Professional Documents

Culture Documents

ASh Silo Sizing Calculation

Uploaded by

Durjoy ChakrabortyOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ASh Silo Sizing Calculation

Uploaded by

Durjoy ChakrabortyCopyright:

Available Formats

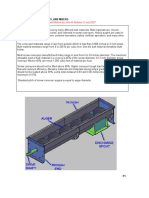

h1

30

h2

h3

60

h4

A. Calculation of Requirement of Silo Capacity

Coal consumption at BMCR per boiler TPH 41.42

% of Ash in worst coal 2%

Quantity of Ash produced per boiler tph 1.010648

Angle of Surcharge of Ash deg 30

Maximum Percentage of Fly Ash in Ash 60%

Maximum Percentage of Bed Ash in Ash 40%

Quantity of Fly ash per boiler tph 0.6063888

Quantity of Bed ash per boiler tph 0.4042592

Quantity of ash from one boiler tph 1.010648

No. of hours of Storage as per Specification hr. 24

Ash Storage Quantity as per Requirement T 24.255552

Bulk density of Fly Ash considered T/m 0.6

Corresponding water volume of Ash m 40.42592

Freeboard Margin to be provided 10%

Additional Volume to be considered m 4.042592

Total Volume of the Silo m 44.468512

Selected Vouleme of the Silo m 50

B. Calculation for Silo Sizing

Radius of Silo considered, R m 1.4

Radius of Opening at Bottom of silo, r m 0.8

Valley Angle at Bottom Conical portion of Silo deg 60

h3+h4 m R x tan 60 2.42

h4 m r x tan 60 1.39

Height of Conical Part at Bottom, h3 m 1.04

Height of Cylindrical Part at Middle, h2 m 8.51

Height of Conical Part at Top, h1 m 0.81

Total Height, H m 10.36

Volume of Conical Part at Bottom, V1 = p/3x{R2x(h3+h4)-r2xh4}

m 4.0

Volume of Cylindrical Part at Middle, V2 m pxR2xh2 52.4

Effective Volume of Conical Part at Top, V3 m pxR3xh1x60% 3.0

(cosidering 60% filling of the cylindrical portion with six feeding points)

Effective Volume of silo m 59.4

> Required Volume

360574615.xls/Fly+Bed Ash 07/15/2017

Selected Diameter of silo m 3

Total Height of silo m 10.36

ASH SILO SIZING CALCULATION Thermax Limited

1x15 MW IPP, DMCI POWER Division

360574615.xls/Fly+Bed Ash 07/15/2017

h1

30

h2

h3

60

h4

A. Calculation of Requirement of Silo Capacity

Coal consumption at BMCR per boiler TPH 10.5

% of Ash in worst coal 15%

Quantity of Ash produced per boiler tph 1.575

Angle of Surcharge of Ash deg 30

Maximum Percentage of Fly Ash in Ash 80%

Maximum Percentage of Bed Ash in Ash 20%

Quantity of Fly ash per boiler tph 1.26

Quantity of Bed ash per boiler tph 0.315

Quantity of ash from one boiler tph 1.575

No. of hours of Storage as per Specification hr. 24

Ash Storage Quantity as per Requirement T 7.56

Bulk density of Bed Ash considered T/m 1.1

Corresponding water volume of Ash m 6.8727272727

Freeboard Margin to be provided 10%

Additional Volume to be considered m 0.6872727273

Total Volume of the Silo m 7.56

Selected Vouleme of the Silo m 8

B. Calculation for Silo Sizing

Radius of Silo considered, R m 1

Radius of Opening at Bottom of silo, r m 0.4

Valley Angle at Bottom Conical portion of Silo deg 60

h3+h4 m R x tan 60 1.73

h4 m r x tan 60 0.69

Height of Conical Part at Bottom, h3 m 1.04

Height of Cylindrical Part at Middle, h2 m 2.00

Height of Conical Part at Top, h1 m 0.58

Total Height, H m 3.62

Volume of Conical Part at Bottom, V1 = p/3x{R2x(h3+h4)-r2xh4}

m 1.7

Volume of Cylindrical Part at Middle, V2 m pxR2xh2 6.3

Effective Volume of Conical Part at Top, V3 m pxR xh1x60%

3

1.1

(cosidering 60% filling of the cylindrical portion with six feeding points)

Effective Volume of silo m 9.1

> Required Volume

Selected Diameter of silo m 2

Total Height of silo m 3.62

ASH SILO SIZING CALCULATION Thermax Limited

1x15 MW IPP, DMCI POWER Division

h1

30

h2

h3

60

h4

A. Calculation of Requirement of Silo Capacity

Coal consumption at BMCR per boiler TPH 10.5

% of Ash in worst coal 15%

Quantity of Ash produced per boiler tph 1.575

Angle of Surcharge of Ash deg 30

Maximum Percentage of Fly Ash in Ash 80%

Maximum Percentage of Bed Ash in Ash 20%

Quantity of Fly ash per boiler tph 1.26

Quantity of Bed ash per boiler tph 0.315

Quantity of ash from one boiler tph 1.575

No. of hours of Storage as per Specification hr. 24

Ash Storage Quantity as per Requirement T 30.24

Bulk density of Fly Ash considered T/m 0.6

Corresponding water volume of Ash m 50.4

Freeboard Margin to be provided 10%

Additional Volume to be considered m 5.04

Total Volume of the Silo m 55.44

Selected Vouleme of the Silo m 56

B. Calculation for Silo Sizing

Radius of Silo considered, R m 1.8

Radius of Opening at Bottom of silo, r m 0.4

Valley Angle at Bottom Conical portion of Silo deg 60

h3+h4 m R x tan 60 3.12

h4 m r x tan 60 0.69

Height of Conical Part at Bottom, h3 m 2.42

Height of Cylindrical Part at Middle, h2 m 4.00

Height of Conical Part at Top, h1 m 1.04

Total Height, H m 7.46

Volume of Conical Part at Bottom, V1 = p/3x{R2x(h3+h4)-r2xh4}

m 10.5

Volume of Cylindrical Part at Middle, V2 m pxR2xh2 40.7

Effective Volume of Conical Part at Top, V3 m pxR xh1x60%

3

6.3

(cosidering 60% filling of the cylindrical portion with six feeding points)

Effective Volume of silo m 57.5

> Required Volume

Selected Diameter of silo m 4

Total Height of silo m 7.46

ASH SILO SIZING CALCULATION Thermax Limited

1x15 MW IPP, DMCI POWER Division

Ash Distribution

Total Fly Ash 1.26

Operating Design

Economiser 0.44 0.53

APH 0.06 0.07

ESP 1st Field 0.68 0.82

ESP 2nd Field 0.07 0.08

ESP 3rd Field 0.00 0.01

1.25 1.50

You might also like

- Travelling Tripper CalculationDocument5 pagesTravelling Tripper CalculationHarshGupta100% (2)

- Design Examples 1 2 of Circular Silo PDFDocument7 pagesDesign Examples 1 2 of Circular Silo PDFAnicet Vincent70% (10)

- Design Examples 1 2 of Circular Silo 1 PDFDocument7 pagesDesign Examples 1 2 of Circular Silo 1 PDFlahlou_d921650% (2)

- Estimation Software For Presure VesselDocument36 pagesEstimation Software For Presure VesselKarthikeyan Shanmugavel0% (1)

- Calculation For D12m SiloDocument3 pagesCalculation For D12m SiloHaftamu Tekle80% (10)

- Silo Design CementDocument4 pagesSilo Design Cementkvamshi_1971100% (7)

- 100cub API 650 STEEL SiloDocument19 pages100cub API 650 STEEL SiloUDayNo ratings yet

- Silo Design WebDocument1 pageSilo Design Weblecongdinh100% (1)

- Design of Hopper BottomDocument1 pageDesign of Hopper Bottomamir1911411No ratings yet

- Calculation Steel Silo - Pellet Hopper 1. Basic Design:: 3 M 3 M 6.407 M 6.5 KN/m3 9.00 m2 12.00 MDocument7 pagesCalculation Steel Silo - Pellet Hopper 1. Basic Design:: 3 M 3 M 6.407 M 6.5 KN/m3 9.00 m2 12.00 MNguyễn Thanh TháiNo ratings yet

- BELT CONVEYOR - Discharge TrajectoryDocument3 pagesBELT CONVEYOR - Discharge TrajectorySergio Diaz DuarteNo ratings yet

- IS Code For Steel Bin Design - 9178Document29 pagesIS Code For Steel Bin Design - 9178krishna kumar50% (2)

- Design of Silos 2010Document21 pagesDesign of Silos 2010Topaca Paec100% (3)

- FAD Calculation For CompressorDocument2 pagesFAD Calculation For CompressorDurjoy ChakrabortyNo ratings yet

- 1000 m3 Ash Silo Calculation ReportDocument15 pages1000 m3 Ash Silo Calculation Reporttranceintt0% (1)

- Silo VoDocument2 pagesSilo Vosuntoshsalvi4859No ratings yet

- Silos DesignDocument7 pagesSilos Designaloyssberg100% (4)

- Silo Data SheetDocument4 pagesSilo Data SheetZoran Danilov100% (1)

- RM Silo Ocp3Document7 pagesRM Silo Ocp3Mahata Priyabrata50% (2)

- Silo DesignDocument12 pagesSilo Designraju_420034520No ratings yet

- Silo Capacity CalculationDocument1 pageSilo Capacity Calculationlbc123No ratings yet

- Silo WallDocument5 pagesSilo WallMunish GaurNo ratings yet

- Design Calculations For SiloDocument3 pagesDesign Calculations For SiloLeera Gonzaga100% (2)

- Steel Silo's DesignDocument2 pagesSteel Silo's Designemad sabri100% (1)

- Calculation For D12m SiloDocument4 pagesCalculation For D12m SiloJuan Carlos Quispe Chara0% (1)

- Silo Cement CalculationDocument11 pagesSilo Cement CalculationFikriaraz AfifNo ratings yet

- Calc. Shell Thickness SiloDocument29 pagesCalc. Shell Thickness SiloJunaid MateenNo ratings yet

- Belt Conveyors With Shaft SizingDocument5 pagesBelt Conveyors With Shaft SizingArun Chopra100% (1)

- Silo SizeDocument1 pageSilo Sizeuvarajmecheri100% (1)

- Design Calculation For Fly Ash Storage Silo Stage-II - Rev.2 - Z1660 TalcherDocument135 pagesDesign Calculation For Fly Ash Storage Silo Stage-II - Rev.2 - Z1660 TalcherSwapan Kumar BoseNo ratings yet

- Design of Steel Bunker & Silo R1Document22 pagesDesign of Steel Bunker & Silo R1sougata1667% (3)

- Wind On SiloDocument7 pagesWind On SiloHgagselim SelimNo ratings yet

- 04 Design of BunkerDocument24 pages04 Design of BunkerJames AugustineNo ratings yet

- Mechanical Conveyors: 29 Materials HandlingDocument2 pagesMechanical Conveyors: 29 Materials HandlingSMNCI Cadet EngineersNo ratings yet

- Bag Filter CalculationDocument2 pagesBag Filter Calculationjenifferrayen71% (7)

- Steel Silo Quantity EstimationDocument4 pagesSteel Silo Quantity EstimationUttam Kumar Ghosh100% (1)

- Hopper Bottom DesignDocument2 pagesHopper Bottom DesignAnonymous ciKyr0tNo ratings yet

- Design of Unburned Clinker Silo Based On BS EN 1991-4:2006Document4 pagesDesign of Unburned Clinker Silo Based On BS EN 1991-4:2006Uttam Kumar GhoshNo ratings yet

- Screw Conveyor DesignDocument14 pagesScrew Conveyor DesignIrwan SattuNo ratings yet

- Bucket Elevator Calculation: Yellow Cell To Be FilledDocument2 pagesBucket Elevator Calculation: Yellow Cell To Be Filledm_verma21100% (2)

- Example 3 Rectangular SiloDocument7 pagesExample 3 Rectangular SiloAhmed Said50% (2)

- Design of ConveyorsDocument15 pagesDesign of ConveyorsRamachandran VenkateshNo ratings yet

- 9178 2 PDFDocument39 pages9178 2 PDFvivekNo ratings yet

- 6 Design of Constant Dia RCC Chimney and Foundation 23052014Document16 pages6 Design of Constant Dia RCC Chimney and Foundation 23052014Ahmad Badsha Quadri0% (1)

- Bag Filter Calculation1234567 IPDocument24 pagesBag Filter Calculation1234567 IPsujith kumarNo ratings yet

- CEMA8 5pgDocument5 pagesCEMA8 5pgkmats100% (2)

- ASh Silo Sizing CalculationDocument7 pagesASh Silo Sizing CalculationBimal DeyNo ratings yet

- ASh Silo Sizing CalculationDocument7 pagesASh Silo Sizing CalculationPascal CustonNo ratings yet

- Bunker Sizing Calculations-Case-4Document1 pageBunker Sizing Calculations-Case-4ssNo ratings yet

- Bunker Sizing Calculations-Case-1Document1 pageBunker Sizing Calculations-Case-1ssNo ratings yet

- Bunker Sizing Calculations-Case-3Document1 pageBunker Sizing Calculations-Case-3ssNo ratings yet

- Process DesignDocument6 pagesProcess DesignDaniel Andres Canro CalderónNo ratings yet

- Bunker Sizing Calculation & Bunker GeometryDocument1 pageBunker Sizing Calculation & Bunker GeometryssNo ratings yet

- Sizing Dryer, Conveyor, ReactorDocument20 pagesSizing Dryer, Conveyor, ReactorirviNo ratings yet

- Ventilation Plan For Confined Space EntryDocument9 pagesVentilation Plan For Confined Space EntryMohamad Nazmi Mohamad Rafian100% (1)

- 1 s2.0 S1750583623000749 mmc1Document10 pages1 s2.0 S1750583623000749 mmc1GCH2SOLNo ratings yet

- PumpDocument3 pagesPumpfazila fauziNo ratings yet

- Presentasi Coal MILL Pulverizer Modeling AwalDocument26 pagesPresentasi Coal MILL Pulverizer Modeling Awalbhisma aktaNo ratings yet

- Comet 5.0 Fiksasi RevisiDocument26 pagesComet 5.0 Fiksasi RevisiKhansa ArkhapNo ratings yet

- Clariflocculator: Description Unit Input Calculated Range Value Value 54000 Mim M 492 M MDocument6 pagesClariflocculator: Description Unit Input Calculated Range Value Value 54000 Mim M 492 M MAnonymous EKxXjqyVHNo ratings yet

- Jacketed Vessel Heat Transfer (Half Pipe Coil) : MM Inch MM RPM MM M /HDocument30 pagesJacketed Vessel Heat Transfer (Half Pipe Coil) : MM Inch MM RPM MM M /Hmanoj67% (3)

- Saff Reactor: Design Flow 600 Incoming BOD To SAFF 300 % BOD Removal 94Document4 pagesSaff Reactor: Design Flow 600 Incoming BOD To SAFF 300 % BOD Removal 94Rakesh Verma100% (3)

- H2 KoreanDocument3 pagesH2 KoreanDurjoy ChakrabortyNo ratings yet

- TG SynchronizationDocument7 pagesTG SynchronizationDurjoy ChakrabortyNo ratings yet

- Glass Fibre Reinforced Products PDFDocument16 pagesGlass Fibre Reinforced Products PDFDurjoy ChakrabortyNo ratings yet

- Coal FLowDocument28 pagesCoal FLowDurjoy ChakrabortyNo ratings yet

- Comparison of Counter Flow and Cross Flow CoolingDocument2 pagesComparison of Counter Flow and Cross Flow CoolingDurjoy ChakrabortyNo ratings yet

- Restriction Orifice Diamater CalculationDocument1 pageRestriction Orifice Diamater CalculationDurjoy ChakrabortyNo ratings yet

- Waste To Energy Plant in SuratDocument18 pagesWaste To Energy Plant in SuratDurjoy ChakrabortyNo ratings yet

- Waste Heat Recovery in Cement Plant IJERTV3IS051014 PDFDocument5 pagesWaste Heat Recovery in Cement Plant IJERTV3IS051014 PDFDurjoy ChakrabortyNo ratings yet

- Gas TurbineInlet Air CoolingDocument41 pagesGas TurbineInlet Air CoolingDurjoy ChakrabortyNo ratings yet

- 1811 Reclaiming SystemsDocument4 pages1811 Reclaiming SystemsDurjoy ChakrabortyNo ratings yet

- 01 GeoStrucAnal Cylinder Elastic PDFDocument12 pages01 GeoStrucAnal Cylinder Elastic PDFSiddhant KaushikNo ratings yet

- High Integrity Aluminum (GENERAL)Document140 pagesHigh Integrity Aluminum (GENERAL)Kmilo Giraldo100% (3)

- Chemical Thermodynamics: Theodore L. Brown H. Eugene Lemay, Jr. and Bruce E. BurstenDocument43 pagesChemical Thermodynamics: Theodore L. Brown H. Eugene Lemay, Jr. and Bruce E. BurstenChery-an PletNo ratings yet

- Softening Point of AsphaltDocument2 pagesSoftening Point of AsphaltMuhammad Rizal RamliNo ratings yet

- Asgmnt HECRASDocument7 pagesAsgmnt HECRASShahruzi MahadzirNo ratings yet

- Ex-Cell XR2750 Pressure Washer Operation ManualDocument16 pagesEx-Cell XR2750 Pressure Washer Operation Manualj_wilson85No ratings yet

- Ain Tsila Development Main EPC Contract A-CNT-CON-000-00282 Subcontract N°: JI-2045/07-002BDocument15 pagesAin Tsila Development Main EPC Contract A-CNT-CON-000-00282 Subcontract N°: JI-2045/07-002BAslaouiNo ratings yet

- The Difference Between The Internet and World Wide WebDocument3 pagesThe Difference Between The Internet and World Wide WebSonal Jain100% (1)

- 4 Rec. ITU-R BS.775-3: Reference Loudspeaker Arrangement With Loudspeakers L/C/R and LS/RSDocument3 pages4 Rec. ITU-R BS.775-3: Reference Loudspeaker Arrangement With Loudspeakers L/C/R and LS/RSPaulo PiresNo ratings yet

- Stock # Carbon Weight Burn Temp Puncture StrengthDocument8 pagesStock # Carbon Weight Burn Temp Puncture StrengthMintNo ratings yet

- Module002 LaboratoryExercise002Document2 pagesModule002 LaboratoryExercise002Joaquin SmithNo ratings yet

- 4 and 6 Pole MotorDocument6 pages4 and 6 Pole Motorarajamani78100% (1)

- 2019 All PDFDocument27 pages2019 All PDFvishesh bhatiaNo ratings yet

- Method StatementDocument4 pagesMethod StatementtayitbatovNo ratings yet

- " " Reach: Ordering InformationDocument8 pages" " Reach: Ordering InformationTrong TranNo ratings yet

- Selling Your Contents To The WorldDocument25 pagesSelling Your Contents To The WorldCreative Malaysia100% (1)

- Water Treatment Process Disinfection PDFDocument6 pagesWater Treatment Process Disinfection PDFAriff JasniNo ratings yet

- 1Document100 pages1Niomi GolraiNo ratings yet

- MJ4502 High-Power PNP Silicon TransistorDocument4 pagesMJ4502 High-Power PNP Silicon Transistorjoao victorNo ratings yet

- Justine J. Beroy: Career ObjectivesDocument5 pagesJustine J. Beroy: Career ObjectivesJustine BeroyNo ratings yet

- Diet Coke & Mentos Geyser Lab 2011-2012Document4 pagesDiet Coke & Mentos Geyser Lab 2011-2012Frederick LoganNo ratings yet

- Cache MemoryDocument20 pagesCache MemoryKeshav Bharadwaj RNo ratings yet

- CovestroDocument2 pagesCovestroRonaldo CamargoNo ratings yet

- IBM System Storage DS8000 - A QuickDocument10 pagesIBM System Storage DS8000 - A Quickmuruggan_aNo ratings yet

- Solar Module CellDocument4 pagesSolar Module CellVinod BabhaleNo ratings yet

- 06-901 Keyed Input SwitchesDocument4 pages06-901 Keyed Input Switchesmajed al.madhajiNo ratings yet

- Folder Fiamm Neptune 2010 EngDocument4 pagesFolder Fiamm Neptune 2010 EngchokribNo ratings yet

- PACSystemsRX3i CS GFA559G (2010)Document4 pagesPACSystemsRX3i CS GFA559G (2010)Omar Alfredo Del CastilloNo ratings yet

- Chapter 2 - 2 Plane Curvilinear MotionDocument37 pagesChapter 2 - 2 Plane Curvilinear MotionAlfredo Ruiz ValenciaNo ratings yet