Professional Documents

Culture Documents

Transport Adores Rastras

Uploaded by

Paul CochonCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Transport Adores Rastras

Uploaded by

Paul CochonCopyright:

Available Formats

Drag Conveyors

+ Heavy-gauge, galvanized steel construction

ensures Sukup Drag Conveyors will last for

years to come.

+ Dust-proof and weather-tight covers.

+ Shaft, sprocket and bearings can be removed

as one piece.

+ UHMW flights prevent steel-to-steel

contact.

Sukup Manufacturing Co. n www.sukup.com

Box 677 n 1555 255th St. n Sheffield, IA 50475-0677 n Phone: 641-892-4222

Fax: 641-892-4629 n Email: info@sukup.com

Six Distribution Arcola, IL 61910 Aurora, NE 68818 Defiance, OH 43512 Jonesboro, AR 72403 Cameron, MO 64429 Watertown, SD 57201

Centers 980 E. State Rd. 1705 Hwy. 34 E. 7724 Rte. 66 N. 5917 E. Johnson Ave. 7426 NE 352nd St. 2701 Piper Ave.

To Serve You Phone: 217-268-3026 Phone: 402-694-5922 Phone: 419-784-9871 Phone: 870-932-7547 Phone: 816-649-2226 Phone: 605-882-6697

Better Fax: 217-268-3522 Fax: 402-694-5921 Fax: 419-784-9872 Fax: 870-933-8946 Fax: 816-649-2225 Fax: 605-884-0467

L1192-032009S

Drag Conveyor Specifications

Conveyor Speed

Model Width Depth 100 ft/min. 125 ft/min. 150 ft/min. 180 ft/min.

1209 12 9 1875 2343 2812 3375

1213 13 3594 4493 5391 6470

1217 17 4705 5881 7058 8470

1609 16 9 3350 4187 5025 6030

1613 13 4741 5927 7112 8535

1617 17 6208 7760 9312 11,175

2109 21 9 4261 5326 6391 7670

2113 13 6036 7545 9054 10,865

2117 17 7902 9877 11,853 14,224

* Capacities bu/hr. based on 45 lbs./ft.

Sukup Manufacturing Co provides the information contained within this brochure to assist you in choosing the optimal equipment for your situation. Many factors, such as

grain variety, maturity levels, grain cleanliness, weather conditions and operation/management, can affect the performance of your equipment and results may vary. This

information is calculated and is not a guarantee of product specifications or performance. Based on these factors, Sukup specifications should only be used as estimates, and

not as a warranty, express or implied, of how a particular Sukup unit will perform under your operating conditions. Because we are continually improving Sukup products,

changes may occur that may not be reflected in the specifications.

Standard Features Head & Tail Sections

+ Galvanized construction for long life. + Head shafts are turned, ground and

+ 10 gauge housings are standard. polished.

+ Bolted, removable bottom construction. + Shaft seals are 1/4 thick UHMW.

+ Roller chain is engineered for each conveyor to + Extended mount flange bearings on 9 tall

maximize working load and prolong system life. conveyors.

+ UHMW flights prevent steel-to-steel contact. + External mount pillow block bearings on 13

+ UHMW return rollers std. - return rails optional. and 17 tall conveyors.

+ Flame cut, hardened steel sprockets.

+ Shaft, sprocket and bearings can be easily

removed as one piece.

+ End relief door with limit switch is optional.

+ ACME threaded screws are used in the chain

tension take-up system.

Options

+ Abrasion-resistant liners and bottoms.

+ By-pass inlets with drive-over grating

+ Drive-over dump hopper with drive-over

grating

+ Bend sections

+ Reversing feature

+ Intermediate discharge gates (manual,

electric, pneumatic)

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Fire Sprinkler System Testing FormDocument2 pagesFire Sprinkler System Testing FormDaniel Flores100% (1)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 4 Stroke Shift Kit Installation InstructionsDocument15 pages4 Stroke Shift Kit Installation InstructionsJ. RussellNo ratings yet

- Automated Cleveland Open Cup Flash Point Tester Model Aco-8/aco-8 As Instruction ManualDocument59 pagesAutomated Cleveland Open Cup Flash Point Tester Model Aco-8/aco-8 As Instruction ManualAbdellah BenadlaNo ratings yet

- SP 1109 1 Earthing and Bonding (ERD 64 10) 2Document45 pagesSP 1109 1 Earthing and Bonding (ERD 64 10) 2RaghuNo ratings yet

- Windows7 PC 2Document5 pagesWindows7 PC 2Okezi AkpokeneNo ratings yet

- Transmission Control DeviceDocument3 pagesTransmission Control DeviceAnton FortovNo ratings yet

- GSK ZJY Spindle Motor Manual Efamatic 1Document31 pagesGSK ZJY Spindle Motor Manual Efamatic 1rayss1978No ratings yet

- Greengate PSG FWBDocument216 pagesGreengate PSG FWBJorge O. OrozcoNo ratings yet

- Manual PLC ZelioDocument16 pagesManual PLC ZelioAlexander FelizNo ratings yet

- Intern at UtcDocument22 pagesIntern at Utcajadrana1100% (1)

- Polaris 180 Repair ManualDocument40 pagesPolaris 180 Repair ManualPool Supply Sales100% (2)

- (SENR3981-03) Systems Operation - Fluid Power and Electrical Symbols - Electrical Power Graphic SymbolsDocument6 pages(SENR3981-03) Systems Operation - Fluid Power and Electrical Symbols - Electrical Power Graphic SymbolsEdin raul Yalle rafaelNo ratings yet

- Bose+Lifestyle+Sa 2+&+sa 3+amplifierDocument27 pagesBose+Lifestyle+Sa 2+&+sa 3+amplifierWalter CzyzyniewskiNo ratings yet

- Juk LH-3128-7 3128Document48 pagesJuk LH-3128-7 3128RHoska100% (1)

- Masterplug Catalogue PDFDocument140 pagesMasterplug Catalogue PDFjdcarnNo ratings yet

- Partlist GX8250-GX6750-AX475-SX4000 PDFDocument28 pagesPartlist GX8250-GX6750-AX475-SX4000 PDFrina ordonoNo ratings yet

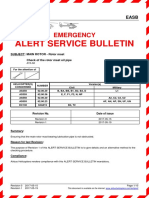

- Alert Service Bulletin: EmergencyDocument13 pagesAlert Service Bulletin: EmergencyRaymond ZamoraNo ratings yet

- Categorisation of DefectsDocument231 pagesCategorisation of DefectsSimon CooperNo ratings yet

- Tech Manual: Tech-5.12 10M Ec Combi Large SHRDocument260 pagesTech Manual: Tech-5.12 10M Ec Combi Large SHROvRrj AhmedNo ratings yet

- Spare Parts Catalogue: AXLE 26.18 - (CM9603) REF: 641902Document8 pagesSpare Parts Catalogue: AXLE 26.18 - (CM9603) REF: 641902SergeyNo ratings yet

- Air Compressor CP9149-05Document5 pagesAir Compressor CP9149-05Andrés RuizNo ratings yet

- Cat Telehandler Th360b Service ManualDocument20 pagesCat Telehandler Th360b Service Manualjoyce100% (48)

- AP1050BDocument2 pagesAP1050BAlex San TanaNo ratings yet

- Pages From Kubota Z602 Sme3b SeriesDocument1 pagePages From Kubota Z602 Sme3b SeriesrickescherNo ratings yet

- Quad Patriot 100Document32 pagesQuad Patriot 100rocco007No ratings yet

- Datasheet PDFDocument8 pagesDatasheet PDFSaad LehlouNo ratings yet

- Caterpillar Cat 336E L Excavator (Prefix JRJ) Service Repair Manual (JRJ00001 and Up)Document27 pagesCaterpillar Cat 336E L Excavator (Prefix JRJ) Service Repair Manual (JRJ00001 and Up)kfsmmeNo ratings yet

- F21aau4 8 PDFDocument34 pagesF21aau4 8 PDFjhfbty100% (1)

- Hydro-Mast Weight Indicator System: Service ManualDocument64 pagesHydro-Mast Weight Indicator System: Service ManualAbdallah Elhendy100% (1)