Professional Documents

Culture Documents

Ei PDF

Uploaded by

Oscar VillaseñorOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ei PDF

Uploaded by

Oscar VillaseñorCopyright:

Available Formats

BODY

EXTERIOR & INTERIOR

SECTION EI B

E

CONTENTS

SERVICE INFORMATION ............................ 2 COWL TOP ....................................................... 16 F

Removal and Installation .........................................16

PRECAUTIONS ................................................... 2

Precaution for Supplemental Restraint System FENDER PROTECTOR .................................... 17 G

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN- Component ..............................................................17

SIONER" ................................................................... 2 Removal and Installation of Front Fender Protec-

Service Notice ........................................................... 2 tor ............................................................................17

Removal and Installation of Rear Fender Protector H

PREPARATION ................................................... 3 ....18

Special Service Tool ................................................. 3

Commercial Service Tool .......................................... 3 MUDGUARD ..................................................... 19 EI

Removal and Installation .........................................19

SQUEAK AND RATTLE TROUBLE DIAGNO-

SIS ....................................................................... 4 OVER FENDER ................................................. 20

Work Flow ................................................................. 4 Removal and Installation .........................................20 J

Generic Squeak and Rattle Troubleshooting ............ 6

Diagnostic Worksheet ............................................... 8

DOOR OUTSIDE MOLDING ............................. 21

Removal and Installation .........................................21 K

CLIP AND FASTENER .......................................10

Clip and Fastener .................................................... 10

DOOR FINISHER .............................................. 23

Removal and Installation .........................................23

FRONT BUMPER ...............................................13 L

Removal and Installation ......................................... 13

BODY SIDE TRIM ............................................. 26

Component ..............................................................26

REAR BUMPER .................................................14 Removal and Installation .........................................27

M

Removal and Installation ......................................... 14

FLOOR TRIM .................................................... 29

FRONT GRILLE .................................................15 Removal and Installation .........................................29

Removal and Installation ......................................... 15 N

HEADLINING .................................................... 31

Removal and Installation .........................................31

O

Revision: September 2009 EI-1 2010 D22 LCV

PRECAUTIONS

< SERVICE INFORMATION >

SERVICE INFORMATION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER" INFOID:0000000005817094

The Supplemental Restraint System such as AIR BAG and SEAT BELT PRE-TENSIONER, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SRS and SB section of

this Service Manual.

WARNING:

To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

Improper maintenance, including incorrect removal and installation of the SRS can lead to personal

injury caused by unintentional activation of the system. For removal of Spiral Cable and Air Bag

Module, see the SRS section.

Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electric power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor(s) and deploy the air bag(s), possibly causing

serious injury.

When using air or electric power tools or hammers, always switch the Ignition OFF, disconnect the

battery, and wait at least 3 minutes before performing any service.

Service Notice INFOID:0000000005472758

When removing or installing various parts, place a cloth or padding on the vehicle body to prevent scratches.

Handle trim, molding, instruments, grille, etc. carefully during removing or installing. Be careful not to soil or

damage them.

Apply sealing compound where necessary when installing parts.

When applying sealing compound, be careful that the sealing compound does not protrude from parts.

When replacing any metal parts (for example body outer panel, members, etc.), be sure to take rust preven-

tion measures.

Revision: September 2009 EI-2 2010 D22 LCV

PREPARATION

< SERVICE INFORMATION >

PREPARATION

A

Special Service Tool INFOID:0000000005472760

The actual shapes of Kent-Moore tools may differ from those of special service tools illustrated here. B

Tool number

(Kent-Moore No.) Description

Tool name C

Locating the noise

(J-39570)

Chassis ear D

F

SBT839

Repairing the cause of noise

G

(J-43980)

NISSAN Squeak and Rattle kit

EI

SBT840 J

Commercial Service Tool INFOID:0000000005472761

K

Tool name

Description

(Kent-Moore No.)

Engine ear Locating the noise L

(J-39565)

SIIA0995E N

Revision: September 2009 EI-3 2010 D22 LCV

SQUEAK AND RATTLE TROUBLE DIAGNOSIS

< SERVICE INFORMATION >

SQUEAK AND RATTLE TROUBLE DIAGNOSIS

Work Flow INFOID:0000000005472762

SBT842

CUSTOMER INTERVIEW

Interview the customer if possible, to determine the conditions that exist when the noise occurs. Use the Diag-

nostic Worksheet during the interview to document the facts and conditions when the noise occurs and any

customer's comments; refer to EI-8, "Diagnostic Worksheet". This information is necessary to duplicate the

conditions that exist when the noise occurs.

The customer may not be able to provide a detailed description or the location of the noise. Attempt to obtain

all the facts and conditions that exist when the noise occurs (or does not occur).

If there is more than one noise in the vehicle, be sure to diagnose and repair the noise that the customer is

concerned about. This can be accomplished by test driving the vehicle with the customer.

After identifying the type of noise, isolate the noise in terms of its characteristics. The noise characteristics

are provided so the customer, service adviser and technician are all speaking the same language when

defining the noise.

Squeak (Like tennis shoes on a clean floor)

Squeak characteristics include the light contact/fast movement/brought on by road conditions/hard surfaces

= higher pitch noise/softer surfaces = lower pitch noises/edge to surface = chirping.

Creak(Like walking on an old wooden floor)

Creak characteristics include firm contact/slow movement/twisting with a rotational movement/pitch depen-

dent on materials/often brought on by activity.

Rattle(Like shaking a baby rattle)

Rattle characteristics include the fast repeated contact/vibration or similar movement/loose parts/missing

clip or fastener/incorrect clearance.

Knock (Like a knock on a door)

Knock characteristics include hollow sounding/sometimes repeating/often brought on by driver action.

Tick(Like a clock second hand)

Tick characteristics include gentle contacting of light materials/loose components/can be caused by driver

action or road conditions.

Thump(Heavy, muffled knock noise)

Thump characteristics include softer knock/dead sound often brought on by activity.

Buzz(Like a bumble bee)

Buzz characteristics include high frequency rattle/firm contact.

Often the degree of acceptable noise level will vary depending upon the person. A noise that you may judge

as acceptable may be very irritating to the customer.

Weather conditions, especially humidity and temperature, may have a great effect on noise level.

DUPLICATE THE NOISE AND TEST DRIVE

If possible, drive the vehicle with the customer until the noise is duplicated. Note any additional information on

the Diagnostic Worksheet regarding the conditions or location of the noise. This information can be used to

duplicate the same conditions when you confirm the repair.

Revision: September 2009 EI-4 2010 D22 LCV

SQUEAK AND RATTLE TROUBLE DIAGNOSIS

< SERVICE INFORMATION >

If the noise can be duplicated easily during the test drive, to help identify the source of the noise, try to dupli-

cate the noise with the vehicle stopped by doing one or all of the following: A

1) Close a door.

2) Tap or push/pull around the area where the noise appears to be coming from.

3) Rev the engine.

B

4) Use a floor jack to recreate vehicle twist.

5) At idle, apply engine load (electrical load, half-clutch).

6) Raise the vehicle on a hoist and hit a tire with a rubber hammer.

Drive the vehicle and attempt to duplicate the conditions the customer states exist when the noise occurs. C

If it is difficult to duplicate the noise, drive the vehicle slowly on an undulating or rough road to stress the

vehicle body.

CHECK RELATED SERVICE BULLETINS D

After verifying the customer concern or symptom, check ASIST for Technical Service Bulletins (TSBs) related

to that concern or symptom.

If a TSB relates to the symptom, follow the procedure to repair the noise. E

LOCATE THE NOISE AND IDENTIFY THE ROOT CAUSE

1. Narrow down the noise to a general area.To help pinpoint the source of the noise, use a listening tool

(Chassis Ear: J-39570, Engine Ear: J-39565 and mechanic's stethoscope). F

2. Narrow down the noise to a more specific area and identify the cause of the noise by:

removing the components in the area that you suspect the noise is coming from.

Do not use too much force when removing clips and fasteners, otherwise clips and fasteners can be broken G

or lost during the repair, resulting in the creation of new noise.

tapping or pushing/pulling the component that you suspect is causing the noise.

Do not tap or push/pull the component with excessive force, otherwise the noise will be eliminated only tem- H

porarily.

feeling for a vibration with your hand by touching the component(s) that you suspect is (are) causing the

noise.

EI

placing a piece of paper between components that you suspect are causing the noise.

looking for loose components and contact marks.

Refer to EI-6, "Generic Squeak and Rattle Troubleshooting".

J

REPAIR THE CAUSE

If the cause is a loose component, tighten the component securely.

If the cause is insufficient clearance between components:

- separate components by repositioning or loosening and retightening the component, if possible. K

- insulate components with a suitable insulator such as urethane pads, foam blocks, felt cloth tape or urethane

tape. A NISSAN Squeak and Rattle Kit (J-43980) is available through your authorized NISSAN Parts Depart-

ment. L

CAUTION:

Do not use excessive force as many components are constructed of plastic and may be damaged.

Always check with the Parts Department for the latest parts information.

The following materials are contained in the NISSAN Squeak and Rattle Kit (J-43980). Each item can be M

ordered separately as needed.

URETHANE PADS [1.5 mm (0.059 in) thick]

Insulates connectors, harness, etc. N

76268-9E005: 100135 mm (3.945.31 in)/76884-71L01: 6085 mm (2.363.35 in)/76884-71L02: 1525

mm (0.590.98 in)

INSULATOR (Foam blocks)

Insulates components from contact. Can be used to fill space behind a panel. O

73982-9E000: 45 mm (1.77 in) thick, 5050 mm (1.971.97 in)/73982-50Y00: 10 mm (0.39 in) thick,

5050 mm (1.971.97 in)

INSULATOR (Light foam block) P

80845-71L00: 30 mm (1.18 in) thick, 3050 mm (1.181.97 in)

FELT CLOTH TAPE

Used to insulate where movement does not occur. Ideal for instrument panel applications.

68370-4B000: 1525 mm (0.590.98 in) pad/68239-13E00: 5 mm (0.20 in) wide tape roll. The following

materials not found in the kit can also be used to repair squeaks and rattles.

UHMW (TEFLON) TAPE

Insulates where slight movement is present. Ideal for instrument panel applications.

Revision: September 2009 EI-5 2010 D22 LCV

SQUEAK AND RATTLE TROUBLE DIAGNOSIS

< SERVICE INFORMATION >

SILICONE GREASE

Used instead of UHMW tape that will be visible or not fit.

Note: Will only last a few months.

SILICONE SPRAY

Use when grease cannot be applied.

DUCT TAPE

Use to eliminate movement.

CONFIRM THE REPAIR

Confirm that the cause of a noise is repaired by test driving the vehicle. Operate the vehicle under the same

conditions as when the noise originally occurred. Refer to the notes on the Diagnostic Worksheet.

Generic Squeak and Rattle Troubleshooting INFOID:0000000005472763

Refer to Table of Contents for specific component removal and installation information.

INSTRUMENT PANEL

Most incidents are caused by contact and movement between:

1. The cluster lid A and instrument panel

2. Acrylic lens and combination meter housing

3. Instrument panel to front pillar garnish

4. Instrument panel to windshield

5. Instrument panel mounting pins

6. Wiring harnesses behind the combination meter

7. A/C defroster duct and duct joint

These incidents can usually be located by tapping or moving the components to duplicate the noise or by

pressing on the components while driving to stop the noise. Most of these incidents can be repaired by apply-

ing felt cloth tape or silicone spray (in hard to reach areas). Urethane pads can be used to insulate wiring har-

ness.

CAUTION:

Do not use silicone spray to isolate a squeak or rattle. If you saturate the area with silicone, you will

not be able to recheck the repair.

CENTER CONSOLE

Components to pay attention to include:

1. Shifter assembly cover to finisher

2. A/C control unit and cluster lid C

3. Wiring harnesses behind audio and A/C control unit

The instrument panel repair and isolation procedures also apply to the center console.

DOORS

Pay attention to the:

1. Finisher and inner panel making a slapping noise

2. Inside handle escutcheon to door finisher

3. Wiring harnesses tapping

4. Door striker out of alignment causing a popping noise on starts and stops

Tapping or moving the components or pressing on them while driving to duplicate the conditions can isolate

many of these incidents. You can usually insulate the areas with felt cloth tape or insulator foam blocks from

the NISSAN Squeak and Rattle Kit (J-43980) to repair the noise.

TRUNK

Trunk noises are often caused by a loose jack or loose items put into the trunk by the owner.

In addition look for:

1. Trunk lid bumpers out of adjustment

2. Trunk lid striker out of adjustment

3. The trunk lid torsion bars knocking together

4. A loose license plate or bracket

Revision: September 2009 EI-6 2010 D22 LCV

SQUEAK AND RATTLE TROUBLE DIAGNOSIS

< SERVICE INFORMATION >

Most of these incidents can be repaired by adjusting, securing or insulating the item(s) or component(s) caus-

ing the noise. A

SUNROOF/HEADLINING

Noises in the sunroof/headlining area can often be traced to one of the following:

1. Sunroof lid, rail, linkage or seals making a rattle or light knocking noise B

2. Sun visor shaft shaking in the holder

3. Front or rear windshield touching headliner and squeaking

C

Again, pressing on the components to stop the noise while duplicating the conditions can isolate most of these

incidents. Repairs usually consist of insulating with felt cloth tape.

OVERHEAD CONSOLE (FRONT AND REAR) D

Overhead console noises are often caused by the console panel clips not being engaged correctly. Most of

these incidents are repaired by pushing up on the console at the clip locations until the clips engage.

In addition look for: E

1. Loose harness or harness connectors.

2. Front console map/reading lamp lens loose.

3. Loose screws at console attachment points. F

SEATS

When isolating seat noise it's important to note the position the seat is in and the load placed on the seat when

the noise is present. These conditions should be duplicated when verifying and isolating the cause of the G

noise.

Cause of seat noise include:

1. Headrest rods and holder H

2. A squeak between the seat pad cushion and frame

3. The rear seatback lock and bracket

These noises can be isolated by moving or pressing on the suspected components while duplicating the con- EI

ditions under which the noise occurs. Most of these incidents can be repaired by repositioning the component

or applying urethane tape to the contact area.

UNDERHOOD J

Some interior noise may be caused by components under the hood or on the engine wall. The noise is then

transmitted into the passenger compartment.

Causes of transmitted underhood noise include: K

1. Any component mounted to the engine wall

2. Components that pass through the engine wall

3. Engine wall mounts and connectors L

4. Loose radiator mounting pins

5. Hood bumpers out of adjustment

M

6. Hood striker out of adjustment

These noises can be difficult to isolate since they cannot be reached from the interior of the vehicle. The best

method is to secure, move or insulate one component at a time and test drive the vehicle. Also, engine RPM

N

or load can be changed to isolate the noise. Repairs can usually be made by moving, adjusting, securing, or

insulating the component causing the noise.

Revision: September 2009 EI-7 2010 D22 LCV

SQUEAK AND RATTLE TROUBLE DIAGNOSIS

< SERVICE INFORMATION >

Diagnostic Worksheet INFOID:0000000005472764

LAIA0072E

Revision: September 2009 EI-8 2010 D22 LCV

SQUEAK AND RATTLE TROUBLE DIAGNOSIS

< SERVICE INFORMATION >

EI

LAIA0071E

Revision: September 2009 EI-9 2010 D22 LCV

CLIP AND FASTENER

< SERVICE INFORMATION >

CLIP AND FASTENER

Clip and Fastener INFOID:0000000005472765

SIIA0315E

Revision: September 2009 EI-10 2010 D22 LCV

CLIP AND FASTENER

< SERVICE INFORMATION >

EI

SIIA0316E

Revision: September 2009 EI-11 2010 D22 LCV

CLIP AND FASTENER

< SERVICE INFORMATION >

SIIA0317E

Revision: September 2009 EI-12 2010 D22 LCV

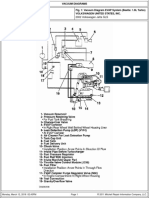

FRONT BUMPER

< SERVICE INFORMATION >

FRONT BUMPER

A

Removal and Installation INFOID:0000000005472766

EI

ALKIA1465ZZ

K

1. Engine undercover 2. Front bumper reinforcement 3. Front bumper fascia

4. Front license plate J-clip 5. Fog lamp opening finisher 6. Side strut brace

L

7. Front bumper upper support bracket 8. Front bumper lower stud block 9. Front bumper end bracket

10. Front bumper end bracket brace

REMOVAL M

1. Remove front grille. Refer to EI-15.

2. Remove engine undercover.

3. Disconnect front portion of fender protectors LH and RH. Refer to EI-17, "Removal and Installation of N

Front Fender Protector".

4. Disconnect front bumper end bracket and brace from lower stud block.

5. Disconnect side strut brace, then remove front bumper reinforcement. O

6. Remove front bumper fascia.

INSTALLATION P

Installation is in the reverse order of removal.

Revision: September 2009 EI-13 2010 D22 LCV

REAR BUMPER

< SERVICE INFORMATION >

REAR BUMPER

Removal and Installation INFOID:0000000005472767

ALKIA1466ZZ

1. Rear bumper frame brace 2. Corner brace 3. Rear bumper base

4. Rear bumper upper plate

REMOVAL

1. Disconnect license lamp harness RH/LH.

2. Remove the bolts and corner brace from rear bumper base.

3. Release clips from license lamp RH/LH, then remove lamps from rear bumper.

4. Remove the bolts and rear bumper base from frame brace RH/LH.

5. Remove the bolts and rear bumper upper plate from frame brace.

INSTALLATION

Installation is in the reverse order of removal.

Revision: September 2009 EI-14 2010 D22 LCV

FRONT GRILLE

< SERVICE INFORMATION >

FRONT GRILLE

A

Removal and Installation INFOID:0000000005472768

EI

ALKIA1467ZZ

1. Front grille 2. Locator clip 3. Center brace J

A. Clips CG101

REMOVAL

K

1. Remove the screw and release the center brace.

2. Twist and release clips, then pull forward and remove front grille from locator clip.

INSTALLATION L

Installation is in the reverse order of removal.

Revision: September 2009 EI-15 2010 D22 LCV

COWL TOP

< SERVICE INFORMATION >

COWL TOP

Removal and Installation INFOID:0000000005472769

ALKIA1468ZZ

1. Cowl top extension RH 2. Cowl top seal 3. Cowl top extension LH

4. Antenna delete cap (if equipped) Vehicle front A Clip C101

B. Clip CE103

REMOVAL

1. Remove the front wiper arms. Refer to WW-6, "Removal and Installation".

2. Remove antenna mast and grommet (if equipped).

3. Release the clips, then remove cowl top seal.

4. Release clips and remove LH and RH cowl top extensions.

INSTALLATION

Installation is in the reverse order of removal.

Revision: September 2009 EI-16 2010 D22 LCV

FENDER PROTECTOR

< SERVICE INFORMATION >

FENDER PROTECTOR

A

Component INFOID:0000000005472770

Front B

G

ALKIA1469ZZ

1. Front fender protector LH A. Clip C103 B. J-clip nut

H

Vehicle front

Rear

EI

ALKIA1527ZZ N

1. Rear protector LH A. Clip C101 Vehicle front

O

Removal and Installation of Front Fender Protector INFOID:0000000005472771

REMOVAL

P

1. Remove the screws and J-clip nuts.

2. Remove the clips.

3. Remove front fender protector.

INSTALLATION

Installation is in the reverse order of removal.

Revision: September 2009 EI-17 2010 D22 LCV

FENDER PROTECTOR

< SERVICE INFORMATION >

Removal and Installation of Rear Fender Protector INFOID:0000000005472772

REMOVAL

1. Remove screws and clip.

2. Remove rear fender protector.

INSTALLATION

Installation is in the reverse order of removal.

Revision: September 2009 EI-18 2010 D22 LCV

MUDGUARD

< SERVICE INFORMATION >

MUDGUARD

A

Removal and Installation INFOID:0000000005472773

EI

ALKIA1470ZZ

N

1. Front mudguard 2. Rear mudguard (2WD) 3. Rear mudguard (4WD)

A. Clip C205 B. J-clip nut

REMOVAL O

Remove the clips and screws, then remove the mudguards.

INSTALLATION P

Installation is in the reverse order of removal.

Revision: September 2009 EI-19 2010 D22 LCV

OVER FENDER

< SERVICE INFORMATION >

OVER FENDER

Removal and Installation INFOID:0000000005472774

ALKIA1471ZZ

1. Body sheet metal 2. Front over fender 3. Over fender extension

4. Rear over fender (single cab) 5. Rear over fender (double cab) A. Clip C101

B. J-clip nut

REMOVAL

1. Remove screws from front or rear over fender.

2. Using a suitable tool, release the clips one at a time, begining at one end working toward the opposite end

and remove over fender.

INSTALLATION

Installation is in the reverse order of removal.

Revision: September 2009 EI-20 2010 D22 LCV

DOOR OUTSIDE MOLDING

< SERVICE INFORMATION >

DOOR OUTSIDE MOLDING

A

Removal and Installation INFOID:0000000005472775

EI

J

ALKIA1472ZZ

1. Front door drip weatherstrip 2. Front door outside molding 3. Rear door outside molding K

4. Rear door drip weatherstrip A. Clip C103

DOOR OUTSIDE MOLDING L

Removal

NOTE:

Double cab shown, single cab similar. M

1. Open the window fully.

2. Remove the door mirror (for front door). Refer to GW-36, "Removal and Installation".

3. Lift molding from the front side off of flange. N

4. Remove the door outside molding.

Installation

O

Installation is in the reverse order of removal.

DRIP WEATHERSTRIP

Removal P

NOTE:

Double cab shown, single cab similar.

1. Open the door fully.

2. Release the clips.

3. Lift weatherstrip away from top of door opening flange.

4. Remove the drip weatherstrip.

Revision: September 2009 EI-21 2010 D22 LCV

DOOR OUTSIDE MOLDING

< SERVICE INFORMATION >

Installation

Installation is in the reverse order of removal.

Revision: September 2009 EI-22 2010 D22 LCV

DOOR FINISHER

< SERVICE INFORMATION >

DOOR FINISHER

A

Removal and Installation INFOID:0000000005472776

COMPONENT B

EI

ALKIA1473ZZ P

1. Inside handle escutcheon 2. Rear door pull handle 3. Rear door finisher

4. Power window switch 5. Front door finisher (power) 6. Front door armrest

7. Power window and door lock/unlock 8. Front door finisher (manual) 9. Pull handle

switch pull handle assembly

A. Clip C103 Clip C101 Vehicle front

Revision: September 2009 EI-23 2010 D22 LCV

DOOR FINISHER

< SERVICE INFORMATION >

ALKIA1474ZZ

1. Inside handle escutcheon 2. Power window and door lock/unlock- 3. Pull handle

switch pull handle assembly

A. Pawl B. Metal clip C. Hook

REMOVAL - FRONT DOOR

1. Release the clips and remove power window and door lock/unlock switch pull handle assembly (if

equipped), or pull handle.

Disconnect harness connectors.

2. Release the pawl and remove inside handle escutcheon, then remove door finisher screw.

3. Remove pull handle/lock lever assembly.

Revision: September 2009 EI-24 2010 D22 LCV

DOOR FINISHER

< SERVICE INFORMATION >

Disconnect lock lever cable and inside pull handle cable from lever assembly. Refer to BL-33, "Exploded

View". A

4. Lift armrest upward to release clips and remove armrest.

Remove screws behind armrest.

5. Disconnect remaining harness connectors if equipped. B

6. Release the clips, pull outward and upward, then remove front door finisher.

INSTALLATION - FRONT DOOR

C

Removal is in the reverse order of removal.

REMOVAL - REAR DOOR

1. Remove the screws, then remove pull handle. D

2. Release the pawl, then remove power window switch (if equipped).

Disconnect harness connector.

3. Release the pawl and remove inside handle escutcheon, then remove door finisher screw. E

4. Remove pull handle/lock lever assembly.

Disconnect lock lever cable and inside pull handle cable from lever assembly. Refer to BL-34, "Exploded

View". F

5. Remove the screws, then remove armrest.

6. Release the clips, pull outward and upward, then remove rear door finisher.

G

INSTALLATION - REAR DOOR

Installation is in the reverse order of removal.

H

EI

Revision: September 2009 EI-25 2010 D22 LCV

BODY SIDE TRIM

< SERVICE INFORMATION >

BODY SIDE TRIM

Component INFOID:0000000005472777

DOUBLE CAB

ALKIA1475ZZ

1. Rear pillar upper finisher 2. Rear pillar lower finisher (if equipped) 3. Rear door welt

4. Rear kick plate 5. Center pillar lower finisher 6. Center pillar upper finisher

7. Front kick plate 8. Lower dash side finisher 9. Front door welt

10. Front pillar finisher A. Clip C103 B. Clip CS101

C. Clip C101 Metal Clip Vehicle front

Revision: September 2009 EI-26 2010 D22 LCV

BODY SIDE TRIM

< SERVICE INFORMATION >

SINGLE CAB

A

EI

L

ALKIA1476ZZ

1. Rear pillar upper finisher 2. Rear pillar lower finisher (if equipped) 3. Kick plate M

4. Lower dash side finisher 5. Door welt 6. Front pillar upper finisher

A. Clip C103 B. Clip CS101 Metal Clip

Vehicle front

N

CAUTION:

Wrap the tip of flat-bladed screwdriver with a cloth when removing metal clips from finishers. O

When removing or installing body side welts, do not allow butyl seal to come in contact with finish-

ers.

Removal and Installation INFOID:0000000005472778 P

CAUTION:

Wrap the tip of flat-bladed screwdriver with a cloth when removing metal clips from finishers.

LOWER DASH SIDE FINISHER

Removal

1. Remove screw from lower dash side finisher.

Revision: September 2009 EI-27 2010 D22 LCV

BODY SIDE TRIM

< SERVICE INFORMATION >

2. Remove kick plate and door welt from the door opening flange.

3. Release the clip, then remove lower dash side finisher.

Installation

Installation is in the reverse order of removal.

CENTER PILLAR LOWER FINISHER (DOUBLE CAB)

Removal

1. Remove front and rear kick plates.

2. Remove front and rear door welts from the door opening flange.

3. Remove front seat belt anchor. Refer to SB-4, "Removal and Installation".

4. Release the clips, then remove center pillar lower finisher.

Installation

Installation is in the reverse order of removal.

CENTER PILLAR UPPER FINISHER (DOUBLE CAB)

Removal

1. Remove center pillar lower finisher.

2. Remove seat belt shoulder anchor and D-ring (or hook if equipped), refer to SB-4, "Removal and Installa-

tion".

3. Release the clips, then remove center pillar upper finisher.

Installation

Installation is in the reverse order of removal.

FRONT PILLAR FINISHER

Removal

1. Remove door welt from the door opening flange.

2. Release the clips, then remove the front pillar upper finisher.

Installation

Installation is in the reverse order of removal.

KICK PLATES

Removal

Remove the clips and remove front and/or rear kick plates.

Installation

Installation is in the reverse order of removal.

DRAFTER DUCT

Removal

1. Remove body rear end (if equipped).

2. Remove the screws, then remove drafter duct(s).

ALKIA1477ZZ

Installation

Installation is in the reverse order of removal.

Revision: September 2009 EI-28 2010 D22 LCV

FLOOR TRIM

< SERVICE INFORMATION >

FLOOR TRIM

A

Removal and Installation INFOID:0000000005472779

COMPONENT B

DOUBLE CAB

C

EI

ALKIA1478ZZ K

1. Front floor trim 2. Rear floor trim A. Clip C103

Vehicle front L

Revision: September 2009 EI-29 2010 D22 LCV

FLOOR TRIM

< SERVICE INFORMATION >

SINGLE CAB

ALKIA1479ZZ

1. Rear floor trim (RH) 2. Front floor trim 3. Rear floor trim (LH)

A. Clip C103 Vehicle front

REMOVAL

1. Remove seats. Refer to SE-7, "Removal and Installation".

2. Remove lower seat belt anchors. Refer to SB-4, "Removal and Installation".

3. Remove lower body side trim finishers. Refer to EI-26.

4. Remove center console (if equipped). Refer to IP-10, "Removal and Installation".

5. Remove rear floor trim (RH/LH on single cab models).

6. Release the clips, then remove front floor trim.

INSTALLATION

Installation is in the reverse order of removal.

Revision: September 2009 EI-30 2010 D22 LCV

HEADLINING

< SERVICE INFORMATION >

HEADLINING

A

Removal and Installation INFOID:0000000005472780

EXPLODED VIEW B

DOUBLE CAB

C

EI

ALKIA1480ZZ K

1. Assist grip 2. Sun visor 3. Sun visor holder

4. Rearview mirror 5. Headlining 6. Room lamp L

7. Coat hook Vehicle front

Revision: September 2009 EI-31 2010 D22 LCV

HEADLINING

< SERVICE INFORMATION >

SINGLE CAB

ALKIA1481ZZ

1. Assist grip 2. Sun visor 3. Sun visor holder

4. Rearview mirror 5. Headlining 6. Room lamp

7. Coat hook Vehicle front

REMOVAL

CAUTION:

Disconnect both the negative and positive battery terminals in advance.

1. Disconnect the negative and positive battery terminals, then wait at least 3 minutes.

2. Remove upper body side trim panels. Refer to EI-26.

3. Remove sun visor (LH and RH).

4. Remove sun visor holders (LH and RH).

5. Remove rear vew mirror. Refer to GW-42, "Removal and Installation".

6. Remove room lamp.

Disconnect harness connector(s).

7. Remove assist grips (if equipped).

8. For double cab models, remove rear window glass.

9. Remove headlining.

NOTE:

Use an assistant to steady the headlining while lowering from roof.

Remove clips from center of headlining (if equipped).

Remove headlining by tilting through rear window opening on double cab models.

10. Remove assist grip brackets from roof.

INSTALLATION

Installation is in the reverse order of removal.

Revision: September 2009 EI-32 2010 D22 LCV

You might also like

- Ei PDFDocument45 pagesEi PDFLeonardo Enrique Barrios PuelloNo ratings yet

- IP - FronDocument31 pagesIP - FronIvan A. VelasquezNo ratings yet

- Exterior & Interior: SectionDocument34 pagesExterior & Interior: SectionAnonymous 64HDY7IiN0No ratings yet

- Exterior & Interior: SectionDocument40 pagesExterior & Interior: Sectionvadim vadimNo ratings yet

- Exterior & Interior: SectionDocument36 pagesExterior & Interior: SectionSilvio ServinNo ratings yet

- Exterior & Interior: SectionDocument32 pagesExterior & Interior: SectionEduardo ColinNo ratings yet

- Ei PDFDocument42 pagesEi PDFМиша ШаулаNo ratings yet

- Instrument Panel: SectionDocument26 pagesInstrument Panel: SectiontecnicofigueroaNo ratings yet

- Exterior: SectionDocument26 pagesExterior: SectionNestor RosalesNo ratings yet

- Exterior: SectionDocument38 pagesExterior: SectionZona Educación Especial ZacapaoaxtlaNo ratings yet

- Exterior: SectionDocument25 pagesExterior: SectionederengNo ratings yet

- Ext 2Document37 pagesExt 2giancarlo sanchezNo ratings yet

- Exterior & Interior: SectionDocument58 pagesExterior & Interior: SectionemenelikNo ratings yet

- Exterior & Interior: SectionDocument44 pagesExterior & Interior: SectionVolkan AKNo ratings yet

- Exterior: SectionDocument38 pagesExterior: SectioncesarNo ratings yet

- Exterior: SectionDocument36 pagesExterior: SectionjasleenNo ratings yet

- 2007 Nissan Xterra 25Document36 pages2007 Nissan Xterra 25Roma Roma100% (1)

- 2011 Nissan Armada 2Document34 pages2011 Nissan Armada 2AlbraaNo ratings yet

- Exterior & Interior: SectionDocument47 pagesExterior & Interior: SectionskpppNo ratings yet

- Srs Airbag: SectionDocument34 pagesSrs Airbag: Sectionratatrampa25No ratings yet

- Ip PDFDocument30 pagesIp PDFcesarNo ratings yet

- Instrument Panel: SectionDocument30 pagesInstrument Panel: SectionZona Educación Especial ZacapaoaxtlaNo ratings yet

- Exterior: SectionDocument34 pagesExterior: SectiontecnicofigueroaNo ratings yet

- Ventilation System: SectionDocument27 pagesVentilation System: SectionZona Educación Especial ZacapaoaxtlaNo ratings yet

- Ventilation System: SectionDocument35 pagesVentilation System: SectionederengNo ratings yet

- SRS AIRBAG SRDocument33 pagesSRS AIRBAG SRciro_svNo ratings yet

- Exterior: SectionDocument29 pagesExterior: SectionhuusonbachkhoaNo ratings yet

- Instrument Panel Nissan NoteDocument26 pagesInstrument Panel Nissan NoteWilmer Elias Quiñonez HualpaNo ratings yet

- Instrument Panel: SectionDocument23 pagesInstrument Panel: Sectionak_adamNo ratings yet

- 10.-Gestiones Electronicas - Tecnicas de VerificaciónDocument29 pages10.-Gestiones Electronicas - Tecnicas de VerificaciónChristian Ramos CamposNo ratings yet

- Int PDFDocument40 pagesInt PDFMisha KulibaevNo ratings yet

- Ventilation System: SectionDocument27 pagesVentilation System: SectioncesarNo ratings yet

- 43 Manual Nissan Sentra 2013Document49 pages43 Manual Nissan Sentra 2013David100% (1)

- Exterior & Interior: SectionDocument40 pagesExterior & Interior: SectionedgarNo ratings yet

- Instrument Panel (Section IP)Document23 pagesInstrument Panel (Section IP)Gleydson Bahiense RamosNo ratings yet

- 27 Manual Nissan Sentra 2013Document45 pages27 Manual Nissan Sentra 2013DavidNo ratings yet

- Engine Cooling System: SectionDocument27 pagesEngine Cooling System: Sectionصالح الدوسريNo ratings yet

- Ext PDFDocument36 pagesExt PDFMisha KulibaevNo ratings yet

- Exterior and InteriorDocument40 pagesExterior and Interiorshortbus22No ratings yet

- Interior: SectionDocument39 pagesInterior: Sectionluis CebergNo ratings yet

- Exterior & Interior: SectionDocument30 pagesExterior & Interior: SectionDozer KamilNo ratings yet

- Srs Airbag: SectionDocument44 pagesSrs Airbag: SectionjorgeNo ratings yet

- InteriorDocument45 pagesInteriordiegoNo ratings yet

- Instrument PanelDocument24 pagesInstrument PaneldiegoNo ratings yet

- Exterior: SectionDocument41 pagesExterior: SectionLuis BarriosNo ratings yet

- Interior (Section INT)Document35 pagesInterior (Section INT)Gleydson Bahiense RamosNo ratings yet

- Ei PDFDocument32 pagesEi PDFCarlos Eduardo ZelidonNo ratings yet

- 8314 Nissan Juke Model F15 SeriesDocument36 pages8314 Nissan Juke Model F15 SeriesEngr Ko VictorNo ratings yet

- Exterior & Interior: SectionDocument52 pagesExterior & Interior: SectionJBNo ratings yet

- Frenos Altima 2004Document32 pagesFrenos Altima 2004Carlos Villalobos VegaNo ratings yet

- Motor Mecánico: ContenidoDocument101 pagesMotor Mecánico: Contenidojohn huancaNo ratings yet

- Front Suspension: SectionDocument24 pagesFront Suspension: Sectiongiancarlo sanchezNo ratings yet

- Exterior: SectionDocument46 pagesExterior: Sectionjair HernandezNo ratings yet

- Frontier - FSUDocument26 pagesFrontier - FSUIvan A. VelasquezNo ratings yet

- Ventilation System: SectionDocument26 pagesVentilation System: SectionDiego496No ratings yet

- Engine Cooling System: SectionDocument23 pagesEngine Cooling System: SectionMaiChiVuNo ratings yet

- CO ENGINE COOLING SYSTEM Nissan Pathfinder R52Document28 pagesCO ENGINE COOLING SYSTEM Nissan Pathfinder R52Pablo Marchese HuertaNo ratings yet

- Sistema de Control de Refrigeración de Motor Nissan 350Z CoupeDocument26 pagesSistema de Control de Refrigeración de Motor Nissan 350Z CoupeHendrick CepedaNo ratings yet

- Engine Mechanical: SectionDocument116 pagesEngine Mechanical: SectionJarden VegaNo ratings yet

- Campaña de Bateria de Carro ElectricoDocument3 pagesCampaña de Bateria de Carro ElectricoOscar VillaseñorNo ratings yet

- Manual Steering System: SectionDocument21 pagesManual Steering System: SectionOscar VillaseñorNo ratings yet

- Dongle User Manual V1.3Document5 pagesDongle User Manual V1.3Eduardo Alvarez HuizaNo ratings yet

- ZED-BULL Installation ExplainDocument7 pagesZED-BULL Installation ExplainHerciu Andreea RoxanaNo ratings yet

- Codigo P076aDocument6 pagesCodigo P076aOscar VillaseñorNo ratings yet

- 1 8Document1 page1 8Oscar VillaseñorNo ratings yet

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Ma PDFDocument51 pagesMa PDFOscar VillaseñorNo ratings yet

- Glasses, Window System & Mirrors: SectionDocument42 pagesGlasses, Window System & Mirrors: SectionOscar VillaseñorNo ratings yet

- Lan System: SectionDocument44 pagesLan System: SectionOscar VillaseñorNo ratings yet

- Lighting System: SectionDocument42 pagesLighting System: SectionOscar VillaseñorNo ratings yet

- Lu PDFDocument28 pagesLu PDFOscar VillaseñorNo ratings yet

- Fsu PDFDocument45 pagesFsu PDFOscar VillaseñorNo ratings yet

- Instrument Panel: SectionDocument14 pagesInstrument Panel: SectionOscar Villaseñor100% (1)

- BL PDFDocument67 pagesBL PDFOscar VillaseñorNo ratings yet

- Di PDFDocument53 pagesDi PDFOscar VillaseñorNo ratings yet

- FL PDFDocument21 pagesFL PDFOscar VillaseñorNo ratings yet

- Front Final Drive: SectionDocument32 pagesFront Final Drive: SectionOscar VillaseñorNo ratings yet

- B D A C E F G H I J K L: Transmission/ TransaxleDocument9 pagesB D A C E F G H I J K L: Transmission/ TransaxleOscar Villaseñor100% (1)

- Fax PDFDocument27 pagesFax PDFOscar VillaseñorNo ratings yet

- BRC PDFDocument74 pagesBRC PDFOscar VillaseñorNo ratings yet

- Ex PDFDocument6 pagesEx PDFOscar VillaseñorNo ratings yet

- Engine Cooling System: SectionDocument47 pagesEngine Cooling System: SectionOscar VillaseñorNo ratings yet

- CL PDFDocument19 pagesCL PDFOscar VillaseñorNo ratings yet

- Acc PDFDocument5 pagesAcc PDFOscar Villaseñor100% (1)

- BR PDFDocument33 pagesBR PDFOscar VillaseñorNo ratings yet

- Audio, Visual & Telephone System: SectionDocument13 pagesAudio, Visual & Telephone System: SectionOscar VillaseñorNo ratings yet

- Diagram AsDocument3 pagesDiagram AsOscar VillaseñorNo ratings yet

- Boletin Codigo 722 y 720 Sensor de VelocidadDocument3 pagesBoletin Codigo 722 y 720 Sensor de VelocidadOscar VillaseñorNo ratings yet

- Review of Documents On Seismic Strengthening of Existing BuildingsDocument12 pagesReview of Documents On Seismic Strengthening of Existing Buildingsm7j7a7No ratings yet

- BPT Notes Applied PsychologyDocument36 pagesBPT Notes Applied PsychologyVivek Chandra0% (1)

- Hindustan Coca-Cola Beverages PVT LTD B-91 Mayapuri Industrial Area Phase-I New DelhiDocument2 pagesHindustan Coca-Cola Beverages PVT LTD B-91 Mayapuri Industrial Area Phase-I New DelhiUtkarsh KadamNo ratings yet

- New Age GeneratorDocument26 pagesNew Age GeneratorDaud Ahmed Fihawango100% (1)

- Vision Medilink Product DetailsDocument4 pagesVision Medilink Product DetailsRaj SekarNo ratings yet

- Dr. Shekhar Challa Joins Bioscience Americas Board of AdvisorsDocument2 pagesDr. Shekhar Challa Joins Bioscience Americas Board of AdvisorsPR.comNo ratings yet

- Left Side View: Electrical System G3516A and G3516B EngineDocument2 pagesLeft Side View: Electrical System G3516A and G3516B EngineAM76100% (1)

- LMA An. I-Sem 1-Engleza LEC-The Category of Aspect & Aspect 3-Reedited OnDocument4 pagesLMA An. I-Sem 1-Engleza LEC-The Category of Aspect & Aspect 3-Reedited OnIlie IonelNo ratings yet

- Questions Related To CodesDocument10 pagesQuestions Related To CodesMayur Mandrekar100% (1)

- Contextual Marketing Based On Customer Buying Pattern In: Nesya Vanessa and Arnold JaputraDocument12 pagesContextual Marketing Based On Customer Buying Pattern In: Nesya Vanessa and Arnold Japutraakshay kushNo ratings yet

- Chapter 4Document6 pagesChapter 4Aung MyatNo ratings yet

- Effect of Educational Environment On Personality and Adjustment of Female Students Studying in Colleges of UttarakhandDocument5 pagesEffect of Educational Environment On Personality and Adjustment of Female Students Studying in Colleges of UttarakhandESSENCE - International Journal for Environmental Rehabilitation and ConservaionNo ratings yet

- Transmission Line BOQ VIMPDocument72 pagesTransmission Line BOQ VIMPkajale_shrikant2325No ratings yet

- Measurement of Poverty and Poverty of Measurement: Martin GreeleyDocument15 pagesMeasurement of Poverty and Poverty of Measurement: Martin GreeleyKule89No ratings yet

- Maxipro NewDocument2 pagesMaxipro NewLokendraNo ratings yet

- Construction of Genomic and cDNA Libraries-AmitDocument10 pagesConstruction of Genomic and cDNA Libraries-AmitPrashant BajpaiNo ratings yet

- Open Delta Purpose in EFDocument2 pagesOpen Delta Purpose in EFnmanikandanNo ratings yet

- Alfa Laval de Alcoholization Module PDFDocument4 pagesAlfa Laval de Alcoholization Module PDFBryam DavidNo ratings yet

- Leviticus 12 Pulpit Commentary Homiletics PDFDocument16 pagesLeviticus 12 Pulpit Commentary Homiletics PDFEmiel AwadNo ratings yet

- AscindiaDocument16 pagesAscindiaHeeman TrivediNo ratings yet

- Black and Decker Vaporera Electrica RecetarioDocument17 pagesBlack and Decker Vaporera Electrica RecetarioFabio AtenógenesNo ratings yet

- DeethanizeranalysisDocument7 pagesDeethanizeranalysismindunder36No ratings yet

- CFM56 3Document148 pagesCFM56 3manmohan100% (1)

- Fuel EnergizerDocument17 pagesFuel Energizerrakshak25100% (1)

- HC SB 61 227Document22 pagesHC SB 61 227Hamed BarjestehNo ratings yet

- Mycesmm2 Quiz: Please Circle Your Answer! Time Allocated To Answer Is 30 MinutesDocument2 pagesMycesmm2 Quiz: Please Circle Your Answer! Time Allocated To Answer Is 30 MinutesSi Qian LuiNo ratings yet

- LOKRING Technical Documentation Submittal Brass enDocument32 pagesLOKRING Technical Documentation Submittal Brass enYamilelcNo ratings yet

- Lecture 16 - Bleeding Tendency DiseasesDocument64 pagesLecture 16 - Bleeding Tendency Diseasesapi-3703352100% (1)

- E28716V9 HRMT20024 Assessment2Document16 pagesE28716V9 HRMT20024 Assessment2bitetNo ratings yet

- Recipe For SuccesDocument27 pagesRecipe For Successtefany alvarezNo ratings yet

- Eat That Frog!: 21 Great Ways to Stop Procrastinating and Get More Done in Less TimeFrom EverandEat That Frog!: 21 Great Ways to Stop Procrastinating and Get More Done in Less TimeRating: 4.5 out of 5 stars4.5/5 (3226)

- Root to Leaf: A Southern Chef Cooks Through the SeasonsFrom EverandRoot to Leaf: A Southern Chef Cooks Through the SeasonsRating: 4.5 out of 5 stars4.5/5 (3)

- The Encyclopedia of Spices & Herbs: An Essential Guide to the Flavors of the WorldFrom EverandThe Encyclopedia of Spices & Herbs: An Essential Guide to the Flavors of the WorldRating: 3.5 out of 5 stars3.5/5 (5)

- House Rules: How to Decorate for Every Home, Style, and BudgetFrom EverandHouse Rules: How to Decorate for Every Home, Style, and BudgetNo ratings yet

- Success at Home with ADHD.: Practical Organization Strategies to Make Your Life Easier.From EverandSuccess at Home with ADHD.: Practical Organization Strategies to Make Your Life Easier.Rating: 4 out of 5 stars4/5 (17)

- Clean Mama's Guide to a Healthy Home: The Simple, Room-by-Room Plan for a Natural HomeFrom EverandClean Mama's Guide to a Healthy Home: The Simple, Room-by-Room Plan for a Natural HomeRating: 5 out of 5 stars5/5 (2)

- How to Keep House While Drowning: A Gentle Approach to Cleaning and OrganizingFrom EverandHow to Keep House While Drowning: A Gentle Approach to Cleaning and OrganizingRating: 4.5 out of 5 stars4.5/5 (845)

- The Fitness Mindset: Eat for energy, Train for tension, Manage your mindset, Reap the resultsFrom EverandThe Fitness Mindset: Eat for energy, Train for tension, Manage your mindset, Reap the resultsRating: 4.5 out of 5 stars4.5/5 (31)

- Lightly: How to Live a Simple, Serene & Stress-free LifeFrom EverandLightly: How to Live a Simple, Serene & Stress-free LifeRating: 4 out of 5 stars4/5 (12)

- 100 Micro Amigurumi: Crochet patterns and charts for tiny amigurumiFrom Everand100 Micro Amigurumi: Crochet patterns and charts for tiny amigurumiRating: 5 out of 5 stars5/5 (2)

- The Martha Manual: How to Do (Almost) EverythingFrom EverandThe Martha Manual: How to Do (Almost) EverythingRating: 4 out of 5 stars4/5 (11)

- Crochet Zodiac Dolls: Stitch the horoscope with astrological amigurumiFrom EverandCrochet Zodiac Dolls: Stitch the horoscope with astrological amigurumiRating: 4 out of 5 stars4/5 (3)

- Crochet with London Kaye: Projects and Ideas to Yarn Bomb Your LifeFrom EverandCrochet with London Kaye: Projects and Ideas to Yarn Bomb Your LifeRating: 5 out of 5 stars5/5 (1)

- The Gentle Art of Swedish Death Cleaning: How to Free Yourself and Your Family from a Lifetime of ClutterFrom EverandThe Gentle Art of Swedish Death Cleaning: How to Free Yourself and Your Family from a Lifetime of ClutterRating: 4 out of 5 stars4/5 (467)

- Crochet Impkins: Over a million possible combinations! Yes, really!From EverandCrochet Impkins: Over a million possible combinations! Yes, really!Rating: 4.5 out of 5 stars4.5/5 (10)

- How To Win Friends And Influence PeopleFrom EverandHow To Win Friends And Influence PeopleRating: 4.5 out of 5 stars4.5/5 (6516)

- Aristotle and Dante Discover the Secrets of the UniverseFrom EverandAristotle and Dante Discover the Secrets of the UniverseRating: 4.5 out of 5 stars4.5/5 (2341)

- Minimalism: Minimalism for Beginners. How to Live Happy While Needing Less in This Modern Material WorldFrom EverandMinimalism: Minimalism for Beginners. How to Live Happy While Needing Less in This Modern Material WorldRating: 4.5 out of 5 stars4.5/5 (39)

- The Botanical Hand Lettering Workbook: Draw Whimsical & Decorative Styles & ScriptsFrom EverandThe Botanical Hand Lettering Workbook: Draw Whimsical & Decorative Styles & ScriptsRating: 4.5 out of 5 stars4.5/5 (2)

- The Joy of Less: A Minimalist Guide to Declutter, Organize, and SimplifyFrom EverandThe Joy of Less: A Minimalist Guide to Declutter, Organize, and SimplifyRating: 4 out of 5 stars4/5 (277)

- Celtic Line Drawing - Simplified InstructionsFrom EverandCeltic Line Drawing - Simplified InstructionsRating: 5 out of 5 stars5/5 (4)

- Crochet Southwest Spirit: Over 20 Bohemian Crochet Patterns Inspired by the American SouthwestFrom EverandCrochet Southwest Spirit: Over 20 Bohemian Crochet Patterns Inspired by the American SouthwestRating: 5 out of 5 stars5/5 (2)

- Martha Stewart's Organizing: The Manual for Bringing Order to Your Life, Home & RoutinesFrom EverandMartha Stewart's Organizing: The Manual for Bringing Order to Your Life, Home & RoutinesRating: 4 out of 5 stars4/5 (11)

- You Need a Budget: The Proven System for Breaking the Paycheck-to-Paycheck Cycle, Getting Out of Debt, and Living the Life You WantFrom EverandYou Need a Budget: The Proven System for Breaking the Paycheck-to-Paycheck Cycle, Getting Out of Debt, and Living the Life You WantRating: 4.5 out of 5 stars4.5/5 (421)

- Colorful Crochet Knitwear: Crochet sweaters and more with mosaic, intarsia and tapestry crochet patternsFrom EverandColorful Crochet Knitwear: Crochet sweaters and more with mosaic, intarsia and tapestry crochet patternsNo ratings yet