Professional Documents

Culture Documents

MUK-61-2-0574-001-9B4 Rev 1 110606

Uploaded by

Suresh MahalingamCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MUK-61-2-0574-001-9B4 Rev 1 110606

Uploaded by

Suresh MahalingamCopyright:

Available Formats

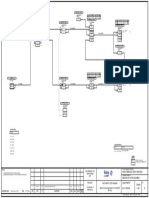

6 CLEAR 76

L65X50X5 (LLV) CURVED TROWEL CORNER L125X75X8 (LLV)

TYP

20 50

AT LEDGER ANGLE ONLY 6 CLEAR /

GRATING OR

GRATING OR (DO NOT CHAMFER)

CHECKERED PLATE 20 25 6 CLEAR 32

CHECKERED PLATE /

/

CL 16 DIA HOLE IN FLOOR

TOP OF 20 BAR (THICKNESS L50X50X6

PLATE AND ANGLE FOR 13

35 CONCRETE TO MATCH PLATE) 6 OR 8

FACE OF DIA x 32 LONG FLAT

THICK PLATE

90

CONCRETE HEAD MACHINE SCREWS IN

FACE OF TOP OF 20 BAR (THICKNESS

COUNTER SUNK HOLES WITH

CL 20 DIA HOLE AT CONCRETE

CONCRETE TO MATCH PLATE)

900 MAX CENTERS (1) SQUARE NUT AT 900 MAX

(LOCATE FIRST AND CENTERS (LOCATE FIRST AND

CL NAIL HOLES TOP OF

75 MIN CL 20 DIA HOLE AT LAST SCREW 150 MAX FROM END

LAST BOLTS 150 MAX 10 450 SEE NOTE 4 CONCRETE

CLEAR (TYP) 900 MAX CENTERS OF EMBEDDED MEMBER) UNLESS

FROM END OF ANGLE) 75 MIN

(LOCATE FIRST AND NOTED OTHERWISE ON DESIGN

FOR 16 DIA ANCHOR CLEAR (TYP)

TYP (SEE 10 450

LAST BOLTS 150 MAX DRAWING

SEE NOTE 2 NELSON STUDS 5

NOTE 5)

FROM END OF ANGLE) SEE NOTE 3 TACK WELD 6 OR 8

PER MANUFACTURERS

FOR 16 DIA ANCHOR 2 PLACES THICK PLATE

REQUIREMENTS PER MANUFACTURERS

SEE NOTE 2

REQUIREMENTS CL NAIL HOLES

NELSON STUDS

SEE NOTE 4

DESIGN BASIS SEE NOTE 3

L75X50X6 (LLH)

38 SQ x 25 THK

ALLOWABLE BENDING DETAIL 1 DESIGN BASIS

STRESS =138 N/mm STYROFOAM POCKET

LEDGER ANGLE ALLOWABLE BENDING DETAIL 2 DETAIL 3 5

AT EACH NUT

LOAD CAPACITY (DOWN ON WALL) STRESS =138 N/mm LEDGER ANGLE CURB ANGLE

765 kg PER LINEAR LOAD CAPACITY

DETAIL 4

(AT TOP OF WALL)

METER OF ANGLE CURB ANGLE

765 kg PER LINEAR

102 METER OF ANGLE

20 76 CL PIPE SUPPORT OR HOLD DOWN

/ 60 (REF)

6 CLEAR 45 75 75

6 CLEAR MIN

CL 21 DIA HOLE IN 38

CL NAIL HOLES TOP OF

BASE PLATE AND ANGLE 25 THK GRATING

SEE NOTE 4 BEARING CL NAIL HOLES

FOR 20 DIA HEAVY HEX

L50X50X6 TOP OF ANGLE SEE NOTE 4

HEAD MACHINE BOLT WITH

20 BAR (THICKNESS TOP OF CONCRETE

(1) HEAVY HEX NUT (SEE L75X50X6 (LLH)

TO MATCH PLATE) CONCRETE

DESIGN DRAWING FOR

LENGTH AND LOCATION)

TOP OF CL NAIL HOLES

CONCRETE SEE NOTE 4

L60X30X5

FOR BASE PLATE 5

NELSON STUDS

10 450 THICKNESS SEE

5 NELSON STUDS

NELSON STUDS SEE NOTE 3

DESIGN DRAWING

SEE NOTE 3 SEE NOTE 3

TACK WELD TOP OF

CL NAIL HOLES

2 PLACES BEARING

SEE NOTE 4

5 ANGLE

13 3

L100X75X8 (LLH) DETAIL 7

NELSON STUDS DETAIL 6

/

SEE NOTE 3 NOSING ANGLE CURB ANGLE

5

50 SQ x 32 THK

STYROFOAM POCKET DETAIL 5

AT EACH NUT

NOTES: DETAIL 8

CURB ANGLE FOR

BEARING ANGLE AT PIPE

PLATE MOUNTED EQUIP 1. FOR CONCRETE GENERAL NOTES,

SUPPORT OR HOLD DOWN

CL NAIL HOLES ABBREVIATIONS AND TYPICAL DETAILS

38 1

SEE DRAWING MUK-61-2-0570-001-9B4-1.

SEE NOTE 4

450 MAX SPACING

2. HILTI ANCHOR SYSTEM TO CONSIST OF: A

CL ANGLE FACE 13 THK EMBEDDED

TOP OF 16 DIA THREADED ROD (A36) WITH (1) T.O. PLATE TO BE

100 PLATE

BEARING ANGLE L75X50X6 (LLH) FLAT WASHER (F436) AND (1) HEAVY HEX LEVEL W/TOC

(TYP)

EQUALEQUAL

NUT (A563 GR DH). ASSEMBLY TO BE HOT

CL (4) NELSON

CL HOLD DOWN TYP (SEE

DIP GALVANIZED PER ASTM A 153. ANCHOR

STUDS

5

25 50 50 TO BE INSTALLED IN 20 DIA HOLE. NOTE 5)

75

USE HILTI RE 500 SD ADHESIVE ANCHOR

WT3

CL NAIL HOLES CL PLATE

B

SYSTEM PER MANUFACTURERS INSTRUCTIONS.

TOP OF SEE NOTE 4

150

PROVIDE 45 DEGREE CHISEL POINT ON NELSON STUD (TYP)

BEARING

WT165X20 EMBEDDED END. 13 DIA X 150 LONG

TEE

CL PLATE

3. USE 13 DIA x 150 LONG NELSON STUDS NOTE:

PARTIAL PLAN

AT 450 MAX CENTERS (LOCATE FIRST AND A & B = 550mm (UNO)

AT TEE ENDS LAST STUD 150 MAX FROM END OF EMBEDDED

NELSON STUDS

5 MEMBER) UNLESS NOTED OTHERWISE ON DETAIL 11

SEE NOTE 3

DESIGN DRAWING. EMBEDDED PLATE

TOP OF

BEARING TEE 4. PROVIDE 5 DIA NAIL HOLES AT 900

MAX CENTERS.

13 3

TYP

5 LOCATE ANCHORS

/

AS SHOWN ON 5. NELSON STUDS WILL BE ATTACHED USING

DETAIL 10 THE NELSON STUD GUN, OTHERWISE USE THE

PARTIAL PLAN

BEARING ANGLE AT AIR WELD AS INDICATED.

NELSON STUDS COOLER SUPPORT

SEE NOTE 3

- - - - - - - - -

DETAIL 9

- - - - - - - - -

BEARING TEE AT HOLD DOWN 1 18 MAY 2011 RA JRB CNK/DDS REVISED FOR CONSTRUCTION - - -

0 11NOV2010 RA JRB CNK/CN ISSUED FOR CONSTRUCTION - - -

PROJ ENG SIGNATURE

DRAWN CHKD APPR.

REV DATE DESCRIPTION CHILD PAR NO.

BY BY BY OXY APPROVAL

PROJECT DRAWING REVISION

Project Unit DocType Eng. Code Seq. No. Rev. Cwp

AREA

-

DH417696 061 STD 1780 006 1 061 AREA MUKHAIZNA

NAME

SCALE:

TECHNIP USA, Inc. TECHNIP USA, INC. TBPE FIRM REG. NO. F-3030

MUK

AREA

CODE

SUB AREA

CENTRAL PROCESSING FACILITIES OCCIDENTAL MUKHAIZNA LLC

61

A subsidiary of Occidental Petroleum Company

DRWG TYPE CIVIL STRUCTURAL SUB ENG SERIAL SHEET PROJ

DRWG AREA AREA DISC NUMBER NUMBER CODE SIZE REV.

DESCRIPTION DRAWING NUMBER REV. BY DATE DESCRIPTION CHKD. ENGR. APRD. MISCELLANEOUS EMBEDMENT DETAILS

DESCRIPTION

NO. MUK 61 2 0574 001 9B4 1 1

NOTES: REFERENCE DRAWINGS MASTER REVISION -

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- MUK-62-MGT-AIC-09010 Rev A Lime & Soa Ash Erec. and Install. Proced. 110314Document28 pagesMUK-62-MGT-AIC-09010 Rev A Lime & Soa Ash Erec. and Install. Proced. 110314Suresh MahalingamNo ratings yet

- MUK-61-2-0658-ERC-2004 Rev 1Document1 pageMUK-61-2-0658-ERC-2004 Rev 1Suresh MahalingamNo ratings yet

- MUK-62-MGT-AIC-09011 Rev A Filter Press Erec. & Install. Proc. 110314Document12 pagesMUK-62-MGT-AIC-09011 Rev A Filter Press Erec. & Install. Proc. 110314Suresh MahalingamNo ratings yet

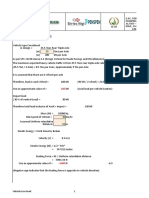

- Base Slab Design - RampDocument6 pagesBase Slab Design - RampSuresh Mahalingam100% (1)

- Corner Wall Design - CulvertDocument5 pagesCorner Wall Design - CulvertSuresh MahalingamNo ratings yet

- TRX 2011 2555Document78 pagesTRX 2011 2555Suresh MahalingamNo ratings yet

- GPM OverviewDocument158 pagesGPM OverviewSuresh MahalingamNo ratings yet

- MUK-61-5-1472-023-9B4-1 Rev 0 110621 PDFDocument1 pageMUK-61-5-1472-023-9B4-1 Rev 0 110621 PDFSuresh MahalingamNo ratings yet

- Braking Distance CalculationDocument4 pagesBraking Distance CalculationSuresh MahalingamNo ratings yet

- Wall Design - CulvertDocument5 pagesWall Design - CulvertSuresh Mahalingam100% (1)

- Base Slab Design - CulvertDocument6 pagesBase Slab Design - CulvertSuresh MahalingamNo ratings yet

- Corner Wall Design - RampDocument5 pagesCorner Wall Design - RampSuresh MahalingamNo ratings yet

- MUK-61-5-1472-007-9B4-1 Rev 0 110510 PDFDocument1 pageMUK-61-5-1472-007-9B4-1 Rev 0 110510 PDFSuresh MahalingamNo ratings yet

- Iqwq KD WPWRK D7 1109 - 0Document76 pagesIqwq KD WPWRK D7 1109 - 0Suresh MahalingamNo ratings yet

- MUK-61-2-0784-001-9B4-1 Rev 1 110707 PDFDocument1 pageMUK-61-2-0784-001-9B4-1 Rev 1 110707 PDFSuresh MahalingamNo ratings yet

- Muk 61 2 PLL 0007 9H8Document34 pagesMuk 61 2 PLL 0007 9H8Suresh MahalingamNo ratings yet

- Punj Lloyd-Aquatech 260311Document4 pagesPunj Lloyd-Aquatech 260311Suresh MahalingamNo ratings yet

- Muk 61 2 PLL 0002 9H8Document105 pagesMuk 61 2 PLL 0002 9H8Suresh MahalingamNo ratings yet

- 340w0141601 Rev 1 120529Document1 page340w0141601 Rev 1 120529Suresh MahalingamNo ratings yet

- MUK-62-MGT-AIC-00003 - Mukhaizna Phase II Equipment Document Reference To Oxy, Aic 110328Document9 pagesMUK-62-MGT-AIC-00003 - Mukhaizna Phase II Equipment Document Reference To Oxy, Aic 110328Suresh MahalingamNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Strategic Plan For NetflixDocument16 pagesStrategic Plan For NetflixShehzadi Mahum (F-Name :Sohail Ahmed)No ratings yet

- MES: ENERO 2020: Uso de VehículosDocument4 pagesMES: ENERO 2020: Uso de Vehículosgustavo guerreroNo ratings yet

- Berlioz MelodyDocument10 pagesBerlioz MelodyKikuko KatoNo ratings yet

- MenuDocument10 pagesMenuRindelene A. CaipangNo ratings yet

- JBL Professional CBT Series Brochure 0712Document4 pagesJBL Professional CBT Series Brochure 0712Sound Technology LtdNo ratings yet

- Horrid Henry Meets GodDocument5 pagesHorrid Henry Meets GodAmhpman86% (7)

- B1 Quiz 2Document2 pagesB1 Quiz 2Назар КуликNo ratings yet

- Hardware and Firmware 1.5Document29 pagesHardware and Firmware 1.5Janice BrownNo ratings yet

- Handel Cantatas Performing EditionsDocument178 pagesHandel Cantatas Performing Editionserast_dudeNo ratings yet

- Carburetion Catalog 2002Document305 pagesCarburetion Catalog 2002LukidjNo ratings yet

- Star Wars Episode III - Revenge of The Sith (Soundtrack)Document5 pagesStar Wars Episode III - Revenge of The Sith (Soundtrack)Isaac TercerosNo ratings yet

- SsDocument5 pagesSsOluap Nosaj100% (1)

- 127 Character Mantra (Parvidhya Bhakshini Mantra)Document5 pages127 Character Mantra (Parvidhya Bhakshini Mantra)Lord MuruganNo ratings yet

- Movie ReviewDocument8 pagesMovie Reviewapi-314128207No ratings yet

- Filthy Crag QDocument3 pagesFilthy Crag Qapi-302173014No ratings yet

- Theremino PointFollower Help ENGDocument9 pagesTheremino PointFollower Help ENGSting EyesNo ratings yet

- Lamb With Pomegranate and Saffron: When A Great Book Inspires Great CookingDocument1 pageLamb With Pomegranate and Saffron: When A Great Book Inspires Great CookingSimon and Schuster23% (31)

- DND Macho CharDocument4 pagesDND Macho CharJason BoNo ratings yet

- Aptitude Probability Concepts and FormulasDocument4 pagesAptitude Probability Concepts and FormulasSamuel DebebeNo ratings yet

- Student ResourceDocument36 pagesStudent Resourceapi-317825538No ratings yet

- Bose Marketing ProjectDocument28 pagesBose Marketing ProjectShirish Aparadh91% (11)

- Quiz Chord Block DiagramsDocument25 pagesQuiz Chord Block Diagramsjoshua_tan_31No ratings yet

- Note 31515 - Service ConnectionsDocument3 pagesNote 31515 - Service ConnectionsMitchel NeyraNo ratings yet

- Stravinsky Soldiers Tale Program Notes1Document4 pagesStravinsky Soldiers Tale Program Notes1Matt GriffithNo ratings yet

- Forensic Ballistics: QandaDocument107 pagesForensic Ballistics: QandaLex Tamen CoercitorNo ratings yet

- Arunachal Pradesh Textile Cultures and TDocument32 pagesArunachal Pradesh Textile Cultures and TshreyaNo ratings yet

- Philips Mc20 SMDocument44 pagesPhilips Mc20 SMsuysuy00No ratings yet

- Colour Theory: For NATA & Jee B.archDocument10 pagesColour Theory: For NATA & Jee B.archpooja100% (1)

- (DK US) - Core Strength Training - 1° Edition PDFDocument226 pages(DK US) - Core Strength Training - 1° Edition PDFNico Sama88% (8)

- Modern Product Catalog BookletDocument12 pagesModern Product Catalog BookletGame TwistersNo ratings yet