Professional Documents

Culture Documents

Prediction of Mass Transfer Coefficient in Solid-Suspended Internal Air

Uploaded by

Ali Abdul-RahmanCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Prediction of Mass Transfer Coefficient in Solid-Suspended Internal Air

Uploaded by

Ali Abdul-RahmanCopyright:

Available Formats

International Journal of Engineering Research & Technology (IJERT)

ISSN: 2278-0181

Vol. 2 Issue 11, November - 2013

Prediction of Mass Transfer Coefficient in Solid-Suspended Internal Air

Lift Loop Reactor Using Newtonian and Non-Newtonian Liquids

Ali Abdul Rahman Al Ezzi *a,b Ghazi Faisal Najmuldeen a

a

Faculty of Chemical & Natural Resources Engineering/ Universiti Malaysia Pahang

b

Department of Chemical Engineering, University of Technology/ Baghdad, Iraq

Abstract upper and lower ends of the riser due to flow

reversal for a solid-suspended airlift reactor

The effect of superficial gas in the riser containing low-density particles Karamanev et al.

[4]

(Vgr) and liquid phase properties,solid-particle Used 3 mm soft polyurethane foam particles in

concentration (50, 100) Kg/m3 and the static liquid their experiments. They found that the gas holdup

height on mass transfer coefficient (KLa), were decreased significantly with increasing solids

studied in a solid suspendedinternal loop airlift loading and the gas holdup was proportional to

reactor. Air was used as a gas phase. Water, Vg1.2. However, most works in the literature that

Ethanol, Iso-Propanol, NaCL were used as study the hydrodynamics in slurry reactors have

Newtonian liquids and (2.0 %) of carboxy methyl been performed under conditions of low solid

cellulose (CMC) solution were used as non- concentrations. These works showed that particles

Newtonian liquids. Spheres, Polyethylene-non- with typical particle sizes smaller than 100m are

RT

porous-solid particles were used as solid phase. uniformly suspended in both the axial and radial

Superficial gas velocity varied from 0.01 m/s to directions in a slurry system. [5,6] In the concentric

0.1 m/s. The experimental result shows that the tube airlift bioreactor, some geometrical

IJE

(KLa) increase with increasing gas velocity and parameters(different height to diameter ratio and

decrease with increasing solid particle different top and bottom clearances) affect gas

concentration, static liquid height, viscosity and holdup, liquid circulation, mixing time and the

surface tension of liquid-phase. volumetric oxygen transfer coefficient. Extensive

Keywords:Internal loop airlift reactor, Mass study of reactor hydrodynamics and reactor

geometry enhances the importance of the

Transfer Coefficient, Newtonian, Non

geometric parameters in the design and scale-up of

Newtonian.

concentric tube airlift bioreactors. [7, 8, 9] To design

and operate the air lift loop reactors with

Introduction confidence, the knowledge of gas-liquid mass

transfer is required to characterize the performance

Three phase internal air lift loop reactors are of the air lift loop reactor. The main parameter

increasingly used in the fields of chemical and used as an indicator for gas-liquid mass transfer

biotechnology as simple and effective contactors rate is the gas-liquid mass transfer coefficient

for processes involving gases, liquids and solids. (Kla). [10, 11, 12] A large number of researchers [13, 14,

The internal loop reactor has found many 15, 16, 17, 18, 19]

have investigated the mass transfer

applications in many industrial processes such as performance in the air lift loop reactors together

hydrogenation, desulfurization, coal liquefaction, with their hydrodynamic behavior. Airlift reactors

Fisher Tropsch synthesis etc. The simplicity of are agitated pneumatically and circulation takes

their design and construction, high heat and mass place in a defined cyclic pattern through a loop,

transfer capacity, and excellent mixing properties which divides the reactor into two zones: a flow-

with low power requirements are making them upward and a flow-downward zone. The gas-

very attractive. [1, 2] Several investigators have sparged zone or the riser has higher gas holdup

studied the hydrodynamics of three-phase internal- than the relatively gas-free zone, the down comer,

loop airlift reactors.Miyahara and where the flow is downward. [2] However, few

Kawate[3]measured the gas holdup in the riser and studies have addressed three-phase airlift reactors

the down comer, and the pressure drop at the with low density solids (<2%, v/v) .[20, 21] The

IJERTV2IS110604 www.ijert.org 1879

International Journal of Engineering Research & Technology (IJERT)

ISSN: 2278-0181

Vol. 2 Issue 11, November - 2013

purpose of this study is to clarify experimentally flow rate was set-up using gate valve and the

the effects of the gas velocity and liquid phase amount measured with a gas meter. The dissolved

properties (coalescing , Newtonian and non oxygen concentration in the liquid phase was

Newtonian behavior) on mass transfer coefficient measured usingoxygen meter device type a (YSI-

(Kla) in a solid suspends concentric tube airlift 5100), which consists of a probe metal electrode.

loop reactor when the ratio of draught tube The liquid phase (batch) consists of the following

diameter to column diameter is equal to 0.5 systems (only water, water and solid, water,

and the air is dispersion into the center of the alcohols and solids (Newtonian), water, CMC and

riser. solids (non Newtonian))the chemicals used in the

present study were procured from Permula

Experimental Section Chemicals Sdn.Bhd., Malaysia. The gas distributor

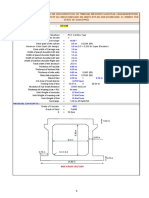

Fig 1.b was constructed from a ceramic material

A schematic diagram of the experimental and thetype is a porous gas distributor. The

setup in this work is shown in Figures 1, 1.a and distributor has an equivalent pore diameter of 0.1

1.b. A Plexiglass column of 0.09 m inside mm and free section of 70%.

diameter and about 1.30 m total height with

draught tube dimensions of 0.045 m inside Results and discussion

diameter and 0.09 m total height was used. The Mass transfer coefficient

top and bottom clearances were maintained

constant at 5 cm. The draught tube was fitted with The average gas hold up g was calculated from

three support legs in the upper and the lower end the equation (1) usingthe data of the clear - liquid

of the column so as to locate it in a central position height (HL) and the height of the aerated liquid

at any distance above the base. The column (HF) which was determined by visual observation:

consists of two main sections namely, the gas inlet HF HL

g

H F Vi / S o

section and the liquid recycling testing section. (1)

RT

The gas inlet section consists of a gas distributor.

At the bottom of this section, two lines are Vi / So In equation (1) is a correction term for

connected together before entering the distributor the volume of the draft tube. [22]The solid-hold-up

section each line has a value to be opened or

IJE

was calculated from the equation(2).Using the date

closed as required. One of these lines is the air of static liquid height (HF) and the height of slurry

inlet flow. Air compressor supplied the line with

the desired amount of air needed; the amount of air after adding solid particles ( H F ):

was measured using a gas meter. The other line is HF HL

the nitrogen gas inlet flow. The nitrogen gas was s (2)

HF

supplied from a cylinder. A gate valve was used in

the nitrogen flow, which must be shut off when the The experimental gas hold up was found by

air was dispersed into the column, and must be measuring the difference between initial liquid

opened during the desorption process. The liquid height and final liquid height. Since it was rather

testing section contains two openings, one for difficult to read directly the level of the aerated

liquid out-flow and the other for liquid in flow. liquid the values of gas hold up thus obtained

The circulation of liquid in the column was probably involves an error of about 5%,

achieved using a dosing pump placed in the established via repeated measurements.

recycling line. A ball valve placed in the middle of The physical absorption of oxygen in the air by the

the recycling line was used to take various samples liquid was employed to determine themass transfer

at various times to measure the concentration of coefficient. A material balance of oxygen in the

liquid gives:-

the dissolved oxygen during the operation. The

column was filled with water to the desired level K La

2.303 1 g s C C

.Log Sa i (3)

above the distributor (0.3,0.5, and 0.7) m. Then the t C Sa Co

solid particles (polyethylene 3.4mm particle Rearranging equation (3) gives

diameter and the density 853.5 Kg/m3) were added

C Ci K La

Log Sa

to the liquid in the column. The concentration of .t (4)

solid particles to each level of static liquid were CSa Ci 2.303 1 g S

(50,100) kg solid /m3slury respectively.

Compressed air at (100-150) psig was supplied

using a reciprocating compressor. The desired air

IJERTV2IS110604 www.ijert.org 1880

International Journal of Engineering Research & Technology (IJERT)

ISSN: 2278-0181

Vol. 2 Issue 11, November - 2013

Plotting the left hand side of equation (4) with (t), coalescence, so that the mass transfer coefficient is

the average slope of the plot will give the term increased. The reduction of bubble size with

K La 2.303 1 g s the values of (g) and (s) increasing gas velocity is a characteristic feature of

pseudo plastic (water-CMC) system [24]; therefore

were determined as mentioned in (1) and (2)

the mass transfer coefficient is smaller than that in

respectively, then (KLa) can be calculated. Figure

water.

(2)shows the effect of gas velocity on mass

transfer coefficients for water system with and

without solid particles. The mass transfer Conclusions

coefficients increase with increasing gas velocity.

The axial dispersion coefficients (DL) increase The presence of suspended solid particles in the

with increasing gas velocity and therefore increase concentric tube airlift loop reactor and the ratio of

(KLa). But the effect without solid particles is the draught tube diameter to column diameter

larger than that with solid particles. Figure (3) equal to 0.5 reduce the values of the volumetric

shows the effect of solid particle concentration on liquidphase mass transfer coefficient KLa. The

(KLa). The presence of solid particle in the liquid reduction of KLavalues due to an addition of solid

will decrease the axial dispersion coefficientand it particles to the column increases with increasing

enhances bubble coalescence. The bubble size will solid concentration and liquid phase (water,

be larger and occupying larger space in the column alcohols and solids, Newtonian and water, CMC

and therefore reduces (KLa). At a higher gas non-Newtonian) viscosity.

velocity (0.1) m/sec, the effect of solid particles on The mass transfer coefficient in airlift loop reactor

(KLa) will be less than in low gas velocities (0.03 with a draught tube, where gas is dispersed into

m/sec). Figures (4) and (5) show the effect of the center of the base of the inner draught tube

static liquid height on the mass transfer using a pours multi hole distributor increase with

coefficient. As the static liquid height is increased, increasing gas velocity, for Vg equal or less than

however the bubble has time to coalesce further 0.1 m/sec. This observation is in agreement with

RT

and ultimately decreases the axial dispersion many experimental works [25, 26].

coefficient and the mass transfer coefficient. When the static liquid height is increased, the

Figure (6) shows the effect of liquid phase bubble has time to coalesce further and ultimately

properties on (KLa). The volumetric-mass transfer

IJE

decreases the axial dispersion coefficient and

coefficient (KLa) is a function of gas hold-up and reduce mass transfer coefficient.

mean bubble size.On account of the strong

coalescence inhibition the volumetric mass Nomenclature

transfer coefficient in (water-isopropanol+ solid)

system reach double the values as in (water-

solid). For aqueous solutions of aliphatic alcohols a Specific gas-liquid interfacial

with solid, (Ethanol), the presence of solid area based on aerated liquid

particles retards the bubble rise velocity and volume m-1

prevents increases in bubble size, so that the mass Ci Concentration of dissolved

transfer coefficients are larger than that in (water- oxygen at any time p.p.m

solid). C0 Initial Concentration of dissolved

The presence of alcohol surfactants increased the oxygen p.p.m

gas hold up in riser (gr). This was mainly due to CSa Saturated concentration of

the suppression of bubble coalescence i.e. number dissolved oxygen p.p.m

of small bubbles produced in the riser had an CS Solid particle concentration

insufficient bubble rise velocity to escape from the KG/m3

liquid. The addition of small amounts of normal DC Column diameter

aliphatic alcohols (iso-propanol) changes the Di Diffusivity of oxygen in solution

hydrodynamics of a draft tube air loop reactor m2/sec

(DT-ALR) while decreasing the surface tension. DL Axial dispersion coefficient

This leads to an increase in the gas holdup and a (liquid) m2/sec

decrease in the down comer liquid velocity, in all g Acceleration of gravity m/sec2

investigated systems, in comparison to water. A HL Static slurry height (m)

similar trend was observed byAl-Masry and HF Level of aerated slurry (m)

Dukkan[23]. The ionic forces in the liquid bulk HF Level of liquid phase+ solids (m)

reduce the bubble rise velocity and the bubble KL Liquid phase mass transfer

IJERTV2IS110604 www.ijert.org 1881

International Journal of Engineering Research & Technology (IJERT)

ISSN: 2278-0181

Vol. 2 Issue 11, November - 2013

coefficient (m.s-1)

KLa Overall mass transfer coefficient,

based on aerated slurry volume. n: flow behavior index

(Sec-1) : shear rate 1/sec

Sc Slurry column T: shear stress

t Time (min) eff= n-1

Vg Gas velocity (m/sec) where eff: effective liquid phase viscosity Pa.s

Y = 5000 Vg[27]

Where Vg: gas velocity m/sec.

Table 2. Physical properties for mixtures used with

various concentrations at T=20oC

Greek letters

(kg/m3)103 (CP) (dyn/cm) L(cm2/sec)

g Gas hold up Water- 0.982 0.972 62.42 0.8932

s Solid hold up Isopropanol

L Liquid phase density kg/m3 10%

S Solid phase density kg/m3 Water- 0.981 0.910 22.64 0.9400

Ethanol

L Liquid phase viscosity(Cp) 10%

L Kinematic viscosity of liquid Water- 1.0216 0.9247 48.375 0.9051

phase (cm2/sec) NaCL, 10%

L Liquid phase surface tension Water- 1.009 K =1.320 69 0.09051

CMC Pasnn=0.5

dyne/cm 2%

RT

Subscripts

IJE

G gas

L liquid

Table 1.Physical-properties for pure liquids

at T = 20 oC

L

(kg/m3)103 (CP) (dyn/cm) (cm2/sec)

Water 0.998 1.002 72.86 1.004

Iso-ropanol 0.785 0.85 66 0.9792

Ethanol 0.789 1.200 22.27 1.520

NaCL 2.165 1.295 72 0.598

CMC 1.008 K=0.01 73 1.23

2 ps.sn

n=0.8

The solution of CMC (carboxy methyl cellulose) shows non

Newtonian, pseudo plastic behavior, which can be described

by the power law of Ostwald and deweale:

(a)

t = K n

Where:-

K: Ostwald factor (consistency index)

IJERTV2IS110604 www.ijert.org 1882

International Journal of Engineering Research & Technology (IJERT)

ISSN: 2278-0181

Vol. 2 Issue 11, November - 2013

RT

IJE

(b)

(c)

Figure 1. (a) Experimental-Apparatus; (b)

Column and (c) Gas distributor Figure 2.Mass transfer coefficient versus gas

velocity for water systems

IJERTV2IS110604 www.ijert.org 1883

International Journal of Engineering Research & Technology (IJERT)

ISSN: 2278-0181

Vol. 2 Issue 11, November - 2013

Figure 5. Mass transfer coefficient versus static

Figure 3. Mass transfer coefficient versus solid liquid height for various solid concentrations

concentration for water system for various gas and for various gas velocities

velocities

RT

IJE

Figure 4. Mass transfer coefficient versus solid Figure 6. Mass transfer coefficient versus gas

concentration for water system for various gas velocity for different liquid phase system

velocities

IJERTV2IS110604 www.ijert.org 1884

International Journal of Engineering Research & Technology (IJERT)

ISSN: 2278-0181

Vol. 2 Issue 11, November - 2013

References [19] T. Zhang, B. Zhao, and J. Wang,Mathematical

models for macro-scale mass transfer in airlift loop

reactors, Chem. Eng. J., 2006; 119, 1926.

[1]W. Y. Wei, L. M. Tiefeng, and Z. Wang,Bubble [20] Y. Kawase, and N. Hashimoto,Gas holdup and

circulation regimes in a multi-stage internal-loop airlift oxygen transfer in three-phase external-loop airlift

reactor, Chem. Eng. J., 2008; 142, 301308. bioreactors: non-Newtonian fermentation broths, J.

[2] M.Y. Chisti, Airlift Bioreactors, Elsevier Applied Chem. Technol. Biotechnol., 1996; 65, 325334.

Science, London, UK, 1989; p.349. [21] H. L. Tung, Y. Y. Chang, T. K. Hwang, and W. T.

[3] T. Miyahara, and O. Kawate, Hydrodynamics of a Wu,liquid mixing and mass transfer in a modified

solid-suspended bubble column with a draught tube bubble column with suspended particles, J. Chin. Inst.

containing low-density particles,Chem. Eng. Sci., Chem. Engrs., 1998; 29, 467472.

1993,48, 127133. [22] K. Koide, K. Katsumi, I. Shinji, I. Yutaka, and H.

[4] D. G. Karamanev, T. Nagamune,and I. Kazuyoshi,Gas holdup and volumetric liquid-phase

Endo,Spouted and Spout-Fluid Beds: Fundamentals and mass transfer coefficient in bubble column with draught

Applications, Chem. Eng. Sci., 1992; 47, 35813588. tube and with gas dispersion into tube, J. Chem. Eng.

[5] R. H. Wilhelm, and M. Kwauk,Fluidization of solid Jap., 1983b; 16(5) 413419.

particles, Chem. Eng. Prog., 1948; 44, 201217. [23] W.A. Al- Masry, and A.R. Dukkan,Hydrodynamics

[6] G. Q. Yang, B. Du, and S. L. Fan, Bubble formation and mass transfer studies in a novel external-loop airlift

and dynamics in gas liquid solid fluidization: a reactor, Chem.Eng.J., 1997; 65, 263271.

review,Chem. Eng. Sci., 2007; 62; 227. [24] M.W. Haque, K.D.P. Nigam, and J.B.

[7] M. Gavrilescu., and R. Z. Tudose,Concentric-tube Joshi,hydrodynamics and mixing in highly viscous

Airlift Bioreactors. Part I: Effects of geometry on Gas pseudo-plastic non-Newtonian solutions in bubble

Holdup, Bioprocess Eng.,1998a; 19;3744. columns, Chem. Eng. Sci., 1986b; 41(9);2321 2331.

[8] M. Gavrilescu, R. Z. Tudose,Concentric-tube Airlift [25] T. Samuel, x. Arnaud, and L. Alain,Global

Bioreactors. Part II: Effects of geometry on Liquid modeling of a gasliquid solid airlift reactor, Chem.

Circulation, Bioprocess Eng.,1998b;19,103109. Eng. Sc., 2005; 60; 59916003.

[9] M. Gavrilescu, R. Z. Tudose, Concentric-tube Airlift [26] D. Zhonghuo, T. Wang, N. Zhang, and Z.

Bioreactors. Part III: Effects of geometry on Mass Wang,Gas holdup, bubble behavior and mass transfer in

Transfer, Bioprocess Eng.,1998bc; 19, 175178.

RT

a 5m high internal-loop airlift reactor with non -

[10] H. Blank, Loop Reactors. Advances in Biochemical Newtonian fluid, Chem. Eng. J., 2010; 160, 729737.

Engineering; Springer-Verlag: New York, 1979;pp. [27] M. Nishikawa, H. Kato, and K.

121-213. Hashimoto,Theoretical prediction of volumetric mass

IJE

[11] H. Blank, Biochemical Loop Reactors. transfer coefficients in bubble columns for Newtonian

Biotechnology, Vol 2, 1985; pp. 465517. and non-Newtonian fluids, Ind. Eng. Chem. Process

[12] M. M. Young, and H.W. Des. Dev., 1977; 16, 133137.

Blanch,Design of biochemical reactors mass transfer

criteria for simple and complex systems,Adv. Biochem.

Eng.,1981;19, 1 69.

[13] K. Koide, S. Hiroyuki, and I. Shinji. J, Gas holdup

and volumetric liquid phase mass transfer coefficient in

bubble column with draught tube and with gas

dispersion into annulus, Chem. Eng. Jap., 1983a; 16(5),

407413.

[14] M. Y.Chisti, and M. M.Young,Hydrodynamics and

oxygen transfer in pneumatic devices, Biotech. Bioeng;

1988; 31, 487 494.

[15] K.H. Choi, and W.K. Lee. J,Circulation liquid

velocity, gas holdup and volumetric oxygen transfer

coefficient in external-loop airlift reactors, Chem. Tech.,

1993; 56, 5158.

[16] J.C. Merchuk, N. Ladwa, A. Cameron, M. Bulmer,

and A. Pickett, Concentric-Tube Airlift Reactors:

Effects of Geometrical Design on Performance,AIChE

J.,1994; 40(7), 11051117.

[17] K. Shimizu, S. Takada, T. Takahashi, and Y.

Kawase, Phenomenological simulation model for gas

holdups and volumetric mass transfer coefficients in

external-loop airlift reactors, Chem. Eng. J., 2001; 84,

599603.

[18] T. Zhang, T. WANG, and J. WANG, Analysis and

measurement of Mass Transfer in Airlift Loop Reactors

,Chin J. Chem. Eng., 2006; 14(5), 604610.

IJERTV2IS110604 www.ijert.org 1885

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- MECH1230 Exam Paper v4 2013 2014 SolutionsDocument18 pagesMECH1230 Exam Paper v4 2013 2014 SolutionssebNo ratings yet

- Open Channel Design Channels PDFDocument27 pagesOpen Channel Design Channels PDFSS100% (1)

- 121 B.P.S. XII - Physics Chapter Notes 2014 15 PDFDocument87 pages121 B.P.S. XII - Physics Chapter Notes 2014 15 PDFkumarnpccNo ratings yet

- 35+530 - VupDocument27 pages35+530 - VupPraveen Cyssan0% (1)

- Flow of Open ChannelDocument61 pagesFlow of Open Channelmr_sam91100% (1)

- Verma S K 1970 04 MasterDocument85 pagesVerma S K 1970 04 MasterAli Abdul-RahmanNo ratings yet

- American Journal of Engineering Research (AJER)Document8 pagesAmerican Journal of Engineering Research (AJER)Ali Abdul-RahmanNo ratings yet

- Ijee 6 (2) - 07Document8 pagesIjee 6 (2) - 07Ali Abdul-RahmanNo ratings yet

- The Final Revesion of My Paper in Wulfenia Journal PDFDocument22 pagesThe Final Revesion of My Paper in Wulfenia Journal PDFAli Abdul-RahmanNo ratings yet

- Aali-Paper, November, With D.reference 2013Document25 pagesAali-Paper, November, With D.reference 2013Ali Abdul-RahmanNo ratings yet

- Hunting in Synchronous Motor: Online Electrical EngineeringDocument5 pagesHunting in Synchronous Motor: Online Electrical EngineeringSasi Kanth KolaNo ratings yet

- NX Nastran 8 Rotor Dynamics User's GuideDocument333 pagesNX Nastran 8 Rotor Dynamics User's GuideMSC Nastran Beginner100% (1)

- Worlds of Flow: A History of Hydrodynamics From The Bernoullis To PrandtlDocument4 pagesWorlds of Flow: A History of Hydrodynamics From The Bernoullis To PrandtljaviNo ratings yet

- Effect of Ni and SB Additions and Testing Conditions On The Mechanical Properties and Microstructures of Lead-Free Solder Joints PDFDocument14 pagesEffect of Ni and SB Additions and Testing Conditions On The Mechanical Properties and Microstructures of Lead-Free Solder Joints PDFGolden ChanNo ratings yet

- Stress Intensity Factor and Crack Tip StressesDocument5 pagesStress Intensity Factor and Crack Tip StressesOsmar DiasNo ratings yet

- Ocean Engineering: Mingsheng Chen, Rodney Eatock Taylor, Yoo Sang ChooDocument12 pagesOcean Engineering: Mingsheng Chen, Rodney Eatock Taylor, Yoo Sang ChooEliotPezoZegarraNo ratings yet

- Introduction - 3 Topics: Flight Dynamics-I Prof. E.G. Tulapurkara Chapter-1Document6 pagesIntroduction - 3 Topics: Flight Dynamics-I Prof. E.G. Tulapurkara Chapter-1alysonmicheaalaNo ratings yet

- Lecture 8 - Dislocation MotionDocument21 pagesLecture 8 - Dislocation Motionadela kingNo ratings yet

- Free Vibration Analysis of Cylindrical Liquid Storage TanksDocument13 pagesFree Vibration Analysis of Cylindrical Liquid Storage TanksJosué Azurín RendichNo ratings yet

- Damping Ratio Workshop Sri AtmajaDocument37 pagesDamping Ratio Workshop Sri AtmajawaltervillanNo ratings yet

- Lab ReportDocument3 pagesLab ReportbluegenesterNo ratings yet

- M-Caps-04: Physics M-Caps-04: Physics M-Caps-04: Physics M-Caps-04: Physics M-Caps-04: PhysicsDocument5 pagesM-Caps-04: Physics M-Caps-04: Physics M-Caps-04: Physics M-Caps-04: Physics M-Caps-04: PhysicsJeel KadiaNo ratings yet

- 4 KinematicsDocument85 pages4 KinematicsCiara Adrianne Tiongzon - ReyesNo ratings yet

- Zeilinger, Interpretation and Philosophical Foundation of Quantum MechanicsDocument12 pagesZeilinger, Interpretation and Philosophical Foundation of Quantum MechanicsManuel SepúlvedaNo ratings yet

- Fluid MechanicsDocument4 pagesFluid MechanicsAmarjit KeneNo ratings yet

- Transport Phenomena and Unit Operations A Combined Approach by Richard G. GriskeyDocument5 pagesTransport Phenomena and Unit Operations A Combined Approach by Richard G. GriskeyRosaNo ratings yet

- Simple Pendulum ExperimentDocument3 pagesSimple Pendulum ExperimentSubesh ShanmugamNo ratings yet

- Lecture Notes 6: The Method of ImagesDocument20 pagesLecture Notes 6: The Method of ImagesZoricaNo ratings yet

- Angular Momentum OperatorsDocument25 pagesAngular Momentum Operatorsarturo_C_MNo ratings yet

- Lecture 09 Rheology PDFDocument29 pagesLecture 09 Rheology PDFsukebadorNo ratings yet

- Thermodynamics of A Rubber BandDocument5 pagesThermodynamics of A Rubber BandAlejandra QuintinNo ratings yet

- 2018 - 10 - Assistant Engineer (Mechanical) - Fnalanswerkey - Withquestion PDFDocument18 pages2018 - 10 - Assistant Engineer (Mechanical) - Fnalanswerkey - Withquestion PDFvjtiitNo ratings yet

- 2007 Liu. Steric Effect A Quantitative Description From Density Functional TheoryDocument6 pages2007 Liu. Steric Effect A Quantitative Description From Density Functional TheoryKarlos Lds NvNo ratings yet

- 1 Performance Task G8 Science Q1Document5 pages1 Performance Task G8 Science Q1jaja genterolaNo ratings yet

- (Guide) Steel Compact & Noncompact RequirementDocument7 pages(Guide) Steel Compact & Noncompact RequirementShaileshRastogiNo ratings yet