by simultaneous variation of

turbine exhaust temperature and ambient temperature. Figure

3 shows that for the particular value of Stack temperature as

The stack temperature can be obtained from well as ambient temperature as the turbine exhaust

ms h f hw m g .C pg .T p Tstack (4) temperature increases the overall efficiency of the combine

cycle power plant increases and this is because of increase of

The total power from the combined cycle is Wgt Wst and steam generation rate in the bottoming cycle i.e. steam power

the overall efficiency is given by plant. Also at the particular value of turbine exhaust

Wgt Wst temperature as well stack temperature with increases of

(5) ambient temperature the overall efficiency of the combine

Q cycle power plant also increases and the reason is same.

Where Wst st .Qst

And Qst m g .C pg .T4 Tstack (6)

This Qst can be expressed in terms of the heat rejection from

the gas turbine assuming that the turbine exhausts gas at T4 is

cooled without useful energy extraction from the Tstack to the

ambient temperature Ta i.e.

mg .C pg .T4 Ta or Q (1 gt )

Thus

Figure 3

ISSN : 0975-4024 428

.K.P.Tyagi et al. / International Journal of Engineering and Technology Vol.2 (6), 2010, 427-429

Effect of Turbine Exhaust Temperature on overall Conclusion

efficiency of combine cycle power plant for various values Based on the analysis of this study the following

of Stack Temperature at the particular value of ambient conclusions are made:

Temperature

The ambient temperature not in our hand, so order to

increase the overall efficiency of combine cycle power

plant the stack temperature should be minimum and gas

turbine exhaust temperature should be maximum.

Out of these three variables i.e. turbine exhaust

temperature, stack temperature and ambient

temperature, the dominating factor of increasing the

overall efficiency of the combine cycle power plant is

the stack temperature.

NOMENCLATURE

Q Heat Supplied (kJ/kg)

Cp Specific Heat at Constant Pressure (kJ/kg)

m Mass flow rate (kg/hr)

T4 Temperature at the exhaust of the gas turbine (K)

TP Pinch Point Temperature (K)

Figure 4 Tstack Stack Temperature (K)

Ta Ambient Temperature (K)

Figure 4 shows effect of turbine exhaust temperature hf Saturated liquid enthalpy of steam (kJ/kg)

h Specific enthalpy at steam turbine inlet (kJ/kg)

on overall efficiency of combine cycle power plant for various hw Specific enthalpy of steam at HRSG inlet (kJ/kg)

values of stack temperature at the particular value of ambient W Power Output (Kw)

temperature and the results shows that for the particular value Overall efficiency

of stack temperature as well as ambient temperature with HRSG Heat Recovery Steam Generator

increases of gas turbine exhaust temperature the overall Suffix

efficiency of the combine cycle power plant increases. gt Gas Turbine

st Steam Turbine

Combine Effect of Turbine Exhaust Temperature, Stack

Temperature and Ambient Temperature on Overall

Efficiency of Combined Cycle Power Plant REFERENCES

In figure 3 and figure 4 out of three variables of equation [1] A. Behbahani-nia, S.Sayadi, M.Solaymani, Thermo-economic

(8) i.e. turbine exhaust temperature, stack temperature and optimization of the pitch point and gas-side velocity in heat recovery

steam generators, Proceedings of Institute of mechanical engineers

ambient temperature one to two variables are constant. Figure part-A, J. power and Energy, Vol.224(6), 2010, pp. 761-777.

5 shows combine effect of turbine exhaust temperature, stack [2] Pasha A and Sanjeev J Combined cycle heat recovery steam

temperature and ambient temperature on overall efficiency of generators optimization capabilities and selection criteria, Heat

combined cycle power plant. The results shows that the peak Recovery system & CHP, Vol.15, 1995, pp. 147-154.

[3] Ongiro A, Ugursal VI, Taweel A.M., Waltor.J.D., Modeling of Heat

efficiency of the combine cycle power plant is achieve when Recovery Steam Generator performance, Applied Thermo Engg.

the stack temperature is minimum, exhaust temperature as Vol.17, 1997, pp. 427-446.

well as ambient temperature is maximum exist simultaneously. [4] Ganapathy.V., Heil.B., Rentz.J., Heat recovery steam generator for

cheng cycle application, International power conf.-PWR, San Diego,

Vol.4, 1998, pp. 61-65.

[5] Srinivas.T., Gupta.AVSSKS., Reddy.B.V., Thermodynamic modeling

and optimization of multi-pressure heat revovery steam generator in

combined power cycle, J. Scientific and Industrial Research, Vol. 67,

2008, pp.827-834.

[6] Srinivas.T., Gupta.AVSSKS., Reddy.B.V., performance simulation of

210 MW natural gas fired combined cycle power plant J. Energy Heat

Mass Transfer, Vol.29, 2007, pp.61-82.

[7] Carsarosa.F., Donatini, Franco.A., Thermo-economic optimization of

heat recovery steam generators operating parameters for combined

plants, Energy, Vol. 29, 2004, pp.389-414.

[8] Yaha.S.M., Turbines, Compressors and Fans, Tata McGraw Hill

Educations Pvt Ltd, III Edition.

[9] Tyagi.K.P., Khan.M.N., Prasad.R.S., Generalized equations for

predicting the performance of gas turbine cycle Int. J. Theoretical

Applied Mechanics, Vol.5, 2010, pp.171-176.

Figure 5

ISSN : 0975-4024 429

You might also like

- Ijet10 02 06 18 PDFDocument3 pagesIjet10 02 06 18 PDFmikeNo ratings yet

- 1214meij02 PDFDocument15 pages1214meij02 PDFAnonymous 9JYURINo ratings yet

- MSR - Externally Fired Gas Combustion TurbineDocument10 pagesMSR - Externally Fired Gas Combustion TurbineAnonymous K3FaYFlNo ratings yet

- Analysis of A Regenerative Gas Turbine Cycle For Power PlantDocument6 pagesAnalysis of A Regenerative Gas Turbine Cycle For Power Plantحسام جدو100% (1)

- Performance Improvement of Combined Cycle Power Plant Based On The Optimization of The Bottom Cycle and Heat RecuperationDocument6 pagesPerformance Improvement of Combined Cycle Power Plant Based On The Optimization of The Bottom Cycle and Heat Recuperationwgxiang100% (4)

- Thermodynamic Analysis of Combined Cycle Power PlantDocument11 pagesThermodynamic Analysis of Combined Cycle Power PlantHarry BraytonNo ratings yet

- Thermodynamic analysis of combined power cyclesDocument19 pagesThermodynamic analysis of combined power cyclesJoao MinhoNo ratings yet

- Gas TurbineDocument14 pagesGas Turbineاحمد الربيعي100% (1)

- Optimization of Combined Cycle Power Plant ReportDocument14 pagesOptimization of Combined Cycle Power Plant ReportbasharalhawarnaNo ratings yet

- Adv Therm Week 10Document16 pagesAdv Therm Week 10Tegin Berkay BudakNo ratings yet

- Integration of A Gas Turbine With An Ammonia Process For Improving Energy EfficiencyDocument11 pagesIntegration of A Gas Turbine With An Ammonia Process For Improving Energy EfficiencynguyentuNo ratings yet

- Analysis of A Regenerative Gas Turbine Cycle For Performance EvaluationDocument10 pagesAnalysis of A Regenerative Gas Turbine Cycle For Performance EvaluationbensouiciNo ratings yet

- Performance Analysis of CCGT Power Plant Using MATLAB Simulink Based SimulationDocument6 pagesPerformance Analysis of CCGT Power Plant Using MATLAB Simulink Based SimulationTochi Krishna Abhishek100% (1)

- 009-177 TangellapalliDocument9 pages009-177 TangellapalliShiyamala SubramaniamNo ratings yet

- Analysis For CombinedDocument17 pagesAnalysis For CombinedGianluca Castoldi QuintanoNo ratings yet

- Assessment of Sustainability Indicators of Two Gas - Turbine Plants With Naphtha and Naphtha-Rfg Mixture As FuelsDocument14 pagesAssessment of Sustainability Indicators of Two Gas - Turbine Plants With Naphtha and Naphtha-Rfg Mixture As FuelsGlobal Research and Development ServicesNo ratings yet

- Exergoeconomic Performance Optimization For An Endoreversible Regenerative Gas Turbine Closed-Cycle Cogeneration PlantDocument9 pagesExergoeconomic Performance Optimization For An Endoreversible Regenerative Gas Turbine Closed-Cycle Cogeneration PlantFernando Andrés Durán DonosoNo ratings yet

- Electricity - Cogeneration - Using - Open - Gas - Turbine PDFDocument10 pagesElectricity - Cogeneration - Using - Open - Gas - Turbine PDFRafael Garcia IllescasNo ratings yet

- Thermo-Economic Analysis of A Heat Recovery Steam Generator Combined CycleDocument6 pagesThermo-Economic Analysis of A Heat Recovery Steam Generator Combined CyclekouroshNo ratings yet

- Thermodynamic Analysis of Combined Open-Cycle-Twin-Shaft Gas Turbine (Brayton Cycle) and Exhaust Gas Operated Absorption Refrigeration UnitDocument10 pagesThermodynamic Analysis of Combined Open-Cycle-Twin-Shaft Gas Turbine (Brayton Cycle) and Exhaust Gas Operated Absorption Refrigeration Unitmce10No ratings yet

- Khartoum University Study Finds Regeneration Increases Gas Turbine EfficiencyDocument6 pagesKhartoum University Study Finds Regeneration Increases Gas Turbine EfficiencymurtadaNo ratings yet

- Study the Performance of Combined Gas Turbine-Steam CyclesDocument22 pagesStudy the Performance of Combined Gas Turbine-Steam CyclesBrandon SánchezNo ratings yet

- Gas-Turbine Cycles: 3.1 PerformanceDocument2 pagesGas-Turbine Cycles: 3.1 PerformancekouroshNo ratings yet

- Evaluation of Advanced Combined Cycle Power PlantsDocument20 pagesEvaluation of Advanced Combined Cycle Power PlantsStergios PanagiotouNo ratings yet

- The Energetic and Exergic Performance of Gas Turbine Cogeneration SystemDocument6 pagesThe Energetic and Exergic Performance of Gas Turbine Cogeneration SystemAneta HaziNo ratings yet

- Effect of Compression Ratio On Performance of Combined Cycle Gas TurbineDocument6 pagesEffect of Compression Ratio On Performance of Combined Cycle Gas TurbinediarniseNo ratings yet

- C5008098319 PDFDocument5 pagesC5008098319 PDFRamkishan SahuNo ratings yet

- Tarea 4Document13 pagesTarea 4Isidro MedranoNo ratings yet

- GAS _TURBINE_CYCLEDocument41 pagesGAS _TURBINE_CYCLEKalpaniNo ratings yet

- MCA 2008may6 BauerDocument12 pagesMCA 2008may6 BauerVarun AggarwalNo ratings yet

- Thermodynamic Evaluation of The Performance of A Combined Cycle Power PlantDocument11 pagesThermodynamic Evaluation of The Performance of A Combined Cycle Power PlanthansleyNo ratings yet

- Heat Pipe in HvacDocument11 pagesHeat Pipe in HvacOmkar ChavanNo ratings yet

- Thermodynamic Evaluation of Gas Compression StationDocument14 pagesThermodynamic Evaluation of Gas Compression StationZetaNo ratings yet

- Thermoeconomic Evaluation of Combined Cycle Cogeneration Systems - MakaleDocument8 pagesThermoeconomic Evaluation of Combined Cycle Cogeneration Systems - Makaley_durNo ratings yet

- Noncondensable Gases From Geothermal Steam at Kizildere Geothermal Power Plant, TurkeyDocument6 pagesNoncondensable Gases From Geothermal Steam at Kizildere Geothermal Power Plant, Turkeyb_wooNo ratings yet

- Thermodynamicperformanceanalysisofgas Turbinepower PlantDocument13 pagesThermodynamicperformanceanalysisofgas Turbinepower Plantbsaid77No ratings yet

- Gas TurbineDocument25 pagesGas TurbineMohammed AlsirajNo ratings yet

- Thermodynamic Analysis of Gas Turbine Powered Cogeneration SystemsDocument6 pagesThermodynamic Analysis of Gas Turbine Powered Cogeneration SystemskkaytugNo ratings yet

- s1359 4311 (01) 00104 1 PDFDocument8 pagess1359 4311 (01) 00104 1 PDFkaushik9595No ratings yet

- Chapter - : Gas Torbines and Jet PropulsionDocument12 pagesChapter - : Gas Torbines and Jet PropulsionVijay KumarNo ratings yet

- Heat and Mass Balance Index: S.N. Topics Page NosDocument50 pagesHeat and Mass Balance Index: S.N. Topics Page NosRavi Satyapal100% (1)

- Desa2011 PDFDocument5 pagesDesa2011 PDFTayyabIsmailNo ratings yet

- Final 00013Document7 pagesFinal 00013kurniawan waskitoNo ratings yet

- Turbocharger Heat FlowsDocument6 pagesTurbocharger Heat FlowsRichart TPNo ratings yet

- Pinch Analysis For Power Plant A Novel Approach For Increase in Efficiency IJERTV3IS060887Document10 pagesPinch Analysis For Power Plant A Novel Approach For Increase in Efficiency IJERTV3IS060887almutlaqNo ratings yet

- Gas Turbine DynamicsDocument12 pagesGas Turbine Dynamicshemanth_satish100% (2)

- Gas Turbine Power Augmentation Using Integrated Steam Injection and Inlet Air CoolingDocument12 pagesGas Turbine Power Augmentation Using Integrated Steam Injection and Inlet Air Coolingherysyam1980No ratings yet

- Analysis of The Gpu-3 Stirling EngineDocument28 pagesAnalysis of The Gpu-3 Stirling EnginesbregoNo ratings yet

- The Performance Prediction of A 30-Kw Multi-Fueled Micro Gas TurbineDocument10 pagesThe Performance Prediction of A 30-Kw Multi-Fueled Micro Gas TurbineTJPRC PublicationsNo ratings yet

- Optimization of The Triple-Pressure Combined Cycle Power PlantDocument14 pagesOptimization of The Triple-Pressure Combined Cycle Power PlantIsaac DiazNo ratings yet

- Second Law Analysis of Waste Heat Recovery Power GenerationDocument9 pagesSecond Law Analysis of Waste Heat Recovery Power Generationyahska1305No ratings yet

- Pinch and Approach Point On HRSGDocument12 pagesPinch and Approach Point On HRSGluaguNo ratings yet

- Targeting of The Trade-Off of Capital Cost and Carbon Footprint For CHPDocument6 pagesTargeting of The Trade-Off of Capital Cost and Carbon Footprint For CHPvazzoleralex6884No ratings yet

- Energy: Y.Y. Hsiao, W.C. Chang, S.L. ChenDocument8 pagesEnergy: Y.Y. Hsiao, W.C. Chang, S.L. Chenminesh.manu6531No ratings yet

- Liu 2017Document12 pagesLiu 2017Kim Ryan DinglasanNo ratings yet

- Energy Conversion and Management: SciencedirectDocument22 pagesEnergy Conversion and Management: SciencedirectAnand PanchalNo ratings yet

- Applied Energy Journal Article on Externally-Fired Gas Turbine CycleDocument11 pagesApplied Energy Journal Article on Externally-Fired Gas Turbine CycleOnnuri WonNo ratings yet

- Thermodynamic Analysis of Combined Cycle Power Plant: NomenclatureDocument6 pagesThermodynamic Analysis of Combined Cycle Power Plant: Nomenclaturefrank sambaNo ratings yet

- Final_Paper_in_JECS_FormatDocument12 pagesFinal_Paper_in_JECS_FormatDobaNo ratings yet

- Performance Evaluation of Gas-Steam Combined Cycle Having Transpiration Cooled Gas TurbineDocument18 pagesPerformance Evaluation of Gas-Steam Combined Cycle Having Transpiration Cooled Gas TurbineRi KoNo ratings yet

- Pressure Vessels - ASMEDocument2 pagesPressure Vessels - ASMERi KoNo ratings yet

- The State of Indonesia's Renewable Energy - UNDP in IndonesiaDocument2 pagesThe State of Indonesia's Renewable Energy - UNDP in IndonesiaRi KoNo ratings yet

- Methods To Reduce or Avoid Thermal Impacts To Surface Water: A Manual For Small Municipal Wastewater Treatment PlantsDocument109 pagesMethods To Reduce or Avoid Thermal Impacts To Surface Water: A Manual For Small Municipal Wastewater Treatment PlantsRi KoNo ratings yet

- Understanding The Basics of BalancingDocument8 pagesUnderstanding The Basics of BalancingRi KoNo ratings yet

- AFBC BoilerDocument12 pagesAFBC BoilerNaman Sharma0% (1)

- Ijet10 02 06 18 PDFDocument3 pagesIjet10 02 06 18 PDFRi KoNo ratings yet

- Siemens DASHDocument3 pagesSiemens DASHRi KoNo ratings yet

- CCPP Technology and RisksDocument44 pagesCCPP Technology and RisksBikash Kr. Agarwal100% (1)

- V. Ganapathy. Simplify Heat Recovery Steam Generator Evaluation PDFDocument7 pagesV. Ganapathy. Simplify Heat Recovery Steam Generator Evaluation PDFgonzalezpcjNo ratings yet

- V. Ganapathy On Calculation of Flue Gas DensityDocument2 pagesV. Ganapathy On Calculation of Flue Gas DensityRi KoNo ratings yet

- Clean Air ActDocument465 pagesClean Air ActRi KoNo ratings yet

- Combined CycleDocument8 pagesCombined CycleRi KoNo ratings yet

- Tepe3 906Document66 pagesTepe3 906daniel adamNo ratings yet

- Toc Asme PTC 6 2004Document4 pagesToc Asme PTC 6 2004Ri KoNo ratings yet

- Pulverized Coal TechnologyDocument7 pagesPulverized Coal TechnologyRi KoNo ratings yet

- PDMS-Design Reference Manual Part1Document140 pagesPDMS-Design Reference Manual Part1Ri KoNo ratings yet

- Advanced Fire FightingDocument52 pagesAdvanced Fire FightingRi Ko67% (3)

- PDMS-Design Reference Manual Part1Document140 pagesPDMS-Design Reference Manual Part1Ri KoNo ratings yet

- Vpi Si 0008 2002 Chemical CleaningDocument2 pagesVpi Si 0008 2002 Chemical CleaningRi KoNo ratings yet

- Steam BlowingDocument49 pagesSteam Blowingliamcs100% (1)

- Geothermal Pipe Line DesignDocument15 pagesGeothermal Pipe Line DesignjohnjuantamadNo ratings yet

- Vpi Si 0008 2002 Chemical CleaningDocument2 pagesVpi Si 0008 2002 Chemical CleaningRi KoNo ratings yet

- Advanced Fire FightingDocument52 pagesAdvanced Fire FightingRi Ko67% (3)

- Vpi Si 0008 2002 Chemical CleaningDocument2 pagesVpi Si 0008 2002 Chemical CleaningRi KoNo ratings yet

- Musashi, A Book of Five Rings PDFDocument46 pagesMusashi, A Book of Five Rings PDFAther AhmadNo ratings yet

- An Inspection Guide For FRP EquipmentDocument36 pagesAn Inspection Guide For FRP Equipmentsajishjm100% (2)

- Fans & Blowers-Calculation of PowerDocument20 pagesFans & Blowers-Calculation of PowerPramod B.Wankhade92% (24)

- Seawater Feed Pump Installation, Operation & Maintenance GuideDocument13 pagesSeawater Feed Pump Installation, Operation & Maintenance GuideRi KoNo ratings yet

- Einstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseFrom EverandEinstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseRating: 4.5 out of 5 stars4.5/5 (50)

- Piping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationFrom EverandPiping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationRating: 4 out of 5 stars4/5 (18)

- Quantum Mechanics 4: Spin, Lasers, Pauli Exclusion & Barrier PenetrationFrom EverandQuantum Mechanics 4: Spin, Lasers, Pauli Exclusion & Barrier PenetrationRating: 1 out of 5 stars1/5 (1)

- Introduction to Petroleum Process SafetyFrom EverandIntroduction to Petroleum Process SafetyRating: 3 out of 5 stars3/5 (2)

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsFrom EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsNo ratings yet

- Guidelines for Implementing Process Safety ManagementFrom EverandGuidelines for Implementing Process Safety ManagementNo ratings yet

- Incidents That Define Process SafetyFrom EverandIncidents That Define Process SafetyNo ratings yet

- A Poison Like No Other: How Microplastics Corrupted Our Planet and Our BodiesFrom EverandA Poison Like No Other: How Microplastics Corrupted Our Planet and Our BodiesRating: 5 out of 5 stars5/5 (1)

- The Laws of Thermodynamics: A Very Short IntroductionFrom EverandThe Laws of Thermodynamics: A Very Short IntroductionRating: 4.5 out of 5 stars4.5/5 (10)

- Formulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsFrom EverandFormulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsNo ratings yet

- Design of Foundations for Offshore Wind TurbinesFrom EverandDesign of Foundations for Offshore Wind TurbinesRating: 5 out of 5 stars5/5 (3)

- Basic Alarm Electronics: Toolbox Guides for Security TechniciansFrom EverandBasic Alarm Electronics: Toolbox Guides for Security TechniciansJohn SangerRating: 4 out of 5 stars4/5 (1)

- Rolling Bearing Tribology: Tribology and Failure Modes of Rolling Element BearingsFrom EverandRolling Bearing Tribology: Tribology and Failure Modes of Rolling Element BearingsNo ratings yet

- Control of Power Electronic Converters and Systems: Volume 1From EverandControl of Power Electronic Converters and Systems: Volume 1Rating: 5 out of 5 stars5/5 (1)

- Inherently Safer Chemical Processes: A Life Cycle ApproachFrom EverandInherently Safer Chemical Processes: A Life Cycle ApproachRating: 5 out of 5 stars5/5 (1)

- Hyperspace: A Scientific Odyssey Through Parallel Universes, Time Warps, and the 10th DimensionFrom EverandHyperspace: A Scientific Odyssey Through Parallel Universes, Time Warps, and the 10th DimensionRating: 4.5 out of 5 stars4.5/5 (3)

- Chemical Process Safety: Learning from Case HistoriesFrom EverandChemical Process Safety: Learning from Case HistoriesRating: 4 out of 5 stars4/5 (14)

- Safety Fundamentals and Best Practices in Construction IndustryFrom EverandSafety Fundamentals and Best Practices in Construction IndustryNo ratings yet

- 1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideFrom Everand1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideRating: 3.5 out of 5 stars3.5/5 (7)

- Operational Amplifier Circuits: Analysis and DesignFrom EverandOperational Amplifier Circuits: Analysis and DesignRating: 4.5 out of 5 stars4.5/5 (2)