Professional Documents

Culture Documents

Halfen Systems For The Support and Restraint of Brickwork

Uploaded by

vtalexOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Halfen Systems For The Support and Restraint of Brickwork

Uploaded by

vtalexCopyright:

Available Formats

Halfen Brickwork Support Systems

Halfen systems for the support and restraint of brickwork

Introduction

Halfen is a leading supplier of channel fixing

systems and building components, with

manufacturing and marketing centres

throughout the world.

The product range consists of:

cast-in channel fixings

brickwork support systems

brick ties and windposts

reinforcement systems

pre-cast lifting systems

pre-cast fixings

curtain wall restraints

natural stone fixings

framing systems.

This brochure covers systems for the support

and restraint of brickwork/masonry.

Brickwork systems

Support of brickwork above horizontal soft joints

The first section of this brochure details bracket

systems for the support of brick, block and

reconstructed stone outer skins above horizontal

soft joints in framed structures.

Lintels

Halfen also manufacture steel end-bearing

lintels and reinforcement systems to allow the

construction of fair-faced arches in facing

brickwork or deep reveals.

Brick ties

Full details are given of cavity wall ties, together

with dovetail and other channel ties, ties for

studwork, frame cramps, sliding brick anchors

and specialist ties.

Windposts

To transfer the wind load on large brick wall

panels to the structure Halfen manufacture

windposts that generally span from slab to slab

in framed structures.

Design Service

Halfen also offer a comprehensive design

service. For full details, please contact Halfen

Limited.

Typical wall construction at intermediate floor level

showing Halfen brick support system bolted to cast-in

channel in insitu concrete slab. (Wall ties, sliding brick

anchors and windposts also shown.)

2 Halfen technical helpline: 08705 316300

Contents Page

Halfen bracket/angle systems

for brick support 4

Lintels 16

Brick ties 18

Sliding brick anchors 28

Windposts 30

Bed joint reinforcement 36

Reconstructed or artificial stone 38

Typical wall construction at roof level showing

Halfen brick support system bolted to Pourstop

metal deck and to structural steel. (Wall ties, parapet

windpost and ties to steel studwork also shown.)

Halfen technical helpline: 08705 316300 3

Halfen Brickwork Support Systems

Windposts

Halfen windposts have been specifically

designed to strengthen masonry panels. They

are set out between structural columns, as Coping

shown, and are used at storey height or as

spandrel or parapet posts. Both cavity Parapet post

windposts and blockwork windposts are

available.

Cavity windposts

Cavity windposts can be used without cutting

blockwork and are therefore the preferred Structure

option, where possible. Cavity windposts are

available in 2 profiles:

CW2

CW2 is formed from 4 or 5 mm thick folded

C profile. Ties are normally the hook-on type

Storey-height post

WPT 1, but posts can also be slotted for ties.

CW3

CW3 is formed from 2 CW2 channels welded

back-to-back, providing a stiffer profile. Spandrel post

Blockwork windposts

Blockwork windposts (BW1) are formed from

angle and built into the blockwork inner skin,

as shown. Blockwork windposts are available

in a range of angle sizes. Storey-height post

BW1

Elevation

Normally the angle is folded from 4, 5 or 6 mm

thick plate. Angle dimensions can be selected

from the Halfen standard schedule (page 33), Windpost profiles

or to suit the project detail. Ties for the outer

skin (if required) are the hook-on type WPT 1.

The inner skin ties may be either WPT 3 or

WPT 3PS to suit the slot in the spine.

Materials

Windposts and brick ties are normally

manufactured from Grade 304 stainless steel.

(Grade 316 is also available, if required.)

For dry internal applications hot dip galvanised CW2 CW3 BW1

windposts can be manufactured, but it is

recommended that the ties in the outer skin Windpost ties

are stainless, even if the windpost is hot dip

galvanised.

Dimensions

Typical profile dimensions are given on

page 33, however profiles are manufactured

on a project basis, so any dimensions are

possible. The lengths of windposts are

specified to suit the project requirements. Flange tie Web tie Web tie with plastic sleeves One way web tie

WPT 1 WPT 3 WPT 3 PS WPT 4

30 Halfen technical helpline: 08705 316300

Storey-height windposts (BW1) Storey-height windposts (CW2) with brick pier

Setting-out Posts are positioned in the cavity where The top fixing on storey-height posts is

Relationship to the structure possible, but, if an angle section is needed to normally a sliding fixing to allow for

take the load, the block is cut to allow the deflection, i.e. to prevent the post being

Windposts are set out between the structural

angle to be built into the inner skin. Posts can pinched by the frame.

columns at centres to suit the wind load. In

be fixed to any structure, as shown: concrete

piers it may be necessary to have 2 posts, as

slabs, steel beams or metal deck.

shown below right.

CW2 windpost with WPT 1 ties CW2 windposts with WPT 1 ties

BW1 windpost inner skin bond BW1 windpost inner skin de-bond

WPT 3 tie in inner skin WPT 3 PS tie with plastic sleeve in inner skin

WPT 1 tie in outer skin HTS-C 12 wall ties across cavity

Halfen technical helpline: 08705 316300 31

Halfen Brickwork Support Systems

Windposts fixing details

Windposts are designed and manufactured by

Halfen complete with top or bottom angles or

shoes for fixing to the structure. The detail

varies on a project basis. Typical examples are

shown on this page.

Windposts should be fixed at top and bottom

before brickwork commences.

Loadings

The data tables opposite show a range of

typical windposts with their sectional

properties and maximum allowable loads for

Type BW1 top fixing to concrete Type CW2 top fixing to concrete

various heights of post. Other windposts can

be designed on a project basis.

The maximum loads are restricted either by

the maximum allowable deflection or by a

maximum allowable stress of 175 kN/mm2.

Loading criteria

Storey-height windposts

The windposts are assumed to be simply

supported top and bottom with a uniformly

distributed load acting over the full height of

the windpost. The loads given opposite are

total loads, i.e. udl x post height. The mid-

span deflection is limited to SPAN/360. Type BW1 top fixing to steel Type CW2 top fixing to steel

Spandrel and parapet windposts

The windposts are assumed to be a cantilever

with a horizontal point load acting at the

unsupported end of the post. The deflection

at the unsupported end of the post is limited

to SPAN/180.

The sectional properties of a range of

windposts are given opposite to allow

engineers to calculate allowable loadings for

conditions other than those quoted.

Brick tie loadings

Type BW1 bottom fixing to slab top Type CW2 top fixing to slab edge

Halfen brick ties used with windposts provide

a safe working load of 1.5 kN per tie in

tension and compression. The spacing of the

ties can be determined from the loading data

table, but should not exceed 450 mm centres.

For applications requiring higher loads than

those quoted, solutions are available using

larger profiles and spines, and with increased

sectional properties. Please consult Halfen.

Type BW1 bottom fixing to hollow core slab: Type CW2 bottom fixing to metal deck

example shows resin sock

32 Halfen technical helpline: 08705 316300

Sectional properties and load data tables for windposts

Cavity windpost type CW2/CW3

CW2 CW3

b b

t a a x x

Code axbxt Area Mass Ixx Zxx Maximum load on windpost (kN)

(mm) (cm2) (kg/m) (cm4) (cm3) Storey height posts (m) Spandrel/parapet posts (m)

2.5 3.0 3.5 4.0 0.75 0.90 1.05 1.20

CW2 6544 65 x 40 x 4 5.13 4.05 32.38 9.96 2.21 1.54 1.13 0.86 1.92 1.33 0.98 0.75

CW2 6545 65 x 40 x 5 6.21 4.90 37.43 11.52 2.56 1.77 1.30 1.00 2.22 1.54 1.13 0.87

CW2 8045 80 x 40 x 5 6.96 5.50 62.19 15.55 4.25 2.95 2.17 1.66 3.63 2.56 1.88 1.44

CW3 6584 65 x 80 x 4 10.26 8.11 64.76 19.93 4.42 3.07 2.26 1.73 3.84 2.67 1.96 1.50

CW3 6585 65 x 80 x 5 12.41 9.81 74.87 23.04 5.11 3.55 2.61 2.00 4.44 3.08 2.26 1.73

CW3 8085 80 x 80 x 5 13.93 11.00 124.39 31.10 8.49 5.90 4.33 3.32 7.26 5.12 3.76 2.88

Blockwork windpost type BW1

BW1

a x x

Code axbxt Area Mass Ixx Zxx Maximum load on windpost (kN)

(mm) (cm2) (kg/m) (cm4) (cm3) Storey height posts (m) Spandrel/parapet posts (m)

3.0 3.5 4.0 4.5 0.75 0.90 1.05 1.35

BW1 1254 125 x 70 x 4 7.47 5.90 125.38 15.21 5.94 4.37 3.34 2.64 3.55 2.96 2.53 1.97

BW1 1255 125 x 70 x 5 9.23 7.29 153.60 18.78 7.28 5.35 4.10 3.24 4.38 3.65 3.13 2.43

BW1 1403 140 x 70 x 3 6.11 4.83 130.18 14.24 6.17 4.53 3.47 2.74 3.32 2.77 2.37 1.85

BW1 1406 140 x 70 x 6 11.85 9.36 246.20 27.53 11.67 8.58 6.57 5.19 6.42 5.35 4.59 3.57

BW1 1605 160 x 70 x 5 10.98 8.68 300.53 29.76 13.89 10.47 8.01 6.33 6.94 5.79 4.96 3.86

BW1 1606 160 x 70 x 6 13.05 10.31 354.15 35.32 16.48 12.34 9.44 7.46 8.24 6.87 5.89 4.58

BW1 2006* 200 x 70 x 6 15.45 12.21 650.90 53.52 24.98 21.41 17.36 13.71 12.49 10.41 8.92 6.94

*Example for extreme condition in 140 mm blockwork.

Note: any size can be made to order, i.e. all windposts are made on a project basis.

Halfen technical helpline: 08705 316300 33

Halfen Brickwork Support Systems

Windposts applications

Spandrel Windpost (CW2) Parapet Windpost (BW1)

Windpost below window sill, showing possible horizontal rail bolted to windpost, Windpost below stone coping, showing fixing to cast-in channel ski assembly in floor

and restraint for reconstructed stone sill slab. Also showing Halfen channel 28/15 built into cavity wall to provide total

adjustability for coping ties

Note: cast-in channel ski assembly is effective at minimal edge distance in slab

Dimensioning examples

Normally fixing plates are

designed by Halfen on a

project basis.

w

w w

p p

34 Halfen technical helpline: 08705 316300

How to specify windposts Windpost variations

The following codes are examples only; any

profile requested can be manufactured to suit

the design detail. Posts may be stainless steel

Grade 304 or hot dip galvanised after

manufacture. Ties are always stainless steel

Grade 304. All posts are supplied complete

with welded base fittings; the design will vary

according to fixing type, position and

structure.

For storey-height posts the length will be

made to suit the structure. A suitable sliding

top shoe will be designed by Halfen to

accommodate differential movement; this will

normally be an angle (code AC). 28/15 channel windpost 28/15 channels welded To avoid drilling of steel beams the top fixing of the

with fin for building into back-to-back for building windpost can be made to suit beam clamps to order,

Fixing bolts can be supplied for fixing to either blockwork, Code BW2 into cavity, Code CW1 Code ND AC

cast-in channel or structural steel, or for site-

drilling into concrete. Fixing variation

For spandrels or parapets the post can be

made any length to order, to avoid clashes

with sills or copings.

Windpost complete with welded base and sliding

top shoe

Storey height

BW1 1254 hdg 3300 SF AC

Code Material Length Structure Type of

axt (mm) sliding

top fitting

Windpost complete with welded base

Parapet

CW3 6584 ss 1050 RC

Code Material Length Structure

axbxt (mm)

Windpost ties

WPT 1 ss 70 inner &/or outer skin

WPT 3 ss 200 inner skin

Code Material Projection Brick skins tied

Abbreviations

Dimensions axbxt windpost dimensions

(see page 33)

Top fitting AC angle cleat

Structure RC concrete

SF steel

PS Pourstop

Material/finish hdg hot dip galvanised

ss stainless steel

CW2 windpost fixed to wall plate in timber roof construction

Halfen technical helpline: 08705 316300 35

You might also like

- Beam Truss AnalogyDocument4 pagesBeam Truss AnalogyspamNo ratings yet

- Tower Failures Causes and CuresDocument42 pagesTower Failures Causes and CuresRm1262No ratings yet

- Pinned Base Plate DesignDocument12 pagesPinned Base Plate DesignvtalexNo ratings yet

- Rigid Frames - Compression & Buckling: NotationDocument12 pagesRigid Frames - Compression & Buckling: Notationdarebusi1No ratings yet

- Masonry Design PDFDocument28 pagesMasonry Design PDFnanaamoakoNo ratings yet

- Earthquake Resistant Design and Risk ReductionFrom EverandEarthquake Resistant Design and Risk ReductionRating: 4 out of 5 stars4/5 (1)

- Ba2487 PDFDocument19 pagesBa2487 PDFHazel Liow HYNo ratings yet

- General Electric: Company OverviewDocument5 pagesGeneral Electric: Company OverviewChirag SinghalNo ratings yet

- Aluminum CurtainwallDocument8 pagesAluminum CurtainwallvtalexNo ratings yet

- As ISO 9705-2003 Fire Tests - Full-Scale Room Test For Surface ProductsDocument10 pagesAs ISO 9705-2003 Fire Tests - Full-Scale Room Test For Surface ProductsSAI Global - APACNo ratings yet

- BS 3580 (Strength of Screw Threads)Document24 pagesBS 3580 (Strength of Screw Threads)Arun NagrathNo ratings yet

- CIRIA Restraint WallDocument5 pagesCIRIA Restraint WallMajdoline SadeddineNo ratings yet

- Beam Design 3 (Unrestrained Beam)Document18 pagesBeam Design 3 (Unrestrained Beam)Mike MatshonaNo ratings yet

- 6.3 - Al-S Tower Innovative Design of A 100 Story RC Tower - Eng Arshad - KhanDocument19 pages6.3 - Al-S Tower Innovative Design of A 100 Story RC Tower - Eng Arshad - KhanAnonymous TvM4DyNo ratings yet

- Nema Ics 2 PDFDocument122 pagesNema Ics 2 PDFEslam ElsayedNo ratings yet

- Seismic Response of Wood-Frame Construction: Part B: The Role of Wood-Framed DiaphragmsDocument4 pagesSeismic Response of Wood-Frame Construction: Part B: The Role of Wood-Framed Diaphragmsrmm99rmm99No ratings yet

- Constn Price List January 2011 FinalDocument40 pagesConstn Price List January 2011 FinalBurak BaşNo ratings yet

- Design Concepts For AnchorageDocument6 pagesDesign Concepts For AnchorageChristopher Aaron SiregarNo ratings yet

- Tesco Maintenance Guide PDFDocument136 pagesTesco Maintenance Guide PDFdraghiceanu50% (2)

- Harmer Drainage Price ListDocument144 pagesHarmer Drainage Price ListZuberYousufNo ratings yet

- Reporters: Clemente, John Andrei de Pedro, John Paul Fajardo, Xandra Ale Soriano, AlgernonDocument19 pagesReporters: Clemente, John Andrei de Pedro, John Paul Fajardo, Xandra Ale Soriano, AlgernonJogz de PedroNo ratings yet

- Quikjoint - Eaves Haunch Calculations PDFDocument9 pagesQuikjoint - Eaves Haunch Calculations PDFvtalexNo ratings yet

- Paralleling Generators of Different Makes, Models and ManufacturersDocument3 pagesParalleling Generators of Different Makes, Models and ManufacturersSohail ANo ratings yet

- Journal of Structural Engineering Volume 110 Issue 7 1984 (Doi 10.1061 - (ASCE) 0733-9445 (1984) 110 - 7 (1513) ) Mitchell, Denis Cook, William D. - Preventing Progressive Collapse of Slab STDocument20 pagesJournal of Structural Engineering Volume 110 Issue 7 1984 (Doi 10.1061 - (ASCE) 0733-9445 (1984) 110 - 7 (1513) ) Mitchell, Denis Cook, William D. - Preventing Progressive Collapse of Slab STsteveh2401No ratings yet

- Application & Construction: Simple Free Standing Walls in Clay BrickworkDocument3 pagesApplication & Construction: Simple Free Standing Walls in Clay BrickworkummerdNo ratings yet

- Quick Dashboard in Excel: Service Level Quality ScoreDocument3 pagesQuick Dashboard in Excel: Service Level Quality ScorevtalexNo ratings yet

- HILTI ExBar Rebar Design Soft WareDocument30 pagesHILTI ExBar Rebar Design Soft WareRodrigo Fuente GarcíaNo ratings yet

- Narrative Statement NPP-0050-QENFB Infra Structure & Utility BuildingsDocument16 pagesNarrative Statement NPP-0050-QENFB Infra Structure & Utility BuildingsLokesh KonganapalleNo ratings yet

- Fixed Base Plate ExampleDocument5 pagesFixed Base Plate ExamplevtalexNo ratings yet

- Kaizen TheoryDocument10 pagesKaizen TheoryMOHD.ARISHNo ratings yet

- Axial Load Behavior of Rectangular Concrete Columns Confined With FRP CompositesDocument10 pagesAxial Load Behavior of Rectangular Concrete Columns Confined With FRP CompositesTariqueNo ratings yet

- Lecture 7ADocument32 pagesLecture 7AAnonymous 37iyUV5No ratings yet

- Hybrid Concrete Masonry Design: TEK 14-9ADocument8 pagesHybrid Concrete Masonry Design: TEK 14-9AMega EstructurasNo ratings yet

- TP401 PDFDocument112 pagesTP401 PDFDaniel Tovar Romero50% (2)

- Welding& Inspection WPS& WelderDocument112 pagesWelding& Inspection WPS& WelderNitesh Garg100% (7)

- Anchorage in Concrete Structures: Doctoral ThesisDocument352 pagesAnchorage in Concrete Structures: Doctoral Thesiskeithth12322No ratings yet

- SP 273 15Document18 pagesSP 273 15Žarko LazićNo ratings yet

- Corporate Circular: Bridge Technical Direction Btd2013/01Document2 pagesCorporate Circular: Bridge Technical Direction Btd2013/01scribdarell100% (1)

- Underpinning Solutions of Historical Constructions PDFDocument10 pagesUnderpinning Solutions of Historical Constructions PDFRose Carla GuerrierNo ratings yet

- Connection HCS PDFDocument25 pagesConnection HCS PDFPranay UpadhyayNo ratings yet

- Design of Fibre Reinforced Concrete Beams and SlabsDocument128 pagesDesign of Fibre Reinforced Concrete Beams and SlabsMisterphylNo ratings yet

- CCL PT Slabs Brochure Eng PDFDocument15 pagesCCL PT Slabs Brochure Eng PDFSharad BornarkarNo ratings yet

- Series 1600 PDFDocument49 pagesSeries 1600 PDFDavidNo ratings yet

- ETCulvert V2 Brochure Web PDFDocument2 pagesETCulvert V2 Brochure Web PDFjorgesalinasengNo ratings yet

- ASCE 7-22 CH 18 - For PC - SouDocument57 pagesASCE 7-22 CH 18 - For PC - SousharethefilesNo ratings yet

- Design of Partially Prestressed Concrete Beams Based On The CrackingDocument15 pagesDesign of Partially Prestressed Concrete Beams Based On The Crackingamino222No ratings yet

- Comparison of One-And Two-Way Slab Minimum Thickness Provisions in Building Codes and StandardsDocument7 pagesComparison of One-And Two-Way Slab Minimum Thickness Provisions in Building Codes and StandardsM Refaat FathNo ratings yet

- Punching ShearDocument7 pagesPunching SheardagetzNo ratings yet

- 䕔䵁吠䕂 - 14M CURVED POLE FATIGUE CHECKDocument38 pages䕔䵁吠䕂 - 14M CURVED POLE FATIGUE CHECKanammominNo ratings yet

- Super 456Document70 pagesSuper 456Alem LoajnerNo ratings yet

- 2000 IBC Handbook Seismic Wind PDFDocument9 pages2000 IBC Handbook Seismic Wind PDFAnonymous xC6bM4x6U6No ratings yet

- EN - 1993-1-1 (2022) - (E) - CópiaDocument9 pagesEN - 1993-1-1 (2022) - (E) - CópiaHugNitNo ratings yet

- AD 263 - Limitations of Bolt Grades To BS 5950-1 and Eurocode 3Document1 pageAD 263 - Limitations of Bolt Grades To BS 5950-1 and Eurocode 3symon ellimacNo ratings yet

- Furche - Bauermeister - Highly Effective Punching Shear Reinforcement For Semi Precast Slabs - Cic2014 OsloDocument10 pagesFurche - Bauermeister - Highly Effective Punching Shear Reinforcement For Semi Precast Slabs - Cic2014 Oslop.c19.22No ratings yet

- 10 Ribbed Slab DesignDocument32 pages10 Ribbed Slab DesignSarah HaiderNo ratings yet

- The Network ArchDocument136 pagesThe Network ArchNG ManMolNo ratings yet

- Chapter 5 Concrete StructuresDocument432 pagesChapter 5 Concrete StructuresrizwanNo ratings yet

- Eurocode 7 Geotechnical Limit AnalysisDocument19 pagesEurocode 7 Geotechnical Limit AnalysisPurdiansyahNo ratings yet

- Connections For Skewed BeamsDocument7 pagesConnections For Skewed BeamstrabajosicNo ratings yet

- Analysis and Design of Inclined ColumnsDocument6 pagesAnalysis and Design of Inclined ColumnsMouhamad WehbeNo ratings yet

- Development of Column Interaction Curves For Higher Grades of ConcreteDocument22 pagesDevelopment of Column Interaction Curves For Higher Grades of Concreteyedida v r aviswanadhNo ratings yet

- Analysis Anda Design Pre Stressd SleepersDocument25 pagesAnalysis Anda Design Pre Stressd SleeperspoezpietaNo ratings yet

- Significant Changes in ACI 318-19Document72 pagesSignificant Changes in ACI 318-19Dana PomaresNo ratings yet

- Ac I DiaphragmDocument10 pagesAc I DiaphragmBintaZoelviaNo ratings yet

- Tying Resistance of A Fin Plate ConnectionDocument9 pagesTying Resistance of A Fin Plate ConnectionSam Samoura0% (1)

- Failure of Structures: by Ir. Tee Horng Hean, B.Eng. (Hons), MSC (Eng.), Mba, M.I.E.MDocument7 pagesFailure of Structures: by Ir. Tee Horng Hean, B.Eng. (Hons), MSC (Eng.), Mba, M.I.E.MRajarshi ChakrabortyNo ratings yet

- Dynamic Set For Shear Resistance UpgradeDocument2 pagesDynamic Set For Shear Resistance Upgradehessian123No ratings yet

- Hilti White Paper - FinalDocument7 pagesHilti White Paper - Finalnoodlehead675No ratings yet

- AISI S230-12-E1Document2 pagesAISI S230-12-E1Jon JacobsNo ratings yet

- Behavior of Corbels With External Prestressing Bars Experimental Study - Nagrodzka Godycka PDFDocument21 pagesBehavior of Corbels With External Prestressing Bars Experimental Study - Nagrodzka Godycka PDFRômulo Menck RomanichenNo ratings yet

- Advanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionFrom EverandAdvanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionNo ratings yet

- Kec Metro ReactionsDocument157 pagesKec Metro ReactionsvtalexNo ratings yet

- Scia Engineer - Load Generators en 2Document3 pagesScia Engineer - Load Generators en 2vtalexNo ratings yet

- Finkster-Python CheatsheetDocument11 pagesFinkster-Python CheatsheetvtalexNo ratings yet

- Purlin Bracing CriteriaDocument19 pagesPurlin Bracing CriteriavtalexNo ratings yet

- Interpolation - MathDocument1 pageInterpolation - MathvtalexNo ratings yet

- Commentary: Standards Secondary and Structural Girts Practices DesignDocument2 pagesCommentary: Standards Secondary and Structural Girts Practices DesignvtalexNo ratings yet

- Pinned Base PlateDocument7 pagesPinned Base PlatevtalexNo ratings yet

- Purlin Bracing CriteriaDocument19 pagesPurlin Bracing CriteriavtalexNo ratings yet

- DM04 04 PDFDocument16 pagesDM04 04 PDFvtalexNo ratings yet

- TNEB Online Payment ReceiptDocument1 pageTNEB Online Payment Receiptvtalex0% (1)

- Doha Festival CIty Aug 16 Rev. 1Document6 pagesDoha Festival CIty Aug 16 Rev. 1vtalexNo ratings yet

- Quikjoint - ResultsDocument15 pagesQuikjoint - ResultsvtalexNo ratings yet

- Calculation Headline: Roof GeometryDocument2 pagesCalculation Headline: Roof GeometryvtalexNo ratings yet

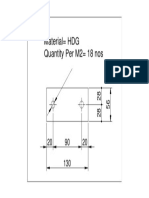

- Material HDG Quantity Per M2 18 NosDocument1 pageMaterial HDG Quantity Per M2 18 NosvtalexNo ratings yet

- A1 60 Stone CladdingDocument1 pageA1 60 Stone CladdingvtalexNo ratings yet

- Hilti - Pull Out Test Report-SampleDocument3 pagesHilti - Pull Out Test Report-SamplevtalexNo ratings yet

- TD For Workflow Purging ProcessDocument5 pagesTD For Workflow Purging ProcessGoogle Support TeamNo ratings yet

- CAM Lab Manual Expereiment - 10-13 - CAMDocument9 pagesCAM Lab Manual Expereiment - 10-13 - CAMmilanmottaNo ratings yet

- 3698 8a2fgDocument3 pages3698 8a2fgJampaNo ratings yet

- MRFDocument11 pagesMRFRohit Gunwani0% (1)

- Shell Omala BrochureDocument2 pagesShell Omala BrochurehuseynseymenNo ratings yet

- Testing Brush UpDocument20 pagesTesting Brush UpsrimkbNo ratings yet

- HP Man ITGk-V5.0userguides-Usingworkbench PDFDocument68 pagesHP Man ITGk-V5.0userguides-Usingworkbench PDFutkarsh_m83No ratings yet

- SQL ServerDocument22 pagesSQL ServerLuis Eduardo Canedo TorresNo ratings yet

- Transportation Code Chapter OneDocument27 pagesTransportation Code Chapter OneKimiko SyNo ratings yet

- Nkumba University BrochureDocument2 pagesNkumba University BrochureApo100% (3)

- Optional Service Bulletin OSB 42-134/1 OSB 42NG-073/1: I Technical DetailsDocument7 pagesOptional Service Bulletin OSB 42-134/1 OSB 42NG-073/1: I Technical DetailsSameer KshitizNo ratings yet

- Cie1 17CS653 or QPDocument2 pagesCie1 17CS653 or QPPratheeksha RaiNo ratings yet

- BCI Castings & Forgings, FinalDocument24 pagesBCI Castings & Forgings, FinalbranthamNo ratings yet

- 3457a SVCDocument191 pages3457a SVCDragan LazicNo ratings yet

- CatalogDocument100 pagesCatalogFrancis Lebel100% (1)

- Compressible Potential FlowDocument15 pagesCompressible Potential FlowChanoNo ratings yet

- Wasser enDocument26 pagesWasser enjalilemadiNo ratings yet

- Tips and Hints For Sharing Data PDFDocument5 pagesTips and Hints For Sharing Data PDFMadhuri MalayathiNo ratings yet

- Inventory Management SystemDocument5 pagesInventory Management SystemSwapnil ChaudhariNo ratings yet

- ASTM C627 Robinson TestDocument4 pagesASTM C627 Robinson TestSiu Hei LauNo ratings yet

- Master Scheduling Chapter 1Document19 pagesMaster Scheduling Chapter 1Bosco GodfreyNo ratings yet