Professional Documents

Culture Documents

ZG0605245247 PDF

Uploaded by

AJER JOURNALOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ZG0605245247 PDF

Uploaded by

AJER JOURNALCopyright:

Available Formats

American Journal of Engineering Research (AJER) 2017

American Journal of Engineering Research (AJER)

e-ISSN: 2320-0847 p-ISSN : 2320-0936

Volume-6, Issue-5, pp-245-247

www.ajer.org

Research Paper Open Access

Construction of Electrochemical System for Hydrogen and

Oxygen Overvoltage Determining under High Current Densities

in Alkaline Water Electrolysis

Ya.I. Turyan

76D Thurston Rd, Newton, MA 02464 USA

Abstract: The construction considered Electrochemical System based on the use of the rotating disk working

electrode with pressed to the electrode immobile thread has obtained farther evolution:

1) Elimination of the air penetration to the rotating, working electrode surface,

2) Utilization of hydrogen reference electrode with the same electrolyte and temperature that for rotating

working electrode,

3) Elimination of the electrolyte and gas movement in electrolytic switch and Luggin capillary,

4) Application of the simple nut arrangement for Luggin capillary vertical movement up and down on the

given distant between Luggin capillary end and the rotating working electrode surface.

Keywords: hydrogen and oxygen overvoltage, high current densities, gas shielding of electrode, gas filling of

electrolyte, rotating disk electrode, concentrating polarization, pressed to electrode thread, mobile Lugging

capillary.

I. INTRODUCTION

The Industrial alkaline water electrolysis for obtaining hydrogen and oxygen most often carry out under

high current densities (i>0.1 A/sm2). At usually method for of the hydrogen and oxygen overvoltage

determination gives positive mistake because of influence of the working electrode surface gas shielding,

electrolyte gas filling and concentrating polarization [1]. Two ways were proposed for elimination of the

indicated factors: 1) the placing of the working electrode in the flowing electrolyte [2], 2) the use of the rotating

working electrode wire [3,4] or disk with pressed to the electrode surface thin polymeric immobile thread [5,6].

Second way respect to construction and exploitation is considerably simpler than first way and his follows to

prefer, especially if to discount that the rotating disk electrode (without thread) is made by different firm.

Therefore in our work the second way with more perspective the rotating disk working electrode with pressed

thin polymeric immobile thread has been chosen.

Tasks of our work were the improving of electrochemical system construction in directions of

containments and elimination of gas and electrolyte movement in electrolytic switch and Luggin capillary..

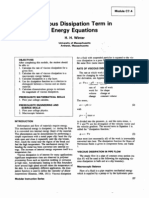

II. ROTATING DISK WORKING ELECTRODE

Rotating disk working electrode (1) with pressed immobile polymeric thread (2) considered in part I

given on the fig.1. Rotating disk working electrode (1) has diameter 4-5 mm. Diameter of the polymeric thread

(2) 0.1-0.2 mm is considerably lower the diameter disk electrode that allows to neglect thread shielding.

Usually hydrogen and oxygen overvoltage determine at different covering. For this covering is better

to choose as the base produced chemical stable rotating electrodes from graphite or glassy carbon. It allows us to

use the same base repeatedly. The construction rotating working electrode with pressed to its surface immobile

thread (2) developed in work [5] shown on fig.1. This construction provides the thread soft stretching and its

soft pressing to the electrode surface due to nuts (3), (4) and rubber washers (5), (6). Simultaneously with

pressing the containment of hole (7) in cover (8) takes place.

Additional containment for the elimination of the air penetration across tube (9) to rotating electrode

surface, that especially undesirably at the hydrogen overvoltage determination in work [5], has been not

considered. The construction on fig.1, taking into account this effect and using lid (10) with rubber laying

(11),allows us to obtain the full containment of the rotating working electrode.

www.ajer.org Page 245

American Journal of Engineering Research (AJER) 2017

Besides indicated in part I advantages of the rotating working electrode the presence of the pressed to the

electrode surface immobile thread must decrease the limiting speed of the working electrode rotation [4] and

hence to increase of Luggin capillary stability.

III. HYDROGEN REFERENCE ELECTRODE

The construction of the reference electrode (Fig.1) consist of following nodes performing different

functions: a) platinized platinum wire (12) provides for reversibility of electrochemical hydrogen redox reaction;

b) electrolytic glass switch (13) with polishing glass stopper (15) for elimination of the gas and electrolyte

movement; c) Luggin glass capillary (16) for the potential measurement in the flatness parallel to electrode

surface (1); d) rubber stopper (17) with holes: (18) for the platinized platinum electro contact, (19) for

hydrogen inlet, (20) for hydrogen outlet; holes (21), (22), (23) in the electrolytic switch for hydrogen bubbles;

f) directing plastic tube (24) provides the contact of Luggin capillary (16) end with electrode surface free from

pressing thread;

g) plastic nut (26) screw up to cylinder (25) glued to glass tube (14) provides vertical transfer of Luggin

capillary (16); h) rubber washer (28) for hydrogen reference electrode containment; j) circular disks (27), (32)

for hydrogen and oxygen overvoltage estimation, circular disk (27) is fastened to nut (26).

At rotation nut (26) on clockwise Luggin capillary (16) is vertical transferred down to up. This is

caused by the vertical movement in the same direction of cylinder (25). Luggin capillary (16) movement is

completed by the soft pressing of Luggin capillary (16) end to the electrode surface. At this also the

containment of hole (37) occurs. Rotation nut (26) do not stimulate rotation of the other construction parts

including Luggin capillary (16) because of immobile directing tube (24).

At rotation nut (26) counter clockwise the vertical movement Luggin capillary (16) from up to down

takes place. It is caused by the movement of cylinder (25) from up to down. Movement of Luggin capillary (16)

from up to down allows us to obtain the dependence of the potential from distance between Luggin capillary

(16) end and electrode surface.

Disk (32) made from organic glass for in order to see the diametric line on disk (27).On disk (32) also

there is circular minute clock dial with 12 marks for hours and 5 marks for minute every hour. Rotation of nut

(26) and disk (27) with diametric line is indicated on disk (32) (dial) proportionally to Luggin capillary

movement. .

At receipt initial condition of Luggin capillary (16) unscrew little nuts (33, 34) and disk (32) turn with

help handless (38, 39) to confluence the mark 12 on disk (32) with the line on disk (27). After that nuts (33, 34)

www.ajer.org Page 246

American Journal of Engineering Research (AJER) 2017

screw up to compact pressing to rubber washers (29, 30). The potential measurement in the direction of the

increase distance between Luggin capillary (16) end and electrode surface are carried using the rotation of nut

(26) counter clockwise to confluence the line on disk (27) with chosen (in minute) marks on the dial. The

extrapolation found potentials to the zero time gives an overvoltage.

Thus proposed construction of the hydrogen reference electrode with displaced Luggin capillary (16)

for potential extrapolation to zero position of Luggin capillary (16) simpler and exacter than proposed [2,7]

the use for this object several Lugin capillaries. Possibility to work with very small distance between luggin

capillary (16) and electrode surface is also by the important peculiarity of our construction when diameter

cylinder form of the working layer electrolyte corresponding to diameter working electrode is kept. At this the

proportionality between potential ohmic drop and the distance between Luggin capillary (16) end and electrode

surface must be kept.

IV. AUXILIARY ELECTRODE

Platinum wire is used mostly as the auxiliary electrode (anode or cathode) without some diaphragm.

The function of the diaphragm carries out the electrolyte layer in vertical glass tube opened down. The auxiliary

electrode presents in the upper part of tube in the same this layer. The external layer of the electrolyte for

working electrode and hydrogen reference electrode is same. This construction is analogous to U-tipe

electrochemical cell for hydrogen and oxygen obtaining without diaphragm.

V. CONCLUSION

Proposed construction of the electrochemical system allows to improve the containment of the rotating

disk working electrode and hydrogen reference electrode and the Luggin capillary vertical transfer instead of

several Luggin capillaries use [2, 7].

ACKNOWLEDGEMENTS

The author is deeply grateful to P. Turyan, D. Frumin and L. Vaysband for their help in preparing of the

manuscript.

REFERENCES

[1]. Ya.I. Turyan, Methods for Determining Oxygen Overvoltage and Anode Poisoning Over Time at Iron-Group Metals, under High

Current Densities in Alkaline Water Electrolysis, Am. J. Engi. Res., 5, 2016, 304-307.

[2]. J. OM. Bockris, A.M. Azzam, The Kinetics of the Hydrogen Evolution Reaction at High Current Densities, Trans. Faraday SOC.,

1952, 145-160.

[3]. Ya.I. Turyan, and I.S. Goldenshtein, Kislorodnoe Perenapryagenie na Nikelevom Electrode pri Bolshikh Plotnostyah Toka, Zhur.

Prikl. Khimii, 29, 1956, 379-384.

[4]. Ya.I. Turyan, and I.A. Gershkovich, Kislorodnoe Perenapryagenie na Kobaltovom Elektrode pri Bolshikh Plotnostyah Toka,

Zhur. Prikl. Khimii, 29, 1956, 600-606.

[5]. L. Vaysband, Ya.I. Turyan, Rotating Disk Electrodewith an Additional Device for Renewing the Electrode Surface and the

Adjacent Solution Layer, J. Solid State Electrochem, 17, 2013, 2895-2896.

[6]. I. Minevich, Ya.I. Turyan, Application of the Modified Polarographic Brichka Method for Cancer Testing, J. Solid State

Electrochem, 17, 2013, 1529-1533.

[7]. Ya.I. Turyan, A.I. Tsinman, Vliyanie Koncentracii i Prirodi Schelochi na Kislorodnoe Perenapryagenie na Nikelevom Anode,

Doklady AN SSSR, 132, 1961, 1154-1158.

[8]. A. Hickling, S. Hill, Oxygen Overvoltage. The Influence of Electrode Material, Current Density, and Time in Aqueous Solution,

Discussion Faraday SOC., 1, 1947, 236-248.

www.ajer.org Page 247

You might also like

- Wind and Environmental Effect On The Overhead High Voltage Transmission LinesDocument12 pagesWind and Environmental Effect On The Overhead High Voltage Transmission LinesMANOJ KUMARNo ratings yet

- IJAER FinalDocument8 pagesIJAER Finalsravan KNo ratings yet

- Pipes and FittingsDocument17 pagesPipes and FittingsRichard Jason LitangNo ratings yet

- Lead Extrusion Dampers For Reducing SeismicDocument9 pagesLead Extrusion Dampers For Reducing Seismic文龙包No ratings yet

- A Practical Guide To Free Energy' DevicesDocument6 pagesA Practical Guide To Free Energy' DevicesFelipe EscuderoNo ratings yet

- The Prediction of Cone-Jet Formation in Electrospray Method Using Computational Fluid Dynamics (CFD)Document9 pagesThe Prediction of Cone-Jet Formation in Electrospray Method Using Computational Fluid Dynamics (CFD)Aji Candra ElNo ratings yet

- Electro Chemical Discharge MachiningDocument20 pagesElectro Chemical Discharge MachininglokeshNo ratings yet

- A Comparative Analysis of Piezoelectric Bending-Mode ActuatorsDocument11 pagesA Comparative Analysis of Piezoelectric Bending-Mode Actuatorsshivgupta2188No ratings yet

- Modelling of Corona DischargeDocument8 pagesModelling of Corona DischargeNishul AroraNo ratings yet

- 05 July 2013Document8 pages05 July 2013IJBSTRNo ratings yet

- US3768541Document5 pagesUS3768541Ronak shahNo ratings yet

- Scirobotics - Adj7246 SMDocument59 pagesScirobotics - Adj7246 SMzhc5057No ratings yet

- Abduh 2020Document9 pagesAbduh 2020enterlogNo ratings yet

- CFD Analysis of Single Phase Flows Inside Vertically and Horizontally Oriented Helically Coiled TubesDocument40 pagesCFD Analysis of Single Phase Flows Inside Vertically and Horizontally Oriented Helically Coiled TubesAnonymous mXicTi8hBNo ratings yet

- Fowler Nordheim Tunneling in Thin SiO2 FilmsDocument7 pagesFowler Nordheim Tunneling in Thin SiO2 FilmskobelkNo ratings yet

- Artg Com Fluxo MBDocument11 pagesArtg Com Fluxo MBFerdinando Marco Rodrigues BorgesNo ratings yet

- Kim 2007Document24 pagesKim 2007Saeid MoradiNo ratings yet

- The Study of Electrohydrodynamic and Wind Ions Direction Produced by Positive Corona Plasma DischargeDocument11 pagesThe Study of Electrohydrodynamic and Wind Ions Direction Produced by Positive Corona Plasma DischargeArina Akmali Yatun NisaNo ratings yet

- Desalination and Water Treatment 36 (2011) 1-9Document10 pagesDesalination and Water Treatment 36 (2011) 1-9adel-jamilaNo ratings yet

- Analysis of Electrohydrodynamic Flow Phenomenon of Positive Corona Discharge On New and Used Lubricant SurfacesDocument6 pagesAnalysis of Electrohydrodynamic Flow Phenomenon of Positive Corona Discharge On New and Used Lubricant SurfacesInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Tip Leakage FlowDocument15 pagesTip Leakage FlowMuhammad Zubair SheikhNo ratings yet

- Solar Photovoltaic Based Water Electrolysis System To Generate Hydrogen and OxygenDocument11 pagesSolar Photovoltaic Based Water Electrolysis System To Generate Hydrogen and OxygenIJRASETPublicationsNo ratings yet

- Critical Length of Straight Jet in Electrospinning: Ji-Huan He, Yue Wu, Wei-Wei ZuoDocument4 pagesCritical Length of Straight Jet in Electrospinning: Ji-Huan He, Yue Wu, Wei-Wei ZuoMuaathe IbrahimNo ratings yet

- Hydrophobic Nanowire (2008)Document6 pagesHydrophobic Nanowire (2008)fanducNo ratings yet

- Simple Free-Energy Devices: Chapter 9: Zach West's Water-Powered MotorcycleDocument11 pagesSimple Free-Energy Devices: Chapter 9: Zach West's Water-Powered MotorcycleRafat Kashoom100% (1)

- Theoretical and Experimental Analysis of Flat Plate CollectorDocument11 pagesTheoretical and Experimental Analysis of Flat Plate Collectorgonzalez2678No ratings yet

- 11.6 Longitudinal Finned Double-Pipe ExchangersDocument14 pages11.6 Longitudinal Finned Double-Pipe Exchangersvatsal07No ratings yet

- Passive Telemetry SensorDocument7 pagesPassive Telemetry SensorprincelylincolnNo ratings yet

- Development of Electrochemical Micro Machining For Air-Lubricated Hydrodynamic BearingsDocument6 pagesDevelopment of Electrochemical Micro Machining For Air-Lubricated Hydrodynamic BearingsMark LambertNo ratings yet

- Long Term Stability of Capacitive De-Ionization Processes For Water Desalination: The Challenge of Positive Electrodes CorrosionDocument10 pagesLong Term Stability of Capacitive De-Ionization Processes For Water Desalination: The Challenge of Positive Electrodes CorrosionPaulo Ossandon SanchezNo ratings yet

- Progress in High Performance DI-BSCCO WireDocument10 pagesProgress in High Performance DI-BSCCO Wirehariyati lubisNo ratings yet

- Viscous Diss Tern in Energy EquationsDocument14 pagesViscous Diss Tern in Energy EquationsJohn Jonnalagadda100% (1)

- Enhancement of Water Electrolyzer EfficiencyDocument10 pagesEnhancement of Water Electrolyzer EfficiencyMarcus WagnerNo ratings yet

- Filament Wound Fiber-Reinforced Sandwich PipeDocument12 pagesFilament Wound Fiber-Reinforced Sandwich PipeAhda Dapong Rizqy MaulanaNo ratings yet

- Helical Coil SG Design CalculationDocument7 pagesHelical Coil SG Design Calculationlram70No ratings yet

- Fluid Dynamic Simulation and Experimental Study of Honeycomb Seal Structures in Electrochemical Discharge Machining PressureDocument17 pagesFluid Dynamic Simulation and Experimental Study of Honeycomb Seal Structures in Electrochemical Discharge Machining PressuremechjournalNo ratings yet

- A Superconducting Homopolar Motor and Generator - New ApproachesDocument12 pagesA Superconducting Homopolar Motor and Generator - New ApproachesAndi1987No ratings yet

- 6-2canal Design Viscous FlowDocument6 pages6-2canal Design Viscous FlowMaiman LatoNo ratings yet

- On The Modelling of The Electro-Hydrodynamic Flow Field in Electrostatic PrecipitatorsDocument27 pagesOn The Modelling of The Electro-Hydrodynamic Flow Field in Electrostatic PrecipitatorsIbtehaj Tasfin RiasatNo ratings yet

- Design of A Low Resistance Grounding System For A Hydro-Electric Plant Located On Highly Resistive SoilsDocument9 pagesDesign of A Low Resistance Grounding System For A Hydro-Electric Plant Located On Highly Resistive SoilsJose Jorge FontalvoNo ratings yet

- 603 DDocument8 pages603 DreluNo ratings yet

- Performance of Multi-Layers Coil PumpDocument15 pagesPerformance of Multi-Layers Coil PumpsupermarioprofNo ratings yet

- Zach West PDFDocument17 pagesZach West PDFRenivaldoRenizete100% (1)

- Dielectric Strength of Different Gases in GISDocument5 pagesDielectric Strength of Different Gases in GISjha_nitinNo ratings yet

- United States PatentDocument6 pagesUnited States Patentaless2056No ratings yet

- Zach WestDocument8 pagesZach WestAleksa Nataša RančićNo ratings yet

- Design 3-Phase Core Type of Transformer and Modification of Symmetrical Star Shaped Core-IJAERDV04I0183936Document8 pagesDesign 3-Phase Core Type of Transformer and Modification of Symmetrical Star Shaped Core-IJAERDV04I0183936Editor IJAERDNo ratings yet

- Study On Electromagnetic Incremental Aluminium Alloy Tube Bulging With Casting PipeDocument6 pagesStudy On Electromagnetic Incremental Aluminium Alloy Tube Bulging With Casting PipeGanat AlrahmanNo ratings yet

- Ref. 3 EcoliDocument8 pagesRef. 3 EcoliwameathNo ratings yet

- Rogowski CoilDocument13 pagesRogowski CoilKanishka AhirwarNo ratings yet

- The Searl Effect GeneratorDocument2 pagesThe Searl Effect GeneratorSrinath Ars100% (2)

- Numerical Simulation of Centrifugal Casting of PipDocument8 pagesNumerical Simulation of Centrifugal Casting of Pipmarco antonio choque hinojosaNo ratings yet

- 24 NanoRes RDEDocument8 pages24 NanoRes RDEŞebnem Gül İlarslanNo ratings yet

- Optimization of Planetary Movement Parameters For Microhole Drilling by Micro-Electrical Discharge MachiningDocument5 pagesOptimization of Planetary Movement Parameters For Microhole Drilling by Micro-Electrical Discharge MachiningAgilAthallahNo ratings yet

- Economic Design of Sleeve Rotor InductioDocument10 pagesEconomic Design of Sleeve Rotor InductioIraqi stormNo ratings yet

- Materials Science PaperDocument6 pagesMaterials Science PaperHouIn CheongNo ratings yet

- Energies: Numerical Study On Thermal Hydraulic Performance of Supercritical LNG in Zigzag-Type Channel PchesDocument19 pagesEnergies: Numerical Study On Thermal Hydraulic Performance of Supercritical LNG in Zigzag-Type Channel PchesCrisMadiRodríguezBarríaNo ratings yet

- Energies: Numerical Study On Thermal Hydraulic Performance of Supercritical LNG in Zigzag-Type Channel PchesDocument19 pagesEnergies: Numerical Study On Thermal Hydraulic Performance of Supercritical LNG in Zigzag-Type Channel PchesSyed Anas SohailNo ratings yet

- Physical Electronics: Handbook of Vacuum PhysicsFrom EverandPhysical Electronics: Handbook of Vacuum PhysicsA. H. BeckNo ratings yet

- An Evaluation of Skilled Labour Shortage in Selected Construction Firms in Edo State, NigeriaDocument12 pagesAn Evaluation of Skilled Labour Shortage in Selected Construction Firms in Edo State, NigeriaAJER JOURNALNo ratings yet

- Switching of Security Lighting System Using Gsm.Document12 pagesSwitching of Security Lighting System Using Gsm.AJER JOURNALNo ratings yet

- The Differentiation Between The Turbulence and Two-Phase Models To Characterize A Diesel Spray at High Injection PressureDocument7 pagesThe Differentiation Between The Turbulence and Two-Phase Models To Characterize A Diesel Spray at High Injection PressureAJER JOURNALNo ratings yet

- Pixel Based Off-Line Signature Verification SystemDocument6 pagesPixel Based Off-Line Signature Verification SystemAJER JOURNALNo ratings yet

- Performance Analysis of LTE in Rich Multipath Environments Considering The Combined Effect of Different Download Scheduling Schemes and Transmission ModesDocument6 pagesPerformance Analysis of LTE in Rich Multipath Environments Considering The Combined Effect of Different Download Scheduling Schemes and Transmission ModesAJER JOURNALNo ratings yet

- Experimental Investigation On The Effects of Digester Size On Biogas Production From Cow DungDocument6 pagesExperimental Investigation On The Effects of Digester Size On Biogas Production From Cow DungAJER JOURNALNo ratings yet

- Structure and Surface Characterization of Nanostructured Tio2 Coatings Deposited Via HVOF Thermal Spray ProcessesDocument9 pagesStructure and Surface Characterization of Nanostructured Tio2 Coatings Deposited Via HVOF Thermal Spray ProcessesAJER JOURNALNo ratings yet

- Improved RSA Cryptosystem Based On The Study of Number Theory and Public Key CryptosystemsDocument7 pagesImproved RSA Cryptosystem Based On The Study of Number Theory and Public Key CryptosystemsAJER JOURNALNo ratings yet

- Recycling of Scrapped Mating Rings of Mechanical Face SealsDocument5 pagesRecycling of Scrapped Mating Rings of Mechanical Face SealsAJER JOURNALNo ratings yet

- Comparative Analysis of Cell Phone Sound Insulation and Its Effects On Ear SystemDocument6 pagesComparative Analysis of Cell Phone Sound Insulation and Its Effects On Ear SystemAJER JOURNALNo ratings yet

- Minimizing Household Electricity Theft in Nigeria Using GSM Based Prepaid MeterDocument11 pagesMinimizing Household Electricity Theft in Nigeria Using GSM Based Prepaid MeterAJER JOURNALNo ratings yet

- Eye State Detection Using Image Processing TechniqueDocument6 pagesEye State Detection Using Image Processing TechniqueAJER JOURNALNo ratings yet

- Weighted Denoising With Multi-Spectral Decomposition For Image CompressionDocument13 pagesWeighted Denoising With Multi-Spectral Decomposition For Image CompressionAJER JOURNALNo ratings yet

- A Concept of Input-Output Oriented Super-Efficiency in Decision Making Units.Document6 pagesA Concept of Input-Output Oriented Super-Efficiency in Decision Making Units.AJER JOURNALNo ratings yet

- Unmanned Aerial Vehicle and Geospatial Technology Pushing The Limits of DevelopmentDocument6 pagesUnmanned Aerial Vehicle and Geospatial Technology Pushing The Limits of DevelopmentAJER JOURNALNo ratings yet

- Experimental Evaluation of Aerodynamics Characteristics of A Baseline AirfoilDocument6 pagesExperimental Evaluation of Aerodynamics Characteristics of A Baseline AirfoilAJER JOURNALNo ratings yet

- Production and Comparartive Study of Pellets From Maize Cobs and Groundnut Shell As Fuels For Domestic Use.Document6 pagesProduction and Comparartive Study of Pellets From Maize Cobs and Groundnut Shell As Fuels For Domestic Use.AJER JOURNALNo ratings yet

- Statistical Method of Estimating Nigerian Hydrocarbon ReservesDocument10 pagesStatistical Method of Estimating Nigerian Hydrocarbon ReservesAJER JOURNALNo ratings yet

- The Role of Citizen Participant in Urban Management (Case Study: Aligudarz City)Document6 pagesThe Role of Citizen Participant in Urban Management (Case Study: Aligudarz City)AJER JOURNALNo ratings yet

- Urbanization and The Risk of Flooding in The Congo Case of The City of BrazzavilleDocument6 pagesUrbanization and The Risk of Flooding in The Congo Case of The City of BrazzavilleAJER JOURNALNo ratings yet

- Utilization of "Marble Slurry" in Cement Concrete Replacing Fine AgreegateDocument4 pagesUtilization of "Marble Slurry" in Cement Concrete Replacing Fine AgreegateAJER JOURNALNo ratings yet

- WHY JESUS CHRIST CAME INTO THE WORLD?... (A New Theory On "TIE MINISTRY")Document12 pagesWHY JESUS CHRIST CAME INTO THE WORLD?... (A New Theory On "TIE MINISTRY")AJER JOURNALNo ratings yet

- DMP Packet Scheduling For Wireless Sensor NetworkDocument8 pagesDMP Packet Scheduling For Wireless Sensor NetworkAJER JOURNALNo ratings yet

- Distinct Revocable Data Hiding in Ciphered ImageDocument7 pagesDistinct Revocable Data Hiding in Ciphered ImageAJER JOURNALNo ratings yet

- An Exponent-Based Propagation Path Loss Model For Wireless System Networks at Vehicular SpeedDocument12 pagesAn Exponent-Based Propagation Path Loss Model For Wireless System Networks at Vehicular SpeedAJER JOURNALNo ratings yet

- Theoretical and Experimental Study of Cavitation Dispersing in "Liquid-Solid" System For Revelation of Optimum Influence ModesDocument10 pagesTheoretical and Experimental Study of Cavitation Dispersing in "Liquid-Solid" System For Revelation of Optimum Influence ModesAJER JOURNALNo ratings yet

- Risk Assessment and Risk MappingDocument7 pagesRisk Assessment and Risk MappingAJER JOURNALNo ratings yet

- Frequency Selective Fading in Wireless Communication Using Genetic AlgorithmDocument6 pagesFrequency Selective Fading in Wireless Communication Using Genetic AlgorithmAJER JOURNALNo ratings yet

- Head Determination and Pump Selection For A Water Treatment Plant in Villages Around Maiduguri, Borno State, NigeriaDocument5 pagesHead Determination and Pump Selection For A Water Treatment Plant in Villages Around Maiduguri, Borno State, NigeriaAJER JOURNALNo ratings yet

- The Design and Implementation of A Workshop Reservation SystemDocument7 pagesThe Design and Implementation of A Workshop Reservation SystemAJER JOURNALNo ratings yet

- Isi BukuDocument183 pagesIsi BukuHayat Hamzah DawiNo ratings yet

- Air CompressorsDocument14 pagesAir CompressorsEduardo Belvis Jr.No ratings yet

- ISCRE 24 Lab Scale Up Workshop NotesDocument2 pagesISCRE 24 Lab Scale Up Workshop NotesSukaran SinghNo ratings yet

- Rapid Fire NewDocument85 pagesRapid Fire NewvarunsanghiNo ratings yet

- Pixl Knowit!: Gcse BiologyDocument66 pagesPixl Knowit!: Gcse BiologyEsther SparksNo ratings yet

- Atf Dexron Iii: Data SheetDocument7 pagesAtf Dexron Iii: Data Sheetwilliam bryantNo ratings yet

- SCH4U - Unit 1 - Version C PDFDocument64 pagesSCH4U - Unit 1 - Version C PDFAbdul Mujeeb100% (1)

- Technical Data Sheet GlasGrid CGL EN 1960442Document2 pagesTechnical Data Sheet GlasGrid CGL EN 1960442vonskemaNo ratings yet

- Lab Report Chemical Process Industries Submitted To: Mam AmaraDocument5 pagesLab Report Chemical Process Industries Submitted To: Mam AmaraMuhammad UsamaNo ratings yet

- CHEM 20024 General Chemistry Practice Exam #2Document7 pagesCHEM 20024 General Chemistry Practice Exam #2Yhana Ruth PajitaNo ratings yet

- Conservation Equations and Modeling of Chemical and Biochemical ProcessesDocument650 pagesConservation Equations and Modeling of Chemical and Biochemical ProcessesArman BasmacıoğluNo ratings yet

- Welding Procedure Specification (WPS) : JointsDocument2 pagesWelding Procedure Specification (WPS) : JointsNavanitheeshwaran SivasubramaniyamNo ratings yet

- Antifoaming Agents For Submerged Microbial Fermentation: BITS Pilani, Hyderabad CampusDocument6 pagesAntifoaming Agents For Submerged Microbial Fermentation: BITS Pilani, Hyderabad CampusShreyanshJain100% (1)

- FTIR Determination of Unsaturation Grade & Isomers FatDocument6 pagesFTIR Determination of Unsaturation Grade & Isomers FatrajdewaanNo ratings yet

- PetroPlate M5800 EP Grease PDFDocument1 pagePetroPlate M5800 EP Grease PDFlukastadeoNo ratings yet

- Process UtilityDocument13 pagesProcess UtilityAnupam Manoj100% (1)

- Saic Q 1048Document1 pageSaic Q 1048Gian Carlo100% (1)

- Materials For Direct RestorationsDocument9 pagesMaterials For Direct RestorationsBerty SusantoNo ratings yet

- Lecture 1 Ideal Gases and Their MixtureDocument24 pagesLecture 1 Ideal Gases and Their MixtureMuez GhideyNo ratings yet

- Hydraulic Drifter: General SpecificationDocument2 pagesHydraulic Drifter: General Specification牛千No ratings yet

- Accesorios de Carga CROSBYDocument52 pagesAccesorios de Carga CROSBYRodolfo AlboresNo ratings yet

- Durebild STE: Surface Tolerant High Build High Solids Epoxy CoatingDocument3 pagesDurebild STE: Surface Tolerant High Build High Solids Epoxy CoatinglivefreakNo ratings yet

- EHV Cables Laying MethodDocument22 pagesEHV Cables Laying MethodSudharsanan Sitrarasu100% (2)

- Masterflow 647R Repair Grout: Technical Data GuideDocument2 pagesMasterflow 647R Repair Grout: Technical Data Guidegazwang478No ratings yet

- Service Manual CSCU-RE12GKE PDFDocument16 pagesService Manual CSCU-RE12GKE PDFJose Vicente Ausina100% (1)

- NTK O2 Sensor HistoryDocument9 pagesNTK O2 Sensor Historyonukvedat7219No ratings yet

- Sika PDS E Intraplast ZDocument2 pagesSika PDS E Intraplast Zlwin_oo2435100% (1)

- Turbine Parts MOC Blog 2Document15 pagesTurbine Parts MOC Blog 2kattukoluNo ratings yet

- Nital EtchDocument2 pagesNital EtchJohn GeddesNo ratings yet

- 3 HerbsDocument260 pages3 HerbsWahyu Edwin SNo ratings yet