Professional Documents

Culture Documents

FAN7602 Data

Uploaded by

Sergio Daniel BarretoCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

FAN7602 Data

Uploaded by

Sergio Daniel BarretoCopyright:

Available Formats

FAN7602 Green Current Mode PWM Controller

November 2006

FAN7602

Green Current Mode PWM Controller

Features Description

Green Current Mode PWM Control The FAN7602 is a green current mode PWM controller. It

Fixed 65kHz Operation with Frequency Modulation is specially designed for off-line adapter application,

Internal High-Voltage Start-up Switch DVDP, VCR, LCD monitor application, and auxiliary

power supplies.

Burst Mode Operation

Line Voltage Feed Forward to Limit Maximum Power The internal high-voltage start-up switch and the burst-

mode operation reduce the power loss in standby mode.

Line Under-Voltage Protection

Because of the internal start-up switch and the burst

Latch Protection & Internal Soft-Start (10ms) Function

mode, it is possible to supply 0.5W load, limiting the

Overload Protection input power to under 1W when the input line voltage is

Over-Voltage Protection 265VAC. On no-load condition, the input power is under

Low Operation Current: Typical 1mA 0.3W.

8-pin DIP/SOP The maximum power can be limited constantly, regard-

less of the line voltage change, using the power limit

Applications function.

Adapter The switching frequency is internally fixed at 65kHz and

LCD Monitor Power the frequency modulation technique reduces EMI.

Auxiliary Power Supply The FAN7602 includes various protections for the sys-

tem reliability and the internal soft-start prevents the out-

Related Application Notes put voltage overshoot at start-up.

AN6014 - Green Current Mode PWM Controller

FAN7602

Ordering Information

Operating Temp. Marking

Part Number Range Pb-Free Package Packing Method Code

FAN7602N 8-DIP Rail FAN7602

FAN7602M -25C to +125C Yes Rail FAN7602

8-SOP

FAN7602MX Tape & Reel FAN7602

2006 Fairchild Semiconductor Corporation www.fairchildsemi.com

FAN7602 Rev. 1.0.2

FAN7602 Green Current Mode PWM Controller

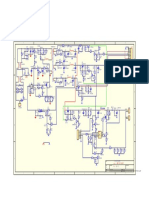

Typical Application Diagram

FAN7602

FAN7602 Rev. 02

Figure 1. Typical Flyback Application

Internal Block Diagram

Vstr

8

6 VCC

LUVP 1 LUVP OVP

Auto Restart

OLP Protection SS End 19V

2V/1.5V OVP

Latch Reset

Latch Protection Circuit

5V Ref

12V/8V

VCC UVLO

10ms SS End

Soft Start

Driver

5 OUT

Circuit

PWM

65kHz Clock Block Plimit

with Offset

Frequency

Modulation 3 CS/FB

Delay

Circuit

0.95V/0.88V

Latch/ Latch

2

Plimit

PWM+

OLP Power Limit

4V Soft-

Start

Plimit

Plimit Offset Plimit

Offset OLP Offset

4 GND

Generator

Soft-Start

FAN7602 Rev. 03

Figure 2. Functional Block Diagram of FAN7602

2006 Fairchild Semiconductor Corporation www.fairchildsemi.com

FAN7602 Rev. 1.0.2 2

FAN7602 Green Current Mode PWM Controller

Pin Assignments

Vstr NC VCC OUT

8 7 6 5

FAN7602

YWW

1 2 3 4

LUVP Latch/ CS/FB GND

Plimit

FAN7602 Rev. 03

Figure 3. Pin Configuration (Top View)

Pin Definitions

Pin Number Pin Name Pin Function Description

1 LUVP Line Under-Voltage Protection Pin. This pin is used to protect the set when the

input voltage is lower than the rated input voltage range.

2 Latch/Plimit Latch Protection and Power Limit Pin. When the pin voltage exceeds 4V, the latch

protection works. The latch protection is reset when the VCC voltage is lower than 5V.

For the power limit function, the Over-Current Protection (OCP) level decreases as

the pin voltage increases.

3 CS/FB Current Sense and Feedback Pin. This pin is used to sense the MOSFET current

for the current mode PWM and OCP. The output voltage feedback information and

the current sense information are added using an external RC filter.

4 GND Ground Pin. This pin is used for the ground potential of all the pins. For proper oper-

ation, the signal ground and the power ground should be separated.

5 OUT Gate Drive Output Pin. This pin is an output pin to drive an external MOSFET. The

peak sourcing current is 450mA and the peak sinking current is 600mA. For proper

operation, the stray inductance in the gate driving path must be minimized.

6 VCC Supply Voltage Pin. IC operating current and MOSFET driving current are supplied

using this pin.

7 NC No Connection.

8 Vstr Start-up Pin. This pin is used to supply IC operating current during IC start-up. After

start-up, the internal JFET is turned off to reduce power loss.

2006 Fairchild Semiconductor Corporation www.fairchildsemi.com

FAN7602 Rev. 1.0.2 3

FAN7602 Green Current Mode PWM Controller

Absolute Maximum Ratings

The Absolute Maximum Ratings are those values beyond which the safety of the device cannot be guaranteed. The

device should not be operated at these limits. The parametric values defined in the Electrical Characteristics tables are

not guaranteed at the absolute maximum ratings.

Symbol Parameter Value Unit

VCC Supply Voltage 20 V

IOH, IOL Peak Drive Output Current +450/-600 mA

VCS/FB CS/FB Input Voltage -0.3 to 20 V

VLUVP LUVP Input Voltage -0.3 to 10 V

VLatch Latch/Plimit Input Voltage -0.3 to 10 V

Vstr Vstr Input Voltage 600 V

TJ Operating Junction Temperature 150 C

TA Operating Temperature Range -25 to 125 C

Tstg Storage Temperature Range -55 to 150 C

PD Power Dissipation 1.2 W

VESD_HBM ESD Capability, Human Body Model 2.0 kV

VESD_MM ESD Capability, Machine Model 300 V

VESD_CDM ESD Capability, Charged Device Model 500 V

Thermal Impedance

Symbol Parameter Value Unit

JA(1) Thermal Resistance, Junction-to-Ambient 8-DIP 100 C/W

Note:

1. Regarding the test environment and PCB type, please refer to JESD51-2 and JESD51-10.

2006 Fairchild Semiconductor Corporation www.fairchildsemi.com

FAN7602 Rev. 1.0.2 4

FAN7602 Green Current Mode PWM Controller

Electrical Characteristics

VCC = 14V, TA = -25C~125C, unless otherwise specified.

Symbol Parameter Condition Min. Typ. Max. Unit

START UP SECTION

Istr Vstr Start-up Current Vstr = 30V, TA = 25C 0.7 1 1.4 mA

UNDER VOLTAGE LOCK OUT SECTION

Vth(start) Start Threshold Voltage VCC increasing 11 12 13 V

Vth(stop) Stop Threshold Voltage VCC decreasing 7 8 9 V

HY(uvlo) UVLO Hysteresis 3.6 4 4.4 V

SUPPLY CURRENT SECTION

Ist Start-up Supply Current TA = 25C 250 320 A

ICC Operating Supply Current Output no switching 1 1.5 mA

SOFT-START SECTION

TSS Soft-Start Time(2) 5 10 15 ms

PWM SECTION

FOSC Operating Frequency VCS/FB = 0.2V, TA = 25C 59 65 73 kHz

F Frequency Modulation 2 kHz

VCS/FB1 CS/FB Threshold Voltage TA = 25C 0.9 1.0 1.1 V

tD Propagation Delay to Output(2) 100 150 ns

DMAX Maximum Duty Cycle 70 75 80 %

DMIN Minimum Duty Cycle 0 %

BURST MODE SECTION

VCS/FB2 Burst On Threshold Voltage TA = 25C 0.84 0.95 1.06 V

VCS/FB3 Burst Off Threshold Voltage TA = 25C 0.77 0.88 0.99 V

POWER LIMIT SECTION

KPlimit Offset Gain VLatch/Plimit = 2V, TA = 25C 0.12 0.16 0.20

OUTPUT SECTION

VOH Output Voltage High TA = 25C, Isource = 100mA 11.5 12 14 V

VOL Output Voltage Low TA = 25C, Isink = 100mA 1 2.5 V

tr Rising Time(2) TA = 25C, Cl = 1nF 45 150 ns

tf Falling Time(2) TA = 25C, Cl = 1nF 35 150 ns

Note:

2. These parameters, although guaranteed by design, are not tested in production.

2006 Fairchild Semiconductor Corporation www.fairchildsemi.com

FAN7602 Rev. 1.0.2 5

FAN7602 Green Current Mode PWM Controller

Electrical Characteristics (Continued)

VCC = 14V, TA = -25C~125C, unless otherwise specified.

Symbol Parameter Condition Min. Typ. Max. Unit

PROTECTION SECTION

VLatch Latch Voltage 3.6 4 4.4 V

TOLP (3)

Overload Protection Time 20 22 24 ms

TOLP_ST Overload Protection Time at Start-up 30 37 44 ms

VOLP Overload Protection Level 0 0.1 V

VLUVPoff Line Under-Voltage Protection On to Off TA = 25C 1.9 2 2.1 V

VLUVPon Line Under-Voltage Protection Off to On TA = 25C 1.4 1.5 1.6 V

VOVP Over Voltage Protection TA = 25C 18 19 20 V

Note:

3. These parameters, although guaranteed by design, are not tested in production.

2006 Fairchild Semiconductor Corporation www.fairchildsemi.com

FAN7602 Rev. 1.0.2 6

FAN7602 Green Current Mode PWM Controller

Typical Performance Characteristics

12.8 8.8

12.4 8.4

VTH[V]

VTL[V]

12.0 8.0

11.6 7.6

11.2 7.2

-25 0 25 50 75 100 125 -25 0 25 50 75 100 125

Temperature [C] Temperature [C]

Figure 4. Start Threshold Voltage vs. Temp. Figure 5. Stop Threshold Voltage vs. Temp.

4.4 350

4.3

UVLO Hysteresis [V]

4.2 300

4.1

Ist [A]

4.0 250

3.9

3.8 200

3.7

3.6 150

-25 0 25 50 75 100 125 -25 0 25 50 75 100 125

Temperature [C] Temperature [C]

Figure 6. UVLO Hysteresis vs. Temp. Figure 7. Start-up Supply Current vs. Temp.

1.5 1.3

1.4

1.2

1.3

Iop [mA]

Istr [mA]

1.2 1.1

1.1 1.0

1.0

0.9

0.9

0.8 0.8

-25 0 25 50 75 100 125 -25 0 25 50 75 100 125

Temperature [C] Temperature [C]

Figure 8. Operating Supply Current vs. Temp. Figure 9. Vstr Star-up Current vs. Temp.

2006 Fairchild Semiconductor Corporation www.fairchildsemi.com

FAN7602 Rev. 1.0.2 7

FAN7602 Green Current Mode PWM Controller

Typical Performance Characteristics (Continued)

1.10 70

CSFB2

1.05

CSFB3 68

CS/FB Threshold [V]

1.00

FOSC [kHz]

0.95 66

0.90

64

0.85

0.80

62

0.75

0.70 60

-25 0 25 50 75 100 125 -25 0 25 50 75 100 125

Temperature [C] Temperature [C]

Figure 10. Burst On/Off Voltage vs. Temp. Figure 11. Operating Frequency vs. Temp.

0.20 80

0.18 78

DMAX [%]

Kplimit

0.16 76

0.14 74

0.12 72

0.10 70

-25 0 25 50 75 100 125 -25 0 25 50 75 100 125

Temperature [C] Temperature [C]

Figure 12. Offset Gain vs. Temp. Figure 13. Maximum Duty Cycle vs. Temp.

20.0 4.4

19.6

4.2

VLATCH [V]

VOVP [V]

19.2

4.0

18.8

3.8

18.4

18.0 3.6

-25 0 25 50 75 100 125 -25 0 25 50 75 100 125

Temperature [C] Temperature [C]

Figure 14. OVP Voltage vs. Temp. Figure 15. Latch Voltage vs. Temp.

2006 Fairchild Semiconductor Corporation www.fairchildsemi.com

FAN7602 Rev. 1.0.2 8

FAN7602 Green Current Mode PWM Controller

Typical Performance Characteristics (Continued)

2.10 1.70

1.65

2.05

1.60

VLUVPon [V]

VLUVPoff [V]

2.00 1.55

1.50

1.95

1.45

1.90 1.40

-25 0 25 50 75 100 125 -25 0 25 50 75 100 125

Temperature [C] Temperature [C]

Figure 16. LUVP On to Off Voltage vs. Temp. Figure 17. LUVP Off to On Voltage vs. Temp.

1.08

CSFB1 Threshold voltage [V]

1.04

1.00

0.96

0.92

-25 0 25 50 75 100 125

Temperature [C]

Figure 18. CS/FB Threshold Voltage vs. Temp.

2006 Fairchild Semiconductor Corporation www.fairchildsemi.com

FAN7602 Rev. 1.0.2 9

FAN7602 Green Current Mode PWM Controller

Applications Information

1. Start-up Circuit and Soft-Start Block Figure 21 shows the current sense and feedback circuits.

RS is the current sense resistor to sense the switch cur-

The FAN7602 contains a start-up switch to reduce the

rent. The current sense information is filtered by an RC

power loss of the external start-up circuit of the conven-

filter composed of RF and CF. According to the output

tional PWM converters. The internal start-up circuit

voltage feedback information, IFB charges or stops charg-

charges the VCC capacitor with 0.9mA current source if

ing CF to adjust the offset voltage. If IFB is zero, CF is dis-

the AC line is connected. The start-up switch is turned off

charged through RF and RS to lower the offset voltage.

15ms after IC starts up, as shown in Figure 19. The soft-

start function starts when the VCC voltage reaches the 67kHz

start threshold voltage of 12V and ends when the internal 16 steps

soft-start voltage reaches 1V. The internal start-up circuit 1 step=250Hz

starts charging the VCC capacitor again if the VCC volt-

age is lowered to the minimum operating voltage, 8V.

The UVLO block shuts down the output drive circuit and 63kHz

some blocks to reduce the IC operating current and the 125Hz

FAN7602 Rev. 02

internal soft-start voltage drops to zero. If the VCC volt-

age reaches the start threshold voltage, the IC starts Figure 20. Frequency Modulation

switching again and the soft-start block works as well.

During the soft-start, pulse-width modulated (PWM) com- Figure 22 shows typical voltage waveforms of the CS/FB

parator compares the CS/FB pin voltage with the soft- pin. The current sense waveform is added to the offset

start voltage. The soft-start voltage starts from 0.5V and voltage as shown in the figure. The CS/FB pin voltage is

the soft-start ends when it reaches 1V and the soft-start compared with PWM+ that is 1V - Plimit offset as shown

time is 10ms. The start-up switch is turned off when the in Figure 22. If the CS/FB voltage meets PWM+, the out-

soft-start voltage reaches 1.5V. put drive is shut off. As shown in Figure 22, if the feed-

back offset voltage is low, the switch on time is

VCC

increased. If the feedback offset voltage is high, the

12V switch on time is decreased. In this way, the duty cycle is

controlled according to the output load condition. In gen-

8V eral, the maximum output power increases as the input

Start-up voltage increases because the current slope during

Current switch on-time increases. To limit the output power of the

Soft-Start converter constantly, the power limit function is included

1.5V Voltage in the FAN7602. Sensing the converter input voltage

1V through the Latch/Plimit pin, the Plimit offset voltage is

0.5V

Soft-Start subtracted from 1V. As shown in Figure 22, the Plimit off-

t

Time (10ms) set voltage is subtracted from 1V and the switch on-time

5ms FAN7602 Rev. 02

decreases as the Plimit offset voltage increases. If the

Figure 19. Start-up Current and VCC Voltage converter input voltage increases, the switch on-time

decreases, controlling the output power constant. The

2. Oscillator Block offset voltage is proportional to the Latch/Plimit pin volt-

age and the gain is 0.16. If the Latch/Plimit voltage is 1V,

The oscillator frequency is set internally and a frequency the offset voltage is 0.16V.

modulation (FM) function reduces EMI. The average fre-

quency is 65kHz and the modulation frequency is 2kHz.

The frequency varies from 63kHz to 67kHz with 16 VCC

steps. The frequency step is 250Hz and FM frequency is

Plimit

125Hz, as shown in Figure 20. PWM Offset

Comparator

RFB

PWM+ Power IFB

Limit

Soft-Start RF

3. Current Sense and Feedback Block 3

CS/FB

Isw

The FAN7602 performs the current sensing for the cur- CF

RS

rent mode PWM and the output voltage feedback with

only one pin, pin 3. To achieve the two functions with one

FAN7602 Rev. 02

pin, an internal LEB (leading edge blanking) circuit to fil-

ter the current sense noise is not included because the Figure 21. Current Sense and Feedback Circuits

external RC filter is necessary to add the output voltage

feedback information and the current sense information.

2006 Fairchild Semiconductor Corporation www.fairchildsemi.com

FAN7602 Rev. 1.0.2 10

FAN7602 Green Current Mode PWM Controller

counting. If the OLP condition persists for 22ms, the

timer generates the OLP signal. And this protection is

1V Power Limit

reset by the UVLO. The OLP block is enabled after the

PWM+ Offset

soft-start finishes.

Clock

CS/FB FB

Offset OLP 22ms 3 CS/FB

Timer

GND 50mV

On Time Soft-Start

FAN7602 Rev. 02

(a) Low Power Limit Offset Case

1V

Figure 24. Overload Protection Circuit

Power Limit

Offset

PWM+

5.2 Line Under-Voltage Protection

CS/FB If the input voltage of the converter is lower than the min-

FB

Offset imum operating voltage, the converter input current

increases too much, causing components failure. There-

GND fore, if the input voltage is low, the converter should be

On Time

protected. In the FAN7602, the LUVP circuit senses the

(b) High Power Limit Offset Case FAN7602 Rev. 02 input voltage using the LUVP pin and, if this voltage is

Figure 22. CS/FB Pin Voltage Waveforms lower than 2V, the LUVP signal is generated. The com-

parator has 0.5V hysteresis. If the LUVP signal is gener-

ated, the output drive block is shut down, the output

4. Burst Mode Block voltage feedback loop is saturated, and the OLP works if

The FAN7602 contains the burst mode block to reduce the LUVP condition persists more than 22ms.

the power loss at a light load and no load as the

Vin

FAN7601. A hysteresis comparator senses the offset

voltage of the Burst+ for the burst mode as shown in Fig-

ure 23. The Burst+ is the sum of the CS/FB voltage and 1 LUVP

+

Plimit offset voltage. The FAN7602 enters the burst

2V/1.5V

mode when the offset voltage of the Burst+ is higher than FAN7602 Rev. 02

0.95V and exits the burst mode when the offset voltage

is lower than 0.88V. The offset voltage is sensed during

Figure 25. Line UVP Circuit

the switch off time.

O ffs e t

D e la y 5.3 Latch Protection

C irc u it B u rs t+

+ 3 C S /F B The latch protection is provided to protect the system

against abnormal conditions using the Latch/Plimit pin.

0 .9 5 V /0 .8 8 V The Latch/Plimit pin can be used for the output over-

FA N7602 R ev. 02

voltage protection and/or other protections. If the Latch/

Plimit pin voltage is made higher than 4V by an external

Figure 23. Burst Mode Block circuit, the IC is shut down. The latch protection is reset

when the VCC voltage is lower than 5V.

5. Protection Block

The FAN7602 contains several protection functions to 5.4 Over-Voltage Protection (OVP)

improve system reliability. If the VCC voltage reaches 19V, the IC shuts down and

the OVP protection is reset when the VCC voltage is

lower than 5V.

5.1 Overload Protection

The FAN7602 contains the overload protection function.

If the output load is higher than the rated output current, 6. Output Drive Block

the output voltage drops and the feedback error amplifier

is saturated. The offset of the CS/FB voltage represent- The FAN7602 contains a single totem-pole output stage

ing the feedback information is almost zero. As shown in to drive a power MOSFET. The drive output is capable of

Figure 24, the CS/FB voltage is compared with 50mV up to 450mA sourcing current and 600mA sinking cur-

reference when the internal clock signal is high and, if rent with typical rise and fall time of 45ns, 35ns respec-

the voltage is lower than 50mV, the OLP timer starts tively with a 1nF load.

2006 Fairchild Semiconductor Corporation www.fairchildsemi.com

FAN7602 Rev. 1.0.2 11

FAN7602 Green Current Mode PWM Controller

Typical application circuit

Application Output power Input voltage Output voltage

Adapter 48W Universal input 12V

(85~265VAC)

Features

Low stand-by power (<0.3W @ 265VAC)

Constant output power control

Key Design Notes

All the IC-related components should be placed close to IC, especially C107 and C110.

If R106 value is too low, there can be subharmonic oscillation.

R109 should be designed carefully to make the VCC voltage higher than 8V when the input voltage is 265VAC at no

load.

R110 should be designed carefully to make the VCC voltage lower than OVP level when the input voltage is 85VAC at

full load.

R103 should be designed to keep the MOSFET Vds voltage lower than maximum rating when the output is shorted.

1. Schematic

R206 C204

D202

D204 L201

1 T1 12

R103

C106

BD101

C201 C202

C105

D101 9

R112 R114 3

Q101 6 D102 R109 R110

R105 C222

C109

R106

C103 C104 5

ZD101

R102

R202

R201

R113

OP1

C102 4 1 R204

C110

1 8

LF1

LUVP Vstr R203 C203

3 2

R107 2 Latch/ 7

FAN7602

Plimit NC 3

R101 C107 1

3 6 IC201

CS/FB VCC R111 2

R104

C101 4 5 R205

RT101

FUSE GND Out

IC101 D103

AC INPUT

OP2 R207

4 1

3 2

R108 C108 ZD201

FAN7602 Rev. 02

Figure 26. Schematic

2006 Fairchild Semiconductor Corporation www.fairchildsemi.com

FAN7602 Rev. 1.0.2 12

FAN7602 Green Current Mode PWM Controller

2. Inductor Schematic Diagram

1 12 3mm 3mm

Np1 Ns Np2

2 9 NVcc

Np2 Shied Shield

Ns

3 5 Ns

5

Shield

Ns

NVcc Shied

Np1

6 5

FAN7602 Rev. 02 FAN7602 Rev. 02

Figure 27. Inductor Schematic Diagram

3. Winding Specification

No Pin (sf) Wire Turns Winding Method

Np1 32 0.3 2 31 Solenoid Winding

Insulation: Polyester Tape t = 0.03mm, 2 Layers

Shield 5 Copper Tape 0.9 Not Shorted

Insulation: Polyester Tape t = 0.03mm, 2 Layers

Ns 12 9 0.65 3 10 Solenoid Winding

Insulation: Polyester Tape t = 0.03mm, 2 Layers

Shield 5 Copper Tape 0.9 Not Shorted

Insulation: Polyester Tape t = 0.03mm, 2 Layers

NVcc 65 0.2 1 10 Solenoid Winding

Insulation: Polyester Tape t = 0.03mm, 2 Layers

Np2 21 0.3 2 31 Solenoid Winding

Outer Insulation: Polyester Tape t = 0.03mm, 2 Layers

4. Electrical Characteristics

Pin Specification Remarks

Inductance 1-3 607H 100kHz, 1V

Inductance 1-3 15H 9 - 12 shorted

5. Core & Bobbin

Core: EER2828

Bobbin: EER2828

Ae(mm2): 82.1

2006 Fairchild Semiconductor Corporation www.fairchildsemi.com

FAN7602 Rev. 1.0.2 13

FAN7602 Green Current Mode PWM Controller

6. Demo Circuit Part List

Part Value Note Part Value Note

Fuse Capacitor

FUSE 1A/250V C101 220nF/275V Box Capacitor

NTC C102 150nF/275V Box Capacitor

RT101 5D-9 C103, C104 102/1kV Ceramic

Resistor C105 150F/400V Electrolytic

R102, 10M 1/4W C106 103/630V Film

R112

R103 56k 1/2W C107 271 Ceramic

R104 150 1/4W C108 103 Ceramic

R105 1k 1/4W C109 22F/25V Electrolytic

R106 0.5 1/2W C110 473 Ceramic

R107 56k 1/4W C201, C202 1000F/25V Electrolytic

R108 10k 1/4W C203 102 Ceramic

R109 0 1/4W C204 102 Ceramic

R110 1k 1/4W C222 222/1kV Ceramic

R111 6k 1/4W MOSFET

R113 180k 1/4W Q101 FQPF8N60C Fairchild

R114 50k 1/4W Diode

R201 1.5k 1/4W D101, D102 UF4007 Fairchild

R202 1.2k 1/4W D103 1N5819 Fairchild

R203 20k 1/4W D202, D204 FYPF2010DN Fairchild

R204 27k 1/4W ZD101, ZD201 1N4744 Fairchild

R205 7k 1/4W BD101 KBP06 Fairchild

R206 10 1/2W TNR

R207 10k 1/4W R101 471 470V

IC Filter

IC101 FAN7602 Fairchild LF101 23mH 0.8A

IC201 KA431 Fairchild L201 10H 4.2A

OP1, OP2 H11A817B Fairchild

2006 Fairchild Semiconductor Corporation www.fairchildsemi.com

FAN7602 Rev. 1.0.2 14

FAN7602 Green Current Mode PWM Controller

7. PCB Layout

Minimize leakage

inductance

DC

Link

Minimize loop area

Pulsating high current

8 7 6 5

Vstr NC VCC OUT

FAN7602

Latch/

YWW

LUVP Plimit CS/FB GND

1 2 3 4

Separate power

and signal ground

Place these cap.

close to IC Signal level low current

FAN7602 Rev. 02

Figure 28. PCB Layout Recommendations for FAN7602

8. Performance Data

85VAC 110VAC 220VAC 265VAC

Input Power at No Load 105.4mW 119.8mW 184.7mW 205.5mW

Input Power at 0.5W Load 739.4mW 761.4mW 825.4mW 872.2mW

OLP Point 4.42A 4.66A 4.6A 4.4A

2006 Fairchild Semiconductor Corporation www.fairchildsemi.com

FAN7602 Rev. 1.0.2 15

FAN7602 Green Current Mode PWM Controller

Mechanical Dimensions

8-DIP

Dimensions are in inches (millimeters) unless otherwise noted.

Figure 29. 8-Lead Dual In-Line Package (DIP)

2006 Fairchild Semiconductor Corporation www.fairchildsemi.com

FAN7602 Rev. 1.0.2 16

FAN7602 Green Current Mode PWM Controller

Mechanical Dimensions (Continued)

8-SOP

Dimensions are in millimeters unless otherwise noted.

Figure 30. 8-Lead Small Outline Package (SOP)

2006 Fairchild Semiconductor Corporation www.fairchildsemi.com

FAN7602 Rev. 1.0.2 17

FAN7602 Green Current Mode PWM Controller

TRADEMARKS

The following are registered and unregistered trademarks Fairchild Semiconductor owns or is authorized to use and is not intended to be an

exhaustive list of all such trademarks.

ACEx GlobalOptoisolator OCXPro PSerDes TinyBuck

ActiveArray GTO OPTOLOGIC SILENT SWITCHER TinyLogic

Bottomless HiSeC OPTOPLANAR SMART START TINYOPTO

2

Build it Now I C PACMAN SPM TinyPower

CoolFET i-Lo POP Stealth TinyPWM

CROSSVOLT ImpliedDisconnect Power247 SuperFET TruTranslation

DOME IntelliMAX PowerEdge SuperSOT-3 UHC

EcoSPARK ISOPLANAR PowerSaver SuperSOT-6 UltraFET

2

E CMOS LittleFET PowerTrench SuperSOT-8 UniFET

EnSigna MICROCOUPLER QFET SyncFET VCX

FACT MicroFET QS TCM Wire

FACT Quiet Series MicroPak QT Optoelectronics TinyBoost

FAST MICROWIRE Quiet Series

FASTr MSX RapidConfigure Across the board. Around the world.

FPS MSXPro RapidConnect Programmable Active Droop

FRFET OCX ScalarPump The Power Franchise

DISCLAIMER

FAIRCHILD SEMICONDUCTOR RESERVES THE RIGHT TO MAKE CHANGES WITHOUT FURTHER NOTICE TO ANY PRODUCTS

HEREIN TO IMPROVE RELIABILITY, FUNCTION OR DESIGN. FAIRCHILD DOES NOT ASSUME ANY LIABILITY ARISING OUT OF THE

APPLICATION OR USE OF ANY PRODUCT OR CIRCUIT DESCRIBED HEREIN; NEITHER DOES IT CONVEY ANY LICENSE UNDER

ITS PATENT RIGHTS, NOR THE RIGHTS OF OTHERS. THESE SPECIFICATIONS DO NOT EXPAND THE TERMS OF FAIRCHILDS

WORLDWIDE TERMS AND CONDITIONS, SPECIFICALLY THE WARRANTY THEREIN, WHICH COVERS THESE PRODUCTS.

LIFE SUPPORT POLICY

FAIRCHILDS PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT DEVICES OR

SYSTEMS WITHOUT THE EXPRESS WRITTEN APPROVAL OF FAIRCHILD SEMICONDUCTOR CORPORATION.

As used herein:

1. Life support devices or systems are devices or systems 2. A critical component in any component of a life support,

which, (a) are intended for surgical implant into the body or device, or system whose failure to perform can be

(b) support or sustain life, and (c) whose failure to perform reasonably expected to cause the failure of the life

when properly used in accordance with instructions for use support device or system, or to affect its safety or

provided in the labeling, can be reasonably expected to effectiveness.

result in a significant injury of the user.

PRODUCT STATUS DEFINITIONS

Definition of Terms

Datasheet Identification Product Status Definition

Advance Information Formative or In This datasheet contains the design specifications for product

Design development. Specifications may change in any manner without

notice.

Preliminary First Production This datasheet contains preliminary data; supplementary data will

be published at a later date. Fairchild Semiconductor reserves the

right to make changes at any time without notice to improve design.

No Identification Needed Full Production This datasheet contains final specifications. Fairchild

Semiconductor reserves the right to make changes at any time

without notice to improve design.

Obsolete Not In Production This datasheet contains specifications on a product that has been

discontinued by Fairchild Semiconductor. The datasheet is printed

for reference information only.

Rev. I21

2006 Fairchild Semiconductor Corporation www.fairchildsemi.com

FAN7602 Rev. 1.0.2 18

You might also like

- Fan7602-U2 SMDDocument18 pagesFan7602-U2 SMDLefter TironNo ratings yet

- Fan7602b 92356Document18 pagesFan7602b 92356asep gunawanNo ratings yet

- FAN7602 Datasheet PDFDocument17 pagesFAN7602 Datasheet PDFSergio Daniel BarretoNo ratings yet

- FAN7602C Green Current Mode PWM Controller: Features DescriptionDocument19 pagesFAN7602C Green Current Mode PWM Controller: Features DescriptionAmjad ZaidNo ratings yet

- Data SheetDocument19 pagesData Sheetwowon junaNo ratings yet

- Fan6754a 76898Document15 pagesFan6754a 76898Brian BarreraNo ratings yet

- Fan6755W / Fan6755Uw Mwsaver PWM Controller: Features DescriptionDocument18 pagesFan6755W / Fan6755Uw Mwsaver PWM Controller: Features DescriptionRober PasqualeNo ratings yet

- FAN6756Document17 pagesFAN6756José A.No ratings yet

- Green Mode PWM Controller Reduces Standby PowerDocument5 pagesGreen Mode PWM Controller Reduces Standby PowerCarlos Marinho SilvaNo ratings yet

- FAN6754 Highly Integrated Green-Mode PWM Controller: Features DescriptionDocument14 pagesFAN6754 Highly Integrated Green-Mode PWM Controller: Features DescriptionHector VasquezNo ratings yet

- FAN6754WA Highly Integrated Green-Mode PWM Controller: Brownout and V Adjustment by HV PinDocument15 pagesFAN6754WA Highly Integrated Green-Mode PWM Controller: Brownout and V Adjustment by HV Pinedgarmrtinez_07No ratings yet

- Design Guideline To Replace FAN6753 With FAN6755: Table 1. Comparison of FAN6753 and FAN6755Document9 pagesDesign Guideline To Replace FAN6753 With FAN6755: Table 1. Comparison of FAN6753 and FAN6755Ántico le RoixNo ratings yet

- DM311Document16 pagesDM311Hernan Ortiz EnamoradoNo ratings yet

- Fan6755W / Fan6755Uw Mwsaver PWM Controller: Features DescriptionDocument17 pagesFan6755W / Fan6755Uw Mwsaver PWM Controller: Features DescriptionJorge MateusNo ratings yet

- 5V/12V Synchronous-Rectified Buck Controller With Reference InputDocument19 pages5V/12V Synchronous-Rectified Buck Controller With Reference InputIgor LabutinNo ratings yet

- Fairchild - Semiconductor FAN73611MX DatasheetDocument14 pagesFairchild - Semiconductor FAN73611MX DatasheetDeddy WilopoNo ratings yet

- Features: TPIC74100-Q1 Buck/Boost Switch-Mode RegulatorDocument30 pagesFeatures: TPIC74100-Q1 Buck/Boost Switch-Mode RegulatorSyah NormanNo ratings yet

- FAN7390 High-Current, High & Low-Side, Gate-Drive IC: Features DescriptionDocument14 pagesFAN7390 High-Current, High & Low-Side, Gate-Drive IC: Features DescriptionjoelpalzaNo ratings yet

- Features Description: Ltc3415 7A, Polyphase Synchronous Step-Down RegulatorDocument28 pagesFeatures Description: Ltc3415 7A, Polyphase Synchronous Step-Down RegulatorAmbarish RameshNo ratings yet

- Viper12Adip Viper12As: Low Power Off Line Smps Primary SwitcherDocument15 pagesViper12Adip Viper12As: Low Power Off Line Smps Primary SwitcherMakhou SoyoNo ratings yet

- Viper20A-E: General FeaturesDocument34 pagesViper20A-E: General Featuresmauricio zamoraNo ratings yet

- Viper12Adip Viper12As: Low Power Off Line Smps Primary SwitcherDocument16 pagesViper12Adip Viper12As: Low Power Off Line Smps Primary Switchermohammed el erianNo ratings yet

- 524945Document16 pages524945Sher BahadarNo ratings yet

- FSQ100 Green Mode Fairchild Power Switch (FPS™) : Features DescriptionDocument13 pagesFSQ100 Green Mode Fairchild Power Switch (FPS™) : Features Descriptionايهاب فوزيNo ratings yet

- FAN7382 Half-Bridge Gate Driver: Features DescriptionDocument14 pagesFAN7382 Half-Bridge Gate Driver: Features DescriptionEriflonaNo ratings yet

- Low Power PWM Controller For Off-Line Adapter Ap3710Document16 pagesLow Power PWM Controller For Off-Line Adapter Ap3710Abdulraouf DefnanyNo ratings yet

- FAN6755WDocument17 pagesFAN6755WAndres AlegriaNo ratings yet

- FS7M0680, FS7M0880: Fairchild Power Switch (FPS)Document18 pagesFS7M0680, FS7M0880: Fairchild Power Switch (FPS)Candelaria CortesNo ratings yet

- VIPer20/SP/DIP and VIPer20A/ASP/ADIP SMPS ICs technical overviewDocument22 pagesVIPer20/SP/DIP and VIPer20A/ASP/ADIP SMPS ICs technical overviewpromatis5746No ratings yet

- AiT Semiconductor AP8022 AC-DC PWM Controller GuideDocument10 pagesAiT Semiconductor AP8022 AC-DC PWM Controller Guidesumit sahaNo ratings yet

- High Voltage Green-Mode PWM Controller With Over Temperature ProtectionDocument19 pagesHigh Voltage Green-Mode PWM Controller With Over Temperature ProtectionHugo BarrosoNo ratings yet

- SG6846C 118502Document16 pagesSG6846C 118502Mike GhanemNo ratings yet

- FSDM0565R: Green Mode Fairchild Power Switch (FPS)Document20 pagesFSDM0565R: Green Mode Fairchild Power Switch (FPS)Najam Ul HassanNo ratings yet

- FAN7529 (IC601) - Datasheet IIDocument20 pagesFAN7529 (IC601) - Datasheet IIJose BenavidesNo ratings yet

- Is Now Part ofDocument10 pagesIs Now Part ofmadumadawa rajapakshaNo ratings yet

- STR-A6252M: Switching RegulatorsDocument13 pagesSTR-A6252M: Switching RegulatorsAntonioPeriniNo ratings yet

- LD7578J LeadtrendDocument19 pagesLD7578J Leadtrendnagahara.eduardoNo ratings yet

- Green-Mode PWM Controller with High Voltage Startup Circuit DatasheetDocument17 pagesGreen-Mode PWM Controller with High Voltage Startup Circuit Datasheetserrano.flia.coNo ratings yet

- LD5760-DS-02 LeadtrendDocument20 pagesLD5760-DS-02 Leadtrendvahid hoseinpourNo ratings yet

- Viper 12ADocument21 pagesViper 12Aahmed hussainNo ratings yet

- FSL206MRDocument16 pagesFSL206MRnightreader99No ratings yet

- AP8025Document12 pagesAP8025SamerNo ratings yet

- Features Description: Ltc3565 1.25A, 4Mhz, Synchronous Step-Down DC/DC ConverterDocument22 pagesFeatures Description: Ltc3565 1.25A, 4Mhz, Synchronous Step-Down DC/DC Converterferney_09No ratings yet

- Datasheeta6259h PDFDocument13 pagesDatasheeta6259h PDFEsteban MaryoryNo ratings yet

- DS 2857FG 02 PDFDocument12 pagesDS 2857FG 02 PDFJohan GuanchezNo ratings yet

- AP8012ADocument13 pagesAP8012ASamerNo ratings yet

- Stra6252m SKDocument13 pagesStra6252m SKLeonildo CostaNo ratings yet

- Buck/Boost Switch-Mode Regulator: FeaturesDocument30 pagesBuck/Boost Switch-Mode Regulator: FeaturesErasmo Franco SNo ratings yet

- Viper53Dip Viper53Sp: Off Line Primary SwitchDocument24 pagesViper53Dip Viper53Sp: Off Line Primary Switchhisfer143No ratings yet

- Critical Conduction Mode PFC Controller: Features DescriptionDocument20 pagesCritical Conduction Mode PFC Controller: Features DescriptiondavidNo ratings yet

- Viper 22aDocument8 pagesViper 22aLuis Carlos Bonilla AldanaNo ratings yet

- FAN6862HRDocument16 pagesFAN6862HRproctepNo ratings yet

- Fan6604 523271Document16 pagesFan6604 523271arf faNo ratings yet

- 4647 FBDocument34 pages4647 FBrehmanb192No ratings yet

- Str-A6251 Str-A6252 PDFDocument7 pagesStr-A6251 Str-A6252 PDFrafalero1No ratings yet

- Viper22a PDFDocument20 pagesViper22a PDFMosqueda Notarion Phil JamesNo ratings yet

- Viper20A-E Viper20Asp-E - Viper20Adip-E: General FeaturesDocument33 pagesViper20A-E Viper20Asp-E - Viper20Adip-E: General FeaturesAdriánNo ratings yet

- Ap3106 Ap3106mtr-G1Document12 pagesAp3106 Ap3106mtr-G1J Fernando GarciaNo ratings yet

- Tea1507 PDFDocument20 pagesTea1507 PDFmiltoncg100% (1)

- Amplificador Ucd Hasta 1250w RmsDocument12 pagesAmplificador Ucd Hasta 1250w RmsAnonymous vl1q0B0% (1)

- BIT3251 Low Cost PWM Controller Data SheetDocument7 pagesBIT3251 Low Cost PWM Controller Data Sheet81968No ratings yet

- Aiwa Cx-jpk33 SMDocument78 pagesAiwa Cx-jpk33 SMSergio Daniel BarretoNo ratings yet

- 4zg 1z3 4Document30 pages4zg 1z3 4Sergio Daniel BarretoNo ratings yet

- Schematic Diagram - 1 (Main 1 / 2: Amp)Document7 pagesSchematic Diagram - 1 (Main 1 / 2: Amp)api-3703813No ratings yet

- Aiwa Mec - AZG-6Document8 pagesAiwa Mec - AZG-6Sergio Daniel BarretoNo ratings yet

- mp123 Fonte de Alimentação PDFDocument1 pagemp123 Fonte de Alimentação PDFSergio Daniel BarretoNo ratings yet

- Amplificador Ucd Hasta 1250w RmsDocument12 pagesAmplificador Ucd Hasta 1250w RmsAnonymous vl1q0B0% (1)

- Aiwa Cx-jpk33 SMDocument78 pagesAiwa Cx-jpk33 SMSergio Daniel BarretoNo ratings yet

- 4ZG 1Z3 1Z4 PDFDocument30 pages4ZG 1Z3 1Z4 PDFSergio Daniel BarretoNo ratings yet

- 4ZG 1Z3 1Z4 PDFDocument30 pages4ZG 1Z3 1Z4 PDFSergio Daniel BarretoNo ratings yet

- Aiwa NSX Sz50Document25 pagesAiwa NSX Sz50Sergio Daniel BarretoNo ratings yet

- 6ZG 1Document23 pages6ZG 1Sergio Daniel BarretoNo ratings yet

- Schematic Diagram - 1 (Main 1 / 2: Amp)Document7 pagesSchematic Diagram - 1 (Main 1 / 2: Amp)api-3703813No ratings yet

- TDA7388Document10 pagesTDA7388Ζαχος ΤσελιοςNo ratings yet

- Panasonic Technical Guide 2013 PDFDocument109 pagesPanasonic Technical Guide 2013 PDFSergio Daniel BarretoNo ratings yet

- Datasheet TDA8358J PDFDocument20 pagesDatasheet TDA8358J PDFJose BenavidesNo ratings yet

- Samsung 2012 LCD PDP TV Training CourseDocument238 pagesSamsung 2012 LCD PDP TV Training CourseSergio Daniel Barreto100% (2)

- Data Sheet of Ic Uc 3844 Part1Document12 pagesData Sheet of Ic Uc 3844 Part1Santosh KumarNo ratings yet

- UAA2016 DatasheetDocument8 pagesUAA2016 DatasheetSergio Daniel BarretoNo ratings yet

- Microondas Daewoo Kog-261m 262m 281m 282mDocument57 pagesMicroondas Daewoo Kog-261m 262m 281m 282mSergio Daniel BarretoNo ratings yet

- UC3842 PDFDocument3 pagesUC3842 PDFSergio Daniel BarretoNo ratings yet

- CountingDocument20 pagesCountingSergio Daniel BarretoNo ratings yet

- UPC PC1366 - Datasheet PDFDocument5 pagesUPC PC1366 - Datasheet PDFSergio Daniel BarretoNo ratings yet

- UC3848Document9 pagesUC3848Sergio Daniel BarretoNo ratings yet

- Uc3843an PDFDocument16 pagesUc3843an PDFSergio Daniel BarretoNo ratings yet

- UC3844A DatasheetDocument8 pagesUC3844A DatasheetSergio Daniel BarretoNo ratings yet

- Fan 7601Document12 pagesFan 7601Walter AlvarengaNo ratings yet

- UTCTA7613AP Datasheet PDFDocument5 pagesUTCTA7613AP Datasheet PDFSergio Daniel BarretoNo ratings yet

- Seven Band Graphic Equalizer Data Sheet: Description FeaturesDocument4 pagesSeven Band Graphic Equalizer Data Sheet: Description FeaturesAlexander MontellanoNo ratings yet

- LA4440 Audio Amplifier CircuitDocument7 pagesLA4440 Audio Amplifier Circuitshu2uNo ratings yet

- 2N4416-Hifrequency Amp JFETDocument2 pages2N4416-Hifrequency Amp JFETsandhantusharNo ratings yet

- rr220401 Communication TheoryDocument8 pagesrr220401 Communication TheorySRINIVASA RAO GANTANo ratings yet

- Study on Latchup Path between HV-LDMOS and LV-CMOS in a 0.16-μm 30-V/1.8-V BCD TechnologyDocument6 pagesStudy on Latchup Path between HV-LDMOS and LV-CMOS in a 0.16-μm 30-V/1.8-V BCD TechnologyKEVIN CHENNo ratings yet

- Integrados 6 TerminalesDocument9 pagesIntegrados 6 TerminalesTitán SotoNo ratings yet

- Clock Gating MethodologyDocument71 pagesClock Gating MethodologyGirish BabuNo ratings yet

- EE212-Tutorial - 2-Power CalculationDocument10 pagesEE212-Tutorial - 2-Power CalculationAbood HamedNo ratings yet

- Vlsi Module-5Document56 pagesVlsi Module-5Phanindra ReddyNo ratings yet

- Build a Decade Counter with IC 7490Document5 pagesBuild a Decade Counter with IC 749003 - Mayuresh GaikwadNo ratings yet

- II. Bias Circuit II. Bias Circuit: OutlineDocument15 pagesII. Bias Circuit II. Bias Circuit: OutlineRaghu McNo ratings yet

- All The Way With QRPDocument3 pagesAll The Way With QRPBenjamin DoverNo ratings yet

- Characterization and Applications of Operational Amplifiers (Op-AmpsDocument10 pagesCharacterization and Applications of Operational Amplifiers (Op-Ampsknighthood4allNo ratings yet

- A Dutch Journey in JLH-land: A Tribute To The JLH 10-15 Watt Class-A AmplifierDocument4 pagesA Dutch Journey in JLH-land: A Tribute To The JLH 10-15 Watt Class-A AmplifierDaniel ScardiniNo ratings yet

- DDF Week 05Document6 pagesDDF Week 05Anusha ChidagniNo ratings yet

- VX-410/-420 Series: Service Manual UHF FM TransceiverDocument45 pagesVX-410/-420 Series: Service Manual UHF FM TransceiverIng Marco Antonio Hernandez LimaNo ratings yet

- PWM Circuit for Velleman G106 EnclosureDocument4 pagesPWM Circuit for Velleman G106 EnclosureMARCELO BetucciNo ratings yet

- EE316 ReceiverDocument1 pageEE316 ReceiverŞamil ŞirinNo ratings yet

- 74HC HCT4051Document27 pages74HC HCT4051CurariuDanielNo ratings yet

- PLL Applications (19.3.2020)Document12 pagesPLL Applications (19.3.2020)Konda Sumanayana100% (1)

- Supervisor FPGA: A/D Converter Can DRVDocument1 pageSupervisor FPGA: A/D Converter Can DRVsaikumarNo ratings yet

- OscillatorsDocument21 pagesOscillatorsemancavNo ratings yet

- Digital Logic Design MCQs With Answers (AB Sir)Document11 pagesDigital Logic Design MCQs With Answers (AB Sir)Amitava BiswasNo ratings yet

- Experiment No. 1: Aim: Study of Tanner Tools THEORY: Tanner ToolsDocument24 pagesExperiment No. 1: Aim: Study of Tanner Tools THEORY: Tanner ToolsVarun GargNo ratings yet

- Transistor Audio Amplifier CircuitDocument2 pagesTransistor Audio Amplifier CircuitMidhun U KNo ratings yet

- Vidyabhushan Mohan MSDocument69 pagesVidyabhushan Mohan MSAbdulrahman sahliNo ratings yet

- Digital Techniques: Understanding Electronic Instrument Systems and Numbering SystemsDocument337 pagesDigital Techniques: Understanding Electronic Instrument Systems and Numbering Systemsaaron89No ratings yet

- E7 Data and Results PUT RELAXATION OSCILLATORDocument3 pagesE7 Data and Results PUT RELAXATION OSCILLATORAaron Cyril NuisaNo ratings yet

- LOGIC DESIGN SUBJECT (40Document2 pagesLOGIC DESIGN SUBJECT (40Matthew BattleNo ratings yet

- Module 5 - BJT BiasingDocument13 pagesModule 5 - BJT BiasingKenNo ratings yet