Professional Documents

Culture Documents

Aalco Metals LTD Stainless Steel 14305 Bar 107

Uploaded by

Puđa TomicaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Aalco Metals LTD Stainless Steel 14305 Bar 107

Uploaded by

Puđa TomicaCopyright:

Available Formats

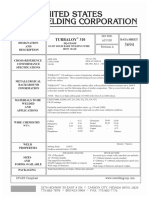

Stainless Steel

1.4305 Bar

SPECIFICATIONS SUPPLIED FORMS

This is a machining bar specification, typically supplied

Commercial 303 as round and hexagon

Bar

Stainless steel type 1.4305 is popularly known as

grade 303 stainless steel. Grade 303 is the most GENERIC PHYSICAL PROPERTIES

readily machineable of all the austenitic grades of

stainless steel. Property Value

The machineable nature of grade 303 is due to the

presence of Sulphur in the steel composition. Whilst Density 8.03 g/cm

the Sulphur improves machining, it also causes a Melting Point 1455 C

decrease in the corrosion resistance and a slight

Thermal Expansion 17.3 x10-6 /K

lowering of the toughness. The corrosion resistance of

type 303 is lower than that for 304. The toughness is Modulus of Elasticity 193 GPa

still excellent as with other austenitic grades.

Thermal Conductivity 16.3 W/m.K

Property data given in this document is typical for bar

products covered by EN 10088-3:2005. ASTM, or other Electrical Resistivity 0.072 x10-6 .m

standards may cover products sold. It is reasonable to

expect specifications in these standards to be similar

but not necessarily identical to those given in this MECHANICAL PROPERTIES

datasheet.

EN 10088-3:2005

Bar

CHEMICAL COMPOSITION Up to 160mm Dia / Thickness

EN 10088-3:2005 Property Value

1.4305 Steel

Proof Stress 190 Min MPa

Element % Present

Tensile Strength 500 to 750 MPa

Chromium (Cr) 17.00 - 19.00

Elongation A50 mm 35 Min %

Nickel (Ni) 8.00 - 10.00

Hardness Brinell 230 Max HB

Manganese (Mn) 0.0 - 2.00

Copper (Cu) 0.0 - 1.00

APPLICATIONS

Silicon (Si) 0.0 - 1.00

Grade 303 is used in applications that require parts to

Sulphur (S) 0.15 - 0.35

be heavily machined. These applications include:

Nitrogen (N) 0.0 - 0.11 Nuts and bolts

Carbon (C) 0.0 - 0.10 Screws

Gears

Phosphorous (P) 0.0 - 0.05 Aircraft fittings

Iron (Fe) Balance Bushings

Shafts

ALLOY DESIGNATIONS CORROSION RESISTANCE

Stainless Steel Grade 1.4305/334 also corresponds to Sulphur additions to the composition act as initiation

the following designations but may not be a direct sites for pitting corrosion. This decreases the corrosion

equivalent: resistance of 303 stainless steel to less than that for

UNS S30300 304. However. corrosion resistance remains good in

BS 303S31 mild environments.

EN 58M In chloride containing environments over 60C, 303

stainless steel is subject to pitting and crevice

corrosion. Grade 303 stainless is not suitable for use in

marine environments.

[1 OF 2] CONTINUED

Aalco is a registered trademark of Aalco Metals Ltd

Copyright: Aalco Metals Ltd, 25 High Street, Cobham, Surrey KT11 3DH

Stainless Steel

1.4305 Bar

HEAT RESISTANCE WELDABILITY

Grade 303 stainless steel has good resistance to The sulphur addition present in 303 stainless steel

oxidation when intermittently exposed to temperature results in poor weldability. If 303 must be welded the

up to 760C temperatures. It also has good oxidation recommended filler rods or electrodes are grades 308L

resistance in continuous service to 870C. This, and 309 stainless steels. For maximum corrosion

however, is not recommended as 303 is sensitive to resistance, the welds must be annealed.

carbide precipitation with continuous use at 425-

860C.

FABRICATION

Fabrication of all stainless steels should be done only

with tools dedicated to stainless steel materials.

Tooling and work surfaces must be thoroughly cleaned

before use. These precautions are necessary to avoid

cross contamination of stainless steel by easily

corroded metals that may discolour the surface of the

fabricated product.

COLD WORKING

Type 303 is not readily cold workable. Some cold

CONTACT

working is possible but sharp bending should not be

attempted.

Address: Please make contact directly with your local

service centre, which can be found via the

Locations page of our web site

HOT WORKING Web: www.aalco.co.uk

Fabrication methods, like forging, that involve hot

working like should occur after uniform heating to

1149-1260C. The fabricated components should then REVISION HISTORY

be rapidly cooled to ensure maximum corrosion

resistance. Datasheet Updated 10 March 2016

MACHINABILITY DISCLAIMER

Grade 303 stainless steel has excellent machinability. This Data is indicative only and as such is not to be relied upon in place of

the full specification. In particular, mechanical property requirements vary

Machining can be enhanced by adhering to the

widely with temper, product and product dimensions. All information is

following rules: based on our present knowledge and is given in good faith. No liability will

Cutting edges must be kept sharp. Dull edges cause be accepted by the Company in respect of any action taken by any third

party in reliance thereon.

excess work hardening.

Cuts should be light but deep enough to prevent work Please note that the 'Datasheet Update' date shown above is no guarantee

of accuracy or whether the datasheet is up to date.

hardening by riding on the surface of the material.

Chip breakers should be employed to assist in ensuring The information provided in this datasheet has been drawn from various

swarf remains clear of the work recognised sources, including EN Standards, recognised industry references

(printed & online) and manufacturers data. No guarantee is given that the

Low thermal conductivity of austenitic alloys results in information is from the latest issue of those sources or about the accuracy of

heat concentrating at the cutting edges. This means those sources.

coolants and lubricants are necessary and must be Material supplied by the Company may vary significantly from this data, but

used in large quantities. will conform to all relevant and applicable standards.

As the products detailed may be used for a wide variety of purposes and as

the Company has no control over their use; the Company specifically

HEAT TREATMENT excludes all conditions or warranties expressed or implied by statute or

otherwise as to dimensions, properties and/or fitness for any particular

Grade 303 stainlesssteel cannot be hardened by heat purpose, whether expressed or implied.

treatment.

Advice given by the Company to any third party is given for that partys

Solution treatment or annealing can be done by rapid

assistance only and without liability on the part of the Company. All

cooling after heating to 1010-1120C. transactions are subject to the Companys current Conditions of Sale. The

extent of the Companys liabilities to any customer is clearly set out in those

Conditions; a copy of which is available on request.

[2 OF 2]

Aalco is a registered trademark of Aalco Metals Ltd

Copyright: Aalco Metals Ltd, 25 High Street, Cobham, Surrey KT11 3DH

You might also like

- A Complete Guide to Watch Repair - Barrels, Fuses, Mainsprings, Balance Springs, Pivots, Depths, Train Wheels and Common Stoppages of WatchesFrom EverandA Complete Guide to Watch Repair - Barrels, Fuses, Mainsprings, Balance Springs, Pivots, Depths, Train Wheels and Common Stoppages of WatchesRating: 4 out of 5 stars4/5 (1)

- Stainless Steel 1.4305 (303) Bar: Specifications Supplied FormsDocument2 pagesStainless Steel 1.4305 (303) Bar: Specifications Supplied FormsElla ChanNo ratings yet

- Stainless Steel Grade 303 / 1.4305: Typical Mechanical PropertiesDocument2 pagesStainless Steel Grade 303 / 1.4305: Typical Mechanical Propertiesonenine2No ratings yet

- Stainless Steel ASTM A815 S31803: Specifications Alloy DesignationsDocument2 pagesStainless Steel ASTM A815 S31803: Specifications Alloy Designationsallouche_abdNo ratings yet

- North American Stainless: Long Products Stainless Steel Grade SheetDocument8 pagesNorth American Stainless: Long Products Stainless Steel Grade Sheettejap314No ratings yet

- Aalco Metals LTD Stainless Steel 14301 Sheet and Plate 343Document3 pagesAalco Metals LTD Stainless Steel 14301 Sheet and Plate 343Manoj ManivasagamNo ratings yet

- Aalco Metals LTD Stainless Steel ASTM A815 S31803 261Document2 pagesAalco Metals LTD Stainless Steel ASTM A815 S31803 261Irvin PajueloNo ratings yet

- Aalco Metals LTD Stainless Steel 14301 Sheet and Plate Quarto Plate CPP Plate 343Document3 pagesAalco Metals LTD Stainless Steel 14301 Sheet and Plate Quarto Plate CPP Plate 343saravananNo ratings yet

- Grade 430 Stainless Steel Technical DataDocument3 pagesGrade 430 Stainless Steel Technical DataMahmood KhanNo ratings yet

- Stainless Steel Grades and Technical Data SheetDocument34 pagesStainless Steel Grades and Technical Data SheetKamil MarszałekNo ratings yet

- Material - (1 4462)Document2 pagesMaterial - (1 4462)Ashutosh PathakNo ratings yet

- Aalco Metals LTD Stainless Steel 14571 Bar 40Document3 pagesAalco Metals LTD Stainless Steel 14571 Bar 40raduonoNo ratings yet

- Atlas Grade Datasheet - All Datasheets Rev Aug 2013 PDFDocument57 pagesAtlas Grade Datasheet - All Datasheets Rev Aug 2013 PDFMikku KattaNo ratings yet

- Kiran - Steel Data SheetDocument57 pagesKiran - Steel Data SheetkirankumargattyNo ratings yet

- 409 Stainless Steel PDFDocument2 pages409 Stainless Steel PDFDang Thanh TuanNo ratings yet

- 304 Technical Data PDFDocument3 pages304 Technical Data PDFNithin BasavaNo ratings yet

- Atlas 304 - 304L: Colour Code: Lilac/TurquoiseDocument3 pagesAtlas 304 - 304L: Colour Code: Lilac/TurquoiseOthoniel MunizNo ratings yet

- 304 Grade SteelDocument6 pages304 Grade SteelShashank SaxenaNo ratings yet

- Stainless Steel SpecDocument3 pagesStainless Steel SpecFrancis BoeyNo ratings yet

- SS304 304L Data SheetDocument2 pagesSS304 304L Data SheetPrakash KumarNo ratings yet

- 2304 Tubing ASTM A789 / ASME SA789 S32304 1.4362 Duplex Steel TubeDocument13 pages2304 Tubing ASTM A789 / ASME SA789 S32304 1.4362 Duplex Steel TubeGonzalo MazaNo ratings yet

- Grade 304 Stainless Steel Properties, Fabrication and ApplicationsDocument1 pageGrade 304 Stainless Steel Properties, Fabrication and ApplicationsHamed GholipourNo ratings yet

- Brown Metals Company Technical Data Sheet on Types 316 and 316L Stainless SteelsDocument1 pageBrown Metals Company Technical Data Sheet on Types 316 and 316L Stainless Steelstris khanNo ratings yet

- 301-301LN Stainless SteelsDocument4 pages301-301LN Stainless SteelsTeka KamNo ratings yet

- 304 Stainless Steel Data Sheet Explains Properties & UsesDocument4 pages304 Stainless Steel Data Sheet Explains Properties & UsesMani KannaNo ratings yet

- 316l Austenitic Stainless Steel BarDocument3 pages316l Austenitic Stainless Steel Barதமிழன் இராமசாமிNo ratings yet

- Aalco Metals LTD Stainless Steel 14462 Sheet and Plate 102Document3 pagesAalco Metals LTD Stainless Steel 14462 Sheet and Plate 102Jessicalba LouNo ratings yet

- SS 304Document4 pagesSS 304Imtinan Mohsin100% (1)

- Grade 316 Stainless Steel Technical DataDocument3 pagesGrade 316 Stainless Steel Technical Dataali kajbafNo ratings yet

- Stainless Steel Grade 304 (UNS S30400)Document5 pagesStainless Steel Grade 304 (UNS S30400)Gangsar DwikaNo ratings yet

- NAS 64 High Corrosion Resistant Duplex Stainless SteelDocument4 pagesNAS 64 High Corrosion Resistant Duplex Stainless SteelAfronie Cepoz D'nextNo ratings yet

- Grade Data SheetDocument2 pagesGrade Data Sheetamitkharb111195No ratings yet

- Table: Common Austenitic Stainless Steel Grades and Their ApplicationsDocument1 pageTable: Common Austenitic Stainless Steel Grades and Their ApplicationshueyliewNo ratings yet

- Technical DataDocument1 pageTechnical DataengrodeNo ratings yet

- GRADE 302: Element Content (%)Document3 pagesGRADE 302: Element Content (%)Shashank Saxena100% (1)

- Grade 309 Stainless Steel Properties and ApplicationsDocument3 pagesGrade 309 Stainless Steel Properties and ApplicationsGabriel BozzaNo ratings yet

- Turbaloy 310 (SS-310) Data SheetDocument1 pageTurbaloy 310 (SS-310) Data SheetcandraNo ratings yet

- Stainless Steel Bar 431 Atlas 431: Colour Code: Signal RedDocument3 pagesStainless Steel Bar 431 Atlas 431: Colour Code: Signal RedNitin AggarwalNo ratings yet

- Stainless Steel 1.4571 - 316ti: Alloy DesignationsDocument3 pagesStainless Steel 1.4571 - 316ti: Alloy DesignationsRohit choudharyNo ratings yet

- 25CR20NIDocument2 pages25CR20NIShariq KhanNo ratings yet

- Aalco Metals LTD - Stainless Steel 14016 430 Sheet and Plate - 95Document3 pagesAalco Metals LTD - Stainless Steel 14016 430 Sheet and Plate - 95bhushansalunkeNo ratings yet

- Stainless Steel Grade 304 (UNS S30400)Document4 pagesStainless Steel Grade 304 (UNS S30400)105034412No ratings yet

- Sales Offices and Product Data for Grade 430 Stainless SteelDocument2 pagesSales Offices and Product Data for Grade 430 Stainless Steeltranngocthuan200No ratings yet

- 430 Data SheetDocument2 pages430 Data SheetweiyaNo ratings yet

- 591 Tig 5Document20 pages591 Tig 5Nadies631No ratings yet

- Grade 316 316LDocument9 pagesGrade 316 316LvsajuNo ratings yet

- Aalco Metals LTD Stainless Steel 14021 Bar 311Document2 pagesAalco Metals LTD Stainless Steel 14021 Bar 311joseocsilvaNo ratings yet

- Grade Data Sheet for 304, 304L and 304H Stainless SteelsDocument2 pagesGrade Data Sheet for 304, 304L and 304H Stainless Steelss swamiNo ratings yet

- Guide To Selection: Stainless SteelDocument3 pagesGuide To Selection: Stainless SteelElla ChanNo ratings yet

- Mig/Tig Arc Welding For Stainless Steels & Carbon SteelsDocument10 pagesMig/Tig Arc Welding For Stainless Steels & Carbon SteelsTrương Ngọc SơnNo ratings yet

- Stainless Steel Grade AISI 304 PDFDocument2 pagesStainless Steel Grade AISI 304 PDFSarita ForgingNo ratings yet

- 409 Data BulletinDocument12 pages409 Data BulletinWilliam PaivaNo ratings yet

- 303 Spec SheetDocument2 pages303 Spec SheetYankMulya MusaNo ratings yet

- Stainless Steel Grade Selection Rev Sep 2008Document11 pagesStainless Steel Grade Selection Rev Sep 2008rastogi18100% (1)

- S31803Document2 pagesS31803Elliott RussellNo ratings yet

- Oxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNo ratings yet

- Handbook of Structural Welding: Processes, Materials and Methods Used in the Welding of Major Structures, Pipelines and Process PlantFrom EverandHandbook of Structural Welding: Processes, Materials and Methods Used in the Welding of Major Structures, Pipelines and Process PlantRating: 3.5 out of 5 stars3.5/5 (3)

- AtestDocument75 pagesAtestPuđa TomicaNo ratings yet

- TALAT Lecture 1501: Properties, Characteristics and Alloys of AluminiumDocument60 pagesTALAT Lecture 1501: Properties, Characteristics and Alloys of AluminiumCORE Materials100% (1)

- Cold Bending DIN 6935 (Eng)Document3 pagesCold Bending DIN 6935 (Eng)Samira Adnan HalilovićNo ratings yet

- En 10025Document4 pagesEn 10025Jayesh83% (6)

- DB Alform M-Series E 14112012Document3 pagesDB Alform M-Series E 14112012Puđa TomicaNo ratings yet

- Steel Plate Specs ComparisonDocument3 pagesSteel Plate Specs ComparisonPuđa TomicaNo ratings yet

- TALAT Lecture 1501: Properties, Characteristics and Alloys of AluminiumDocument60 pagesTALAT Lecture 1501: Properties, Characteristics and Alloys of AluminiumCORE Materials100% (1)

- BS ISO 8015 - 1985 - Technical Drawings - Fundamental Tolerancing PrincipleDocument12 pagesBS ISO 8015 - 1985 - Technical Drawings - Fundamental Tolerancing PrincipledarlanschulzNo ratings yet

- TALAT Lecture 1501: Properties, Characteristics and Alloys of AluminiumDocument60 pagesTALAT Lecture 1501: Properties, Characteristics and Alloys of AluminiumCORE Materials100% (1)

- Pizza HitDocument2 pagesPizza HitPuđa TomicaNo ratings yet

- DB Alform M-Series E 14112012Document3 pagesDB Alform M-Series E 14112012Puđa TomicaNo ratings yet

- Table of Tolerances: (Reprinted From Design Data, PSG Tech, 1995)Document2 pagesTable of Tolerances: (Reprinted From Design Data, PSG Tech, 1995)Puđa TomicaNo ratings yet

- Pizza HitDocument2 pagesPizza HitPuđa TomicaNo ratings yet

- HARDOX - OznakebDocument24 pagesHARDOX - OznakebPuđa TomicaNo ratings yet

- Land Deep Production Casings in Menengai Geothermal FieldDocument30 pagesLand Deep Production Casings in Menengai Geothermal FieldShafeeq ChappuNo ratings yet

- Omeprazole: by Jennica Mae V. CuicoDocument7 pagesOmeprazole: by Jennica Mae V. Cuicoジェンニカ メイNo ratings yet

- Packed bed axial thermal conductivityDocument7 pagesPacked bed axial thermal conductivityAdriano HenriqueNo ratings yet

- Adam Lechter: Resident Course in Confectionery TechnologyDocument73 pagesAdam Lechter: Resident Course in Confectionery TechnologyJulio KinenNo ratings yet

- Studies On The Production of Defatted Sunflower Meal With Low Polyphenol and Phytate Contents and Its Nutritional ProfileDocument4 pagesStudies On The Production of Defatted Sunflower Meal With Low Polyphenol and Phytate Contents and Its Nutritional Profileamco2kNo ratings yet

- PERCENT BY MASS OF HYDROGEN PEROXIDE (H2O2) IN AGUA OXIGENADA (A Post-Laboratory Report)Document10 pagesPERCENT BY MASS OF HYDROGEN PEROXIDE (H2O2) IN AGUA OXIGENADA (A Post-Laboratory Report)Angel Ombid100% (1)

- SDS Asam SulfatDocument8 pagesSDS Asam SulfatQuality AssuranceNo ratings yet

- MScSYChem18 19Document40 pagesMScSYChem18 19kumarNo ratings yet

- Cniai 34686 0003Document45 pagesCniai 34686 0003Nirosha Dilrangi PereraNo ratings yet

- Banana Peel Shoe PolishDocument11 pagesBanana Peel Shoe PolishGMae Lim100% (4)

- Sansico Top Access Floor Trap - S3Document20 pagesSansico Top Access Floor Trap - S3Biggie ColdAngelNo ratings yet

- Lecture 4 - Reinforced Concrete - Bond, Development LengthDocument55 pagesLecture 4 - Reinforced Concrete - Bond, Development LengthChristopher PaladioNo ratings yet

- C.02 - Gas-Freeing and Cleaning of TanksDocument7 pagesC.02 - Gas-Freeing and Cleaning of TanksmkkamarajNo ratings yet

- Sierra Gorda - Feasibility (2011)Document240 pagesSierra Gorda - Feasibility (2011)Nicolas CarrascoNo ratings yet

- Onions: Vegetable Crops Production Guide For The Atlantic ProvincesDocument8 pagesOnions: Vegetable Crops Production Guide For The Atlantic ProvincesEglNo ratings yet

- Advanced Manufacturing Technology 2-Marks Question and Answer Unit-IDocument44 pagesAdvanced Manufacturing Technology 2-Marks Question and Answer Unit-IM.ThirunavukkarasuNo ratings yet

- PVC FlamethrowerDocument21 pagesPVC FlamethrowerMike Nichlos100% (4)

- Jyothy Institute of TechnologyDocument4 pagesJyothy Institute of TechnologyBasavaraj hsNo ratings yet

- Utilization of Sugarcane Bagasse Ash and Rice Husk Ash On Compressive Strength and Durability of Sustainable Pavement Quality ConcreteDocument10 pagesUtilization of Sugarcane Bagasse Ash and Rice Husk Ash On Compressive Strength and Durability of Sustainable Pavement Quality ConcreteEditor IJTSRDNo ratings yet

- Organic Name Reactions GuideDocument12 pagesOrganic Name Reactions GuidechinmayaNo ratings yet

- Sample IPM PlanDocument4 pagesSample IPM PlanEricNo ratings yet

- Selig Sealing ProductsDocument60 pagesSelig Sealing Productslaurentiu29No ratings yet

- A STUDY ON THE ECOFRIENDLY DYES EXTRACTED FROM THREE DIFFERENT SPECIES OF Curcuma LDocument3 pagesA STUDY ON THE ECOFRIENDLY DYES EXTRACTED FROM THREE DIFFERENT SPECIES OF Curcuma Lanon_285184956No ratings yet

- S1XBIG58 M500 4 Tech InfoDocument15 pagesS1XBIG58 M500 4 Tech InfoFredy DanielNo ratings yet

- 11th Chemistry EM - Public Exam 2022 - Model Question Paper - English Medium PDF DownloadDocument3 pages11th Chemistry EM - Public Exam 2022 - Model Question Paper - English Medium PDF DownloadAshwini Shankar KumarNo ratings yet

- Pogil - Periodic Trends RHSDDocument7 pagesPogil - Periodic Trends RHSDErin DodsonNo ratings yet

- SIP MeenakshDocument17 pagesSIP MeenakshRati GuptaNo ratings yet

- Schunk Carbon Technology Sealring Bearing SiSiC SSiC EN PDFDocument2 pagesSchunk Carbon Technology Sealring Bearing SiSiC SSiC EN PDFMUHAMMAD ASYRAAF BIN ANUARNo ratings yet

- FuelsDocument22 pagesFuelsADITYA GAURNo ratings yet

- DESN 10041 - Exam-2020-MainDocument4 pagesDESN 10041 - Exam-2020-MainZikani NyirendaNo ratings yet