Professional Documents

Culture Documents

Lifting Lug Calculation

Uploaded by

rustamriyadiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Lifting Lug Calculation

Uploaded by

rustamriyadiCopyright:

Available Formats

Page 4

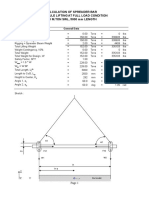

STANDARD LIFTING LUG DESIGN

20 TONS CAPACITY

Generals:

total weight (Empty Skid + lifted equipment) = 20000 kgs = 44,092 lbs

number of lifting points = 1

Safety Factor, FS = 2.0

Min. sling angle, q = 60 degrees

Max. load per lifting lug = 40,000 kgs = 88,184 lbs

Lug Dimensions:

Height of hole centreline, H = 120 mm = 4.72 inch

Width of Lug, W L = 300 mm = 11.81 inch

Radius of Lug, R = 150 mm = 5.91 inch

Diameter of Hole, DH = 60 mm = 2.36 inch

Thickness of Lug, tL = 28 mm = 1.10 inch

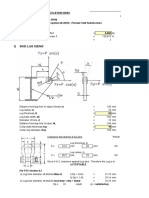

Allowable Stresses:

Lug Material A 36 Fy = 36,000 psi

Allowable Tension Stress, 0.6 x Fy = 1,519 Kg/cm2 = 21,600 psi

Allowable Shear Stress, 0.4 x Fy = 1,012 Kg/cm2 = 14,400 psi

DH/2R = 0.20

Stress-Concentration Factor (near hole), K = 2.5

(for flat plate with centrally located circular hole in tension based on DH/2R value)

Tension Stresses in the Lug:

Weight in each Lug, W = 40,000 kgs = 88,160 lbs

Cable Tension at Lug, F = 46,188 kgs = 101,798 lbs

Inertia Moment of Lug, IL = 6,300 cm4 = 151.36 in4

Stress at Lug to Beam Joint = 1,136 Kg/cm2 = 16,153 psi

ST = F.cos (q). H.(W L/2)/IL +

Safe Ratio = 74.78%

F.sin(q)/(W L.tL)

Stress at near the hole = 1,488 Kg/cm2 = 21,160 psi

ST = K .F. sin (q) / [(2.R -DH).tL] Safe Ratio = 97.96%

Shear Stresses in the Lug:

Stress at Lug to Beam Joint = 275 Kg/cm2 = 3,909 psi

SS = F.cos(q) / (tL.W L) Safe Ratio = 27.15%

Stress at near the hole = 344 Kg/cm2 = 4,887 psi

SS = F.cos(q) / [(2.R - DH).tL] Safe Ratio = 33.93%

Page 5

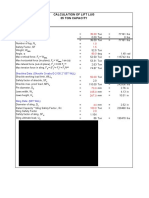

Stresses in Weld:

The calculation used is conservative as it only includes top fillet welds (actual stresses are lower)

Leg size of fillet weld, LW = 25.0 mm = 0.98 in

use 45 degree fillet weld

Throat size of fillet feld, tW = 17.68 mm = 0.70 in

Length of weld, Ww1 = 2.W L + 2.tL 656.0 mm = 25.83 in

Length of weld including welding in web of beam, W 1,743.4 mm = 68.64 in

W w2 = W w1 + W L + 2.Hbeam

Section Modulus of weld lines, SW = 530,330 mm3 = 32.36 in3

SW= tw.W L2/3

Efficiency of weld, n = 100%

Allowable Load on weld 675 Kg/cm2 = 9,600 psi

Tension Stress at the weld = 652 Kg/cm2 = 9,276 psi

ST=[F.cos(q).H/SW+ F.sin(q)/

Safe Ratio = 96.62%

(W w2.tw)] / n

Shear Stress at the Weld = 30.86 Kg/cm2 = 2,832 psi

ST=[ F.cos(q)/ (W w1.tw)]/ n Safe Ratio = 29.50%

You might also like

- Strength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresFrom EverandStrength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresRating: 4 out of 5 stars4/5 (1)

- Master of Lifting CalculationDocument7 pagesMaster of Lifting CalculationSudar MyshaNo ratings yet

- Spreader BarDocument5 pagesSpreader Barmramico100% (1)

- Spreader 150T - PL100 A36Document8 pagesSpreader 150T - PL100 A36rustamriyadiNo ratings yet

- Spreader Bar CalculationDocument2 pagesSpreader Bar Calculationmahhor82_63564383870% (10)

- Lifting CalculationDocument1 pageLifting CalculationJaycee Bareng Pagador100% (1)

- Monorail DesignDocument24 pagesMonorail DesignBolarinwadeNo ratings yet

- Calculation Lifting LugDocument4 pagesCalculation Lifting Lugelang purbayaNo ratings yet

- Load Calculation For StaadDocument6 pagesLoad Calculation For StaadDipeshNo ratings yet

- Padeye CalculationDocument6 pagesPadeye CalculationKarun DasNo ratings yet

- ASME SpreaderBar DWGDocument1 pageASME SpreaderBar DWGInspetor SoldagemNo ratings yet

- Design Calculation LiftingDocument19 pagesDesign Calculation LiftingAbu Al Sayyid100% (1)

- Lifting Beam DesignDocument4 pagesLifting Beam DesignAnonymous XAqiBJ100% (4)

- ASME SpreaderBar CalcsDocument5 pagesASME SpreaderBar Calcsganesh100% (1)

- Lifting Beam DesignDocument4 pagesLifting Beam DesignX100% (1)

- Lifting Lug CalculationDocument3 pagesLifting Lug Calculationdhirendarji83% (6)

- Spreader Beam: ASME BTH-1: InputsDocument17 pagesSpreader Beam: ASME BTH-1: InputsGokul AmarnathNo ratings yet

- Spreader Calculation (ISMC-200)Document4 pagesSpreader Calculation (ISMC-200)mechmohan26No ratings yet

- Lifting LugDocument39 pagesLifting LugSasikumar JothiNo ratings yet

- Lifting Lug DesignDocument4 pagesLifting Lug DesignRohith V VNo ratings yet

- Lifting Lug Calc-Single CPI - RFDocument7 pagesLifting Lug Calc-Single CPI - RFRustam RiyadiNo ratings yet

- Pad Eye Design CalculationDocument7 pagesPad Eye Design CalculationLưu Xuân0% (1)

- Spreader Beam BLOCK EDocument26 pagesSpreader Beam BLOCK ESteve MoonNo ratings yet

- Design of Base Plate & Anchor Bolts For Service Water Tank (Narimanam Site)Document3 pagesDesign of Base Plate & Anchor Bolts For Service Water Tank (Narimanam Site)Yatendra TyagiNo ratings yet

- Lifting Lug Calculation-1Document1 pageLifting Lug Calculation-1dtgpand100% (4)

- Spreader Beam Calculation ReportDocument15 pagesSpreader Beam Calculation ReportGurhan Atalay100% (1)

- Vitec Equipments PVT LTD Filename: Spreader Beam CalculationDocument48 pagesVitec Equipments PVT LTD Filename: Spreader Beam CalculationDarshan PanchalNo ratings yet

- Spreader Bar Calculation PDFDocument2 pagesSpreader Bar Calculation PDFFernando Humberto100% (2)

- Lifting Beam Deign Staad 82187560 Design Calc 10T Spreader BeamDocument20 pagesLifting Beam Deign Staad 82187560 Design Calc 10T Spreader BeamJurie_sk360888% (8)

- Spreader BeamDocument2 pagesSpreader Beamwisnu_bayusakti75% (4)

- Lifting Lug AnalysisDocument3 pagesLifting Lug Analysisராபர்ட் ஆன்றோ ரெனி67% (3)

- Lifting Lug CalculationsDocument6 pagesLifting Lug CalculationsYash RamiNo ratings yet

- Spreader Bar For LiftingDocument1 pageSpreader Bar For LiftingTran ThoNo ratings yet

- Sample Section Modulas CalculationDocument18 pagesSample Section Modulas CalculationShamik ChowdhuryNo ratings yet

- 44.lifting Lug With Collar CalculationDocument44 pages44.lifting Lug With Collar CalculationAnonymous AyDvqg100% (1)

- Spreader Beam CalculationDocument2 pagesSpreader Beam Calculationhombre.muerto595977% (13)

- Lift Analysis: R L T LDocument27 pagesLift Analysis: R L T Lgarateta100% (5)

- Lifting and Tailing StackDocument42 pagesLifting and Tailing StackSudar MyshaNo ratings yet

- Gantry CraneDocument31 pagesGantry CraneWaheed AhmadNo ratings yet

- Lifting Lug 75 TDocument2 pagesLifting Lug 75 Trustamriyadi0% (1)

- Lifting 2Document2 pagesLifting 2sbituban talaveraNo ratings yet

- Lifting Lug HorizontalDocument5 pagesLifting Lug HorizontalRidho ZiskaNo ratings yet

- Jn1399 - 71t Lifting LugDocument5 pagesJn1399 - 71t Lifting LugRiyan EsapermanaNo ratings yet

- Anchor BTD DefgDocument5 pagesAnchor BTD DefgAKSHAY BHATKARNo ratings yet

- Hat PurlinDocument3 pagesHat PurlinAniket DubeNo ratings yet

- Master Bolt CalculationDocument2 pagesMaster Bolt CalculationSudar MyshaNo ratings yet

- Beam Design 2 TypeDocument3 pagesBeam Design 2 TypeRidho ZiskaNo ratings yet

- Horizontal Lifting LugDocument1 pageHorizontal Lifting LugTushar MangratiNo ratings yet

- Lifting Lug For Vessel calculation-FInalDocument17 pagesLifting Lug For Vessel calculation-FInalSiva baalan100% (1)

- Anchor Bolts DesignDocument6 pagesAnchor Bolts DesignAKSHAY BHATKARNo ratings yet

- Machine FoundationDocument4 pagesMachine FoundationGovendan GopalakrishnanNo ratings yet

- WHP-East Piatu-Roark Calc & Stiffener-Rev0Document18 pagesWHP-East Piatu-Roark Calc & Stiffener-Rev0namasral100% (4)

- Purlin DesignDocument2 pagesPurlin DesignParam SinghNo ratings yet

- Saddle CalcDocument26 pagesSaddle CalcVamsi S100% (2)

- Design of Purlins: Section 1: Properties of SectionDocument3 pagesDesign of Purlins: Section 1: Properties of SectionajNo ratings yet

- Toaz - Info Lifting Beam Design PRDocument4 pagesToaz - Info Lifting Beam Design PRHari Kiran100% (1)

- SAS FoundationDocument18 pagesSAS FoundationGooddayBybsNo ratings yet

- Cal. Stanchion Pipe 3 In. SCH80 - Lifting Lug 2Document5 pagesCal. Stanchion Pipe 3 In. SCH80 - Lifting Lug 2Anisa Rifqi0% (1)

- Purlin Fixing Bolt DesignDocument4 pagesPurlin Fixing Bolt DesignKaran PrabhakarNo ratings yet

- Bolt TorqueDocument3 pagesBolt TorqueHeri KurniawanNo ratings yet

- Hook Pallet Capacity CalculationDocument2 pagesHook Pallet Capacity CalculationrustamriyadiNo ratings yet

- Bentley Limcon v3.63Document4 pagesBentley Limcon v3.63rustamriyadiNo ratings yet

- Calculation of Lifting (Horizontal Position) Piperack Module 14A 24tons Total WeightDocument14 pagesCalculation of Lifting (Horizontal Position) Piperack Module 14A 24tons Total WeightrustamriyadiNo ratings yet

- Davit CalcDocument4 pagesDavit CalcrustamriyadiNo ratings yet

- Lifting Calculation Pipe-Pipe Jn680 Turret Access Structure, Bluewater 110 Ton WeightDocument10 pagesLifting Calculation Pipe-Pipe Jn680 Turret Access Structure, Bluewater 110 Ton WeightrustamriyadiNo ratings yet

- Flat Head Calculation (Based On Ug 34)Document2 pagesFlat Head Calculation (Based On Ug 34)rustamriyadiNo ratings yet

- Rectangular Tank Calc - STDDocument24 pagesRectangular Tank Calc - STDrustamriyadiNo ratings yet

- SPMT BrochureDocument15 pagesSPMT BrochureAnonymous qT66pyKNo ratings yet

- Lifting Lug STD Design 5tDocument3 pagesLifting Lug STD Design 5trustamriyadi50% (2)

- Shape 2000Document217 pagesShape 2000rustamriyadiNo ratings yet

- Mech-HT 13.0 L05 SteadyStateDocument9 pagesMech-HT 13.0 L05 SteadyStaterustamriyadiNo ratings yet

- Beam DesignDocument6 pagesBeam DesignrustamriyadiNo ratings yet

- Tutorial Manual Safi PDFDocument53 pagesTutorial Manual Safi PDFrustamriyadiNo ratings yet

- Mech-Intro 13.0 WS07.1 SStherm PDFDocument14 pagesMech-Intro 13.0 WS07.1 SStherm PDFrustamriyadiNo ratings yet

- Weld KcalculationDocument1 pageWeld KcalculationrustamriyadiNo ratings yet

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- AnsysDocument26 pagesAnsysrustamriyadiNo ratings yet

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- LDS Conference Report 1930 Semi AnnualDocument148 pagesLDS Conference Report 1930 Semi AnnualrjjburrowsNo ratings yet

- 2nd Exam 201460 UpdatedDocument12 pages2nd Exam 201460 UpdatedAlbert LuchyniNo ratings yet

- MATH 7S eIIaDocument8 pagesMATH 7S eIIaELLA MAE DUBLASNo ratings yet

- Project Dayan PrathaDocument29 pagesProject Dayan PrathaSHREYA KUMARINo ratings yet

- Ch3 Review QuestionsDocument15 pagesCh3 Review Questionsave estillerNo ratings yet

- Elements of Visual Design in The Landscape - 26.11.22Document15 pagesElements of Visual Design in The Landscape - 26.11.22Delnard OnchwatiNo ratings yet

- Sta 305Document156 pagesSta 305mumbi makangaNo ratings yet

- Personal Development: Quarter 2 - Module 2: Identifying Ways To Become Responsible in A RelationshipDocument21 pagesPersonal Development: Quarter 2 - Module 2: Identifying Ways To Become Responsible in A RelationshipTabada Nicky100% (2)

- A Management and Leadership TheoriesDocument43 pagesA Management and Leadership TheoriesKrezielDulosEscobarNo ratings yet

- Medical Surgical Nursing Nclex Questions 5Document18 pagesMedical Surgical Nursing Nclex Questions 5dee_day_8No ratings yet

- Imam Zainul Abideen (RA) 'S Service To The Poor and DestituteDocument3 pagesImam Zainul Abideen (RA) 'S Service To The Poor and DestituteShoyab11No ratings yet

- 01 History of Grammatical StudyDocument9 pages01 History of Grammatical StudyRomanNo ratings yet

- Womack - Labor History, Industrial Work, Economics, Sociology and Strategic Position PDFDocument237 pagesWomack - Labor History, Industrial Work, Economics, Sociology and Strategic Position PDFhmaravilloNo ratings yet

- Thailand Day 2Document51 pagesThailand Day 2Edsel BuletinNo ratings yet

- Eurokids Parent Manual (ECity) - PDF-EJ and ESDocument18 pagesEurokids Parent Manual (ECity) - PDF-EJ and ESsabarin_72100% (2)

- TreeAgePro 2013 ManualDocument588 pagesTreeAgePro 2013 ManualChristian CifuentesNo ratings yet

- Hanssen, Eirik.Document17 pagesHanssen, Eirik.crazijoeNo ratings yet

- ( (LEAD - FIRSTNAME) ) 'S Spouse Visa PackageDocument14 pages( (LEAD - FIRSTNAME) ) 'S Spouse Visa PackageDamon Culbert0% (1)

- Di Franco Amended Factum 2021-05-03Document30 pagesDi Franco Amended Factum 2021-05-03Michael BueckertNo ratings yet

- English 7 Compare Contrast The People Could Fly Harriet TubmanDocument3 pagesEnglish 7 Compare Contrast The People Could Fly Harriet Tubmanapi-508729334No ratings yet

- Norman 2017Document7 pagesNorman 2017Lee HaeunNo ratings yet

- FA2Document6 pagesFA2yuktiNo ratings yet

- PctcostepoDocument4 pagesPctcostepoRyan Frikkin MurgaNo ratings yet

- 10 Chapter 3Document29 pages10 Chapter 3felefel100% (1)

- Disorders of NewbornDocument4 pagesDisorders of NewbornBRUELIN MELSHIA MNo ratings yet

- Darshan Institute of Engineering & Technology Unit: 7Document9 pagesDarshan Institute of Engineering & Technology Unit: 7AarshenaNo ratings yet

- Eapp Module 1Document6 pagesEapp Module 1Benson CornejaNo ratings yet

- Adventures in Parenting RevDocument67 pagesAdventures in Parenting Revmakj_828049No ratings yet

- The First Step Analysis: 1 Some Important DefinitionsDocument4 pagesThe First Step Analysis: 1 Some Important DefinitionsAdriana Neumann de OliveiraNo ratings yet

- Edward William Lane's Lexicon - Volume 7 - Page 186 To 277Document92 pagesEdward William Lane's Lexicon - Volume 7 - Page 186 To 277Serge BièvreNo ratings yet

- The Cyanide Canary: A True Story of InjusticeFrom EverandThe Cyanide Canary: A True Story of InjusticeRating: 4 out of 5 stars4/5 (52)

- Building Physics -- Heat, Air and Moisture: Fundamentals and Engineering Methods with Examples and ExercisesFrom EverandBuilding Physics -- Heat, Air and Moisture: Fundamentals and Engineering Methods with Examples and ExercisesNo ratings yet

- A Place of My Own: The Architecture of DaydreamsFrom EverandA Place of My Own: The Architecture of DaydreamsRating: 4 out of 5 stars4/5 (242)

- Art of Commenting: How to Influence Environmental Decisionmaking With Effective Comments, The, 2d EditionFrom EverandArt of Commenting: How to Influence Environmental Decisionmaking With Effective Comments, The, 2d EditionRating: 3 out of 5 stars3/5 (1)

- Pressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedFrom EverandPressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedRating: 5 out of 5 stars5/5 (1)

- The Aqua Group Guide to Procurement, Tendering and Contract AdministrationFrom EverandThe Aqua Group Guide to Procurement, Tendering and Contract AdministrationMark HackettRating: 4 out of 5 stars4/5 (1)

- How to Estimate with RSMeans Data: Basic Skills for Building ConstructionFrom EverandHow to Estimate with RSMeans Data: Basic Skills for Building ConstructionRating: 4.5 out of 5 stars4.5/5 (2)

- The Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialFrom EverandThe Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialNo ratings yet

- Building Construction Technology: A Useful Guide - Part 1From EverandBuilding Construction Technology: A Useful Guide - Part 1Rating: 4 out of 5 stars4/5 (3)

- Principles of Welding: Processes, Physics, Chemistry, and MetallurgyFrom EverandPrinciples of Welding: Processes, Physics, Chemistry, and MetallurgyRating: 4 out of 5 stars4/5 (1)

- Estimating Construction Profitably: Developing a System for Residential EstimatingFrom EverandEstimating Construction Profitably: Developing a System for Residential EstimatingNo ratings yet

- The Complete Guide to Building Your Own Home and Saving Thousands on Your New HouseFrom EverandThe Complete Guide to Building Your Own Home and Saving Thousands on Your New HouseRating: 5 out of 5 stars5/5 (3)

- Waste: One Woman’s Fight Against America’s Dirty SecretFrom EverandWaste: One Woman’s Fight Against America’s Dirty SecretRating: 5 out of 5 stars5/5 (1)

- Civil Engineer's Handbook of Professional PracticeFrom EverandCivil Engineer's Handbook of Professional PracticeRating: 4.5 out of 5 stars4.5/5 (2)

- The Complete Guide to Building With Rocks & Stone: Stonework Projects and Techniques Explained SimplyFrom EverandThe Complete Guide to Building With Rocks & Stone: Stonework Projects and Techniques Explained SimplyRating: 4 out of 5 stars4/5 (1)

- Field Guide for Construction Management: Management by Walking AroundFrom EverandField Guide for Construction Management: Management by Walking AroundRating: 4.5 out of 5 stars4.5/5 (3)

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsFrom EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsRating: 3.5 out of 5 stars3.5/5 (3)

- Woodworking: 25 Unique Woodworking Projects For Making Your Own Wood Furniture and Modern Kitchen CabinetsFrom EverandWoodworking: 25 Unique Woodworking Projects For Making Your Own Wood Furniture and Modern Kitchen CabinetsRating: 1 out of 5 stars1/5 (4)

- The Everything Woodworking Book: A Beginner's Guide To Creating Great Projects From Start To FinishFrom EverandThe Everything Woodworking Book: A Beginner's Guide To Creating Great Projects From Start To FinishRating: 4 out of 5 stars4/5 (3)

- History of Smart Textiles: A Comprehensive Guide To E-TextilesFrom EverandHistory of Smart Textiles: A Comprehensive Guide To E-TextilesNo ratings yet

- Post Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&AFrom EverandPost Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&ANo ratings yet

- Exposure: Poisoned Water, Corporate Greed, and One Lawyer's Twenty-Year Battle Against DuPontFrom EverandExposure: Poisoned Water, Corporate Greed, and One Lawyer's Twenty-Year Battle Against DuPontRating: 4.5 out of 5 stars4.5/5 (18)