Professional Documents

Culture Documents

Modulus of Subgrade Reaction - Which One To Use

Uploaded by

dubai_santanuOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Modulus of Subgrade Reaction - Which One To Use

Uploaded by

dubai_santanuCopyright:

Available Formats

Structural Services, Inc.

Modulus of Subgrade Reaction - Which One Should be Used?

By Wayne W. Walker, P.E. , F.ACI and Jerry A. Holland, P.E., F.ACI

The modulus of subgrade reaction is an often misunderstood and misused concept for the thickness design of

slabs-on-ground. Terzaghi in 1955 (Ref. 1, P. 300) attributed this confusion to the initial work by Hayashi in

1921 (Ref. 2), who stated that the subgrade reaction should be determined by a load test but failed to mention

that the tested results depend on the size of the loaded area. Additionally, Terzaghi noted that the well-known

book by Hetenyi Beams on Elastic Foundation (Ref. 3), published in 1946, did not contain any statement

regarding the adjustment factors necessary to the subgrade reaction value for the different loading conditions.

As stated by Terzaghi, This condition led to the erroneous conception, widespread among engineers, that the

numerical value of the coefficient of subgrade reaction depends exclusively on the nature of the subgrade. In

other words, it became customary to assume that this coefficient has a definite value for any given subgrade.

Terzaghi had hoped his paper in 1955 would finally clear up this confusion and provide the necessary factors

for making the appropriate adjustments to the subgrade reaction load test value. It has been over 60 years

since his paper has been published, and we still often see engineers using inappropriate values for the

subgrade reaction. Even with the many well-known text books that discuss the issue of subgrade reaction

adjustment factors (Ref. 4, P. 286 & 489; Ref. 5, P. 516-517; Ref. 6, P. 501-503; and Ref. 7, P. 416-417), this

issue is still frequently not being properly addressed. We hope, by providing detailed examples and specific

subgrade reaction values for different soil types for industrial slab loadings, that this approach will provide

clarity to this issue.

What is the modulus of subgrade reaction?

To add to the confusion, especially for the novice slab designer, this value has been called by many different

names in various publications such as modulus of subgrade reaction, subgrade reaction, subgrade modulus,

coefficient of subgrade reaction, Winkler foundation (E. Winkler first proposed the subgrade reaction in 1867

[Ref. 16]) , Winkler subgrade, K value, etc.. In our paper, we will use either subgrade reaction or the

shortened K for our discussions.

The basic equation is:

which has units of pounds/in2/in or commonly used units of pounds/in3 or pci. There is an ASTM D1196 (Ref.

8) for the plate load test, which typically uses a 30 in. diameter plate as shown in Fig. 1.

Structural Services, Inc. Page 1 of 11

In our paper, we will refer to Kp as the subgrade reaction based on the 30 in. diameter plate load test.

The subgrade reaction is not a fundamental soil property. It is a lump constant of which the subgrade reaction

from the plate load test should be adjusted because the subgrade reaction is a function of:

1. Soil elastic properties, both the initial response and the long-term response due to soil consolidation

from the sustained loading.

2. Loading intensity that will influence the long-term consolidation settlement.

3. Amount of surface area loaded and load shape over which the load is applied. Wider and larger area

loadings will involve consolidation of the deeper soil layers.

4. Stiffness of the slab, which will influence the distribution of the soil bearing pressure.

Additionally, using the subgrade reaction (Winkler foundation) has other analytical limitations. The

displacement at one location does not influence the settlements at other locations, which is not correct as

shown in Fig. 2.

Structural Services, Inc. Page 2 of 11

Using the subgrade reaction soil springs (Winkler foundation) has been referred to as an uncoupled

foundation because the springs do not interact with each other. Whereas using the solid finite element

foundation, the soil settlements are coupled. In other words, the soil settlements at the loaded areas also

cause other unloaded areas to settle as well. To improve the accuracy of the subgrade reaction adjustment

factors, we have equated the slab stresses for a slab on a solid finite element foundation (coupled model) with

a slab using an equivalent subgrade reaction (uncoupled model), as shown in Fig. 5 and values in Table 1.

This equalization will adjust the subgrade reaction value for wide area loading effects, consolidation of the

deeper layers of the soil, and help minimize the uncoupled analytical limitation of the subgrade reaction

foundation system.

Who makes the adjustments to the subgrade reaction values?

Along with the widespread misconception that the subgrade reaction is a single value, this issue is further

complicated because it is not clear in the industry who makes the adjustments to the subgrade reaction for the

different load cases. The structural engineer often sees a single value in the geotechnical report that typically

does not have any qualifiers regarding how the stated subgrade reactions is to be used and assumes (or more

likely is uninformed on the limitations on using the subgrade reaction foundation) the geotechnical engineer

has made the adjustments to the provided subgrade reaction. The geotechnical engineer typically provides in

the geotechnical report the value to use for wheel loadings but often does not provide any qualifiers or limits on

how the subgrade reaction is to be used. The geotechnical engineer assumes (or more likely did not consider

the limits of the provided subgrade reaction) the structural engineer will make the adjustments based on the

different loading cases. As you can see from the scenario above, there is much confusion regarding who is

responsible for making the adjustments to the subgrade reaction for the different load cases.

In our opinion, the responsibility is shared jointly between the structural engineer and the geotechnical

engineer for determining the proper subgrade reaction to be used for the different load cases. The structural

engineer has the responsibility to:

1. Provide the load intensity on the slab and the type of load (such as lift-truck or other vehicle loadings,

long-term uniform storage or rack loads, line or wall loads, etc.)

2. Provide the amount and size of slab surface areas that will be loaded and the length of time the load

will be applied. It is important that the geotechnical engineer know if the slab will have a wide area

loading. Wide area loadings will cause deeper soil consolidation settlements (assuming long-term

settlements are significant for the project soil types) if the loads are sustained for a long period of time.

3. Provide the owners and/or equipments sensitivity to slab cracking, soil settlements (initial and long-

term consolidation), slab sloping due to soil settlements, etc.

The geotechnical engineer has the responsibility to:

1. Use the information provided by the structural engineer and the site soil properties to provide

recommendations for subgrade reactions to be used for the different load cases.

2. Recommend any testing that needs to be performed to support the provided subgrade reactions values.

Typically for industrial slabs, the geotechnical engineer should provide two subgrade reactions. The first

subgrade reaction is for short-term loadings to be used for loads such as lift-truck wheel loads. These loads

only affect the first few feet of the soil and have little, if any, long-term consolidation settlements. The second

subgrade reaction is for long-term loadings to be used for loads such as wide area rack or uniform storage

loads. These loads affect many feet of soil below the slab and have both initial and possible long-term soil

consolidation settlements (depending on the soil type). These subgrade reaction values should be stated on

the structural project drawing general notes design criteria. ACI 360R (Ref. 9, P. 67) has provided an example

design criteria showing how these subgrade reaction values should be shown on the drawings.

Structural Services, Inc. Page 3 of 11

Subgrade reaction values for short-term loads over small areas, such as wheel loads

For short duration loadings over small areas, such as wheel loads from lift trucks, where only a few feet of soil

is affected below the slab and where long-term soil consolidation is not a concern, the subgrade reaction value

from the plate load test should be used. Because these types of loads only affect the first few feet of soil, the

subgrade reaction can be improved or increased with a granular aggregate or cement-treated (or other

stabilizing materials) base material (Refs. 10 and 11). Tables and charts for these increased subgrade

reaction values using base materials can be found in a number of publications (Ref. 12, P. 6; Ref. 13, P. 6;

Ref. 14, P. 3).

Subgrade reaction values for wide area long-term sustained loads, such as uniform loading or rack

loads

Determining the appropriate subgrade reaction values for wide area sustained loadings is more complicated

than for short-term loadings. These loads involve deeper layers of soil that may or may not have significant

long-term consolidation settlements, depending on the soil type. Additionally, as discussed by Terzaghi

(Ref. 1, P. 306), the soil settlements used to adjust the plate load subgrade reaction are the settlements above

the nearly uniform pressure elevation, as shown in Fig. 3.

For soil settlements occurring below the nearly uniform pressure line, the entire slab moves down causing little

influence on the differential deflections of the slab, and therefore the slab moments are not significantly

affected. Some papers and text books have provided linear relationships of subgrade reaction with the bearing

pressure used for foundation design, but these relationships would not be entirely correct because these

relationships include the soil settlements below the nearly uniform pressure line. Additionally, using a thin

layer of granular aggregate or cement treated base material to improve or increase the subgrade reaction for

wheel loadings will only have a minimal effect for wide area sustained loadings because the deeper layers of

soil are affected more.

Structural Services, Inc. Page 4 of 11

To provide reasonable approximations of subgrade reactions for wide area sustained loadings, we have used

two computer models as shown in Fig. 5. Fortunately, the slab stress analysis is not sensitive to the value of

the subgrade reaction (large changes to the subgrade reaction only causes small changes to the slabs

stresses); therefore, a reasonably approximate subgrade reaction is all that is needed for slab designs. The

first computer model uses solid finite elements, which by the nature of the analysis will only produce stresses

in the slab for settlements above the nearly uniform pressure elevation. The second computer model will use

an equivalent subgrade reaction that will produce the same maximum stresses in the slab. By equating these

two computer models, the equivalent subgrade reaction will have the reduction due to the wide area sustained

loading.

The following is an example to illustrate our approach for determining the subgrade reaction for wide area

sustained loadings. Fig. 4 shows the typical rack configuration of 4 ft. by 8 ft. with a 1 ft. flue space and an 8 ft.

wide aisle used for our analysis. Aisle spacing can vary depending on the type of storage racking systems

used. A storage racking system using a conventional lift truck commonly has aisle widths of 10 to 11 ft. A

storage racking system that uses a narrow aisle racking system typically has aisle widths of 5 to 6 ft. As

discussed above, only a reasonably approximate subgrade reaction is needed for slab design; therefore, we

used an 8 ft. aisle width to approximate the two different storage racking system aisle widths.

Structural Services, Inc. Page 5 of 11

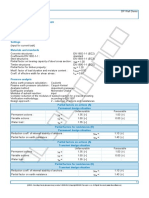

Fig. 5 shows the two computer models side-by-side. We used a 6 thick concrete slab supporting a rack post

load of 7,000 pounds per post, which is a common long-term sustained loading for a distribution warehouse

facility. Table 1 shows the soils elastic moduli Es and Poissons ratios used for the different soil types.

These soil values have a wide variation and are a composite from Ref.s 5, 6 and 17. Fortunately, the way the

analysis is performed by equating the two different models, only reasonable approximations of these soil

values are needed.

For our example, we used a medium stiff clay with the soil modulus and Poissons ratio values shown in

Table 1. To approximate the long-term soil consolidation for the clay soils, we used of the soil modulus. For

our example, that would provide a value of 2,400 psi ( of 4,800 psi). Using of the soil modulus would

approximately estimate the soil consolidation settlement to be nearly equal to the initial elastic settlement. For

sandy soils, typically there are only initial elastic settlements and little long-term consolidation settlements.

Therefore, long-term soil consolidation settlements were not considered for the sandy soils (the full elastic soil

modulus was used in the analysis for sandy soils). These soil assumptions should be reviewed by the project

geotechnical engineer and modified if needed for the site specific soil conditions.

By running several computer iterations, the equivalent subgrade reaction that produces the same maximum

slab stress as the solid element model can be determined. For our example, the equivalent modulus of

subgrade reaction was determined to be 80 pci. The 80 pci would have both the reduction of wide area

loading and the reduction for long-term soil consolidation. The 80 psi would be 35% (80 pci/230 pci X 100%)

of the plate subgrade reaction value. This reduction is in the range of other published reductions (Ref. 9,

P. 13). The slab stresses are shown in Fig. 6.

Structural Services, Inc. Page 6 of 11

As discussed above, the nearly uniform soil pressure location for this model is approximately 14 ft. below the

slab as shown in Fig. 7. In other words, the settlements in the 14 ft. of soil below the slab are the only ones

that significantly affect the slabs stresses.

Structural Services, Inc. Page 7 of 11

Fig. 8 shows the computer models side-by-side slab deflections. The computer model using the solid finite

elements will provide the total settlements for the loading, which has a maximum deflection of 0.152 in. The

computer model using the subgrade reaction only provides the differential deflection from the slabs top surface

and has a maximum deflection of 0.033 in. Notice that the differential deflection of 0.031 in. and 0.024 in are

nearly the same for both models, which correspondingly provides the same slab maximum stresses for both

computer models. The differential deflections will not be exactly the same because the springs in the subgrade

reaction model are uncoupled.

Structural Services, Inc. Page 8 of 11

To determine the plate subgrade reaction Kp as shown in Fig. 1 above, the equation (Ref. 15, P. 408) for a

concentrated load applied to a circular plate on a semi-infinite solid can be used.

1

.1

2

Where:

P = Load applied to the plate

= Deflection of the circular plate

R = Radius of the plate

Es = Soils elastic modulus

= Poissons ratio

Substituting the following two equations EQ. 2 and EQ. 3 into EQ. 1:

. 2

. 3

Where:

Kp = Plate subgrade reaction

= Average soil pressure below the plate

= Deflection of the circular plate

And writing the equation in terms of Kp provides:

2

. 4

1

Structural Services, Inc. Page 9 of 11

It can be clearly seen from EQ. 4 that the subgrade reaction is not a defined value but depends on both the soil

type and area loaded. This equation was used to determine plate subgrade modulus values in Table 1.

These values are shown for information only

and should not be used for slab designs with

these types of soils. The Kws values should

Table 1 Subgrade Reaction Design Values be used for these types of soils.

Ratio Ratio

Es Kp Kw Kw Kws Kws

Soil Type (psi) (PCI) (PCI) Kp (PCI Kp

Clay Soft 2,000 0.45 110 70 0.64 50 0.45

Medium 4,800 0.35 230 130 0.57 80 0.35

Hard 10,600 0.20 470 260 0.55 140 0.30

Sandy 15,600 0.25 710 390 0.55 200 0.28

Sand Silty 2,000 0.30 90 70 0.78 --- ---

Loose 2,500 0.30 120 80 0.67 --- ---

Dense 9,500 0.35 460 240 0.52 --- ---

Plate subgrade reaction Subgrade reaction design Subgrade reaction design

design values used for short- values reduced for wide area values reduced for wide

term loadings over small storage loadings, such as area storage loadings,

areas, such as vehicle wheel uniform or rack loads. such as uniform or rack

loads. Typically, sandy soils have loads, and reduced due to

mostly initial elastic long-term soil

settlements and little long- consolidation settlements

term soil consolidation. typical of clay types of

Therefore, these values are soils.

not reduced for long-term soil

consolidation.

Table 1 - Notes:

1. Kp is the plate subgrade reaction value.

2. Kw is the subgrade reaction reduced for wide area loading.

3. Kws is the subgrade reaction reduced for wide area loading and long-term soil settlement

consolidation.

Conclusion

It is our hope that this paper will provide the much needed clarity regarding what value of subgrade reaction

should be used for the different loading cases, how the value should be determined, and the joint

responsibilities of the structural and geotechnical engineers for determining the proper subgrade value to be

used.

As discussed above, the proper subgrade reaction is a function of several variables, and the values in Table 1

are only valid for the stated assumptions. These values may not be appropriate for mats, large/heavy

equipment foundations, tank foundations, continuous beams, etc.

Structural Services, Inc. Page 10 of 11

References:

1. Terzaghi, K., 1955, "Evaluation of Coefficient of Subgrade Reaction," Geotechnique, vol. 5, no. 4 Dec.,

pp. 297-326.

2. Hayashi, K., 1921, Theory of Beams on Elastic Foundation, Springer-Verlag (in German).

3. Hetenyi, M., 1946, Beams on Elastic Foundation: Theory with Applications in the Fields of Civil and

Mechanical Engineering , Univ. of Michigan Press, Ann Arbor, Michigan.

4. Peck, Ralph B., and Terzaghi, Karl, 1967, Soil Mechanics in Engineering Practice, John Wiley & Sons, Inc.

New York.

5. Winterkorn, Hans F., and Fang, Hsai- Yang, 1975, Foundation Engineering Handbook, Van Nostrand

Reinhold Company.

6. Bowles, Joseph E., 1996, Foundation Analysis and Design, 5th ed., McGraw- Hill Co.

7. Sowers, George B., and Sowers, George F., 1970, Introductory Soil Mechanics and Foundations, 3rd ed.,

Macmillan Publishing Co.

8. ASTM D 1196 12 Standard Test Method for Nonrepetitive Static Plate Load Tests of Soils and Flexible

Pavement Components, for Use in Evaluation and Design of Airport and Highway Pavements

9. American Concrete Institute (ACI) 360R-10 "Guide to Design of Slabs-on-Ground", Farmington Hills, MI.

10. Childs, L. D., 1967, Cement-Treated Subbases for Concrete Pavements, Highway Research Record 189,

Highway Research Board, pages 19 to 43; also PCA Development Department Bulletin DX125.

11. Burmister, D. M., 1943, The Theory of Stresses and Displacements in Layered Systems and Applications

to Design of Airport Runways, " Highway Research Board Proceedings, Vol. 23, pages 126 to 148.

12. American Concrete Institute (ACI) 330R-08 "Guide for the Design and Construction of Concrete Parking

Lots, Farmington Hills, MI.

13. Portland Cement Association, 1984, Thickness Design for Concrete Highway and Street Pavements,

Engineering Bulletin No. EB109.01P, Portland Cement Association, Skokie, IL.

14. Packard, R. G., 1976, Slab Thickness Design for Industrial Concrete Floors on Grade, ISI95.01D,

Portland Cement Association, Skokie, IL.

15. Timoshenko, S. P., Goodier, J. N., 1970, Theory of Elasticity, 3rd ed., McGraw- Hill Co.

16. Winkler, E. ,1867, "Die Lehre von der Elastizitat and Festigkeit (on elasticity and fixity)", Prague, Verlag,

p. 182.

17. EM 1110-1-1904, 1990, U.S. Army Corps of Engineers Engineer Manual, Settlement Analysis, 30SEP90.

Wayne W. Walker, P.E., F.ACI, is a Principal and the Director of

Engineering Services at Structural Services, Inc. He is on several

ACI committees and has been a speaker at ACI seminars. He has

also published other papers and has developed many computer

programs to analyze and design slabs and other structures.

Jerry A. Holland, P.E., F.ACI, is a Principal, Vice-President and the

Director of Design Services for Structural Services, Inc. He is on

several ACI committees, teaches seminars for ACI and the World of

Concrete. He has also published other papers and has more than 45

years of experience worldwide with the design, construction, and

troubleshooting of concrete slabs other structures.

Download paper from SSIs Web site: http://www.ssiteam.com/publications

Structural Services, Inc. Page 11 of 11 08APR16

You might also like

- How To Calculate Bearing Capacity of Soil From Plate Load TestDocument5 pagesHow To Calculate Bearing Capacity of Soil From Plate Load TestDEBOPRASAD BISWASNo ratings yet

- Terzaghi and PeckDocument7 pagesTerzaghi and PeckRaja Hendra Solihin RambeNo ratings yet

- Finite Element Analysis of Soil Bearing Capacity Using PlaxisDocument5 pagesFinite Element Analysis of Soil Bearing Capacity Using PlaxisRehan HakroNo ratings yet

- Lateral Load PileDocument21 pagesLateral Load PileCarlos FilipusNo ratings yet

- Unit2 - Plate Load TestDocument30 pagesUnit2 - Plate Load TestSajja Satish Assistant Professor, CE, VRSECNo ratings yet

- Design of PileDocument12 pagesDesign of PileAniket DNo ratings yet

- Geotech Report For Water PipelineDocument106 pagesGeotech Report For Water PipelineZohair AtaullahNo ratings yet

- Terzaghi's Bearing Capacity TheoryDocument9 pagesTerzaghi's Bearing Capacity TheoryBe civil Sixth batchNo ratings yet

- Heat of Hydration StressesDocument7 pagesHeat of Hydration StressesAnkur BarsainyaNo ratings yet

- Pile Testing For Driven or Jack-In Pile PDFDocument25 pagesPile Testing For Driven or Jack-In Pile PDFBMZNo ratings yet

- 1 PDFDocument22 pages1 PDFNeeraj Sharma0% (1)

- Evaluation of Modulus of Elasticity and Modulus of Subgrade Reaction of Soils Using CBR TestDocument7 pagesEvaluation of Modulus of Elasticity and Modulus of Subgrade Reaction of Soils Using CBR TestMyzael ValdiviaNo ratings yet

- Modulus of Subgrade ReactionDocument4 pagesModulus of Subgrade ReactionDennis SagaoNo ratings yet

- 400kv Sanand (Charal) - SBC ReportDocument65 pages400kv Sanand (Charal) - SBC Report400KVNo ratings yet

- Report Schmidt HammerDocument3 pagesReport Schmidt HammerIhsan FakhryNo ratings yet

- SoilTest ProjectDocument115 pagesSoilTest ProjectMd Shahimul HaqueNo ratings yet

- SM Triaxial Compression Test 1978 PDFDocument5 pagesSM Triaxial Compression Test 1978 PDFNicolás Silva0% (1)

- Individual Footing With MomentsDocument2 pagesIndividual Footing With MomentseramitdhanukaNo ratings yet

- Bearing Capacity Improvement of Soil Using Bamboo MicropilesDocument14 pagesBearing Capacity Improvement of Soil Using Bamboo MicropilesIsrael AdegboyegaNo ratings yet

- Triaxial Test, UCS and Vane Shear TestDocument40 pagesTriaxial Test, UCS and Vane Shear TestMGKalyanshettiNo ratings yet

- Keynote D.V. KarandikarDocument47 pagesKeynote D.V. KarandikarlingamkumarNo ratings yet

- Ultimate Bearing Capacity of A SINGLE STONE COLUMNDocument11 pagesUltimate Bearing Capacity of A SINGLE STONE COLUMNAnirudh Rathore100% (1)

- Plaxis ValidationDocument5 pagesPlaxis Validationعصام السامرائيNo ratings yet

- Calculation of SBC of A Square Footing With Vertical Loading in Cohesionless Soil, Using SPT "N" ValuesDocument1 pageCalculation of SBC of A Square Footing With Vertical Loading in Cohesionless Soil, Using SPT "N" ValuesNicholas ThompsonNo ratings yet

- CE-452 CBR TestDocument15 pagesCE-452 CBR TestNandon RoyNo ratings yet

- Dynamic Bearing CapacityDocument38 pagesDynamic Bearing CapacityEdgar De LeonNo ratings yet

- 6 Defects in Brickwork Due To Poor WorkmanshipDocument7 pages6 Defects in Brickwork Due To Poor WorkmanshipMichael Matshona100% (1)

- Axial Capacity of Pile FoundationDocument32 pagesAxial Capacity of Pile FoundationChowdhury Priodeep100% (1)

- Vibroreplacement PDFDocument9 pagesVibroreplacement PDFthadikkaranNo ratings yet

- Optimal Deign of Pile FoundationDocument13 pagesOptimal Deign of Pile FoundationJustin Johnson100% (1)

- Permeability Test-Double Packer Test - Template01Document1 pagePermeability Test-Double Packer Test - Template01Mohammed AliNo ratings yet

- Semiemperical Estimate of Pile Capacity Conforming Aashto Lrfd-2007Document1 pageSemiemperical Estimate of Pile Capacity Conforming Aashto Lrfd-2007civixxNo ratings yet

- Maccaferri Flexible Pavement Design SpreadsheetDocument10 pagesMaccaferri Flexible Pavement Design SpreadsheetAlbaro Andres TorricoNo ratings yet

- Ev2 Test PDFDocument1 pageEv2 Test PDFBinod SharmaNo ratings yet

- Pile BOQDocument5 pagesPile BOQanon_388492125No ratings yet

- KDS 11 70 20 Rockfall and Debris Prevention Facility Design StandardsDocument15 pagesKDS 11 70 20 Rockfall and Debris Prevention Facility Design StandardsSH Big ShimNo ratings yet

- Plate Load Test Is.1888.1982Document16 pagesPlate Load Test Is.1888.1982cmthebossNo ratings yet

- Annexure A Nimli Hydrological SurveyDocument23 pagesAnnexure A Nimli Hydrological SurveyUmesh MishraNo ratings yet

- DCP Manual K100 Models OCT2007Document36 pagesDCP Manual K100 Models OCT2007arypauloNo ratings yet

- Soil Test Report KhagariaDocument28 pagesSoil Test Report KhagariaSajan SinghNo ratings yet

- SBC, BH-01Document15 pagesSBC, BH-01Kundan SinghNo ratings yet

- Evaluation of Modulus of Elasticity and Modulus of Subgrade Reaction of Soils Using CBR TestDocument7 pagesEvaluation of Modulus of Elasticity and Modulus of Subgrade Reaction of Soils Using CBR TestJorge Vanegas100% (1)

- Chew (2018) Pile Group EfficiencyDocument4 pagesChew (2018) Pile Group Efficiencynebot100% (1)

- 1 RMR PDFDocument14 pages1 RMR PDFchakrapanithotaNo ratings yet

- Bearing Capacity of RockDocument19 pagesBearing Capacity of RockAhmad PooladiNo ratings yet

- SPREW Part 3 of 3 PDFDocument122 pagesSPREW Part 3 of 3 PDFhz135874No ratings yet

- Soil MechanicsDocument3 pagesSoil MechanicsPradum Kumar GuptaNo ratings yet

- Unit7 SKP PDFDocument36 pagesUnit7 SKP PDFAGT 6BNo ratings yet

- Appc Soil Properties 718Document5 pagesAppc Soil Properties 718pinkuru100% (1)

- ModulusofSubgradeReaction PDFDocument11 pagesModulusofSubgradeReaction PDFHAMIDNo ratings yet

- Effect of Soil Nonlinearity On AnalysisDocument9 pagesEffect of Soil Nonlinearity On AnalysisArjun PaudelNo ratings yet

- 78-84 H.G. Poulos - Piled Raft Foundations For Tall BuildingsDocument7 pages78-84 H.G. Poulos - Piled Raft Foundations For Tall Buildingsajaymr100% (1)

- The Design of High-Rise Building FoundationsDocument12 pagesThe Design of High-Rise Building Foundationswilliam_cheangNo ratings yet

- Design of Piled Raft Foundations For Tall BuildingsDocument7 pagesDesign of Piled Raft Foundations For Tall BuildingsnhulugallaNo ratings yet

- Effect of Pile Diameter On Subgrade Modulus - 3 PagesDocument3 pagesEffect of Pile Diameter On Subgrade Modulus - 3 PagesScooby DooNo ratings yet

- Konstanta Pegas Dan Interaksi Struktur TanahDocument10 pagesKonstanta Pegas Dan Interaksi Struktur Tanahlimara65No ratings yet

- Ultimate Lateral Capacity of Single Piles & Lpiles PDFDocument34 pagesUltimate Lateral Capacity of Single Piles & Lpiles PDFNicole Carrillo100% (4)

- ReSlope Supplemental NotesDocument28 pagesReSlope Supplemental Notessimone stanoNo ratings yet

- Correlation Between Soil Bearing Capacity and Modulus of Subgrade ReactionDocument12 pagesCorrelation Between Soil Bearing Capacity and Modulus of Subgrade ReactionAnonymous q0irDXlWAmNo ratings yet

- Power DistributionDocument57 pagesPower Distributiondubai_santanu100% (1)

- Candidate Basic Information SheetDocument6 pagesCandidate Basic Information Sheetdubai_santanuNo ratings yet

- Twy-M5 M4Document3 pagesTwy-M5 M4dubai_santanuNo ratings yet

- Appendix D - Packer Test Data Analysis 101029Document82 pagesAppendix D - Packer Test Data Analysis 101029dubai_santanu100% (1)

- Standard Specs For ConstructionDocument542 pagesStandard Specs For Constructiondubai_santanuNo ratings yet

- Proposal Form Andaman SantanuDocument4 pagesProposal Form Andaman Santanudubai_santanuNo ratings yet

- Selection - Design and Operation of Rotodynamic Pumps - 2004Document277 pagesSelection - Design and Operation of Rotodynamic Pumps - 2004leadmarineNo ratings yet

- Castellated BeamsDocument16 pagesCastellated Beamssohcahtoa100% (3)

- Pokharel Ku 0099D 11271 DATA 1Document349 pagesPokharel Ku 0099D 11271 DATA 1Vetriselvan ArumugamNo ratings yet

- Outcome 2 T 1Document14 pagesOutcome 2 T 1R ASTUSNo ratings yet

- Sheeting Structure Verification Input DataDocument35 pagesSheeting Structure Verification Input DataanonimusazNo ratings yet

- ANSYS Tutorials - SubstructuringDocument12 pagesANSYS Tutorials - Substructuringgopal06No ratings yet

- SAHC Report1 SA2Document12 pagesSAHC Report1 SA2SoniaGPNo ratings yet

- Title:-The Suitability of Coal Bottom Ash in Hot Mix AsphaltDocument20 pagesTitle:-The Suitability of Coal Bottom Ash in Hot Mix AsphaltDuncanNo ratings yet

- Optimization of The Geometrical Parameters of Bonded Composite Wrap For Repairing Cracked PipelinesDocument12 pagesOptimization of The Geometrical Parameters of Bonded Composite Wrap For Repairing Cracked PipelinesjeovanNo ratings yet

- DEsign RSIDocument61 pagesDEsign RSIRajeshNo ratings yet

- SANS 1418-1 2009 Aerial Bundled Conductor Systems - Part 1 CoresDocument13 pagesSANS 1418-1 2009 Aerial Bundled Conductor Systems - Part 1 CoresHichèm BerjèbNo ratings yet

- ASTM C 1528 (Specification Dimension Stones)Document17 pagesASTM C 1528 (Specification Dimension Stones)Ali ArsalanNo ratings yet

- Leaf Spring PDFDocument7 pagesLeaf Spring PDFEngSafwanQadousNo ratings yet

- Dcs 1Document130 pagesDcs 1Mukesh Kumar SamotaNo ratings yet

- Journal of Constructional Steel ResearchDocument13 pagesJournal of Constructional Steel ResearchWilliam PolNo ratings yet

- Experiment # 2: Modulus of ElasticityDocument6 pagesExperiment # 2: Modulus of ElasticityUsamaNo ratings yet

- Comparison Study of Common Brick With S+WPSA Brick: June 2012Document7 pagesComparison Study of Common Brick With S+WPSA Brick: June 2012Hadi Iz'aanNo ratings yet

- Astm d747 Pdqv6897Document5 pagesAstm d747 Pdqv6897Nayth Andres GalazNo ratings yet

- DME QB All UnitsDocument11 pagesDME QB All UnitsPrakash ThangavelNo ratings yet

- CGJ 1987 24 (1) 114-125 Rowe and ArmitageDocument12 pagesCGJ 1987 24 (1) 114-125 Rowe and ArmitageCoolioDragoonNo ratings yet

- Integrated Approach To Evaluate Unconventional and Tight Reservoirs in Abu DhabiDocument19 pagesIntegrated Approach To Evaluate Unconventional and Tight Reservoirs in Abu DhabiNarendra AhiraoNo ratings yet

- Standard Techniques of Stress Corrosion Cracking Testing - A ReviewDocument15 pagesStandard Techniques of Stress Corrosion Cracking Testing - A ReviewMarly Blanco VeraNo ratings yet

- Anisotropic Damage Model For Woven Fabric Composites During Tension-Tension FatigueDocument5 pagesAnisotropic Damage Model For Woven Fabric Composites During Tension-Tension FatigueFederico LamonNo ratings yet

- Astm D7205D7205M 06Document13 pagesAstm D7205D7205M 06Besian SinaniNo ratings yet

- SHAH ALAM - Corrected: Fakulti Kejuruteraan Awam Universiti Teknologi Mara Laboratory Manual # 1Document4 pagesSHAH ALAM - Corrected: Fakulti Kejuruteraan Awam Universiti Teknologi Mara Laboratory Manual # 1Ainur NasuhaNo ratings yet

- Activity 2Document2 pagesActivity 2ChristianNo ratings yet

- Defects As A Root Cause of Fatigue Failure of Metallic Components. II No..Document12 pagesDefects As A Root Cause of Fatigue Failure of Metallic Components. II No..mirosekNo ratings yet

- Activity6 2c More Engineering ProblemsDocument7 pagesActivity6 2c More Engineering ProblemsChristianNo ratings yet

- Masterflow 980 TdsDocument5 pagesMasterflow 980 Tdsrobin rezkNo ratings yet

- CSA Lab Manual IV YEAR 2015 2016 1Document95 pagesCSA Lab Manual IV YEAR 2015 2016 1Marc MathieuNo ratings yet

- Hero Found: The Greatest POW Escape of the Vietnam WarFrom EverandHero Found: The Greatest POW Escape of the Vietnam WarRating: 4 out of 5 stars4/5 (19)

- Dirt to Soil: One Family’s Journey into Regenerative AgricultureFrom EverandDirt to Soil: One Family’s Journey into Regenerative AgricultureRating: 5 out of 5 stars5/5 (125)

- The End of Craving: Recovering the Lost Wisdom of Eating WellFrom EverandThe End of Craving: Recovering the Lost Wisdom of Eating WellRating: 4.5 out of 5 stars4.5/5 (82)

- Sully: The Untold Story Behind the Miracle on the HudsonFrom EverandSully: The Untold Story Behind the Miracle on the HudsonRating: 4 out of 5 stars4/5 (103)

- The Fabric of Civilization: How Textiles Made the WorldFrom EverandThe Fabric of Civilization: How Textiles Made the WorldRating: 4.5 out of 5 stars4.5/5 (58)

- The Beekeeper's Lament: How One Man and Half a Billion Honey Bees Help Feed AmericaFrom EverandThe Beekeeper's Lament: How One Man and Half a Billion Honey Bees Help Feed AmericaNo ratings yet

- The Future of Geography: How the Competition in Space Will Change Our WorldFrom EverandThe Future of Geography: How the Competition in Space Will Change Our WorldRating: 4 out of 5 stars4/5 (6)

- Mini Farming: Self-Sufficiency on 1/4 AcreFrom EverandMini Farming: Self-Sufficiency on 1/4 AcreRating: 4 out of 5 stars4/5 (76)

- Permaculture for the Rest of Us: Abundant Living on Less than an AcreFrom EverandPermaculture for the Rest of Us: Abundant Living on Less than an AcreRating: 4.5 out of 5 stars4.5/5 (33)

- When the Heavens Went on Sale: The Misfits and Geniuses Racing to Put Space Within ReachFrom EverandWhen the Heavens Went on Sale: The Misfits and Geniuses Racing to Put Space Within ReachRating: 3.5 out of 5 stars3.5/5 (6)

- Four Battlegrounds: Power in the Age of Artificial IntelligenceFrom EverandFour Battlegrounds: Power in the Age of Artificial IntelligenceRating: 5 out of 5 stars5/5 (5)

- The Intel Trinity: How Robert Noyce, Gordon Moore, and Andy Grove Built the World's Most Important CompanyFrom EverandThe Intel Trinity: How Robert Noyce, Gordon Moore, and Andy Grove Built the World's Most Important CompanyNo ratings yet

- Pale Blue Dot: A Vision of the Human Future in SpaceFrom EverandPale Blue Dot: A Vision of the Human Future in SpaceRating: 4.5 out of 5 stars4.5/5 (588)

- The Technology Trap: Capital, Labor, and Power in the Age of AutomationFrom EverandThe Technology Trap: Capital, Labor, and Power in the Age of AutomationRating: 4.5 out of 5 stars4.5/5 (46)

- Faster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestFrom EverandFaster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestRating: 4 out of 5 stars4/5 (28)

- Transformed: Moving to the Product Operating ModelFrom EverandTransformed: Moving to the Product Operating ModelRating: 4 out of 5 stars4/5 (1)

- Restoration Agriculture: Real-World Permaculture for FarmersFrom EverandRestoration Agriculture: Real-World Permaculture for FarmersRating: 4.5 out of 5 stars4.5/5 (86)

- The Knowledge: How to Rebuild Our World from ScratchFrom EverandThe Knowledge: How to Rebuild Our World from ScratchRating: 3.5 out of 5 stars3.5/5 (133)

- How to Build a Car: The Autobiography of the World’s Greatest Formula 1 DesignerFrom EverandHow to Build a Car: The Autobiography of the World’s Greatest Formula 1 DesignerRating: 4.5 out of 5 stars4.5/5 (54)

- ChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindFrom EverandChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindNo ratings yet

- The Assassination Complex: Inside the Government's Secret Drone Warfare ProgramFrom EverandThe Assassination Complex: Inside the Government's Secret Drone Warfare ProgramRating: 4 out of 5 stars4/5 (55)

- The Weather Machine: A Journey Inside the ForecastFrom EverandThe Weather Machine: A Journey Inside the ForecastRating: 3.5 out of 5 stars3.5/5 (31)

- Process Plant Equipment: Operation, Control, and ReliabilityFrom EverandProcess Plant Equipment: Operation, Control, and ReliabilityRating: 5 out of 5 stars5/5 (1)

- The Manager's Path: A Guide for Tech Leaders Navigating Growth and ChangeFrom EverandThe Manager's Path: A Guide for Tech Leaders Navigating Growth and ChangeRating: 4.5 out of 5 stars4.5/5 (99)