Professional Documents

Culture Documents

Production of Nail Polish Remover

Uploaded by

Samuel GaétanCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Production of Nail Polish Remover

Uploaded by

Samuel GaétanCopyright:

Available Formats

PRODUCTION OF NAIL POLISH REMOVER & NAIL

GLUE REMOVER

Posted on September 15, 2011by udomma

INTRODUCTION: The nail paint (polish) and glue removers are a

combination of strong but safe solvents for the purpose of removing nail

paints, polish, hardener and other nail coatings. It comes in clear to

amber or other colours. Some are perfumed.

SCOPE OF USAGE: As economic and social life improve, more people get more

conscious

of their body make ups. Most adult women use and reuse nail decorations and as

such use nail

paint removers along with these decorators. It is estimated that over 40% of the

female adult

population in Nigeria use nail coatings and coating removers. This puts the market at

the

disposal of the few manufacturers of the products in Nigeria.

RAW MATERIALS REQUIREMENT

The needed raw materials are:

1. Acetone or M.E.K as active ingredient

2. Ethyl Acetate as alternative to (a) above

3. Buthyl Acetate as for glue remover

4. Buthyl Acetate as alternative to (c) above

5. Glycerine as gloss agent

6. Waterr as filler for low grades.

7. Colourant (oil basetype), optional

8. Perfume (oil base type), optonal.

All these inputs are readily available in our local chemical shops even at retail.

EQUIPMENTS & TOOLS REQIREMENT

Due to the strong nature of the needed raw materials, all containers for processing

these products should be stainless steel or plastic tanks. Galvanized steel may be used

as a cheap alternative as last choice.

The equipment include:

a. Low speed mixer of about 200 300rpm. (manual or motorized)

b. Strong tanks

c. Measuring Device (cylinder, scale, etc.)

d. Filling unit (manual or automated)

e. Labeling device (manual or automated)

f. Personal protective gadgets (P.P.G)

g. Laboratory testing instruments.

PACKAGING MATERIALS REQUIREMENTS

The products are best packed in plastic bottles with inner seal. These

bottles are neatly labeled and packed in cartons of corrugated board or

film laminates. Labels must carry brand names, manufacturer, location,

batch numbers, NAFDAC registration numbers (if any) and other

information that can help sell the products.

Glass and metal bottles are alternative packaging materials but they are

very expensive and bulky. Take the route of packaging that the market

will pay you more. Products must carry users precautions.

PRODUCTION PROCESS

1. Formulations:

1. Nail paint remover: 20 litres batch

a. Acetone 14litres

M.E.K. 5litres

Glycerine 1litre

Colour Q.S. (Optional)

Perfume Q.S. (Optional)

20 LITRES

b. Acetone 19 litres

Glycerine 1 litre

20 litres

c. M.E.K. or Ethyl Acetate 19litres

Glycerine 1 litre

20LITRES

NOTE: Colours and perfumes may be added in b and c as required.

d. Acetone 18litres Clean water 2 litres

20LITRES

Note: This can also be coloured and perfumed. It is the cheaper and the lowest grade

of nail polish remover in the market today.

II Nail Glue Remover (20 litres Batch)

a. Butyl Glycol 15litres

Butyl Acetate 5litres

20 LITRES

b. Ethyl Acetate 10litres

Butyl Acetate 10litres

20LITRES

c. Butyl Glycol or B. Acetate 15litres

M.E.K. 5litres

20LITRES

Note: All the formulations can be coloured and perfumed as desired (Q.S). Q.S.

Means sufficient quantity as required.

M.E.K. Means methylethylketone.

PRODUCTION METHOD: This is a simple mixing process. Measure out all the

materials needed in the formulation (except colour and perfume) and place in the

mixer and mix for about 10 15 minutes if batch is up to and above 100litres. For

batches below 100litres mixing can be ok within 5minutes. After the initial mixing,

add the colour and perfume then mix for another 2 3 minutes and test the product

and pack if ok.

QUALITY PARAMETERS

1. Product must clean nail and other domestic paints within 1 2 minutes of

application.

2. The product must dry off within 2 3minutes after usage.

3. The nail glue remover should dissolve the glue without damaging the artificial nail.

4. It should also clean nail paints.

5. Odours of both products should not be offensive.

You might also like

- LipstickDocument10 pagesLipstickFarez ZainudinNo ratings yet

- Building Material - PaintDocument19 pagesBuilding Material - PaintDedikas Jinghao100% (1)

- 2 ShampoosDocument22 pages2 ShampoosRatih PramintariNo ratings yet

- Biariq SLES 70% TDSDocument2 pagesBiariq SLES 70% TDSAbdullah AzzamNo ratings yet

- Dial Liquid Soap RedesignDocument6 pagesDial Liquid Soap RedesignHailey LewisNo ratings yet

- Emulsified and Special MixturesDocument26 pagesEmulsified and Special MixturesharNo ratings yet

- Denim 2Document18 pagesDenim 2ADINAN MOHAMMED100% (1)

- (NIIR) Herbal Soaps & Detergents HandbookDocument18 pages(NIIR) Herbal Soaps & Detergents HandbookHaneen MohammadNo ratings yet

- Shampoo 12 19Document48 pagesShampoo 12 19LinhNguye0% (1)

- Production Profile of Alkyd ResinsDocument16 pagesProduction Profile of Alkyd ResinschayanunNo ratings yet

- Final Soap Production 1Document13 pagesFinal Soap Production 1SuvamNo ratings yet

- Cereal Products AssignmentsDocument9 pagesCereal Products AssignmentsSaima100% (1)

- Formulation of Rice Flour BiscuitDocument10 pagesFormulation of Rice Flour BiscuitLaksilu Viduraga Peiris100% (1)

- Machining Processes - I MT 164: Cutting FluidsDocument18 pagesMachining Processes - I MT 164: Cutting FluidsMusab LatifNo ratings yet

- HarpicDocument12 pagesHarpicreptilia89No ratings yet

- Machining Process - I: Cutting Fluids and TypesDocument22 pagesMachining Process - I: Cutting Fluids and TypesNajshhsNo ratings yet

- Emulsifier For Base Cutting OilsDocument3 pagesEmulsifier For Base Cutting Oilscm_chemical810% (1)

- Surfactant BrochureDocument8 pagesSurfactant BrochureRaj Aryan YadavNo ratings yet

- Introduction to Soap IngredientsDocument25 pagesIntroduction to Soap IngredientsMelissa Arnold0% (1)

- TDS - KemFoamX 2550 - ENDocument2 pagesTDS - KemFoamX 2550 - ENSteven CoultonNo ratings yet

- Comperlan® 100: Product Data SheetDocument2 pagesComperlan® 100: Product Data SheetR Bunardi100% (1)

- Et 45 2001 PDFDocument9 pagesEt 45 2001 PDFmy09No ratings yet

- Castor Oil & Its Derivatives Oleoresin, Turkey Red Oil, Dco, Hco, Sebacic Acid, 12-Hydroxy Stearic AcidDocument5 pagesCastor Oil & Its Derivatives Oleoresin, Turkey Red Oil, Dco, Hco, Sebacic Acid, 12-Hydroxy Stearic Acidkunal agiwaleNo ratings yet

- Detergent (Group 1,2)Document29 pagesDetergent (Group 1,2)Sourav SutradharNo ratings yet

- Petroleum JellyDocument8 pagesPetroleum JellyMichael AjibadeNo ratings yet

- SDS Heavy Duty Degreaser DegreaserDocument23 pagesSDS Heavy Duty Degreaser DegreaserAradhwik MagotraNo ratings yet

- Project Profile On Petroleum JellyDocument10 pagesProject Profile On Petroleum JellyG.p.AiyerNo ratings yet

- Metal Cutting Fluids: Meaning, Functions and Types: in Metal Cutting Process Heal Is Generated Due To Following ActionsDocument3 pagesMetal Cutting Fluids: Meaning, Functions and Types: in Metal Cutting Process Heal Is Generated Due To Following ActionsTulsi ChouhanNo ratings yet

- Personal Care Product Range Latin America English VersionDocument8 pagesPersonal Care Product Range Latin America English VersionAlfonso PeñarandaNo ratings yet

- Cutting FluidDocument20 pagesCutting FluidVickyVenkataramanNo ratings yet

- Detergent Powder Manufacturing Unit Rs. 28.83 Million Jun-2021Document23 pagesDetergent Powder Manufacturing Unit Rs. 28.83 Million Jun-2021Syed Fawad AhmadNo ratings yet

- How To Produce Laundry Soap in NigeriaDocument18 pagesHow To Produce Laundry Soap in NigeriaDemelash GebreNo ratings yet

- Soap, Cosmetics, ProductionDocument34 pagesSoap, Cosmetics, ProductionEmmaNo ratings yet

- Soap and Detergent Manufacturing Processes ExplainedDocument40 pagesSoap and Detergent Manufacturing Processes ExplainedShahzil RehmanNo ratings yet

- GHee EssenceDocument9 pagesGHee EssencemuralismatNo ratings yet

- Top Performing Detergent Brands by Price CategoryDocument12 pagesTop Performing Detergent Brands by Price CategoryKhaled SlevinNo ratings yet

- PRIMO Auto & Home Care Product CatalogDocument47 pagesPRIMO Auto & Home Care Product CatalogPrimo Talk100% (1)

- Cosmetic Product DevelopmentDocument15 pagesCosmetic Product DevelopmentGizelle Mae Pasiol-MacayanNo ratings yet

- Dry Wall PuttyDocument4 pagesDry Wall PuttyAnurag Agrawal100% (1)

- Dishwasher Explanation TextDocument3 pagesDishwasher Explanation TextMai - Patcharee RushNo ratings yet

- Concrete Crack PrventiveDocument4 pagesConcrete Crack PrventiveJuthi Rahman100% (1)

- National Center For Home Food PreservationDocument3 pagesNational Center For Home Food PreservationGail Aid100% (1)

- Project Report On Transparent Soap Base (Melt & Pour) and Noodle SoapDocument9 pagesProject Report On Transparent Soap Base (Melt & Pour) and Noodle SoapEIRI Board of Consultants and Publishers100% (2)

- Soap Manufacturing ProcessDocument15 pagesSoap Manufacturing ProcessMarjhel HalligNo ratings yet

- MSDS Liquid Shoe PolishDocument4 pagesMSDS Liquid Shoe PolishAhmAd GhAziNo ratings yet

- All Purpose CleanersDocument50 pagesAll Purpose CleanersKalai Selvan100% (1)

- Carpet Shampoo HCLF23Document1 pageCarpet Shampoo HCLF23Gurinder SinghNo ratings yet

- Specialty Clarification & Coagulation Solutions: Chemistry For A Greener WorldDocument6 pagesSpecialty Clarification & Coagulation Solutions: Chemistry For A Greener Worldnithinc10100% (1)

- Sustainable Manufacturing Techniques for Cutting ProcessesDocument30 pagesSustainable Manufacturing Techniques for Cutting ProcessesAmbati TejaswararaoNo ratings yet

- Project Report On Natural Oil Based Soaps & Shampoos (Bars and Liquids) Made by Cold Process SaponificationDocument5 pagesProject Report On Natural Oil Based Soaps & Shampoos (Bars and Liquids) Made by Cold Process SaponificationEIRI Board of Consultants and PublishersNo ratings yet

- Production and Formulation of Cosmetics, Cleaners, Drugs, Soaps and Detergents PDFDocument84 pagesProduction and Formulation of Cosmetics, Cleaners, Drugs, Soaps and Detergents PDFfarkad rawiNo ratings yet

- Proraso Shaving Cream Common Ingredients of 3 TypesDocument2 pagesProraso Shaving Cream Common Ingredients of 3 Typeschimene madiNo ratings yet

- AIR PRODUCTS Agrochemical Adjuvants GuideDocument8 pagesAIR PRODUCTS Agrochemical Adjuvants GuideRomán M Martín del CNo ratings yet

- Production Process - II (Module 3 - Notes) : Elements Mentioned in These NotesDocument9 pagesProduction Process - II (Module 3 - Notes) : Elements Mentioned in These NotesDeepak DevasagayamNo ratings yet

- H1platinum Blonde Virgin Human Hair Wig Sixteenh1wywowDocument3 pagesH1platinum Blonde Virgin Human Hair Wig Sixteenh1wywowclavelyre2No ratings yet

- Formulation and manufacturing methods for paints and coatingsDocument30 pagesFormulation and manufacturing methods for paints and coatingsShivpoojan SinghNo ratings yet

- Handbook of Vinyl FormulatingFrom EverandHandbook of Vinyl FormulatingRichard F GrossmanRating: 3 out of 5 stars3/5 (1)

- Homemade Hand Sanitizer - Learn How to Make Your Own Natural Hand Sanitizer Recipes for a Healthier LifestyleFrom EverandHomemade Hand Sanitizer - Learn How to Make Your Own Natural Hand Sanitizer Recipes for a Healthier LifestyleNo ratings yet

- Nail PolishDocument5 pagesNail PolishRetinaAghistniRahmawatiNo ratings yet

- Chapter One: 1.1.vision, Mission, Goals and ObjectivesDocument7 pagesChapter One: 1.1.vision, Mission, Goals and Objectivesmekonnen kasaNo ratings yet

- Restaurant Business Plan Template Download inDocument28 pagesRestaurant Business Plan Template Download inSamuel GaétanNo ratings yet

- Fluid Pressure Fundamentals ExplainedDocument23 pagesFluid Pressure Fundamentals ExplainedSamuel GaétanNo ratings yet

- Accounting Principles - A Business Perspective, Financial AccountingDocument433 pagesAccounting Principles - A Business Perspective, Financial Accountinggimi21100% (6)

- 93 Sample ChapterDocument23 pages93 Sample ChapterSamuel GaétanNo ratings yet

- ERO Opportunity Framing 11-3 PDFDocument27 pagesERO Opportunity Framing 11-3 PDFSamuel Gaétan75% (4)

- The Revenue Cycle: Learning ObjectivesDocument19 pagesThe Revenue Cycle: Learning ObjectivesSamuel GaétanNo ratings yet

- Graduation Thesis MOT - Sara Kraus - 1311085Document94 pagesGraduation Thesis MOT - Sara Kraus - 1311085Samuel GaétanNo ratings yet

- AbsaDocument1 pageAbsaSamuel GaétanNo ratings yet

- 05-DEMINERALIZED TREAtMENTDocument2 pages05-DEMINERALIZED TREAtMENTSamuel GaétanNo ratings yet

- Catalogue 1Document113 pagesCatalogue 1Samuel GaétanNo ratings yet

- Proposed House Improvement List:: OutsideDocument2 pagesProposed House Improvement List:: OutsideSamuel GaétanNo ratings yet

- Lab Report Performance Characteristics of Centrifugal PumpDocument10 pagesLab Report Performance Characteristics of Centrifugal PumpRam Krishna Singh85% (33)

- NitrogenDocument15 pagesNitrogenSamuel GaétanNo ratings yet

- South African Learner Driver ManualDocument42 pagesSouth African Learner Driver ManualjohnfloryNo ratings yet

- Hydrogen 1BDocument32 pagesHydrogen 1BSamuel GaétanNo ratings yet

- This UNOFFICIAL Copy Was Downloaded From The Tshwane University of Technology WebsiteDocument10 pagesThis UNOFFICIAL Copy Was Downloaded From The Tshwane University of Technology WebsiteSamuel GaétanNo ratings yet

- CET33ATnov Main 08Document11 pagesCET33ATnov Main 08inagnobNo ratings yet

- 2016 Cet 33b Chapter 1Document66 pages2016 Cet 33b Chapter 1Samuel GaétanNo ratings yet

- Tshwane UoT CET33AT 2012 May Exam Unofficial CopyDocument8 pagesTshwane UoT CET33AT 2012 May Exam Unofficial CopySamuel GaétanNo ratings yet

- ContentDocument1 pageContentSamuel GaétanNo ratings yet

- Kingdom of LesothoDocument19 pagesKingdom of LesothoSamuel GaétanNo ratings yet

- CET33AT (4) ExamDocument19 pagesCET33AT (4) ExamSamuel GaétanNo ratings yet

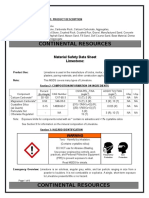

- Limestone MSDSDocument6 pagesLimestone MSDSSamuel GaétanNo ratings yet

- Gabon: Land of Unique Biodiversity and Oil WealthDocument16 pagesGabon: Land of Unique Biodiversity and Oil WealthSamuel GaétanNo ratings yet

- Mass Transfer IDocument107 pagesMass Transfer Ishivamlal94No ratings yet

- MSDSDocument6 pagesMSDSSamuel GaétanNo ratings yet

- 11 Things I Wish I KnewDocument8 pages11 Things I Wish I KnewSamuel GaétanNo ratings yet

- CET33ATnov Main 08Document11 pagesCET33ATnov Main 08inagnobNo ratings yet

- Cet33at - pdf2010 June SuppDocument9 pagesCet33at - pdf2010 June SuppSamuel GaétanNo ratings yet

- Utilizing Styrofoam and Oyster Shells in Concrete Brick ProductionDocument4 pagesUtilizing Styrofoam and Oyster Shells in Concrete Brick ProductionShane Giacinth AmarilaNo ratings yet

- Separation of Acetonitrile From Hazardous Waste: Honors Senior Thesis Pass With DistinctionDocument42 pagesSeparation of Acetonitrile From Hazardous Waste: Honors Senior Thesis Pass With DistinctionJoshua JohnsonNo ratings yet

- Feasibility of an Acetone and Cigarette Filter-Based AdhesiveDocument10 pagesFeasibility of an Acetone and Cigarette Filter-Based AdhesiveLance HeindrickNo ratings yet

- Growing Salvinorin CrystalsDocument3 pagesGrowing Salvinorin Crystalsbiatch0% (1)

- Production of Bisphenol ADocument86 pagesProduction of Bisphenol ARahul Agrawal100% (19)

- CUMENEDocument24 pagesCUMENEhiteshNo ratings yet

- Synthesis of 1,5 Benzodiazepines A ReviewDocument13 pagesSynthesis of 1,5 Benzodiazepines A ReviewEditor IJTSRDNo ratings yet

- United States Patent: Steward Et A1. (10) Patent N0.: (45) Date of PatentDocument13 pagesUnited States Patent: Steward Et A1. (10) Patent N0.: (45) Date of PatentRashmi GopalakrishnanNo ratings yet

- Dielectric Constant TableDocument51 pagesDielectric Constant TableJoaquin Luna100% (1)

- Phenolic Resin PreparationDocument7 pagesPhenolic Resin PreparationmitaasthaNo ratings yet

- Stefan/Arnold Diffusion ExperimentDocument6 pagesStefan/Arnold Diffusion Experimentnmhatitye100% (2)

- Msds PDFDocument6 pagesMsds PDFToni ChandraNo ratings yet

- Acetone Production Process OptimizationDocument31 pagesAcetone Production Process OptimizationVaibhav Vaidya0% (1)

- Conservar Património 2182-9942: E-IssnDocument15 pagesConservar Património 2182-9942: E-Issnvarvara3No ratings yet

- Acetone Safety Data Sheet PDFDocument8 pagesAcetone Safety Data Sheet PDFMarkChenNo ratings yet

- Operating Instructions: Digital Pirani GaugeDocument24 pagesOperating Instructions: Digital Pirani GaugenyaaaaaaaNo ratings yet

- Biochemistrhy Experiment 10Document9 pagesBiochemistrhy Experiment 10JaphaNo ratings yet

- ASPEN PLUS Lecture PresentationDocument101 pagesASPEN PLUS Lecture PresentationTeeni Abeysekara100% (1)

- SDFCL Price List PDFDocument263 pagesSDFCL Price List PDFmppatilmayur1679No ratings yet

- A Simple Guide to Labelling Museum ObjectsDocument7 pagesA Simple Guide to Labelling Museum ObjectsSARAI ELI LANDA ROJASNo ratings yet

- EphedrineDocument43 pagesEphedrineArthit SomrangNo ratings yet

- Zingiberone Synth - Method of Preparing Zingiberone - PatentDocument2 pagesZingiberone Synth - Method of Preparing Zingiberone - PatentyunusNo ratings yet

- Rolls-Royce Technical Publications - (Overhaul Processes Manual (OP, TSDJ) ) (Task 70-00-00Document21 pagesRolls-Royce Technical Publications - (Overhaul Processes Manual (OP, TSDJ) ) (Task 70-00-00limhonghan1987No ratings yet

- CPE604 - Mini Project Plant Design Produ PDFDocument136 pagesCPE604 - Mini Project Plant Design Produ PDFAgung Siswahyu0% (1)

- BSDM0503Document17 pagesBSDM0503federico.montesNo ratings yet

- Unlock-Treinamento Netstal Discjet 600Document308 pagesUnlock-Treinamento Netstal Discjet 600marioNo ratings yet

- Deepak Nitrite - Initiation ReportDocument20 pagesDeepak Nitrite - Initiation Report9avinashrNo ratings yet

- Design ReportDocument71 pagesDesign ReportEmmanuelNo ratings yet

- Common Laboratory TechniquesDocument5 pagesCommon Laboratory Techniquesyouni_2005No ratings yet

- Adequacy of Fusion of Extruded Poly (Vinyl Chloride) (PVC) Pipe and Molded Fittings by Acetone ImmersionDocument3 pagesAdequacy of Fusion of Extruded Poly (Vinyl Chloride) (PVC) Pipe and Molded Fittings by Acetone ImmersionAndres Camilo BenitezNo ratings yet