Professional Documents

Culture Documents

Figure 1: Block Diagram of Gain Scheduling Adaptive Control Using DC Servomotor

Uploaded by

afqzfieOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Figure 1: Block Diagram of Gain Scheduling Adaptive Control Using DC Servomotor

Uploaded by

afqzfieCopyright:

Available Formats

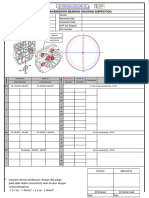

The project setup is as shown in the figure 1 below.

Where the connection are between the

Arduino, PWM amplifier, encoder, DC motor and power supply. Figure 2 shows the block diagram for the

desired project. PID controller is used in this test. A rectangular glass load is used in this test to represent

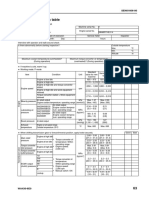

the unbalance condition. Figure 3 below shows the flow chat for the system algorithm. To achieve the

required angle, there are four operating point set which are 0-90, 90-180, 180-270 and 270. For each

operating point, different set of gain parameters (Kp, Ki, Kd) are scheduled. After running the coding, the

data (time and position) obtained is recorded and plotted to the graph for further discussion.

Figure 1: Block diagram of Gain Scheduling Adaptive control using DC servomotor

Figure 2: Schematic diagram of system's connection

Start

Set first Gain parameter set (Kp, Ki,

Kd) for operating point 0-90

D

B

Rotate motor

Obtain position

Rotate motor

Obtain time

Yes

C Check position in range 0-90 parameter for operating point of 0-9

Set Gain

No

Yes Check position No

in range 90- A

Set Gain parameter for operating point of 90-180

180

A B

Yes

Check position in range 180-270

Set Gain parameter for operating point of 90-180

No

No No

Check position = 270 Check position > 270 C

Yes

Yes Set Gain parameter for operating point direction motor backward > 270

End

Figure 3: Flowchart for the computer algorithm

C

You might also like

- Control and Computing Laboratory (EE615) ReportDocument6 pagesControl and Computing Laboratory (EE615) ReportsandeepNo ratings yet

- Lecture 420 - Compensation of Op Amps-I: (READING: Text-Sec. 9.2, 9.3, 9.4)Document16 pagesLecture 420 - Compensation of Op Amps-I: (READING: Text-Sec. 9.2, 9.3, 9.4)Monika JindalNo ratings yet

- calibracion de gobernador 320CDocument9 pagescalibracion de gobernador 320CymaqservicesNo ratings yet

- Concentrycity Pto Ex 3600Document2 pagesConcentrycity Pto Ex 3600Irwanto ManafNo ratings yet

- Neostat v2 DatasheetDocument1 pageNeostat v2 DatasheetermimaeNo ratings yet

- PDF Governor Actuator Calibrate CompressDocument4 pagesPDF Governor Actuator Calibrate Compressjuan camilo quinteroNo ratings yet

- GEO PSI ESP+ Downhole Gauge: Reliable, Accurate, and Re-DeployableDocument2 pagesGEO PSI ESP+ Downhole Gauge: Reliable, Accurate, and Re-DeployableEdwin OrtegaNo ratings yet

- Sison, Marcus Ceazar - Module 2 - SurveyingDocument3 pagesSison, Marcus Ceazar - Module 2 - SurveyingMarcus Ceazar Sison0% (1)

- Energy Offer Calculation Education: CDS January 14, 2021Document25 pagesEnergy Offer Calculation Education: CDS January 14, 2021Lahiru Prabhatha AmarasenaNo ratings yet

- CASE PTO ONLY IDDocument5 pagesCASE PTO ONLY IDIrwanto ManafNo ratings yet

- PICKUP - QCM:: Test ModuleDocument2 pagesPICKUP - QCM:: Test Moduledwiki septianNo ratings yet

- Ws Rotations Not at Origin Notes and PracticeDocument2 pagesWs Rotations Not at Origin Notes and Practiceapi-334137347No ratings yet

- 546 DGII With AZ Cut SheetDocument2 pages546 DGII With AZ Cut SheetJeannot MpianaNo ratings yet

- Tec-Campus Qro Control Lab-MR3029: L A 5 A C SDocument2 pagesTec-Campus Qro Control Lab-MR3029: L A 5 A C SHugo EGNo ratings yet

- Lab Activity 5 - ReactorDocument2 pagesLab Activity 5 - ReactorHugo EGNo ratings yet

- MM Meccalte Mec1275Document4 pagesMM Meccalte Mec1275HabibNo ratings yet

- Cube Small PX-0056-NEGDocument6 pagesCube Small PX-0056-NEGClau MendozaNo ratings yet

- Timing - Calibrate (RENR5012-03)Document5 pagesTiming - Calibrate (RENR5012-03)MichaelMonguiNo ratings yet

- 07.1-8300 Adjusting Start of Delivery (After Testing)Document6 pages07.1-8300 Adjusting Start of Delivery (After Testing)asdNo ratings yet

- C Ontrol SystemDocument39 pagesC Ontrol SystemARVINDNo ratings yet

- Reconstructions 105230Document6 pagesReconstructions 105230mathuba25No ratings yet

- Rotations WsDocument6 pagesRotations WsZol IbrahimNo ratings yet

- Digital temperature controller multi-input multi-outputDocument6 pagesDigital temperature controller multi-input multi-outputHenry Avilés ChongNo ratings yet

- CTI Test Summary Report (Advent IT Park) T43A 178 16A 2016Document9 pagesCTI Test Summary Report (Advent IT Park) T43A 178 16A 2016Shahab Z AhmedNo ratings yet

- CBE - Rear Steering Pot Setup-Rev 1Document2 pagesCBE - Rear Steering Pot Setup-Rev 1crash2804No ratings yet

- Control SystemDocument36 pagesControl SystemARVINDNo ratings yet

- Control LabDocument6 pagesControl LabVIKAS JAATNo ratings yet

- Self-Diagnosis: Specified Display ValuesDocument8 pagesSelf-Diagnosis: Specified Display ValuesСергій XрестикNo ratings yet

- Model KM936 / KM945: Digital ThermometerDocument1 pageModel KM936 / KM945: Digital ThermometerMeet KataraNo ratings yet

- Quickcmc1: Test ModuleDocument6 pagesQuickcmc1: Test ModuleOemar JieNo ratings yet

- Counter Meter PDFDocument4 pagesCounter Meter PDFM saleemNo ratings yet

- Directional residual delayed overcurrent protection functionDocument4 pagesDirectional residual delayed overcurrent protection functionrichardt999No ratings yet

- L4-Bearing and AzimuthDocument16 pagesL4-Bearing and AzimuthTaleb AbboudNo ratings yet

- AlignementDocument35 pagesAlignementIbrahim Meghdour50% (2)

- Calibración Gobernador 320c PDFDocument15 pagesCalibración Gobernador 320c PDFRforceIbañezNo ratings yet

- ACF624 680and625manualsDocument2 pagesACF624 680and625manualsGreg OneofakindNo ratings yet

- Ge Ge752 User Manual 67 73Document7 pagesGe Ge752 User Manual 67 73RICHARDNo ratings yet

- GEA 55-9187-CA-37: Encastrés de Sol IP65/IP67 GEA G12 70W Acier Inox AISI 316 3739lmDocument11 pagesGEA 55-9187-CA-37: Encastrés de Sol IP65/IP67 GEA G12 70W Acier Inox AISI 316 3739lmAmine MoutaouakilNo ratings yet

- Product Datasheet Product Datasheet SF CIRC 400 V 24W 840 IP44Document6 pagesProduct Datasheet Product Datasheet SF CIRC 400 V 24W 840 IP44Catalin DulceataNo ratings yet

- IGV Commissioning For AddFem POCO+ LogicDocument17 pagesIGV Commissioning For AddFem POCO+ LogicHankar Aravins100% (3)

- Lombardo Presentation PDFDocument20 pagesLombardo Presentation PDFGkkNo ratings yet

- Graphing and Describing 90° and 270° Rotations About The Origin (0, 0)Document13 pagesGraphing and Describing 90° and 270° Rotations About The Origin (0, 0)Paul Hamilton11nNo ratings yet

- Product Datasheet Product Datasheet DP 1500 81W 865 IP65 GYDocument6 pagesProduct Datasheet Product Datasheet DP 1500 81W 865 IP65 GYDani Good VibeNo ratings yet

- ME2142E Feedback and Control Lab - Speed Position Control of A DC MotorDocument12 pagesME2142E Feedback and Control Lab - Speed Position Control of A DC MotorLinShaodun100% (13)

- Temperature Control ExperimentDocument5 pagesTemperature Control ExperimentJomeNo ratings yet

- PM Clinic WA500-6Document3 pagesPM Clinic WA500-6Naughty VongNo ratings yet

- Precal 1Document4 pagesPrecal 1Louise CarolineNo ratings yet

- Concentricity PtoDocument3 pagesConcentricity PtoIrwanto ManafNo ratings yet

- GEA 55-9433-Y4-37 Encastrés de sol IP67 70WDocument11 pagesGEA 55-9433-Y4-37 Encastrés de sol IP67 70WAmine MoutaouakilNo ratings yet

- Argus Dual System Pi enDocument2 pagesArgus Dual System Pi enfahmi1987No ratings yet

- EH782Document93 pagesEH782jorgeNo ratings yet

- TSH Math36Document9 pagesTSH Math36Jada BrownNo ratings yet

- Principle of The Resolver Fault CompensationDocument5 pagesPrinciple of The Resolver Fault CompensationMarlon JaksNo ratings yet

- CNC CodingDocument26 pagesCNC CodingNEF RIDERSNo ratings yet

- Pm-Click Inspection Table: 30 Testing and Adjusting SEN01606-00Document3 pagesPm-Click Inspection Table: 30 Testing and Adjusting SEN01606-00Henry SalasNo ratings yet

- Trigonometric IdentitiesDocument4 pagesTrigonometric IdentitiesEngr SkyNo ratings yet

- PID - Compact Error CodesDocument3 pagesPID - Compact Error CodesMokhtar ShamsNo ratings yet

- Bab 8Document6 pagesBab 8leslierobloxgamingNo ratings yet

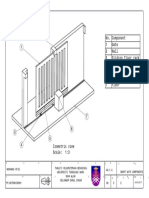

- Smart Gate ComponentDocument1 pageSmart Gate ComponentafqzfieNo ratings yet

- Assembly PDFDocument1 pageAssembly PDFafqzfieNo ratings yet

- List The Main Activities of The Project. Indicate The Length of Time Needed For Each Activity.Document1 pageList The Main Activities of The Project. Indicate The Length of Time Needed For Each Activity.afqzfieNo ratings yet

- List The Main Activities of The Project. Indicate The Length of Time Needed For Each Activity.Document1 pageList The Main Activities of The Project. Indicate The Length of Time Needed For Each Activity.afqzfieNo ratings yet

- Eduinnovationmahathir PDFDocument1 pageEduinnovationmahathir PDFMahathir FansuriNo ratings yet

- The Subtle Art of Not Giving A FuckDocument10 pagesThe Subtle Art of Not Giving A FuckPili Pardo30% (10)

- Science of Cooking Every Question Answered To Perfect Your Cooking PDFDocument1 pageScience of Cooking Every Question Answered To Perfect Your Cooking PDFafqzfieNo ratings yet

- Owser - Fileprovider - External - Files - Download - The Science of Cooking Every Question Answered To Perfect Your Cooking PDFDocument1 pageOwser - Fileprovider - External - Files - Download - The Science of Cooking Every Question Answered To Perfect Your Cooking PDFafqzfieNo ratings yet

- Owser - Fileprovider - External - Files - Download - The Science of Cooking Every Question Answered To Perfect Your Cooking PDFDocument1 pageOwser - Fileprovider - External - Files - Download - The Science of Cooking Every Question Answered To Perfect Your Cooking PDFafqzfieNo ratings yet

- PQRDocument2 pagesPQRafqzfieNo ratings yet

- Machinelearningforkids ApikeysDocument39 pagesMachinelearningforkids ApikeysNavdeep GoelNo ratings yet

- Oracle Fusion Pricing - Base List Price Override: An Oracle White Paper January 2018Document14 pagesOracle Fusion Pricing - Base List Price Override: An Oracle White Paper January 2018Siva Kumaran0% (1)

- 2G Commands EricssonDocument4 pages2G Commands EricssonTri Setyawan50% (2)

- Senior IT Infrastructure Project Manager - M Tariq Nazar Resume Rev11Document5 pagesSenior IT Infrastructure Project Manager - M Tariq Nazar Resume Rev11socafay369No ratings yet

- Bio-Medical Engineer C.VDocument4 pagesBio-Medical Engineer C.Veng_aymanhamdan80% (5)

- List of Default Router Admin Passwords and IP AddressesDocument6 pagesList of Default Router Admin Passwords and IP AddressesBen KaniaNo ratings yet

- What Is Scratch 1611213348 1617187994Document4 pagesWhat Is Scratch 1611213348 1617187994JatadharNo ratings yet

- Manasa Tatavarthy: E-Mail: MobileDocument4 pagesManasa Tatavarthy: E-Mail: MobileDivya SushmaNo ratings yet

- Plasma Donation System: A Project OnDocument29 pagesPlasma Donation System: A Project OnArshiya Mobile ShopeeNo ratings yet

- SParx UML BasicsDocument73 pagesSParx UML BasicsRomarMroNo ratings yet

- Galaxy Note 3 Manual SM-N9005 UM EU Jellybean Eng Rev.1.0 130910 ScreenDocument177 pagesGalaxy Note 3 Manual SM-N9005 UM EU Jellybean Eng Rev.1.0 130910 Screensuperdavec100% (2)

- What Is Hadoop - Introduction, Architecture, Ecosystem, ComponentsDocument8 pagesWhat Is Hadoop - Introduction, Architecture, Ecosystem, ComponentsAhmed MohamedNo ratings yet

- Delphi 5 Chapter 8Document96 pagesDelphi 5 Chapter 8Premanand ShenoyNo ratings yet

- Unisoc Baseband Slides zpUCkXFDocument35 pagesUnisoc Baseband Slides zpUCkXFKirill KirpichevNo ratings yet

- Integrating ROS and MATLABDocument3 pagesIntegrating ROS and MATLABAlessioHrNo ratings yet

- Impact of Practical Skills On Academic Performance A Data-Driven AnalysisDocument20 pagesImpact of Practical Skills On Academic Performance A Data-Driven AnalysisMarcelino Halili IIINo ratings yet

- Principles of Scalable Performance and Parallelism MetricsDocument41 pagesPrinciples of Scalable Performance and Parallelism MetricsHarminder SokhiNo ratings yet

- Software UsageDocument1 pageSoftware UsageAshish BagariaNo ratings yet

- Online Banking AbstractDocument14 pagesOnline Banking AbstractNeelanjal Singh100% (2)

- D95501GC10 AgDocument372 pagesD95501GC10 AgL LLNo ratings yet

- 12 CS Practical 1 To 5 Oct2022Document6 pages12 CS Practical 1 To 5 Oct2022Priyesh KumarNo ratings yet

- XML - Extensible Markup Language (TMS) - PhraseDocument9 pagesXML - Extensible Markup Language (TMS) - PhraseZhihao WangNo ratings yet

- Android 2022 CourseDocument6 pagesAndroid 2022 CourseMuhammad ShahidNo ratings yet

- Lecture 1 at A Glance: Lecture No 2: Writing Basic SQL SELECT StatementsDocument41 pagesLecture 1 at A Glance: Lecture No 2: Writing Basic SQL SELECT Statementslovely personNo ratings yet

- SmartPRO 5000U Plus ManualDocument10 pagesSmartPRO 5000U Plus ManualMugiranezaNo ratings yet

- 【SIEMENS】Cios Select-with-FD-FlyerDocument6 pages【SIEMENS】Cios Select-with-FD-FlyerAshleyNo ratings yet

- BSNL Gujarat Telecom Circle..Document2 pagesBSNL Gujarat Telecom Circle..ggtgtretNo ratings yet

- CSE 2 Marks Questions & AnswersDocument4 pagesCSE 2 Marks Questions & AnswersAnithaNo ratings yet

- Hype Cycle For Application Architecture and Integration, 2021Document82 pagesHype Cycle For Application Architecture and Integration, 2021dennyliaoNo ratings yet

- 38689d1425073616 CDR Sample Telecom Network Engineer TvistrapDocument44 pages38689d1425073616 CDR Sample Telecom Network Engineer TvistraptoluNo ratings yet

- Defensive Cyber Mastery: Expert Strategies for Unbeatable Personal and Business SecurityFrom EverandDefensive Cyber Mastery: Expert Strategies for Unbeatable Personal and Business SecurityRating: 5 out of 5 stars5/5 (1)

- Dealers of Lightning: Xerox PARC and the Dawn of the Computer AgeFrom EverandDealers of Lightning: Xerox PARC and the Dawn of the Computer AgeRating: 4 out of 5 stars4/5 (88)

- Scary Smart: The Future of Artificial Intelligence and How You Can Save Our WorldFrom EverandScary Smart: The Future of Artificial Intelligence and How You Can Save Our WorldRating: 4.5 out of 5 stars4.5/5 (54)

- Algorithms to Live By: The Computer Science of Human DecisionsFrom EverandAlgorithms to Live By: The Computer Science of Human DecisionsRating: 4.5 out of 5 stars4.5/5 (722)

- ChatGPT Side Hustles 2024 - Unlock the Digital Goldmine and Get AI Working for You Fast with More Than 85 Side Hustle Ideas to Boost Passive Income, Create New Cash Flow, and Get Ahead of the CurveFrom EverandChatGPT Side Hustles 2024 - Unlock the Digital Goldmine and Get AI Working for You Fast with More Than 85 Side Hustle Ideas to Boost Passive Income, Create New Cash Flow, and Get Ahead of the CurveNo ratings yet

- Digital Gold: Bitcoin and the Inside Story of the Misfits and Millionaires Trying to Reinvent MoneyFrom EverandDigital Gold: Bitcoin and the Inside Story of the Misfits and Millionaires Trying to Reinvent MoneyRating: 4 out of 5 stars4/5 (51)

- ChatGPT Millionaire 2024 - Bot-Driven Side Hustles, Prompt Engineering Shortcut Secrets, and Automated Income Streams that Print Money While You Sleep. The Ultimate Beginner’s Guide for AI BusinessFrom EverandChatGPT Millionaire 2024 - Bot-Driven Side Hustles, Prompt Engineering Shortcut Secrets, and Automated Income Streams that Print Money While You Sleep. The Ultimate Beginner’s Guide for AI BusinessNo ratings yet

- Generative AI: The Insights You Need from Harvard Business ReviewFrom EverandGenerative AI: The Insights You Need from Harvard Business ReviewRating: 4.5 out of 5 stars4.5/5 (2)

- The Infinite Machine: How an Army of Crypto-Hackers Is Building the Next Internet with EthereumFrom EverandThe Infinite Machine: How an Army of Crypto-Hackers Is Building the Next Internet with EthereumRating: 3 out of 5 stars3/5 (12)

- 8-Bit Apocalypse: The Untold Story of Atari's Missile CommandFrom Everand8-Bit Apocalypse: The Untold Story of Atari's Missile CommandRating: 3.5 out of 5 stars3.5/5 (10)

- AI Superpowers: China, Silicon Valley, and the New World OrderFrom EverandAI Superpowers: China, Silicon Valley, and the New World OrderRating: 4.5 out of 5 stars4.5/5 (398)

- CompTIA Security+ Get Certified Get Ahead: SY0-701 Study GuideFrom EverandCompTIA Security+ Get Certified Get Ahead: SY0-701 Study GuideRating: 5 out of 5 stars5/5 (2)

- Chip War: The Quest to Dominate the World's Most Critical TechnologyFrom EverandChip War: The Quest to Dominate the World's Most Critical TechnologyRating: 4.5 out of 5 stars4.5/5 (227)

- The Master Algorithm: How the Quest for the Ultimate Learning Machine Will Remake Our WorldFrom EverandThe Master Algorithm: How the Quest for the Ultimate Learning Machine Will Remake Our WorldRating: 4.5 out of 5 stars4.5/5 (107)

- Blood, Sweat, and Pixels: The Triumphant, Turbulent Stories Behind How Video Games Are MadeFrom EverandBlood, Sweat, and Pixels: The Triumphant, Turbulent Stories Behind How Video Games Are MadeRating: 4.5 out of 5 stars4.5/5 (335)

- The Future of Geography: How the Competition in Space Will Change Our WorldFrom EverandThe Future of Geography: How the Competition in Space Will Change Our WorldRating: 4.5 out of 5 stars4.5/5 (4)

- So You Want to Start a Podcast: Finding Your Voice, Telling Your Story, and Building a Community that Will ListenFrom EverandSo You Want to Start a Podcast: Finding Your Voice, Telling Your Story, and Building a Community that Will ListenRating: 4.5 out of 5 stars4.5/5 (35)

- The Corporate Startup: How established companies can develop successful innovation ecosystemsFrom EverandThe Corporate Startup: How established companies can develop successful innovation ecosystemsRating: 4 out of 5 stars4/5 (6)

- Artificial Intelligence: A Guide for Thinking HumansFrom EverandArtificial Intelligence: A Guide for Thinking HumansRating: 4.5 out of 5 stars4.5/5 (30)

- Data-ism: The Revolution Transforming Decision Making, Consumer Behavior, and Almost Everything ElseFrom EverandData-ism: The Revolution Transforming Decision Making, Consumer Behavior, and Almost Everything ElseRating: 3.5 out of 5 stars3.5/5 (12)

- Who's Afraid of AI?: Fear and Promise in the Age of Thinking MachinesFrom EverandWho's Afraid of AI?: Fear and Promise in the Age of Thinking MachinesRating: 4.5 out of 5 stars4.5/5 (12)

- ChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindFrom EverandChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindNo ratings yet