Professional Documents

Culture Documents

Engineering Materials

Uploaded by

Ashok PradhanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Engineering Materials

Uploaded by

Ashok PradhanCopyright:

Available Formats

Engineering materials:

Almost every substance known to man has found its way into the engineering workshop at some time or

other. The most convenient way to study the properties and uses of engineering materials is to classify them

into families as shown in figure below:

Figure 1. classification of engineering materials.

1. Metals

1.1 Ferrous metals

These are metals and alloys containing a high proportion of the element iron.

They are the strongest materials available and are used for applications where high strength is required at

relatively low cost and where weight is not of primary importance.

As an example of ferrous metals such as : bridge building, the structure of large buildings, railway lines,

locomotives and rolling stock and the bodies and highly stressed engine parts of road vehicles.

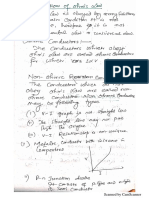

The ferrous metals themselves can also be classified into "families', and these are shown in figure 2.

Figure 2. Classification of ferrous metals.

1.2 Non ferrous metals

These materials refer to the remaining metals known to mankind.

The pure metals are rarely used as structural materials as they lack mechanical strength.

They are used where their special properties such as corrosion resistance, electrical conductivity and

thermal conductivity are required. Copper and aluminum are used as electrical conductors and, together

with sheet zinc and sheet lead, are use as roofing materials.

They are mainly used with other metals to improve their strength.

Some widely used non-ferrous metals and alloys are classified as shown in figure 3.

2. Non metallic materials

2.1 Non metallic (synthetic materials )

These are non metallic materials that do not exist in nature, although they are manufactured from natural

substances such as oil, coal and clay. Some typical examples are classified as shown in figure 4.

2.2 Non metallic (Natural materials )

Such materials are so diverse that only a few can be listed here to give a basic introduction to some typical

applications.

Wood: This is naturally occurring fibrous composite material used for the manufacture of casting patterns.

Rubber :This is used for hydraulic and compressed air hoses and oil seals. Naturally occurring latex is too

soft for most engineering uses but it is used widely for vehicle tyres when it is compounded with carbon

black.

Glass : This is a hardwearing, abrasion-resistant material with excellent weathering properties. It is used

for electrical insulators, laboratory equipment, optical components in measuring instruments etc and, in the

form of fibers, is used to reinforce plastics. It is made by melting together the naturally occurring materials :

silica (sand), limestone (calcium carbonate ) and soda (sodium carbonate).

Emery : This is a widely used abrasive and is a naturally occurring aluminum oxide. Nowadays it is

produced synthetically to maintain uniform quality and performance.

Ceramic: These are produced by baking naturally occurring clays at high temperatures after moulding to

shape. They are used for high voltage insulators and high temperature resistant cutting tool tips.

Diamonds: These can be used for cutting tools for operation at high speeds for metal finishing where

surface finish is greater importance. For example, internal combustion engine pistons and bearings. They are

also used for dressing grinding wheels.

Oils : Used as bearing lubricants, cutting fluids and fuels.

Silicon : This is used as an alloying element and also for the manufacture of semiconductor devices.

These and other natural, non-metallic materials can be classified as shown in figure 7.

Composite materials (composites )

These are materials made up from, or composed of, a combination of different materials to take overall

advantage of their different properties. In man-made composites, the advantages of deliberately combining

materials in order to obtain improved or modified properties was understood by ancient civilizations. An

example of this was the reinforcement of air-dried bricks by mixing the clay with straw.this helped to reduce

cracking caused by shrinkage stresses as the clay dried out. In more recent times, horse hair was used to

reinforce the plaster used on the walls and ceiling of buildings. Again this was to reduce the

onset of drying cracks.

Nowadays, especially with the growth of the plastics industry and the development of high-strength fibers, a

vast range combinations of materials is available for use in composites.

For example, carbon fiber reinforced frames for tennis rackets and shafts for golf clubs have revolutionized

these sports.

Factors affecting materials properties:

The following are the more important factors which can be influence the properties and performance of

engineering materials.

1. Heat treatment

This is the controlled heating and cooling of metals to change their properties to improve their performance

or to facilitate processing.

An example of heat treatment is the hardening of a piece of high carbon steel rod. If it is heated to dull red

heat and plunged into cold water to cool it rapidly (quenching), it will become hard and brittle. If it is again

heated to dull red heat but allowed to cold very slowly it will become softer and less brittle (more tough). In

this condition it is said to be annealed.

After the heat treatment happened on the material it will be in its best condition for flow forming, during

flow forming (working) the grains will be distorted and this will result in most metals becoming work

hardened if flow formed at room temperature. To remove any locked in stresses resulting from the forming

operations and to prepare the material for machining, the material has to be normalized.

2. ProcessingHot and cold working process will be referred to understand what is meant by terms hot and

cold working as applied to metals. Figure 8 shows examples of hot and cold working

Metal is hot worked or cold worked depending upon the temperature at which it is flow formed to shape .

These temperatures are not easy to define . for instance , lead hot works at room temperature and can be

beaten into complex shapes without cracking , but steel does not hot work until it is red hot . When metal are

examined under the microscope it can be seen that they consist of very small grains. When most metals are

bent or worked at room temperature (cold worked) these grains become distorted and the metal becomes

hard and brittle . When metals are hot worked the crystals are also distorted. however, they reform instantly

into normal crystals because the process temperature is above the temperature of recrystallisation for the

metal being used and work hardening does not occur. this cold working is the flow forming of metals below

the temperature the recrystallisation, whilst hot working is the flow forming of metals above the temperature

of recrystallisation.

3. Environmental reactions

The properties of materials can also be effected by reaction with environment in which they are used. For

example:

Resting of steel

Unless steel structures are regularly maintained by rest neutralization and painting process, resting will

occur. The rest will eat into the steel, reduce its thickness and, therefore, its strength. In extreme cases an

entire structure made from steel may be eaten away.

Dezincification of brass

Brass is an alloy of copper and zinc and when brass is exposed to a marine environment for along time, the

salt in the sea water pray react with the zinc content of the brass so as remove it and leave it behind on

spongy, porous mass of copper. This obviously weakness the material which fails under normal working

conditions.

Degradation of plastic

Many plastic degrade and become weak and brittle when exposed to the ultraviolet content of sunlight.

Special dyestuffs have to be incorporated into the plastic to filter out these harmful rays.

You might also like

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- 33 ch6Document13 pages33 ch6swccgopalNo ratings yet

- 12 Physics Lyp 2016 Central Outside Delhi Set3Document7 pages12 Physics Lyp 2016 Central Outside Delhi Set3Ashok PradhanNo ratings yet

- Form 4 Add Maths Chapter 1Document25 pagesForm 4 Add Maths Chapter 1Azhar GameMaster100% (1)

- (Zym© (Av G Kêq O A (Yh$V A H$Document30 pages(Zym© (Av G Kêq O A (Yh$V A H$Ashok PradhanNo ratings yet

- M¡ (VH$ (DKMZ (G¡Õmpývh$) : ZmoqDocument37 pagesM¡ (VH$ (DKMZ (G¡Õmpývh$) : ZmoqAshok PradhanNo ratings yet

- Examples On Mathematical Induction: Trigonometry: Sin Sin 1 SinDocument11 pagesExamples On Mathematical Induction: Trigonometry: Sin Sin 1 SinAshok PradhanNo ratings yet

- Oscillations PDFDocument12 pagesOscillations PDFRaviKumarNo ratings yet

- COLUMMNDocument2 pagesCOLUMMNAshok PradhanNo ratings yet

- Strength of Materials: Er. S K MondalDocument3 pagesStrength of Materials: Er. S K MondalAshok PradhanNo ratings yet

- Comparison Between Edge and Screw DislocationDocument5 pagesComparison Between Edge and Screw DislocationAshok PradhanNo ratings yet

- Curret 2Document2 pagesCurret 2Ashok PradhanNo ratings yet

- State Biot Servat Law and Hence Obtain An Expression For The Magnetic Induction Produced by Infinite Long Current Carrying Conductor at Any Point Near ItDocument5 pagesState Biot Servat Law and Hence Obtain An Expression For The Magnetic Induction Produced by Infinite Long Current Carrying Conductor at Any Point Near ItAshok PradhanNo ratings yet

- Solution, Success Study CircleDocument4 pagesSolution, Success Study CircleAshok PradhanNo ratings yet

- Cold Working and AnnealingDocument10 pagesCold Working and AnnealingAshok PradhanNo ratings yet

- Reproduction in OrganismsDocument10 pagesReproduction in OrganismsAshok PradhanNo ratings yet

- Cold Working and AnnealingDocument10 pagesCold Working and AnnealingAshok PradhanNo ratings yet

- Cold Working and AnnealingDocument10 pagesCold Working and AnnealingAshok PradhanNo ratings yet

- Comparison Between Edge and Screw DislocationDocument5 pagesComparison Between Edge and Screw DislocationAshok PradhanNo ratings yet

- Cold Working and AnnealingDocument10 pagesCold Working and AnnealingAshok PradhanNo ratings yet

- Cold Working and AnnealingDocument10 pagesCold Working and AnnealingAshok PradhanNo ratings yet

- Manufacturing Process 1 Question BankDocument6 pagesManufacturing Process 1 Question BankAshok PradhanNo ratings yet

- Surprize TestDocument3 pagesSurprize TestAshok PradhanNo ratings yet

- Weekly Test July MMMMMMMMDocument2 pagesWeekly Test July MMMMMMMMAshok PradhanNo ratings yet

- Moving Coil GalvanometerDocument5 pagesMoving Coil GalvanometerAshok PradhanNo ratings yet

- Chapter7cor1 2Document19 pagesChapter7cor1 2senthilkumar100No ratings yet

- Current ElectricityDocument2 pagesCurrent ElectricityAshok PradhanNo ratings yet

- Ess at 12 CN StuDocument11 pagesEss at 12 CN Stujsmith012xNo ratings yet

- L No 01Document38 pagesL No 01Annas Equity AnalystNo ratings yet

- Cold Working and AnnealingDocument10 pagesCold Working and AnnealingAshok PradhanNo ratings yet

- OpticsDocument6 pagesOpticsAshok PradhanNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- GlennClavel ElectronicsEngineerDocument1 pageGlennClavel ElectronicsEngineerGlenn Carlo ClavelNo ratings yet

- Soil Investigation and Sampling by Auger Borings: Standard Practice ForDocument2 pagesSoil Investigation and Sampling by Auger Borings: Standard Practice ForgadNo ratings yet

- Senior Engineer SW AutosarDocument2 pagesSenior Engineer SW AutosarDeepak Kumar RautNo ratings yet

- RH..3 TurbochargerDocument43 pagesRH..3 Turbochargerlavkesh100% (5)

- Trident CTD - 11 B LeafletDocument2 pagesTrident CTD - 11 B LeafletBOOBALANNo ratings yet

- AlloysDocument4 pagesAlloyslinguy007No ratings yet

- Chapter 6 Brick WorkDocument17 pagesChapter 6 Brick WorkFaisal KhanNo ratings yet

- Ahmed A'Nasser Handover 22 November PDFDocument3 pagesAhmed A'Nasser Handover 22 November PDFmohamed hamedNo ratings yet

- Pi GEA Omni en-US 1.1 tcm25-27710Document62 pagesPi GEA Omni en-US 1.1 tcm25-27710Edgar Joel Torres OlórteguiNo ratings yet

- Hydraulic Motors MLHT: ApplicationDocument14 pagesHydraulic Motors MLHT: ApplicationMateus Manoel CarvalhoNo ratings yet

- Unit III Heat Exchange EquipmentDocument17 pagesUnit III Heat Exchange EquipmentaberraneNo ratings yet

- E84aycer Profinet Mci Module v2-0 enDocument94 pagesE84aycer Profinet Mci Module v2-0 enRafaelNo ratings yet

- Esquema Electrico Hidrauliuco 117.120Document34 pagesEsquema Electrico Hidrauliuco 117.120ivanNo ratings yet

- BASF - APE System PDFDocument86 pagesBASF - APE System PDFrendroedywibowoNo ratings yet

- Blank Copy of PHE - Estimate For BLOCK 4Document34 pagesBlank Copy of PHE - Estimate For BLOCK 4basantadrreddys100% (2)

- Moderate ClimateDocument13 pagesModerate Climatevaibhav0% (1)

- Parts Catalogue Mio 2007Document58 pagesParts Catalogue Mio 2007fitomoto50% (2)

- LG - WT5170 Washer Spec SheetDocument2 pagesLG - WT5170 Washer Spec SheetAlejandro ErroNo ratings yet

- Biodiesel in ThailandDocument32 pagesBiodiesel in Thailandinfo_thesisNo ratings yet

- Selden Hydralic Package Manual PDFDocument60 pagesSelden Hydralic Package Manual PDFNils BrantingNo ratings yet

- KTM Duke 200 2015 Owner ManualDocument177 pagesKTM Duke 200 2015 Owner ManualMichal wojcikNo ratings yet

- To Find Out The Scope of Submersible Pumps in Present Era of AgricultureDocument84 pagesTo Find Out The Scope of Submersible Pumps in Present Era of Agricultureshahinnocent100% (1)

- Build Your Own French Doors - Popular Woodworking Magazine PDFDocument1 pageBuild Your Own French Doors - Popular Woodworking Magazine PDFNei Souza100% (1)

- MTN/1185W Applications: Submersible Velocity Transducer 4-20ma Output For PLC InterfaceDocument2 pagesMTN/1185W Applications: Submersible Velocity Transducer 4-20ma Output For PLC Interfacevikivarma147No ratings yet

- (Core 2) Prepare Computer-Aided DrawingsDocument116 pages(Core 2) Prepare Computer-Aided DrawingsOliver Sanchez82% (11)

- Facility Inspection ChecklistDocument8 pagesFacility Inspection ChecklistTimNo ratings yet

- HENNLICH Telescopic Loading SpoutsDocument34 pagesHENNLICH Telescopic Loading SpoutsTomas masquimillanNo ratings yet

- Ecoflam BurnersDocument40 pagesEcoflam Burnerseuroused100% (1)

- ASCE 7-10 - Tabla4-1 - Minimum Uniformly Distributed Live Loads PDFDocument4 pagesASCE 7-10 - Tabla4-1 - Minimum Uniformly Distributed Live Loads PDFAlvaro Jaen Kravarovic100% (1)