Professional Documents

Culture Documents

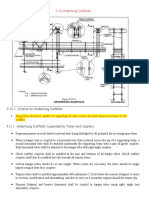

Chevron-JO Lift Procedure For Tubulars

Uploaded by

zhiqianxuOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Chevron-JO Lift Procedure For Tubulars

Uploaded by

zhiqianxuCopyright:

Available Formats

JO Lift Procedure for Tubulars

Tubular handling and tubular management is a complex process. Full information for the handling

and management of Oilfield Casing and Tubular Goods (OCTG) can be found in API RP 5C1

Recommended Practice for the Care and Use of Casing and Tubing. This is carbon steel, hot

drawn, extruded pipe. There are other procedures for the handling of special steels such as 13% and

25% Chrome tubing and casing API 5CT 13 Cr L80 and for other exotic steels such as Stainless

Steel API 5CT 13Cr C95 (Stainless) and Titanium.

The items below are abbreviated guidelines for the handling of OCTG.

1. The safe working load (SWL) of each sling shall not be exceeded by the entire bundle weight.

2. Make odd number joints of tubular in each bundle to make bundles more round. (3 x 13.3/8; 5

x 9.5/8 & 7 x 7.5/8 are common pipes within a bundle)

3. Slings should be placed at equal distance (approximately 25%) from the ends of the load with

the internal angle at the hook not to exceed 90 deg.

4. The slings should be double wrapped and choked (using a bulldog grip and tie wrap) around the

tubular bundle.

5. Tubulars are graded in three grades of length, Range 1 (16 25 Feet), Range 2 (25 34 feet)

and Range 3 (34 48 feet). Only tubulars within a specific range should be bundled together.

Tubulars below 16 feet in length are referred to as pup joints and these should be transported by

marine vessels in either a basket or shipping container. When it is necessary to bundle tubulars

of different lengths within the range, the shortest tubular should not be less than 75% of the

length of the longest tubular

6. In the case of slung tubulars a wire rope grip (bull dog grip) should be used above the reeved

eye that forms the choke.

7. A tie wrap should be used on the reeved eye of the sling to prevent the eye from slipping over

the roped grip.

8. Excessively long tubular lifts may have two tag lines attached. The tag lines shall not be

attached to the slings but may be attached round the bundle outside of the sling area.

9. Only tubulars of the same diameter should be bundled together and whenever possible should

be of similar length.

10. Tubulars, whether individual or in bundles, shall be supported at various lengths along the tube,

(minimum of 3 supports) to prevent hogging and sagging of the tube. Wood or soft materials

shall be used to support the tube or bundle. It is also important that wedges or chocks are used

on the end tubes in a stow to prevent them rolling. Wedges and chocks should be nailed to the

supporting wood to minimize movement of the wedge or chock.

11. Extreme care should be taken when walking on top of tubulars. Handling crews must wear the

correct PPE, in particular steel toe capped boots and gloves.

12. Ensure that protection end caps are correctly fitted prior to the movement of tubulars to trucks

and vessels. End caps can be a dropped object incident if incorrectly fitted and tighten up.

13. Ensure that no foreign objects such as stones or short timber pieces are inserted into any of the

open ended tubulars as these can also lead to dropped object incidents.

You might also like

- Worming, Parcelling, Serving and StoppersDocument4 pagesWorming, Parcelling, Serving and StoppersMitanshu ChadhaNo ratings yet

- Mooring & Wire RopesDocument14 pagesMooring & Wire RopesAlexNo ratings yet

- Drum Handlingstorage Installation GuidelineDocument12 pagesDrum Handlingstorage Installation GuidelineShubham Baderiya100% (1)

- Timber Notes PH 1 Class 2Document16 pagesTimber Notes PH 1 Class 2Yash SaxenaNo ratings yet

- Razor Wire InstallationDocument2 pagesRazor Wire InstallationrazvanbratNo ratings yet

- Installation Manual UPP PipingDocument68 pagesInstallation Manual UPP Pipingnitroxx7100% (1)

- Military MountaineeringDocument21 pagesMilitary MountaineeringSean Ben Kadusale100% (1)

- Tow LinesDocument11 pagesTow Linesbill baileyNo ratings yet

- Handling Ropes and WiresDocument22 pagesHandling Ropes and WiresSeaman NavigatorNo ratings yet

- Correct Usage Instructions For Lifting EquipmentDocument6 pagesCorrect Usage Instructions For Lifting Equipmentmiraç burak navruzNo ratings yet

- Semanship Notes Sem 1 Dec 2021Document12 pagesSemanship Notes Sem 1 Dec 2021maninderNo ratings yet

- Anchoring CiiDocument13 pagesAnchoring CiiDelando CoriahNo ratings yet

- 9 DNS Heaving Line, StoppersDocument4 pages9 DNS Heaving Line, Stopperstusharmalik9350No ratings yet

- Rigging Equipment 29cfr1926Document13 pagesRigging Equipment 29cfr1926Ishmael WoolooNo ratings yet

- Operation Maintenance Manual PDFDocument28 pagesOperation Maintenance Manual PDFbulentbulutNo ratings yet

- Technical Wire RopesDocument17 pagesTechnical Wire RopesAdrian CantaragiuNo ratings yet

- Nonel LPDocument2 pagesNonel LPchandraNo ratings yet

- 9.15 Underhung Scaffold.Document3 pages9.15 Underhung Scaffold.AfshadNo ratings yet

- Practical Deck Skills Topic 1 - Mooring Lines SWL WLL BS-1Document48 pagesPractical Deck Skills Topic 1 - Mooring Lines SWL WLL BS-1yxone acedo100% (1)

- Draft MOS For Cable LayingDocument8 pagesDraft MOS For Cable LayingHtun SoeNo ratings yet

- Cables Drum Handling and InstallationDocument5 pagesCables Drum Handling and InstallationAmit Jayaprakash Koodathil100% (1)

- Bondstrand Series 7000 M Installation ManualDocument84 pagesBondstrand Series 7000 M Installation ManualPavel Vicentiu0% (1)

- Eco-Friendly Long Lining Technique for Sustainable FishingDocument7 pagesEco-Friendly Long Lining Technique for Sustainable FishingAbhi BlackNo ratings yet

- Handling Installation Rev 21Document23 pagesHandling Installation Rev 21yildirimonlineNo ratings yet

- Anchoring EquipmentsDocument32 pagesAnchoring EquipmentsKseniia KrupchakNo ratings yet

- Mooring Ropes 22-03 Document1Document2 pagesMooring Ropes 22-03 Document1Cesar RodriguezNo ratings yet

- Manual Instalacion Lineas Calentadas pn50035Document8 pagesManual Instalacion Lineas Calentadas pn50035Fredy Vázquez VelázquezNo ratings yet

- Cable Drum Handling ManualDocument40 pagesCable Drum Handling Manualjeb13No ratings yet

- Secure Your AircraftDocument20 pagesSecure Your AircraftacdfsaNo ratings yet

- Care Maint. StrengthDocument8 pagesCare Maint. StrengthMitanshu ChadhaNo ratings yet

- User S Manual Wire RopesDocument13 pagesUser S Manual Wire RopesRajesh NairNo ratings yet

- English Iv Timber and Bill of LadingDocument12 pagesEnglish Iv Timber and Bill of LadingRizky Akbar MillensepdhioNo ratings yet

- Instructions For Stow and Securing Steel CoilsDocument8 pagesInstructions For Stow and Securing Steel CoilsKhoai Sai GonNo ratings yet

- Timber Deck CargoesDocument6 pagesTimber Deck CargoesGauravRaiNo ratings yet

- Fleet Angle SignificanceDocument13 pagesFleet Angle SignificanceAshish Kumar JhaNo ratings yet

- Noose: Sea, Although It Is Often Used On Land byDocument101 pagesNoose: Sea, Although It Is Often Used On Land bycmw0ngNo ratings yet

- ANCHOR SystemDocument32 pagesANCHOR SystemenglisgoNo ratings yet

- FOCLaying ProceduresDocument10 pagesFOCLaying ProceduresjahanzaibNo ratings yet

- Hmpe Manual Rev 1Document11 pagesHmpe Manual Rev 1Kathrin KatsNo ratings yet

- Carefully Carry Timber CargoesDocument6 pagesCarefully Carry Timber Cargoescptmehmetkaptan100% (2)

- 2008 RCL Accepting Steel Coils ProceduresDocument8 pages2008 RCL Accepting Steel Coils ProceduresMauricio Gomes de BarrosNo ratings yet

- Updated - SOT II Assignment 12 - JITHU KRISHNA JDocument3 pagesUpdated - SOT II Assignment 12 - JITHU KRISHNA JmarinerNo ratings yet

- HDPE Handling and StorageDocument2 pagesHDPE Handling and StorageFiras DabboucyNo ratings yet

- E 45 GP 005 - Installation of Belts On ConveyorsDocument11 pagesE 45 GP 005 - Installation of Belts On Conveyorsthiru_jsrNo ratings yet

- Material: Rope Wire Helix Wrought Iron SteelDocument6 pagesMaterial: Rope Wire Helix Wrought Iron Steelrea_rodriguezNo ratings yet

- General Guidelines For TowageDocument1 pageGeneral Guidelines For TowageAlan LloydNo ratings yet

- Guide Notes For MODU Towing ArrangementsDocument12 pagesGuide Notes For MODU Towing ArrangementsAnonymous UCveMQ100% (1)

- Hapag-LLoyd Flatracks Lashing Guide Nov 2015Document3 pagesHapag-LLoyd Flatracks Lashing Guide Nov 2015Allen Alex LalisNo ratings yet

- Specific method for stringing conductors between towersDocument73 pagesSpecific method for stringing conductors between towerssasa milosevicNo ratings yet

- Duct Installation of Fiber Optic Cable PDFDocument9 pagesDuct Installation of Fiber Optic Cable PDFnecmettinsengunNo ratings yet

- Student Outline Knots and Rope ManagementDocument10 pagesStudent Outline Knots and Rope ManagementrahanianNo ratings yet

- important points on wires and ropes - копияDocument2 pagesimportant points on wires and ropes - копияВлад РайлиNo ratings yet

- The Knot Book - Knots, Bends and Hitches - A Guide for Sailors, Adventurers and HobbyistsFrom EverandThe Knot Book - Knots, Bends and Hitches - A Guide for Sailors, Adventurers and HobbyistsNo ratings yet

- Illustrated Seamanship: Ropes & Ropework, Boat Handling & AnchoringFrom EverandIllustrated Seamanship: Ropes & Ropework, Boat Handling & AnchoringNo ratings yet

- A Camper's Guide to Knots and Lashing - A Collection of Historical Camping Articles on Useful Knots for the CampsiteFrom EverandA Camper's Guide to Knots and Lashing - A Collection of Historical Camping Articles on Useful Knots for the CampsiteNo ratings yet

- Outokumpu Machining Guideline Ultra 254SMODocument2 pagesOutokumpu Machining Guideline Ultra 254SMOzhiqianxuNo ratings yet

- List of Licensees: All Country All ProductsDocument4 pagesList of Licensees: All Country All ProductszhiqianxuNo ratings yet

- Metals and Alloys in The Unified Numbering System (UNS) - 13th Edition - DS56L-EBDocument3 pagesMetals and Alloys in The Unified Numbering System (UNS) - 13th Edition - DS56L-EBzhiqianxuNo ratings yet

- 001 Completion PDFDocument3 pages001 Completion PDFzhiqianxuNo ratings yet

- TPS CRA & Sour Service Tubing DatasheetDocument2 pagesTPS CRA & Sour Service Tubing DatasheetzhiqianxuNo ratings yet

- Outokumpu Machining Guideline Ultra 254SMODocument2 pagesOutokumpu Machining Guideline Ultra 254SMOzhiqianxuNo ratings yet

- Outokumpu Machining Guidelines For Forta DX2205Document2 pagesOutokumpu Machining Guidelines For Forta DX2205chavico113No ratings yet

- UPA-The - World's 1st-Hand-Held-Beta-Backscatter-InstrumentDocument4 pagesUPA-The - World's 1st-Hand-Held-Beta-Backscatter-InstrumentzhiqianxuNo ratings yet

- Norsok M-001Document34 pagesNorsok M-001Puskar Gupta100% (1)

- TN PipeAndConnectionIdentification ENGDocument9 pagesTN PipeAndConnectionIdentification ENGzhiqianxuNo ratings yet

- World Oil Article Visonic July 2004Document10 pagesWorld Oil Article Visonic July 2004zhiqianxuNo ratings yet

- Astm b850 PDFDocument3 pagesAstm b850 PDFzhiqianxuNo ratings yet

- E1e 013Document10 pagesE1e 013zhiqianxuNo ratings yet

- TenarisHydril Wedge 625 Running GuidelinesDocument15 pagesTenarisHydril Wedge 625 Running GuidelineszhiqianxuNo ratings yet

- Ball Transfer Units PDFDocument40 pagesBall Transfer Units PDFHyundianto AgNo ratings yet

- US9243729B2 (Hunting)Document10 pagesUS9243729B2 (Hunting)zhiqianxuNo ratings yet

- US4582348 (Hunting Variable Pitch) PDFDocument14 pagesUS4582348 (Hunting Variable Pitch) PDFzhiqianxuNo ratings yet

- US8926771Document13 pagesUS8926771zhiqianxuNo ratings yet

- Fatigue Analysis of OCTG Premium Connec..Document2 pagesFatigue Analysis of OCTG Premium Connec..zhiqianxuNo ratings yet

- Workstring International MaXit 807 Completion Landing StringDocument2 pagesWorkstring International MaXit 807 Completion Landing StringzhiqianxuNo ratings yet

- US9243729B2 (Hunting)Document10 pagesUS9243729B2 (Hunting)zhiqianxuNo ratings yet

- ISIJ-Production and Technology of Iron and Steel in Japan During 2013-1Document8 pagesISIJ-Production and Technology of Iron and Steel in Japan During 2013-1zhiqianxuNo ratings yet

- CDS 5.500 23.00lb VM+140 VAM+TOP®+CasingDocument1 pageCDS 5.500 23.00lb VM+140 VAM+TOP®+CasingzhiqianxuNo ratings yet

- Operating Instructions Pumps en 2016 09Document56 pagesOperating Instructions Pumps en 2016 09zhiqianxuNo ratings yet

- ISIJ-Production and Technology of Iron and Steel in Japan During 2016-1Document13 pagesISIJ-Production and Technology of Iron and Steel in Japan During 2016-1zhiqianxuNo ratings yet

- US2893759A (T. Blose Smith)Document3 pagesUS2893759A (T. Blose Smith)zhiqianxuNo ratings yet

- US8926771Document13 pagesUS8926771zhiqianxuNo ratings yet

- US4600225 (Interlock)Document8 pagesUS4600225 (Interlock)zhiqianxuNo ratings yet

- Us20140168414a1 (TN)Document20 pagesUs20140168414a1 (TN)zhiqianxuNo ratings yet

- DC Jan4 ExpandablesDocument2 pagesDC Jan4 ExpandableszhiqianxuNo ratings yet

- Balloon Price List LeafletDocument2 pagesBalloon Price List LeafletHolly-Jane WoontonNo ratings yet

- Internship REPORT Espee Kumaran Textiles (Weaving)Document10 pagesInternship REPORT Espee Kumaran Textiles (Weaving)Rebel DopeNo ratings yet

- Labrie Optimizer Maintenance Manual PDFDocument81 pagesLabrie Optimizer Maintenance Manual PDFstainless31620039126100% (1)

- Fabrics Store Com Classic Duvet CoverDocument23 pagesFabrics Store Com Classic Duvet Coverdafemsta_05No ratings yet

- Oct 29, Pennywise - Trail, Beaver Valley, RosslandDocument40 pagesOct 29, Pennywise - Trail, Beaver Valley, RosslandPennywise PublishingNo ratings yet

- JENNIFER - Tobin) - The - Glory - That - Was - Greece - GREEK ART AND ARCHAEOLOGY PDFDocument65 pagesJENNIFER - Tobin) - The - Glory - That - Was - Greece - GREEK ART AND ARCHAEOLOGY PDFathanasios1940B100% (1)

- A Complete Guide To HeraldryDocument1,038 pagesA Complete Guide To HeraldryjehovNo ratings yet

- Computer Application 1 Practical July 2017 1Document8 pagesComputer Application 1 Practical July 2017 1Samson Oteba100% (1)

- Advise guests on hotel services and itemsDocument13 pagesAdvise guests on hotel services and itemsFleet Calixto VII TrillanesNo ratings yet

- Podushkin SR14 2016 58 70 PDFDocument13 pagesPodushkin SR14 2016 58 70 PDFellipiNo ratings yet

- Styleguide - US Spring Summer 2013 Lia Sophia CatalogDocument51 pagesStyleguide - US Spring Summer 2013 Lia Sophia CatalogJillian WhiteNo ratings yet

- Section 4 - Valves Penstocks and ActuatorsDocument16 pagesSection 4 - Valves Penstocks and Actuatorsgomaa83No ratings yet

- Teddy Bear in A Hoodie: Crochet Pattern by Kristi TullusDocument18 pagesTeddy Bear in A Hoodie: Crochet Pattern by Kristi TullusLizeth Zambrano100% (2)

- The Cultural Communities in Luzon and Elements of ArtDocument43 pagesThe Cultural Communities in Luzon and Elements of ArtHR BCONo ratings yet

- English 4-Week 3Document13 pagesEnglish 4-Week 3JENNIFER SERVONo ratings yet

- English and Romanian Business Discourse: Conf. Univ. Dr. Tatiana IAŢCU Universitatea Petru Maior", Târgu-MureşDocument8 pagesEnglish and Romanian Business Discourse: Conf. Univ. Dr. Tatiana IAŢCU Universitatea Petru Maior", Târgu-Mureşjose300No ratings yet

- Rapunzel Pequwña AmiguDocument15 pagesRapunzel Pequwña AmiguLizeth Lima ApazaNo ratings yet

- The Last Green Valley by Mark SullivanDocument419 pagesThe Last Green Valley by Mark SullivanSaldivar Aguilera YerikNo ratings yet

- Kannada language basics for everyday conversationsDocument15 pagesKannada language basics for everyday conversationsMalladi Harsha Vardhan ShowriNo ratings yet

- Acetone MSDS PDFDocument5 pagesAcetone MSDS PDFYan Lean DollisonNo ratings yet

- Risala - Ibn Fadlan's Account of The RusDocument28 pagesRisala - Ibn Fadlan's Account of The RusErika Campos-CorrentinNo ratings yet

- Winnie and FriendsDocument21 pagesWinnie and FriendsClarissa Garcia98% (92)

- Fnan Teklay Million Dollar Image EbookDocument33 pagesFnan Teklay Million Dollar Image Ebookapi-522153804No ratings yet

- Crochet Christmas OrnamentsDocument13 pagesCrochet Christmas OrnamentsJulieta Hernández Otero100% (5)

- Peace Corps Samoa Welcome Book - April 2012 (June 2013 CCD Updated) wswb491Document48 pagesPeace Corps Samoa Welcome Book - April 2012 (June 2013 CCD Updated) wswb491Accessible Journal Media: Peace Corps DocumentsNo ratings yet

- Personal HygieneDocument19 pagesPersonal HygieneGraystone LitratoNo ratings yet

- Yard Machine 700 Series Riders Repair Manual.Document186 pagesYard Machine 700 Series Riders Repair Manual.mazda8616No ratings yet

- Apparel Merchandising 2020Document101 pagesApparel Merchandising 2020Nidhi ChadhaNo ratings yet

- Old TimesDocument41 pagesOld Timeshilaryy95100% (2)

- FHM True StoriesDocument39 pagesFHM True StoriesSarpiouS_20®No ratings yet