Professional Documents

Culture Documents

A10 A Pid Va 449162 001 - 01a

Uploaded by

zhangOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

A10 A Pid Va 449162 001 - 01a

Uploaded by

zhangCopyright:

Available Formats

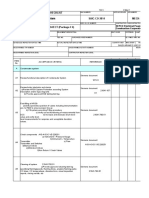

GENERAL NOTES ABBREVIATIONS FLUID CODES - LINE SERVICE NOTES:

1. FOR GENERAL NOTES, SYMBOLS AND DETAILS SEE DRAWING

A AIR / COMBUSTION AIR HCD HYDROGEN CLOSED DRAIN PCS POTENTIALLY CONTAMINATED SEWER A10-A-PID-VA-449162-001 THRU A10-A-PID-VA-449165-005.

1. ALL VENTS AND DRAINS SHOWN BY THE FOLLOWING SYMBOLS REPRESENT A VENT OR DRAIN GA1 VALVE.

EXCEPT AS NOTED. SEE SAUDI ARAMCO STANDARD DRAWING AC-036045 FOR SIZING THE DRAIN NOZZLES. AOV AIR OPERATED VALVE LLL LOW LIQUID LEVEL ACD AROMATICS CLOSED DRAIN HCL HYDROCHLORIC ACID PE POND EFFLUENT

VENT NOZZLES TO BE SIZED ACCORDINGLY WITH DRAIN SIZE.

ATM ATMOSPHERE LLLL LOW LOW LIQUID LEVEL AG ACID GAS HFW HIGH PRESSURE BFW PG PROCESS GAS

VENT/DRAIN BL BATTERY LIMIT LO LOCKED OPEN AH ACID HYDROCARBON HHC HIGH HIGH PRESSURE STEAM CONDENSATE PO PUMP OUT

VENT/DRAIN

WITH PLUG AML AMMONIA LIQUID HHS HIGH HIGH PRESSURE STEAM POC POTENTIALLY CONTAMINATED SEWER

BOP BOTTOM OF PIPE LOP LOCAL OPERATOR PANEL

AMV AMMONIA VAPOR HO HYDRAULIC OIL / CONTROL OIL PT PUMP TRIMS

ALL VENTS AND DRAINS SHOWN BY THE FOLLOWING SYMBOLS REPRESENT ONE 3/4" THREADED BY CCB CENTER CONTROL BUILDING LP LOW PRESSURE

AS ACID SEWER HPC HIGH PRESSURE STEAM CONDENSATE PTG PILOT GAS

SOCKETWELD VALVE, AND ONE SOCKETWELD BY SOCKETWELD VALVE, EXCEPT AS NOTED.

CL CENTERLINE MAG MAGNETIC (LEVEL GAUGE) BBD BOILER BLOWDOWN HPF HP FLARE PW PROCESS WATER

CP COKE PIT MAX MAXIMUM BCW BURNER COOLING WATER HPN HIGH PRESSURE NITROGEN R REFRIGERANTS

VENT/DRAIN

BD BLOWDOWN HPO HIGH PRESSURE OXYGEN RAM RICH AMINE

WITH PLUG CSC CAR SEALED CLOSE MCC MOTOR CONTROL CENTER

BFW BOILER FEED WATER HPS HIGH PRESSURE STEAM RL RELIEF LINE

CSO CAR SEALED OPEN MCP MARSHALLING CONTROL PANEL

BRN BRINE HRH HOT REHEAT STEAM RLC COLD RELIEF LINE

2. ALL VALVED CONNECTIONS TO ATMOSPHERE IN PROCESS SERVICE WILL BE PLUGGED OR BLIND FLANGED.

D DRAIN MIN MINIMUM BS BIO-SLUDGE HSF HIGH SULFUR FUEL OIL RLW WARM RELIEF LINE

DCS DISTRIBUTED CONTROL SYSTEM MOV MOTOR OPERATED VALVE C CHEMICAL HSG HYDROGEN SULFIDE GAS ROG REFINERY OFF-GAS

3. HIGH POINT VENTS AND LOW POINT DRAINS USED FOR HYDROTEST PURPOSES ONLY ARE PROVIDED BUT

ARE NOT SHOWN ON THE FLOW SHEETS FOR PIPING, EXCHANGERS AND ROTARY EQUIPMENT. DIA DIAMETER MP MEDIUM PRESSURE CA CAUSTIC IA INSTRUMENT AIR RW RAW WATER

CAS CAUSTIC SEWER IPC INTERMEDIATE PRESSURE STEAM CONDENSATE SA SULFURIC ACID

4. FOR GENERAL PIPING REQUIREMENTS SEE SAES-L-105 FOR MORE INFORMATION. DISP DISPLACER MW MANWAY

CAT CATALYST IPS INTERMEDIATE PRESSURE STEAM SC STEAM CONDENSATE

5. DEFINITIONS: DP DIFFERENTIAL PRESSURE NA ANNUNCIATOR

CCC COOLED CLEAN CONDENSATE LAM LEAN AMINE SCA SPENT CAUSTIC

DSP DRUM STEAM PRESSURE NIL NORMAL INTERFACE LEVEL CD CARBON DIOXIDE LCO LOW PRESSURE CO2 SF SULFUR

GRAVITY FLOW ELEVATIONS DOWNSTREAM NEVER EXCEED INLET ELEVATIONS.

LINE MAY CONTAIN POCKETS. EIV EMERGENCY ISOLATION VALVE NLL NORMAL LIQUID LEVEL CHR CHILLED WATER RETURN LFW LOW PRESSURE BFW SG SYNGAS

CHS CHILLED WATER SUPPLY LIN LIQUID NITROGEN SGH HIGH PRESSURE SYNGAS

ESD EMERGENCY SHUTDOWN SYSTEM ORP OXIDATION REDUCTION POTENIAL

SLOPE ELEVATIONS CHANGES ARE CONSTANTLY DOWNWARD ONLY. NO POCKETS ARE CNW DIRECT CONTACT CONDENSED WATER LLN LOW LOW PRESSURE NITROGEN SGL LOW PRESSURE SYNGAS

PERMITTED. SPECIFIC SLOPES REQUIRED ARE SHOWN BY SYMBOLS. F FIELD LOCATION OSBL OUTSIDE BATTERY LIMIT

COC CONTINUOUSLY OIL CONTAMINATED LO LUBE OIL SGW SOUR GAS (SO2) WATER

FC FAIL CLOSED PLC PROGRAMMABLE LOGIC CONTROLLER

CRH COLD REHEAT STEAM LOX LIQUID OXYGEN SO SEAL OIL

LEGEND

FF FOUNDATION FIELDBUS PV PROCESS VARIABLE CRO CRUDE OIL LPC LOW PRESSURE STEAM CONDENSATE SOG SULFUR DIOXIDE GAS

PIPING MATERIAL INSTRUMENT DEFINITION & SYMBOLS SAES-J-004

I CS CHEMICAL SEWER LPF LP FLARE SOT SOOT WATER SPECIFICATION SAES-L-105

FI FAIL INTERMEDIA PX PRESSURE POINT AC/AFO -AIR TO CLOSE/ VE -VIBRATION ELEMENT

AIR FAILURE OPEN VS -VIBRATION SWITCH

CSW CLEAN STORM WATER LPG LIQUEFIED PETROLEUM GAS SOW SOUR WATER AC/AFS -AIR TO CLOSE/AIR

FL FAIL LAST R REFLEX LEVEL GAUGE PROCESS LINE VT -VIBRATION TRANSMITTER

FAILURE STEADY XL -PILOT LIGHT

CW CHILLED WATER LPN LOW PRESSURE NITROGEN SPO SLOP OIL

X INSTRUMENT AO/AFC -AIR TO OPEN/ (NOT FOR MOTOR)

FLC FAIL LOCKED VALVE CLOSES ON DECREASING CONTROL RADAR LEVEL RADAR AIR FAILURE CLOSE

CWR CLOSED COOLING WATER RETURN LPO LOW PRESSURE OXYGEN SR SEWER (STORM) AIR LINE XS -LIMIT SWITCH

AO/AFS -AIR TO OPEN/AIR ZV -SAFETY SHUTDOWN VALVE

FLM FLOW METER RCP REMOTE CONTROL PANEL INSTRUMENT

CWS CLOSED COOLING WATER SUPPLY LPS LOW PRESSURE STEAM STM STEAM (MISCELLANEOUS) FAILURE STEADY

WHERE X HAS UNITS THE SAME AS I. ELECTRICAL LINE DATA LOGGER POINT

AOV -AIR OPERATED VALVE

FLO FAIL LOCKED VALVE OPENS ON DECREASING CONTROL RS REMOVABEL SPOOL DMW DEMINERALIZED WATER MDA METHYL-DI-ETHANOL-AMINE SW SALT WATER / SEA WATER F-FLOW P-PRESS.

INPUTS

AT -ANALYZER TRANSMITTER

L-LEVEL T-TEMP.

DT -DENSITY TRANSMITTER

THIS DRAWING AND THE INFORMATION CONTAINED HEREIN ARE THE SOLE PROPERTY OF SAUDI ARAMCO. NO REPRODUCTION IN FULL, OR IN PART, SHALL BE OBTAINED FROM THIS DRAWING WITHOUT THE WRITTEN CONSENT OF SAUDI ARAMCO.

DSW DESALINATED WATER ME METHANOL SWS SANITARY WASTE WATER X-MISC. A-ALARM

FO FAIL OPEN RTD RESIS. TEMP. DETECTOR REDUCER ESD -EMER. SHUTDOWN SYSTEM

LOCAL PANEL

FREE DRAINING ELEVATION CHANGES ARE DOWNWARD ONLY. NO POCKETS ARE PERMITTED. DT DUCT TRIMS MO MIST OIL TG TAIL GAS FC - FLOW CONTROLLER

MOUNTED INSTR.

SPECTACLE FV -FLOW CONTROL VALVE

FP FULL PORT SC SAMPLE CONNECTION PLATE-OPEN

DW DRINKING WATER MPC MEDIUM PRESSURE STEAM CONDENSATE TPW TEMPERED WATER FCV -FLOW CONTROL VALVE

BOARD MOUNTED

NO POCKETS NO LIQUID POCKETS IN THE LINE. WHEN NECESSARY TO PREVENT VAPOR (SELF-ACTUATED) INSTRUMENT

POCKETS. THE NOTE WILL READ NO VAPOR POCKETS. FSP FRACTIONATOR STEAM PRESSURE SIS SAFETY INSTRUMENTED SYSTEM SPECTACLE

E EXHAUST STEAM MPN MEDIUM PRESSURE NITROGEN TW TREATED WATER PLATE-CLOSED

FE -FLOW ELEMENT

R/G

FG -FLOW SIGHT GLASS

STATUS LIGHTS

FV FULL VACUUM SO STEAM OUT EIA EMERGENCY INSTRUMENT AIR MPO MEDIUM PRESSURE OXYGEN UA UTILITY AIR GATE VALVE FHV -FLOW MANUAL CONT. VALVE XL R=RED, G=GREEN

FHTD -FLOW MANUAL TRANSDUCER PILOT LIGHT (DO NOT

GWR GUIDED WAVE RADAR SP SET POINT EXG EXHAUST / FLUE / STACK GAS MPS MEDIUM PRESSURE STEAM UW UTILITY WATER GLOBE VALVE FIC -FLOW INDICATOR CONTROLLER USE FOR MOTOR STATUS)

6. INLET LEADS TO PRESSURE RELIEF DEVICES EXCEEDING 15M IN LENGTH OR HAVING MORE THAN FAG ACID GAS FLARE VFW VERY HIGH PRESSURE BFW CHECK VALVE FM -FLOW METER

TWO ELBOWS UNLESS OTHERWISE NOTED, MUST BE APPROVED BY PROCESS ENGINEERING/PMT. HHLL HIGH HIGH LIQUID LEVEL SRA SYSTEM ROUTING APPROVAL MAIN STEAM-VERY HIGH PRESSURE RO -RESTRICTION ORIFICE MOTOR STATUS

MS PILOT LIGHT

FG FUEL GAS SUPERHEATED STEAM VG VENT GAS PLUG VALVE FQI -FLOW TOTALIZER INDICATOR

FR -FLOW RECORDER

7. ALL CLOSED PRESSURE RELIEF VALVE DISCHARGE LEADS SHALL BE FREE DRAINING FROM THE PRESSURE HIL HIGH INTERFACE LEVEL STOP/LO STOP/LOCKOUT (MOTOR CONTROL) BALL VALVE ML LOCAL MOUNTED

RELIEF VALVE TO THE TOP OF THE DISCHARGE HEADER. EACH LEAD IS TO BE CHECKED FOR A DOWNWARD FGH HIGH PRESSURE FUEL GAS N NITROGEN VPC VERY HIGH PRESSURE CONDENSATE FT -FLOW TRANSMITTER INSTRUMENT

DOUBLE DISC FY -FLOW RELAY

SLOPE AFTER CONSTRUCTION. HLL HIGH LIQUID LEVEL T TRANSPARENT LEVEL GAUGE FGL LOW PRESSURE FUEL GAS NG NATURAL GAS VPS VERY HIGH PRESSURE STEAM GATE VALVE -HAND INDICATOR CONTROLLER

HIC MOUNTED BEHIND

ANGLE VALVE HS -HAND SWITCH LOCAL PANEL

8. ALL PRESSURE RELIEF VALVES DISCHARGING TO ATMOSPHERE AT SAFE LOCATION SHALL CONFORM TO HP HIGH PRESSURE TL TANGENT LINE FLO FLUSHING OIL OS OILY SLUDGE VR VACUUM RESID LA -LEVEL ALARM

SAES-J-600 SECTION 9.7.5 PRESS. RELIEF VALVE LV -LEVEL CONTROL VALVE RACK MOUNTED

HV 50% FULL VACUUM TOP TOP OF PIPE FO FUEL OIL OW OILY WATER VS VENT STEAM LCV -LEVEL CONTROL VALVE (OR BACK OF PANEL)

9. FOR UNSPARED PRESSURE RELIEVING DEVICES. WHEN AN INLET BLOCK VALVE IS PROVIDED BETWEEN (SELF-ACTUATED)

FTT FILTRATE OWS OILY WATER SEWER VT VESSEL TRIM

A VESSEL AND ITS PRESSURE RELIEVING DEVICE OR WHEN A DISCHARGE BLOCK VALVE IS PROVIDED INT INTEGRAL TSO TIGHT SHUTOFF LG -LEVEL GAUGE GLASS ELECTRICAL

FW FIRE WATER P OIL & OIL PRODUCTS W WATER LIC -LEVEL INDICATOR CONTROLLER SUPPLY REQUIRED

BETWEEN A PRESSURE RELIEVING DEVICE AND A COMMON DISCHARGE HEADER. THE BLOCK VALVE SHALL VACUUM RELIEF VALVE

LI -LEVEL INDICATOR

BE ARRANGED SO THAT IT CAN BE LOCKED OR SEALED OPEN. ADMINISTRATIVE PROCEDURES SHALL INTH INTER HIGH LEVEL T/T TANGENT TO TANGENT

GLW GLYCOL WATER PA PROCESS AIR WAW WASH WATER LR -LEVEL RECORDER INSTRUMENT

INSURE THAT THE BLOCK VALVE WILL NOT BE CLOSED WHILE THE VESSLE IS IN OPERATION EXCEPT M LS -LEVEL SWITCH AIR SUPPLY REQUIRED

BY AN AUTHORIZED PERSON WHO SHALL REMAIN STATIONED THERE DURING THE VESSLE'S OPERATION INTL INTER LOW LEVEL TYP TYPICAL MOTOR OPERATED

H HYDROGEN PC PROCESS CONDENSATE WW WASTEWATER VALVE LT -LEVEL TRANSMITTER

H

AND WHO SHALL AGAIN LOCK OR SEAL THE BLOCK VALVE OPEN BEFORE LEAVING. UNDER NO CONDITION LTD -LEVEL TRANSDUCER HIGH LOW

SHALL A DISCHARGE BLOCK VALVE BE CLOSED. WHILE THE VESSLE IS IN OPERATION. BEFORE THE ISBL INSIDE BATTERY LIMIT UC UTILITY CONNECTION ML -MOTOR STATUS LIGHT L

INLET BLOCK VALVE IS CLOSED.(REFER TO ASME PRESSURE VESSLE CODE SECTION VIII, DIVISION 1, P MOV -MOTOR OPERATED VALVE

APPENDIX M AND ASME PRESSURE VESSLE CODE SECTION VIII, DIVISION 2, ARTICLE AR.) LC LOCKED CLOSED VAC VACUUM PISTON OPERATED NA -ANNUNCIATOR TWO PEN RECORDER

VALVE PB -PUSHBUTTON

LCP LOCAL CONTROL PANEL VB VORTEX BRAKER PC -PRESSURE CONTROLLER FF

CONTROL VALVE PV -PRESS. CONTROL VALVE FOUNDATION

PCV -PRESS. CONTROL VALVE FIELDBUS INSTRUMENT

LIL LOW INTERFACE LEVEL V VENT LINE NOMENCLATURE (SELF ACTUATED)

10. UNLESS OTHERWISE SPECIFIED BY A LICENSOR, WHEN PIPE STRAINERS ARE INDICATED, BALL TYPE PDC -PRESS. DIFF. CONTROLLER DISTRIBUTED CONTROL/SHARED

P

THE STRAINER BODY, SCREEN AND SIZE OF OPENINGS ARE AS SPECIFIED BY SAUDI ARAMCO EW EYE WASH UNIT ZIC RESET. CLOSE AND OPEN ACTION CONTROL VALVE PDI -PRESS. DIFF. INDICATOR DISPLAY SYMBOLS

SPECIFICATION 01-SAMSS-Y40. AS PER SAES-A-202 (MODIFIED), PIPING TAG NUMBERS SHALL HAVE THE FOLLOWING FORMAT. WITH POSITIONER PDIC -PRESSURE DIFFERENTIAL

(DCS) DISTRIBUTED CONTROL

ES EMERGENCY SHOWER UNIT ZIK SAFETY CONTROL STATION S INDICATOR CONTROLLER SYSTEM, OPERATOR ACCESSIBLE

11. 6mm WEEP HOLES ARE PROVIDED AT LOW POINTS OF RUPTURE DISK DISCHARGE LINES TO SOLENOID VALVE PDIS -PRESSURE DIFFERENTIAL IN CONTROL ROOM

ATMOSPHERE. FB FULL BORE INDICATOR SWITCH (DCS) DISTRIBUTED CONTROL

PDT -PRESS. DIFF. TRANSMITTER

VALVE NORMALLY SYSTEM, OPERATOR INACCESSIBLE

12. REDUCERS IN PRESSURE RELIEF VAVLE INLET OR OUTLET PIPING SHALL BE MINIMUM DISTANCE PDTD -PRESS. DIFF. TRANSDUCER IN CONTROL ROOM

CLOSED

PG -PRESSURE GAGE

FROM THE PRESSURE RELIEF VALVES. (DCS) DISTRIBUTED CONTROL

PI -PRESSURE INDICATOR

SYSTEM, OPERATOR INACCESSIBLE

PIC -PRESS. INDICATOR CONTROLLER

13. DOCUMENTED ADMINSTRATIVE PROCEDURES SHALL ENSURE THAT WHENEVER SELECTIED EQUIPMENT SERVICE CODE SEQUENCE NUMBER PR -PRESSURE RECORDER

IN FIELD

ITEMS (FOR EXAMPLE. EXCHANGERS OR FILTERS) ARE ISOLATED FOR MAINTENANCE, THEY SHALL BE 1 TO 3 CHARACTER ALPHANUMERIC CODE FOR THE FLUID 5 DIGIT NUMBER. FOR EACH LINE WITHIN A UNIT, PS -PRESSURE SWITCH

VENTED AND DRAINED IMMEDIATELY. CARRIED BY THE PIPE OUT FOR 5 DIGIT SEQUENCE NUMBER, FIRST 2 DIGITS PT -PRESSURE TRANSMITTER DISTRIBUTED CONTROL

WILL REPRESENT TRAIN NUMBER WITHIN SAME UNIT. PX -PRESSURE POINT INTERCONNECTING LOGIC

14. LINES LABELED "SRA" REQUIRE APPROVAL OF FINAL ROUTING BY PROCESS ENGINEERING/PMT. INSULATION TYPES LAST 3 DIGITS WILL BE THE SEQUENCE NUMBER STARTING PY -PRESS. COMPUTATION MOD. CONTROLLER WITH BINARY

PZV -PRESSURE RELIEF VALVE OR SEQUENTIAL FUNCTIONS

FROM "001" FOR ALL LINES. IF THE UNIT DOES NOT HAVE

15. TSO FOR A CONTROL VALVE WILL RESULT IN CLASS V MINIMUM SHUT OFF. ON-OFF VALVES WILL MEET API598. LINE SIZE ANY TRAINS THE FIRST 2 DIGIT OF SEQUENCE NUMBER IS

RTD -RESIST. TEMP. DETECTOR

(PLC) PROGRAMMABLE LOGIC

SI -SPEED INDICATOR

UP TO 5 CHARACTERS FOLLOED BY THE INCH SYMBOL. GOING TO BE "00". SS -SPEED SWITCH

CONTROLLER, NORMALLY

16. ALL RELIEF VALVE BYPASS TO BE AT THE SAME ELEVATION AS THE RELIEF VALVE TO ALLOW FOR FREE DRAINING. ALL NOMINAL LINE SIZES WILL BE EXPRESSED IN

INACCESSIBLE OR BEHIND THE

TC -TEMP. CONTROLLER PANEL DEVICE OR FUNCTIONS

INCHES (EVEN ON METRIC DRAWINGS) TV -TEMP. CONTROL VALVE (PLC) PROGRAMMABLE LOGIC

17. LEAVE HYDROSTATIC VENT/DRAINS FOR CW EXCHANGERS IN PLACE AFTER HYDROTEST. LINE CLASS DESIGNATOR

ACA ACOUSTIC CONTROL INSULATION (ACOUSTIC CLASS A) TCV -TEMP. CONTROL VALVE CONTROLLER FUNCTION,

(SELF-ACTUATED) CAN BE NORMALLY

5 OR 6 CHARACTER ALPHANUMERIC CODE PER

18. PIPING TO ROUTE PUMP BASEPLATE DRAIN TO OILY WATER(OW) DRAIN SYSTEM. EXCEPT FOR TE -TEMP. ELEMENT DISPLAYED ON CRT

ACB ACOUSTIC CONTROL INSULATION (ACOUSTIC CLASS B) UNIT NUMBER SAES-L-105 AND PIPING SPECIFICATION INDEX FOR JIGCC

MACHINERY INSIDE CURBED CHEMICAL AMINE AREA. WHICH ARE TO BE ROUTED TO THE CHEMICAL TSO -TIGHT SHUT OFF TG -THERMOMETER

3 CHARACTER ALPHANUMERIC CODE. (DOC. NO A00-A-DOC-VE-722050) LOCAL DCS OR AUXILIARY

DRAIN SYSTEM. LINE SIZE TO MATHC BASEPLATE DRAIN CONNECTION SIZE. S.C. - SAMPLE CONN. THS -TEMP. HAND SWITCH DCS LOCATION NORMALLY

ACC ACOUSTIC CONTROL INSULATION (ACOUSTIC CLASS C) TI -TEMP. INDICATOR ACCESSIBLE TO OPERATOR

S -DRAIN TO

19. INSTRUMENT TAG NUMBERS ON UNIT P&IDS DO NOT SHOW THE UNIT NUMBER UNLESS THE PRESSURE SEWER TR -TEMP. RECORDER

INSTRUMENT IS FOR ANOTHER UNIT. WHEN THE INSTRUMENT BELONGSTO ANOTHER UNIT. CC COLD SERVICE TS -TEMP. SWITCH

(PLC) PROGRAMMABLE LOGIC

THE UNIT NUMBER FOR THAT UNIT SHALL BE DISPLAYED OUTSIDE THE INSTRUMENT BUBBLE A00 - 6" - P - 00000 - 1CS1P OWS -OILY WATER SEWER TT -TEMP. TRANSMITTER

CONTROLLER I/O POINT

NORMALLY INACCESSIBLE

CCAA COLD SERVICE ACOUSTIC INSULATION (ACOUSTIC CLASS A) D -DRAIN TTD -TEMP. TRANSDUCER

IN THE UPPER LEFT QUADRANT. CCAA - (300 C) 75 mm V -VENT TW -THERMOWELL

BY OPERATOR

EXAMPLE: PT FROM CLOSED COOLING WATER SYSTEM (UNIT NUMBER A25) IS SHOWN ON WATER SYSTEMS CCAB COLD SERVICE ACOUSTIC INSULATION (ACOUSTIC CLASS B)

(UNIT NUMBER A23) P&IDS. REFERENCE DRAWINGS

CCAC COLD SERVICE ACOUSTIC INSULATION (ACOUSTIC CLASS C)

LETTER IDENTIFICATION OF LINES AE-036204

INSULATION THICKNESS (mm)

CP CONDENSATION CONTROL PIPING SYMBOLS AB-036227

EQUIPMENT SYMBOLS AB-036305

A25 A10 DT DUAL TEMPERATURE

PT INSTRUMENT SYMBOLS AC-036950

XXXX ET ELECTRIC TRACED INSULATION TYPE (4 CHAR. MAX) PIPING LAYOUT INDEX

INSULATION TEMPERATURE

(NORMAL OPERATING TEMP) PLOT PLAN

FX FIRE PROJECTION INSULATION

PROCESS FLOW DIAGRAM

HC HEAT CONSERVATION HYDROSTATIC TEST DIAGRAM

DRAWING CONTROL FOR J.O.

HO HOT OIL (HEATING MEDIUM)

20. PZV INLET SHALL BE LOCATED AS CLOSE AS POSSIBLE AND SELF DRAINING TO THE INSTRUMENT INSTALLATION SCHEDULES

PROTECTED EQUIPMENT. THE DISCHARGE LINES SHALL BE SELF DRAINING WITH A MINIMUM HJ HOT FLUID JACKETED

HORIZONTAL SLOPE OF 21MM: 10M TOWARDS THE DISCHARGE END OF THE LINE.

Jazan - \A10\A10\VA-449162-001.pid - 12/22/2016 8:28:41 AM - [JE07]

21. OWNER AND DETAILED ENGINNERING CONTRATOR SHALL DESIGN THE SAFETY INSTRUMENTED MS METAL SHELD FOR PERSONNEL PROTECTION

SYSTEM (SIS) IN ACCORDANCE WITH APPLICABLE PROCESS INDUSTRY STANDARDS SUCH AS

ISA S84. IEC 61511 AND IEC 61508. OWNER AND DETAILED ENGINEERING CONTRACTOR SHALL ALSO NI NO INSULATION

BE RESPONSIBLE FOR DEVELOPING AND IMPLEMENTING THE SAFETY INSTRUMENTED FUNCTIONS PIPING SPECIFICATION

(SIF) AND PERFORMING SAFETY INTEGRITY LEVEL (SIL) DETERMINATION TO ALL SAFETY INSTRUMENTED PP PERSONNEL PROTECTION

FUNCTIONS IN ACCORDANCE WITH OWNER'S RISK MANAGEMENT POLICY.

ST1 STEAM TRACED (LP STEAM)

22. THE SIS DETAILS PROVIDED ARE TO BE CONSIDERED AS "FOR INFORMATION ONLY" AND ARE NOT

REPRESENTED TO BE INCOMPLIANCE WITH THE OWNER'S RISK MANAGEMENT CRITERIA. OR ISA S84 ST2 STEAM TRACED (MP STEAM)

OR THE APPLICABLE IEC DOCUMENTS. REVISION VALIDATION

SY PROCESS STABILITY INSULATION THIS REVISION NO. 01A IS COVERED, FOR ALL APPROVAL AND CERTIFICATION

23. THE OWNER IS RESPONSIBLE FOR ESTABLISHING ADMINISTRATIVE CONTROLS AND PROCEDURES

FOR UES WITH ANY SHUTDOWN SYSTEM BYPASS FEATURES FOR TESTING OR MAINTENANCE OF THE REQUIREMENTS, PER SAEP-334, UNDER DRAWING COMPLETION CERTIFICATE NO:

SYSTEM. ANY PROCESS INTERLOCK OR SAFETY INTEGRITY SIL-3 SHALL NOT BE BYPASSED 10-01525-0004-048

UNDER ANY CIRCUMSTANCES.

24. ALL THERMOWELL CONNECTION ARE FLANGED CONNECTION UNLESS OTHERWISE NOTED.

1 CS 2 P DESIGN CERTIFICATION

(DESIGN AGENCY)

REVIEW FOR KEY DRAWINGS

REQUIRED (SAUDI ARAMCO)

OTHER

ENGG./DATE CERTIFIED BY/DATE CONST. AGENCY/DATE OPERATIONS/DATE BY/DATE

25. NEITHER FLOW INDUCED VIBRATION (FIV) NOR ACOUSTIC INDUCED VIBRATION (AIV) HAVE BEEN HL.ZENG B.ANDERS

CONSIDERED AS PART OF BASIC ENGINEERING DESIGN. THESE DESIGN ASPECTS ARE TO BE

LIST OF USED SYMBOLS SERVICE APPLICATION 11/30/16 11/30/16

CONSIDERED DURING THE DETAIL ENGINEERING DESIGN PHASE. REFER TO SAES-F-007 AND SAER-5317. REV.NO. DATE REVISION DESCRIPTION

CORROSION ALLOWANCE 01A 11/30/16 ISSUED FOR CONSTRUCTION

26. GATE VALVES USED AS PZV INLET/OUTLET BLOCK VALVES SHALL BE INSTALLED WITH THE STEM

HORIZONTAL OR SLOPING DOWN AWAY FROM THE VAVLE. P GAUGE PRESSURE PRIMARY MATERIAL JOB ORDER/EWO NO.

THIS REVISION IS NOT TO BE USED FOR

27. DISCHARGE PIPING SERVING PZV'S RELIEF TO ATMOSPHERE SHALL BE PROVIDED WITH A 20mm QM MASS RATE OF FLOW 10-01525-0004 CONSTRUCTION UNTIL CERTIFIED AND DATED

DRAIN HOLE AT THE LOW-POINT. FOR COMBUSTIBLE GSA SERVICES THE DISCHARGE FROM THE PRESSURE RATING

DRAIN HOLE SHALL BE DIRECTED AWAY FROM PERSONNEL AREAS. EQUIPMENT OR PIPING BY

ITS ORIENTATION. OR BY USE OF A MINIMUN LENGTH NIPPLE AND AN ELBOW. g

DIFFERENCE

SAUDI ARABIAN OIL COMPANY

TEMPERATURE DRAWING TYPE

PIPING & INSTRUMENTATION DIAGRAM PID

28. DETAILED ENGINEERING CONTRACTOR SHALL ENSURE THAT EQUIPMENT AND BATTERY LIMIT

ISOLATIONS ARE DESIGNED INACCORDANCE WITH PROCESS SPECIFICATION A00-A-VE-722324 SEE SAES-L-105 FOR MORE INFORMATION LEGENDS - GENERAL NOTES

(ISOLATION PHILOSOPHY).

29. DETIALED ENGINEERING CONTRACTOR SHALL ENSURE THAT VENT AND DRAIN CONFIGURATIONS

POWER GENERATION UNIT

ARE IN ACCORDANCE WITH PROJECT SPECIFICATION A00-A-VE-722325 (VENT AND DRAIN PHILOSOPHY).

30. VESSELS IN SERVICE OTHER THAN AIR AND WATER SHALL BE PROVIDED WITH A MIN. 2" FLANGED

JAZAN SAUDI ARABIA

STEAM-OUT CONNECTION AS PER 32-SAMSS-004 PARA.8.1.8. IN THIS CASE, BLOCK VALVE, SPECTACLE PLANT NO. INDEX DRAWING NUMBER SHT. NO. REV. NO.

BLIND FLANGE AND BLEED VALVE TO BE SHOWN.

A10 A VA-449162 001 01A

Saudi Aramco 5994 ENG. (09/03)

RESTRICTED SMART CADD-05

You might also like

- Attachment - #5 Valve Inspection ListDocument4 pagesAttachment - #5 Valve Inspection ListzhangNo ratings yet

- Satip Co 3001Document3 pagesSatip Co 3001zhangNo ratings yet

- Ses-Pgb-Co-Itp-0058 Itp For HRSG SystemDocument4 pagesSes-Pgb-Co-Itp-0058 Itp For HRSG SystemzhangNo ratings yet

- Attachment#9 Auxiliary SystemDocument3 pagesAttachment#9 Auxiliary SystemzhangNo ratings yet

- Review of Pressure Testing ProceduresDocument24 pagesReview of Pressure Testing ProcedureszhangNo ratings yet

- Saudi Aramco Test Report: Commissioning of HRSG System MechDocument2 pagesSaudi Aramco Test Report: Commissioning of HRSG System MechzhangNo ratings yet

- Saic Co 3014Document8 pagesSaic Co 3014zhangNo ratings yet

- Commissioning Completion Certificate: Attachment#4Document3 pagesCommissioning Completion Certificate: Attachment#4zhangNo ratings yet

- Attachment#5 Blowdown SystemDocument3 pagesAttachment#5 Blowdown SystemzhangNo ratings yet

- Commissioning Completion Certificate: Attachment#4Document3 pagesCommissioning Completion Certificate: Attachment#4zhangNo ratings yet

- Commissioning Completion Certificate: Attachment#4Document3 pagesCommissioning Completion Certificate: Attachment#4zhangNo ratings yet

- Attachment#6 Burner SystemDocument3 pagesAttachment#6 Burner SystemzhangNo ratings yet

- Satr Co 3008Document1 pageSatr Co 3008zhangNo ratings yet

- Attachmnet#8 Rotor Air SystemDocument3 pagesAttachmnet#8 Rotor Air SystemzhangNo ratings yet

- Installation of Main Steel Structure/ Platform & Steam SilencerDocument4 pagesInstallation of Main Steel Structure/ Platform & Steam SilencerzhangNo ratings yet

- Saudi Arabian Oil Company: A10-24"-HRH-11001-9CM1P Hot Reheat SteamDocument1 pageSaudi Arabian Oil Company: A10-24"-HRH-11001-9CM1P Hot Reheat SteamzhangNo ratings yet

- Saudi Aramco Typical Commissioning Inspection Plan: Ot Procedure Name Ses-Pgb-Co-Otp-0003Document2 pagesSaudi Aramco Typical Commissioning Inspection Plan: Ot Procedure Name Ses-Pgb-Co-Otp-0003zhangNo ratings yet

- Satip Co 3014Document3 pagesSatip Co 3014zhangNo ratings yet

- Steam Line SummaryDocument9 pagesSteam Line SummaryzhangNo ratings yet

- Satip Co 3014Document3 pagesSatip Co 3014zhangNo ratings yet

- Saudi Aramco Hot Reheat Steam ChecklistDocument12 pagesSaudi Aramco Hot Reheat Steam ChecklistzhangNo ratings yet

- Saic Co 3014Document18 pagesSaic Co 3014zhangNo ratings yet

- Satr Co 3008Document1 pageSatr Co 3008zhangNo ratings yet

- A10 L Iso VB 433961 105 - 01BDocument1 pageA10 L Iso VB 433961 105 - 01BzhangNo ratings yet

- Saudi Aramco Hot Reheat Steam ChecklistDocument12 pagesSaudi Aramco Hot Reheat Steam ChecklistzhangNo ratings yet

- VHP Steam LineDocument9 pagesVHP Steam LinezhangNo ratings yet

- Installation of Main Steel Structure/ Platform & Steam SilencerDocument4 pagesInstallation of Main Steel Structure/ Platform & Steam SilencerzhangNo ratings yet

- SATR-P-3413 Rev 7 FinalDocument4 pagesSATR-P-3413 Rev 7 FinalzhangNo ratings yet

- Satr-P-3219 Rev 7 FinalDocument7 pagesSatr-P-3219 Rev 7 FinalzhangNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5784)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- AlphaDocument49 pagesAlphaJelor MatundanNo ratings yet

- Economic Geology GuideDocument9 pagesEconomic Geology GuideJameel JameelNo ratings yet

- MCQ CsatDocument9 pagesMCQ CsatParth BadiyaniNo ratings yet

- Vitotrans 300 TDMDocument28 pagesVitotrans 300 TDMradusettNo ratings yet

- Water Cycle E-BookDocument13 pagesWater Cycle E-Bookapi-322786693No ratings yet

- Test Bank For Environment and You 1st Edition ChristensenDocument12 pagesTest Bank For Environment and You 1st Edition ChristensenPeggy Gebhart100% (33)

- Chapter 4 Preparing Salting Curing Solutions and MixturesDocument10 pagesChapter 4 Preparing Salting Curing Solutions and MixturesGraceCayabyabNiduaza100% (3)

- Rtaf CatalogDocument60 pagesRtaf CatalogRoger Akl67% (3)

- Steam vs Thermal Oil Heating: Which is BestDocument3 pagesSteam vs Thermal Oil Heating: Which is BestjoseNo ratings yet

- Status and Potential of Groundwater Use in Ethiopian FloodplainsDocument24 pagesStatus and Potential of Groundwater Use in Ethiopian FloodplainsTEMESGENNo ratings yet

- Lake Oroville California - Google SearchDocument1 pageLake Oroville California - Google SearchRoss RuckerNo ratings yet

- Norma Epa 445 ClorfilaDocument22 pagesNorma Epa 445 Clorfilaprofe42No ratings yet

- Flow Assurance Solutions With PipefloDocument27 pagesFlow Assurance Solutions With PipefloheriNo ratings yet

- Heat and Mass Transfer Modeling GeostudioDocument80 pagesHeat and Mass Transfer Modeling GeostudiomrloadmovieNo ratings yet

- Running of Dopeless®connectionsDocument4 pagesRunning of Dopeless®connectionsHector BarriosNo ratings yet

- English and Filipino Gened QuestionsDocument25 pagesEnglish and Filipino Gened QuestionsGelo JarabeNo ratings yet

- PLAN 4 - Senior 1 PhysicsDocument20 pagesPLAN 4 - Senior 1 PhysicspazzagliacarmelaNo ratings yet

- Long Quiz.. Exogenic ProcessDocument3 pagesLong Quiz.. Exogenic ProcessSheryl Lou AngelesNo ratings yet

- S.No. Pump Name Type Steam Turbine SectionDocument15 pagesS.No. Pump Name Type Steam Turbine SectionSaad AhmedNo ratings yet

- LEED Gold Certified Island City Center in MumbaiDocument34 pagesLEED Gold Certified Island City Center in MumbaiPERVEZ AHMAD KHANNo ratings yet

- Microwave-Assisted Extraction of Phenolic Compounds From Olive Leaves A Comparison With MacerationDocument8 pagesMicrowave-Assisted Extraction of Phenolic Compounds From Olive Leaves A Comparison With MacerationThu LeNo ratings yet

- Rilem Ii.4Document4 pagesRilem Ii.4manil_5No ratings yet

- Dehydration of Bacterial Cellulose and The Water Content e Ects On Its Viscoelastic and Electrochemical PropertiesDocument9 pagesDehydration of Bacterial Cellulose and The Water Content e Ects On Its Viscoelastic and Electrochemical PropertiesvivekanandNo ratings yet

- IGS System-1Document11 pagesIGS System-1manojNo ratings yet

- Service Manual Am15-2Document64 pagesService Manual Am15-2javier vilchez romeroNo ratings yet

- Notice of Intent (NOI) For Discharges Incidental To The Normal Operation of A Vessel Under The NPDES Vessel General PermitDocument3 pagesNotice of Intent (NOI) For Discharges Incidental To The Normal Operation of A Vessel Under The NPDES Vessel General Permitmohamed abdallaNo ratings yet

- Diagnostic Test - EnglishDocument4 pagesDiagnostic Test - EnglishCathy APNo ratings yet

- Work and Power - AnsDocument32 pagesWork and Power - AnsSurbhi DungraniNo ratings yet

- Rose Clay: Material Safety Data SheetDocument3 pagesRose Clay: Material Safety Data SheetLABORATORIUM FERTILINDONo ratings yet

- Aquarea User Guide PDFDocument68 pagesAquarea User Guide PDFDel MonteNo ratings yet