Professional Documents

Culture Documents

3m 33

Uploaded by

udomkarn Samanmit0 ratings0% found this document useful (0 votes)

9 views3 pages3M data sheet

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Document3M data sheet

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

9 views3 pages3m 33

Uploaded by

udomkarn Samanmit3M data sheet

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 3

DEE My Ito

Scotch” 23

All-Voltage Splicing Tape

1. Product Description

Scotch™ 23 Electrical Tape is a highly

conformable self-fusing EPR

(Ethylene Propylene Rubber) based,

high voltage splicing tape. It is a

non-vulcanizing, shelf-stable tape

with excellent electrical properties.

23 tape can be used as an insulation

for low-voltage applications as well

as an insulation for splices up to

6,000 volts.

Tape Features

© Can be used to splice and

terminate cables whose

emergency overload temperatures

can reach 130°C. .

© Based on Ethylene Propylene

Rubber (EPR).

© Physical and electrical properties,

are unaffected by the degree of

stretch. ~

© Self-fusing tape.

© Excellent electrical properties.

‘© A special polyester liner which

‘wil not stick to the tape upon

unwind,

‘© Compatible with all solid

dielectric cable insulation.

1. Polyethylene (high and low

density).

2. Cross-linked polyethylene

oar).

Polyvinyl chloride (PVC).

Butyl rubber

‘5. Ethylene Propylene Rubber

VC).

6. Oil-based rubber.

2. Applications

© Primary electrical insulation for

splicing cable from 600 volts

through 69,000 volts on all solid

dielectric cables.

‘© Primary insulation for building

stress cones on cables up to 35,000

volts on all solid dielectric cables.

© Jacketing on high-voltage splices

and terminations.

© Moisture sealing electrical

connections.

© Bus bar insulations.

© End sealing high-voltage cables.

3. Data:

Typical Properties

Physical Properties

Test Method Tical Values

Color Black

© Thickness 30 mils

ASTM D-4325 (076mm)

© Tensile Strength <8 ibs/in

ASTM D-4325 (1.4 N/m)

Utimate Elongation 100%

ASTM D-4325

@ Operating Temperature 90°C

(194°F)

© Emergency Operating 130°C

‘Temperature (66°F)

Fusion, ASTM D-4388 Passes

© Thermal Conductivity 1208 Buu

ASTM D-1518 misqm)

CF perf)

‘* Modulus @ 130°C See Section 5

‘© Ozone Resistance Passes

ASTM D-4388

Electrical Properties

Test Method ‘Ticalvalue’

© Dielectric Srengin

ASTM-D-4325

‘Afler Standard 800 Vimit

Conditioning (81.5 MV/m)

‘Afer 98 hrs >80% of Std

‘at96% RH Condition Value

Insulation Resistance

ASTM-1000

(indirect method

of electrolytic >ixio®

corrosion) megohms

© Dissipation Factor See Section 5

© Dielectric Constant See Section 5

© Dielectric Strength

at elevated

temperature See Section

* This data is rot to be used tor

specification, Values listed are for

typical properties and should not be

considered minimum or maximum.

4. Specifications

Product

‘The high-voltage corona-resistant

tape must be based on ethylene

propylene rubber and be capable of

operation at the emergency cable

temperature of 130°C (266°F). The

tape must be capable of being applied

in either the stretched or unstretched

condition without any resulting loss

in either physical or electrical

properties.

‘The tape must not split, crack, sip or

flag when exposed to various

environments (indoor or outdoor).

The tape must be compatible with all

synthetic cable insulations. The tape

must have a dissipation factor of less

than 5% at 130°C (266°F) and must

have a shelf life of 5 years.

Engineering/Architectural

Specification

Splicing and terminating solid

dielectric cables shall be done in

accordance with drawings engineered

by the splice material manufacturer

such as the 2047 series available from

3M Company. All splices and

terminations shall be insulated using

Scotch™ Brand 23 Electrical Tape.

Characteristics and

Test Data

Modulus at 130°C (266°F)

A high-voltage splicing tape must

constantly maintain a rubber-like

consistency throughout the life of a

splice. One method of determining a

rubber material consistency is by

measuring the modulus of the

material. The modulus of a material

is the stress required to elongate the

material to a given elongation.

Figure J shows the 100% modulus

(tress required to elongate 23 Tape

Dissipation Factor

Figure 2 shows the dissipation of

23 Tape. This test was run according

to ASTM D-150 at a stress of 50

V/mil (2.0 MV/m) and a frequency of

60 cycles per second.

‘iSsPATON FACTOR vs TEMP

Dielectric Strength at Elevated

‘Temperatures

A high-voltage splice must not only

have a high dielectric strength at

room temperature, but it must also

have good values at the temperature

at which itis expected to operate.

Figure 4 shows a plot of dielectric

strength versus temperature. This

test was run according to

ASTM-1000.

PT

OISIPATION FACTOR

Baa8

‘TEMPERATURE "E

Figure 2

Dielectric Constant

Figure 3 shows the dielectric constant

versus temperature of 23 Tape. Tais

Yo 100% elongation) after heat aging $65 w25 run according 19 ASTM

the samples at 150°C (66°F) for aD ASTata sess of $0 Vinil

vabying numberof day. Tne results @OMV/m)and af

indicate a very stable product with Pet

excelent “body” or elastic after

coven aging at 130°C (265°P). cusenegneasr

oe MODIS ve TE i |

= ae BEE |

gr gnc

mb vol i

oats

Figure 1

TEMPERATURE

Figure 3

DIELECTRIC STRENGTH

WOLTS/ MIL

go # 8

os 5108 80

TEMPERATURE °C

Figure 4

Dielectric Strength Versus

Thickness

Figure 5 shows a plot of dielectric

strength in volts per mil versus

thickness. As can be seen by the

‘curve, the dielectric strength in the

original thickness of .030" (.76mm) is

800 Vinal (1.5MV/m). However, the

dielectric strength of a 020" (Simm)

thickness of 23 Tape is 1200 Vimil

(47.2 MV/m). This test was run

according to ASTM-1000.

DELECTc smeNG vs MEANS

sue eee

TWcRNESS MIS

. OELECTAIC STRENGTH

WOUTS/MIL

Figure §

)

6. Installation Techniques

‘Scotch™ Brand 23 Electrical Tape

should be applied in successive

hhalf-lapped, level-wound layers until

esired buildup is reached. To

eliminate voids in critical areas,

highly elongate 23 Tape.

Stretch tape in these critical areas

just short of its breaking point. Doing

so will not alter its physical or

electrical properties. In less critical

areas, less elongation may be used.

Normally, 23 Tape is stretched 10%

of its original width in these less

critical areas. Always attempt 10 +

half-lap to produce a uniform

buildup. When using 23 Tape for

splicing cables from 35 kV to 69 KV,

always elongate the tape throughout

the entire splice.

‘Techniques for the proper use of 23

‘Tape ase contained in standard and

special prints available through the

3M Systems for Splicing and

‘Terminating Program. These are

available through the local 3M

Electrical Products Division

representative.

7. Maintenance

Under normal storage conditions, 23

‘Tape has a S-year shelf life. The tape

is not impaired by freezing nor by

overheated storage up to the point of

flow which prevents removal from

the package.

8. Availability

Scotch™ Brand 23 Electrical Tape is

available in the following roll sizes,

from your local authorized 3M

electiical distributor:

Yin 30 ft

Linx 30ft

Win x30h

2im x30 ft

Other lengths and widths are

available by special request.

Complete Product and Use

Specifications are available through

the Electrical Products Division, 3M

Company.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- 3178 001Document1 page3178 001udomkarn SamanmitNo ratings yet

- Manualbook Distribution TransformerDocument20 pagesManualbook Distribution Transformerudomkarn SamanmitNo ratings yet

- Exothermic Welding Between Bare Copper 4/0 Awg & Rebar SteelDocument1 pageExothermic Welding Between Bare Copper 4/0 Awg & Rebar Steeludomkarn SamanmitNo ratings yet

- 02Document180 pages02Krisada ThongkamsaiNo ratings yet

- CPC 100 Reference ManualDocument366 pagesCPC 100 Reference ManualhaydarNo ratings yet

- 17-5 Report1Document1 page17-5 Report1udomkarn SamanmitNo ratings yet

- BAHRA Medium - Voltage PDFDocument120 pagesBAHRA Medium - Voltage PDFudomkarn SamanmitNo ratings yet

- CPC 100 Brochure ENU PDFDocument44 pagesCPC 100 Brochure ENU PDFudomkarn SamanmitNo ratings yet

- A Case Study of 3-MW Scale Grid-Connected Solar Photovoltaic Power Plant at Kolar, KarnatakaDocument38 pagesA Case Study of 3-MW Scale Grid-Connected Solar Photovoltaic Power Plant at Kolar, KarnatakaAnant Joshi67% (3)

- 3MWPV Plant PDFDocument38 pages3MWPV Plant PDFudomkarn SamanmitNo ratings yet

- Amata City PDFDocument1 pageAmata City PDFudomkarn SamanmitNo ratings yet

- Chap 212Document105 pagesChap 212udomkarn SamanmitNo ratings yet

- Appendix Fifth 20170217033956295Document101 pagesAppendix Fifth 20170217033956295udomkarn SamanmitNo ratings yet

- 75°c Temperatura Maxima de Diseño para Conductores de AluminioDocument22 pages75°c Temperatura Maxima de Diseño para Conductores de AluminioVICTORMARCENo ratings yet

- ธนวัฒน์ PDFDocument11 pagesธนวัฒน์ PDFudomkarn SamanmitNo ratings yet

- ระยะการตอก Ground RodDocument2 pagesระยะการตอก Ground Rodudomkarn SamanmitNo ratings yet

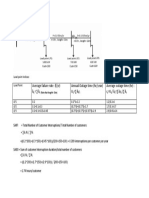

- Average failure rate (f/yr) λ = ∑ λ Annual Outage time (hr/year) U =∑ λ r Average outage time (hr) : r =U / λ =∑ λ r /∑ λDocument1 pageAverage failure rate (f/yr) λ = ∑ λ Annual Outage time (hr/year) U =∑ λ r Average outage time (hr) : r =U / λ =∑ λ r /∑ λudomkarn SamanmitNo ratings yet

- Comparacion IEEE Vs CIGRE Calculo de AmpacidadDocument4 pagesComparacion IEEE Vs CIGRE Calculo de AmpacidadCristian Yeis HernandezNo ratings yet

- Energies 07 06306 PDFDocument17 pagesEnergies 07 06306 PDFAnushiMaheshwariNo ratings yet

- Circuit Breaker Interrupting Capacity and Short Time Current RatingsDocument6 pagesCircuit Breaker Interrupting Capacity and Short Time Current RatingsNagendra PrasadNo ratings yet

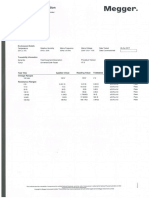

- เอกสาร Certificate เครื่องมือDocument1 pageเอกสาร Certificate เครื่องมือudomkarn SamanmitNo ratings yet

- Theory and Technology of Instrument Transformers: Training Booklet: 2Document48 pagesTheory and Technology of Instrument Transformers: Training Booklet: 2Xabi AlonsoNo ratings yet

- Sensors 16 00367Document19 pagesSensors 16 00367udomkarn SamanmitNo ratings yet

- งานแสดงเทคโนโลยีแลการะประชุมนานาชาติด้านพลังงานทดแทนDocument1 pageงานแสดงเทคโนโลยีแลการะประชุมนานาชาติด้านพลังงานทดแทนudomkarn SamanmitNo ratings yet

- IEC 62305-2010 Tieu Chuan Chong SetDocument489 pagesIEC 62305-2010 Tieu Chuan Chong SetThuậnHồ80% (5)

- E907w Wwen PDFDocument92 pagesE907w Wwen PDFDarshana Herath LankathilakNo ratings yet

- Omicron Mag v8Document37 pagesOmicron Mag v8udomkarn SamanmitNo ratings yet

- Cigre - Brasil - Treinamento - Distance - Protection PDFDocument353 pagesCigre - Brasil - Treinamento - Distance - Protection PDFZokiNo ratings yet

- Omicron Mag v8Document37 pagesOmicron Mag v8udomkarn SamanmitNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)