Professional Documents

Culture Documents

18 Butterfly Valves A Disc Bray

Uploaded by

Ali FananiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

18 Butterfly Valves A Disc Bray

Uploaded by

Ali FananiCopyright:

Available Formats

Section 18

Butterfly Valves

A-Disc & Bray

0800 276 877 267

STEEL PRODUCTS

BUTTERFLY VALVES

A-Disc Butterfly Valves

Resilient seat Butterfly Valves are used in a wide range of Industries including HVAC, Gas, Petrochemical, Pulp & Paper, Water & Wastewater

Treatment, Brewing, Food processing, Mining, Textile and General Industry. They are compact and give bubble tight shut off as well as having

good regulating capabilities.

Wafer Butterfly Style

The body design is such that it can be used with most international flanges including AS2129, BS10, ANSI, & DIN Standards. The wafer style

is designed for inline service and relies on a flange either side of the valve to secure it in the pipeline.

Lugged Butterfly Style

Like the wafer style, the lugged body is compact but has a series of lugs cast into the body which are tapped with a thread for the fixing of a

flange on one side at a time. The benefit of this being the valve can be mounted at the end of a pipeline without the need for a flange on the

downstream (discharge) side of the valve. ie dead end service.

Gear Operators (Optional)

For precise regulation where flow control is critical, or on larger diameters & higher pressures.

Resilient Seat Material for Butterfly Valves

ASTM DESIGNATION GENERALLY GENERALLY AFFECTED

COMMON NAME COMPOSITION

D1418-64 RESISTANT TO OR ATTACKED BY

NBR Many Hydrocarbons, Ozone's, keytones,

fats, oils, greases, esters, aldehydes,

Buna-N or Nitrile Nitrile Butadiene

Temp. + 80C hydraulic fluids and chlorinated and nitro

chemicals hydrocarbons

EPDM Animal and vegetable

Ethylene-propylene- Mineral oils and solvents,

EPT or EPDM oils, ozone, strong and

Temp. + 110C dieneterpolymer aromatic hydrocarbons

oxidising chemicals

FPM All aliphatic, aromatic

Keytones, Low mole

Hexfluoropropylene and halogenated

Viton weight ester and nitro

Temp. + 150C Vinylidene Fluoride Hydrocarbons, acids,

containing compounds

animal and vegetable oils

TFE Tetrafluoro-Ethylene Most known fluid

Teflon -

Temp. + 230C Resin chemicals

Specific Resistance

NBR EPDM VITON TFE

Abrasion Good Good Good Good

Oxidisation Good Excellent Excellent Excellent

Heat Aging Good Excellent Very Good Excellent

Flame Poor Poor Excellent Excellent

Oil Very Good Poor Excellent Excellent

Fuel Good Poor Excellent Excellent

Keytones/Esters Fair Excellent Poor Excellent

Aliphatic Hydrocarbon Excellent Poor Excellent Excellent

Aromatic Hydrocarbon Fair Poor Excellent Excellent

Water Good Very Good Very Good Excellent

Other Seat materials available on request. Refer to Asmuss for operating torque details.

MATERIALS SPECIFICATIONS

PART MATERIAL Cold Working

Pressure sizes 1600 Kpa

Body Cast Iron

50-300mm

Handle Ductile Iron

Cold Working

Stem SS431 Pressure sizes 1000 Kpa

Disc SS304 or SS316 350-600mm

Seat EPDM or Nitrile MAX Working

EPDM 110C

Temperature EPDM

Bushing Epoxy Glass Fibre Composite

MAX Working

Notch Plate SS304 Nitrile 80C

Temperature Nitrile

O-Ring EPDM or Nitrile

268 0800 ASMUSS

BUTTERFLY

STEEL PRODUCTS

VALVES

A Disc Wafer Butterfly Valve

Wafer Butterfly Valve with Stainless Steel Disc

CODE FACE TO

SIZE H1 H2 H3 ISO5211 WEIGHT KG

EPDM NBR FACE

ADVWE ADVWN 50 143 55 29 43 F07 3.4

ADVWE ADVWN 65 155 64 29 46 F07 3.5

ADVWE ADVWN 80 162 72 29 46 F07 4.5

ADVWE ADVWN 100 181 90 29 52 F07 6.5

ADVWE ADVWN 125 197 101 29 56 F07 8.5

ADVWE ADVWN 150 210 114 29 56 F07 10

ADVWE ADVWN 200 240 145 35 60 F10 17

ADVWE ADVWN 250 286 178 35 68 F10 26

ADVWE ADVWN 300 309 204 35 78 F10 39

H3

n-d

D1

H1

H2

A Disc Wafer Butterfly Valve with Gear-Operator

Wafer Butterfly Valve with Stainless Steel Disc and Gear Operator

CODE FACE TO

SIZE H1 H2 H3 ISO5211 WEIGHT KG

EPDM NBR FACE

ADVWEG ADVWNG 350 328 264 45 78 F10 58

ADVWEG ADVWNG 400 360 293 51.2 102 F14 120

ADVWEG ADVWNG 450 400 324 51.2 114 F14 136

ADVWEG ADVWNG 500 460 350 64.2 127 F14 160

ADVWEG ADVWNG 600 540 440 70.2 154 F16 260

H3

n-d1

D1

H1

H2

0800 276 877 269

STEEL PRODUCTS

BUTTERFLY VALVES

A Disc Lugged Table E Butterfly Valve

Tappings are metric for lugged table E valves

Lugged T/E Butterfly Valve with Stainless Steel Disc

CODE FACE TO WEIGHT

SIZE H1 H2 H3 ISO5211 n-M

EPDM NBR FACE KG

ADVLE ADVLN 50 143 55 29 43 F07 4-M16 4.1

ADVLE ADVLN 65 155 64 29 46 F07 4-M16 4.8

ADVLE ADVLN 80 162 72 29 46 F07 4-M16 4.9

ADVLE ADVLN 100 181 90 29 52 F07 8-M16 8.5

ADVLE ADVLN 125 197 101 29 56 F07 8-M16 9.9

ADVLE ADVLN 150 210 114 29 56 F07 8-M20 12.5

ADVLE ADVLN 200 240 145 35 60 F10 8-M20 18.5

ADVLE ADVLN 250 286 178 35 68 F10 12-M20 20.6

ADVLE ADVLN 300 309 204 35 78 F10 12-M24 45.2

H3

D1

H1

n-M

H2

A Disc Lugged Table E Butterfly Valve with Gear-Operator

Tappings are metric for lugged table E valves

Lugged T/E Butterfly Valve with Stainless Steel Disc and Gear Operator

CODE FACE TO WEIGHT

SIZE H1 H2 H3 ISO5211 n-M

EPDM NBR FACE KG

ADVLEG ADVLNG 350 328 264 45 78 F10 12-M24 81

ADVLEG ADVLNG 400 360 293 51.2 102 F14 12-M24 140

ADVLEG ADVLNG 450 400 324 51.2 114 F14 16-M24 176

ADVLEG ADVLNG 500 460 350 64.2 127 F14 16-M24 226

ADVLEG ADVLNG 600 540 440 70.2 154 F16 16-M30 370

H3

C

n-M

H1

H2

270 0800 ASMUSS

BUTTERFLY

STEEL PRODUCTS

VALVES

A Disc Lugged ANSI 150 Butterfly Valve NBR Seat

Tappings are UNC for lugged ANSI valves

CODE FACE WEIGHT

SIZE H1 H2 H3 ISO5211 n-M

NBR SEAT TO FACE KG

ADVLNA 50 143 55 29 43 F07 4x5/8 4.1

ADVLNA 65 155 64 29 46 F07 4x5/8 4.8

ADVLNA 80 162 72 29 46 F07 4x5/8 4.9

ADVLNA 100 181 90 29 52 F07 8x5/8 8.5

ADVLNA 125 197 101 29 56 F07 8x3/4 9.9

ADVLNA 150 210 114 29 56 F07 8x3/4 12.5

ADVLNA 200 240 145 35 60 F10 8x3/4 18.5

ADVLNA 250 286 178 35 68 F10 12x7/8 20.6

ADVLNA 300 309 204 35 78 F10 12x7/8 45.2

Larger sizes available on request

H3

D1

H1

n-M

H2

A Disc Lugged DIN PN16 Butterfly Valve EPDM Seat

Tappings are metric for lugged table E valves

Lugged DIN PN16 Butterfly Valve with Stainless Steel Disc

FACE WEIGHT

CODE SIZE H1 H2 H3 ISO5211 n-M

TO FACE KG

ADVLEM 50 143 55 29 43 F07 4-M16 4.1

ADVLEM 65 155 64 29 46 F07 4-M16 4.8

ADVLEM 80 162 72 29 46 F07 8-M16 4.9

ADVLEM 100 181 90 29 52 F07 8-M16 8.5

ADVLEM 125 197 101 29 56 F07 8-M16 9.9

ADVLEM 150 210 114 29 56 F07 8-M20 12.5

ADVLEM 200 240 145 35 60 F10 12-M20 18.5

ADVLEM 250 286 178 35 68 F10 12-M24 20.6

ADVLEM 300 309 204 35 78 F10 12-M24 45.2

Larger sizes available on request

H3

D1

H1

n-M

H2

0800 276 877 271

STEEL PRODUCTS

BUTTERFLY VALVES

Gear Operators for A-Disc Butterfly Valve

Gear Operators

CODE SIZES H L W RATIO WEIGHT KG

ADGOSS/050-080 50-80mm 128 205 127 24:1 4.5

ADGOSS/100 100mm 128 205 127 24:1 4.5

ADGOSS/125-150 125-150mm 128 205 127 24:1 6.2

ADGOSS/200 200mm 179 295 170 32:1 8.5

ADGOSS/250 250mm 179 295 170 32:1 8.5

ADGOSS/300 300mm 200 291 190 50:1 10.9

A full range of pneumatic & electric actuation options is available

272 0800 ASMUSS

BUTTERFLY

STEEL PRODUCTS

VALVES

Bray Butterfly Valves, Actuators & Controls

MATERIALS SPECIFICATIONS

PART MATERIAL Cold Working

Pressure sizes 1200 Kpa

Cast Iron ASTM

Body 50-300mm

A126 Class B

MAX Working

Ductile Iron EPDM 121C

Handle Temperature EPDM

ASTM A536

MAX Working

Stem SS316 Nitrile 100C

Temperature Nitrile

Disc SS316 or NDI

MAX Working

EPDM/Nitrile/ Viton 204C

Seat Temperature Viton

Viton/PTFE

Stem Bushing Acetal (Delrin)

Notch Plate Nickel Plated Steel

Stem Seal EPDM or Nitrile

Bray Wafer Series 30 & Lugged Series 31 Butterfly Valves 1 Piece Body

Wafer bodies suitable for BS10 T/D, T/E & ANSI 125 flanges. BS10 T/E Lugged bodies are Tapped Metric. ANSI 150 bodies are Tapped UNC.

Sizes 350-500mm available on request.

Bray Butterfly Valves

CODE* WEIGHT

SIZE L E J B ISO5211

WAFER LUG KG

BRVW30 BRVL31 50 58 140 32 43 F07 2.95

BRVW30 BRVL31 65 65 152 32 46 F07 3.86

BRVW30 BRVL31 80 71 159 32 46 F07 4.31

BRVW30 BRVL31 100 104 178 32 52 F07 5.44

BRVW30 BRVL31 125 117 190 32 56 F07 7.26

BRVW30 BRVL31 150 129 203 32 56 F07 9.07

BRVW30 BRVL31 200 154 241 32 60 F12 15.9

BRVW30 BRVL31 250 195 273 50 68 F12 22.7

BRVW30 BRVL31 300 229 311 50 78 F12 39.5

* Bray product code suffix is dependent upon seat & disc materials.

0800 276 877 273

STEEL PRODUCTS

BUTTERFLY VALVES

Bray Wafer Series 20 Butterfly Valves 2 Piece Body

These bodies have special Nylon 11 coating for high corrosion protection. Wafer bodies suitable for BS10 T/D & T/E flanges.

Available also with PTFE Seats, PTFE Encapsulated Discs and EPDM Encapsulated Discs.

Bray Butterfly Valves

CODE* FACE TO WEIGHT

SIZE L E J ISO5211

WAFER FACE KG

BRVW20 25 35 90 25 30 F05 0.8

BRVW20 40 35 105 25 32 F05 1.4

BRVW20 50 51 140 32 43 F07 2.95

BRVW20 65 59 152 32 46 F07 3.86

BRVW20 80 67 159 32 46 F07 4.31

BRVW20 100 87 178 32 52 F07 5.44

BRVW20 125 107 190 32 56 F07 7.26

BRVW20 150 120 203 32 56 F07 9.07

BRVW20 200 153 241 32 60 F12 15.9

BRVW20 250 188 273 50 68 F12 22.7

BRVW20 300 213 311 50 78 F12 39.5

Lugged pattern series 21 valves also available on indent basis.

* Bray product code suffix is dependant upon seat & disc materials.

Bray Handle Kits

Ductile iron lever and nickel-plated Handle Kits

notch plate.

CODE FOR VALVE SIZES LENGTH WEIGHT KG

BRVHK01/025-040 25-40 185 0.4

BRVHK01/050-080 50-80 270 1.02

BRVHK01/100 100 270 1.02

BRVHK01/125-150 125-150 270 1.02

BRVHK01/200 200 298 1.25

BRVHK01/250-300 250-300 298 1.25

274 0800 ASMUSS

BUTTERFLY

STEEL PRODUCTS

VALVES

Bray Gear Operators

Gear Operators

FOR VALVE WEIGHT

CODE A N P RATIO

SIZES KG

BRVGO04/0200 50-150mm 115 136 203 20:1 3.4

BRVGO04/0300 200-300mm 175 191 203 30:1 6.4

Bray Pneumatic Actuators

- Self Energizing Piston Seals - Adjustable travel Stops

- Acetal Piston Guides - Anodized Body Inside and Out

- One Piece Rack & Pinion - ISO5211 Mounting

- Plated Output Shaft & Pinion Gear - Anti-Blowout Pinion

- High Corrosion Resistance - Honed Cylinder Wall

- Pinion Supported on Acetal Bearings - Integral Porting

Bray Double Acting & Spring Return Pneumatic Actuators

Bray Pneumatic Actuators

CODE

WEIGHT WEIGHT

DOUBLE SPRING F E N+P

DA SR

ACTING RETURN

BRVACT92/063 BRVACT93/063 132 110 70 1.4 1.6

BRVACT92/083 BRVACT93/083 177 130 90 2.5 3.2

BRVACT92/092 BRVACT93/092 202 137 100 3.3 4.3

BRVACT92/118 BRVACT93/118 215 176 119 7 9

BRVACT92/127 BRVACT93/127 290 196 136 8.6 11.4

BRVACT92/160 BRVACT93/160 368 240 171 15.9 22.3

BRVACT92/210 BRVACT93/210 450 296 224 29.5 43.2

BRVACT92/255 BRVACT93/255 665 338 271 65.3 87.4

Spring return actuators available as fail open or fail close.

0800 276 877 275

STEEL PRODUCTS

BUTTERFLY VALVES

Bray Proximity Sensors

The Series 52 Prox Sensor has 2 sensors in one self contained fully sealed compact enclosure.

Sensors are completely encapsulated with Epoxy Resin in a rigid polymer enclosure that is

impervious to moisture & most chemicals.

This unit provides a bounce-free electronic signal for all PLC & solid state circuitry.

LED Indicators show verification of functionality along with yellow Hi Vis Pointer.

Solid state sensors mean no moving electrical parts to wear out.

A multi pin electrical connector is available for ease of installation.

Bray Positioners

Available in Pneumatic, Electro-pneumatic & Digital Smart options.

The Digital version includes self diagnostic checks, auto calibration, alarm messages, LCD display

& keyboard.

276 0800 ASMUSS

You might also like

- Rubber Material Selection Guide HNBR or Highly Saturated Nitrile Hydrogenated Acryonitrile ButadieneDocument3 pagesRubber Material Selection Guide HNBR or Highly Saturated Nitrile Hydrogenated Acryonitrile Butadienevivekanand bhartiNo ratings yet

- Styrene Butadiene Rubber (SBR)Document1 pageStyrene Butadiene Rubber (SBR)NPNo ratings yet

- Comparision of GasketsDocument3 pagesComparision of Gasketsanwer_quadriNo ratings yet

- Rubber Properties Chart PDFDocument1 pageRubber Properties Chart PDFsefaNo ratings yet

- Rubber Properties ChartDocument1 pageRubber Properties Chartabhay guptaNo ratings yet

- Rubber Properties Chart PDFDocument1 pageRubber Properties Chart PDFshalabh.g864177No ratings yet

- Rubber Properties Chart PDFDocument1 pageRubber Properties Chart PDFArasarethina KumarNo ratings yet

- CarboxylatedNitrileRubber - XNBR PDFDocument3 pagesCarboxylatedNitrileRubber - XNBR PDFJitendra BhosaleNo ratings yet

- Silicone RubberDocument3 pagesSilicone RubberSh.nasirpurNo ratings yet

- Rubber Elastomer Chemical Resistance Guide by TLARGI and WARCO BILTRITEDocument12 pagesRubber Elastomer Chemical Resistance Guide by TLARGI and WARCO BILTRITEpriyaprasad367792No ratings yet

- J Flex Product Info - Nitrile Types Comparison ChartDocument2 pagesJ Flex Product Info - Nitrile Types Comparison ChartPeggy ITURBURU VILLACRESESNo ratings yet

- Rubber Material Selection Guide ACM or Polyacrylate Acrylic RubberDocument3 pagesRubber Material Selection Guide ACM or Polyacrylate Acrylic RubberHemanth KumarNo ratings yet

- General Properties of Elastomers Summary ChartDocument1 pageGeneral Properties of Elastomers Summary ChartvenkatramanNo ratings yet

- CMchloropolyethyleneDocument3 pagesCMchloropolyethyleneCarlosNo ratings yet

- Lube Base StockDocument60 pagesLube Base StockKrishnamoorthy VijayalakshmiNo ratings yet

- Rubber Property ComparisonDocument1 pageRubber Property ComparisonKrzysztof OkrajekNo ratings yet

- Chemical Resistances MaterialDocument4 pagesChemical Resistances MaterialCecep AtmegaNo ratings yet

- Let There Be Oils!: An Introduction To Crude Oil Distillation. (Technical)Document56 pagesLet There Be Oils!: An Introduction To Crude Oil Distillation. (Technical)YustinusNo ratings yet

- Seat Material Guide 2" 345 Butterfly ValveDocument1 pageSeat Material Guide 2" 345 Butterfly ValveAndrey IVanNo ratings yet

- Codan Chemical Resistance 2015Document4 pagesCodan Chemical Resistance 2015Gokul VenugopalNo ratings yet

- Характеристики покрытийDocument13 pagesХарактеристики покрытийgrandtechNo ratings yet

- Resins: Singh Plasticisers & Resins (I) Pvt. LTDDocument26 pagesResins: Singh Plasticisers & Resins (I) Pvt. LTDmadumaxNo ratings yet

- Petroleum Refining Processes OverviewDocument21 pagesPetroleum Refining Processes OverviewCNAltNo ratings yet

- Industrial Hose Chemical Resistance GuideDocument32 pagesIndustrial Hose Chemical Resistance Guidemat gaiatoNo ratings yet

- There Are Three Main Groups of Resin:: Polyester ResinsDocument1 pageThere Are Three Main Groups of Resin:: Polyester ResinsmukeshNo ratings yet

- Chemical Resistance of Rubbers (AIP)Document7 pagesChemical Resistance of Rubbers (AIP)윤병택No ratings yet

- TR 301 Temperature Range For ElastomersDocument1 pageTR 301 Temperature Range For ElastomerscochcorpNo ratings yet

- PDF Elastomerguide PDFDocument1 pagePDF Elastomerguide PDFCristhianVilchezNo ratings yet

- Glove Chemical Resistance ChartDocument2 pagesGlove Chemical Resistance ChartChris March100% (1)

- Chemical Resistance PlasticsDocument1 pageChemical Resistance PlasticsLuana Cantú AngeliNo ratings yet

- Packings: Static Applications For Pumps For ValvesDocument9 pagesPackings: Static Applications For Pumps For ValvesИштванNo ratings yet

- Baghouse Filter Material GuideDocument1 pageBaghouse Filter Material GuideBülent BulutNo ratings yet

- O-Ring GuideDocument1 pageO-Ring GuideChris TNo ratings yet

- O-Ring Material GuideDocument1 pageO-Ring Material Guidecupid75No ratings yet

- Chemical Resistance of Thermoplastics for Process ApplicationsDocument1 pageChemical Resistance of Thermoplastics for Process ApplicationsLisbeth Roos RoosNo ratings yet

- Chemistry of Crude OilDocument33 pagesChemistry of Crude OilCNAltNo ratings yet

- AkzoNobel MEA PIS Tcm53-24552Document1 pageAkzoNobel MEA PIS Tcm53-24552Desi Apriyanti RahayuNo ratings yet

- Model 2: General Methods of Assaying Volatile OilsDocument6 pagesModel 2: General Methods of Assaying Volatile OilsAliza EsplanadaNo ratings yet

- Gland Packing, Carbon Fiber Based: Valqua No. 6201 Product Name Carbonized Fiber Coil PackingDocument2 pagesGland Packing, Carbon Fiber Based: Valqua No. 6201 Product Name Carbonized Fiber Coil PackingReza MirashehNo ratings yet

- Gasoline KeroseneDocument45 pagesGasoline KeroseneCNAltNo ratings yet

- Material SealDocument2 pagesMaterial SealDennis SetiawanNo ratings yet

- Thordon Material Selection Guide General Pumps Rev 201307Document1 pageThordon Material Selection Guide General Pumps Rev 201307NuM NaNo ratings yet

- Dercolyte Ts 105 - TdsDocument2 pagesDercolyte Ts 105 - TdsFREDY CORREANo ratings yet

- Seat Selection Guide: Choosing A Suitable ElastomerDocument16 pagesSeat Selection Guide: Choosing A Suitable ElastomerYing Kei ChanNo ratings yet

- Tanker Cargo SheetDocument1 pageTanker Cargo SheetpardeepNo ratings yet

- Linde WAO TechnologyDocument30 pagesLinde WAO Technologyrzlisk01No ratings yet

- Sifat-Sifat Minyak Dan GasDocument29 pagesSifat-Sifat Minyak Dan GasJesicha Aulia AdamNo ratings yet

- Elastomers OverviewDocument2 pagesElastomers OverviewJobita JMNo ratings yet

- Fundamentals of the Petrochemical IndustryDocument19 pagesFundamentals of the Petrochemical IndustryDikul BrahmbhattNo ratings yet

- 2015 L13 Distillation Applications - Low-Temperature Separations PDFDocument34 pages2015 L13 Distillation Applications - Low-Temperature Separations PDFfegcopNo ratings yet

- Fuel Types and Storage Times TableDocument1 pageFuel Types and Storage Times TablecadcomputerservicesNo ratings yet

- Polymer Description and General Information Chart 3Document2 pagesPolymer Description and General Information Chart 3Hartomo Batahan SiahaanNo ratings yet

- Ring Design Chapter016Document1 pageRing Design Chapter016ismail güleçNo ratings yet

- CLS DL An 226Document1 pageCLS DL An 226Stas NicolasNo ratings yet

- Epdm Rubber Gasket HydrotechDocument3 pagesEpdm Rubber Gasket Hydrotechmusafir mufiNo ratings yet

- Eccentric Plug Valve - Series 601: Elastomer SelectionDocument1 pageEccentric Plug Valve - Series 601: Elastomer SelectionИбрагим НурмамедовNo ratings yet

- Seat MaterialsDocument4 pagesSeat MaterialsabidalimirzaNo ratings yet

- Anderol 555Document1 pageAnderol 555rewindingidsNo ratings yet

- CH 6 Conversion Processes 2018-2019 BDocument118 pagesCH 6 Conversion Processes 2018-2019 BayaNo ratings yet

- Pig Catcher 12 in Rev.4Document1 pagePig Catcher 12 in Rev.4Ali FananiNo ratings yet

- Pig Catcher 16 in Rev.3Document1 pagePig Catcher 16 in Rev.3Ali FananiNo ratings yet

- FloXpress TutorialDocument4 pagesFloXpress TutorialSudhish KamalNo ratings yet

- Nicholson Thermostatic Steam TrapsDocument18 pagesNicholson Thermostatic Steam TrapsAli Fanani100% (1)

- Technical Data Sheet ZTC1000V563Document62 pagesTechnical Data Sheet ZTC1000V563Ali Fanani0% (1)

- Fire Hydrant EquipmentDocument3 pagesFire Hydrant EquipmentAli FananiNo ratings yet

- Qy50k Ii 02Document10 pagesQy50k Ii 02Ali Fanani100% (1)

- Cutting Stud BoltDocument1 pageCutting Stud BoltAli FananiNo ratings yet

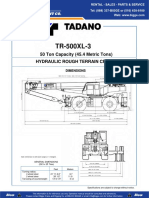

- TR500XL 3Document10 pagesTR500XL 3Ali FananiNo ratings yet

- Crane Lifting Plan Method Statement & Risk AssessmentDocument20 pagesCrane Lifting Plan Method Statement & Risk Assessment101ar85% (13)

- 2015thermal PDFDocument26 pages2015thermal PDFBenAmmareImed0% (1)

- Ta U BoltsDocument3 pagesTa U BoltsAli FananiNo ratings yet

- APG 2013 DynaBolt Sleeve Anchors PDFDocument3 pagesAPG 2013 DynaBolt Sleeve Anchors PDFAnonymous zMWvcTNo ratings yet

- Ramset 13 CatalogueDocument48 pagesRamset 13 CatalogueAli FananiNo ratings yet

- Calculating Vertical and Horizontal Forces on a Poros1 ShaftDocument1 pageCalculating Vertical and Horizontal Forces on a Poros1 ShaftAli FananiNo ratings yet

- PemDocument15 pagesPemAli FananiNo ratings yet

- VISCOSITY CLASSIFICATION GUIDE FOR INDUSTRIAL LUBRICANTSDocument8 pagesVISCOSITY CLASSIFICATION GUIDE FOR INDUSTRIAL LUBRICANTSFrancisco TipanNo ratings yet

- Spek UboltDocument2 pagesSpek UboltRafiazis75No ratings yet

- poros 3 panjang poros 2 =L karena τmax < Ssyp maka amanDocument1 pageporos 3 panjang poros 2 =L karena τmax < Ssyp maka amanAli FananiNo ratings yet

- PemDocument15 pagesPemAli FananiNo ratings yet

- ReadmeDocument1 pageReadmenoorulhuqNo ratings yet

- PemDocument15 pagesPemAli FananiNo ratings yet

- Endlesslove02 MidDocument1 pageEndlesslove02 MidAli FananiNo ratings yet

- PemDocument15 pagesPemAli FananiNo ratings yet

- ReadmeDocument1 pageReadmenoorulhuqNo ratings yet

- Endlesslove02 MidDocument1 pageEndlesslove02 MidAli FananiNo ratings yet

- Addd Roda Gigi1-9Document1 pageAddd Roda Gigi1-9Ali FananiNo ratings yet

- DR 1Document9 pagesDR 1Ali FananiNo ratings yet

- DR 1Document9 pagesDR 1Ali FananiNo ratings yet

- Testing For Biological MoleculesDocument3 pagesTesting For Biological MoleculessariniNo ratings yet

- Materials for shoes, optical lenses and water bottlesDocument3 pagesMaterials for shoes, optical lenses and water bottlesJpricarioNo ratings yet

- Characterization of Minerals, Metals and MaterialsDocument723 pagesCharacterization of Minerals, Metals and Materialslfvorster99No ratings yet

- 00-H-0008 Air-Cooled Water ChillersDocument14 pages00-H-0008 Air-Cooled Water Chillershabibansari2010No ratings yet

- Tut 9 - PH 102 - 30052023Document1 pageTut 9 - PH 102 - 30052023PS SuryaNo ratings yet

- Introduction To Mass TransferDocument44 pagesIntroduction To Mass TransferGhazanferAliNo ratings yet

- 2 Year Chemistry Weightage: V. Kumar Dean Sri Chaitanya Educational Institutions HyderabadDocument4 pages2 Year Chemistry Weightage: V. Kumar Dean Sri Chaitanya Educational Institutions Hyderabadnithish0% (1)

- Taller de GasesDocument20 pagesTaller de GasesAle Cruz DNo ratings yet

- Daphne Eponex No2Document5 pagesDaphne Eponex No2Fu NamNo ratings yet

- TranslateDocument9 pagesTranslateWira AdjieNo ratings yet

- CombustionDocument35 pagesCombustionm_mukbel8752No ratings yet

- Heat Transfer Equations and Critical Insulation RadiusDocument18 pagesHeat Transfer Equations and Critical Insulation RadiusPon ShanmugakumarNo ratings yet

- Calculation Sheet For Spit Anchors: TAPCON XTREM HFL Min. Anchorage 10x120/65-35Document6 pagesCalculation Sheet For Spit Anchors: TAPCON XTREM HFL Min. Anchorage 10x120/65-35abdallah badrNo ratings yet

- Rheological Properties of Some Oil Based Muds Used in Reservoirs in The Niger Delta, NigeriaDocument6 pagesRheological Properties of Some Oil Based Muds Used in Reservoirs in The Niger Delta, NigeriaNurfatini CheNo ratings yet

- 19th Southeast Asian Geotechnical Conference ProceedingsDocument6 pages19th Southeast Asian Geotechnical Conference ProceedingsSen HuNo ratings yet

- Repair and RehabilitationDocument115 pagesRepair and RehabilitationBala Subramanian0% (1)

- Lecture 1Document7 pagesLecture 1Dr. Aung Ko LattNo ratings yet

- WWW Visionalloys Com Stainless Steel Fasteners HTMLDocument4 pagesWWW Visionalloys Com Stainless Steel Fasteners HTMLNikhil JainNo ratings yet

- Strut and Tie Model Analysis of Prestressed Deep BeamsDocument24 pagesStrut and Tie Model Analysis of Prestressed Deep BeamsKannan Chandrabhanu100% (1)

- Tube To Tubesheet Weld Joint Design & Welding Qualifications MicroDocument21 pagesTube To Tubesheet Weld Joint Design & Welding Qualifications MicroSiva baalanNo ratings yet

- Lab 4-Measurement of Plastic Viscosity of Different Mud Samples by Viscometer.Document20 pagesLab 4-Measurement of Plastic Viscosity of Different Mud Samples by Viscometer.Sunny BbaNo ratings yet

- Ar-Bt5 RSW Mt-02 Dela CruzDocument11 pagesAr-Bt5 RSW Mt-02 Dela CruzMark Aldrin Dela CruzNo ratings yet

- Advanced Nanotechnology Unlocks Potential of Thermoelectric GeneratorsDocument3 pagesAdvanced Nanotechnology Unlocks Potential of Thermoelectric GeneratorsmarijpotNo ratings yet

- CPVC - Cat VIKING Conexiones UL FM BlazemasterDocument28 pagesCPVC - Cat VIKING Conexiones UL FM BlazemasterpvaldezmtzNo ratings yet

- PCC Technova Series CPL Cylindrical ValvesDocument5 pagesPCC Technova Series CPL Cylindrical ValvesAnju VijayanNo ratings yet

- 34crnimo6: Steel GradeDocument4 pages34crnimo6: Steel Gradeanu swamiNo ratings yet

- Duct Tape and Insulation Tape GuideDocument2 pagesDuct Tape and Insulation Tape GuideDhanish AhsenNo ratings yet

- Quality Tests RequirementDocument6 pagesQuality Tests RequirementSandip PaulNo ratings yet

- Exp. 4 LipidsDocument6 pagesExp. 4 LipidsAna LuisaNo ratings yet

- Acceptance Creiteria Asme IiiDocument5 pagesAcceptance Creiteria Asme Iiimostafa aliNo ratings yet