Professional Documents

Culture Documents

5.2.3 Tension Loading:: Casing Depth, (FT) Tension, (LB) Over Pull 100000, (LB) Apply-DF 1.6 (LB)

Uploaded by

eng20072007Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

5.2.3 Tension Loading:: Casing Depth, (FT) Tension, (LB) Over Pull 100000, (LB) Apply-DF 1.6 (LB)

Uploaded by

eng20072007Copyright:

Available Formats

5.2.

3 Tension loading:

W1 = 47 * 5857 = 275279 lb, in air

W2 = 43.5 * 3000 = 130500 lb, in air

F=p*A

Where: -

P = 0.052 * 9.5 * 8857 = 4375 psi

A = /4 (9.625^2 8681^2) = 13.57 in^2

F1 = 4375* 13.57 = 59369 lb

P = 0.052 * 9.5 * 3000 = 1482 psi

A = /4 (8.755^2 8.681 ^2) = 1.01 in^2

F2 = 1482 * 1.01 = 1497 Lb

The tensile loading at each depth can be calculated for drill

string design.

Over pull Apply-DF*1.6

Casing Depth, (ft) Tension, (lb)

100000, (lb) (LB)

N80 0 338829 438829 5421264

43.5 3000 208329 308329 333326

N80 3000 206832 306832 330931

47 8857 - 68447 31553

Table (5-10)

F1 = 68447

W1 F1 = 275279 68447 =206832

206832 + F2 = 206832 + 1497 =208329

208329 + W2 = 208329 +130500 =338829

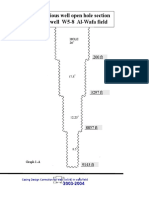

73 Casing Design Correction for Well (w5-8) in wafa field

2003-2004

Tensile Loading Plotted as show in the chart (5-F).

Pipe bode

Casing, (LB/FT)

strength, (LB) BTC, (LB)

N80 43.5 1005000 1074000

N80 47 108000 1161000

Table (5-11)

5- 2- 4 Check axial Effects:

Pipe De-rated

Casing, Depth. Tension,

yield, X Y collapse,

(lb/ft) (ft) (lb)

(lb) (lb)

N 80 0 338829 1005000 0.34 0.83 3162

43.5 3000 208329 0.21 0.87 3810

N 80 3000 206832 1080000 0.19 0.88 4189

47 8857 -68447 0.063 0.97 4760

Table (5-12)

Actual loading factory (X) = Tension Loading / Body yield string.

Where: -

X1 = 338829 / 1005000 = 0.34 , Y = 0.82

X2 = 208329 / 1005000 = 0.21 , Y = 0.87

X3 = 206832 / 1080000 = 0.19 , Y = 0.88

X4 = 68447 / 1080000 = 0.063 , Y = 0.97

The value of (y) from chart (5-J).

74 Casing Design Correction for Well (w5-8) in wafa field

2003-2004

5-3 7 Design of Liner casing :-

TOP of liner 8557 ft.

Reservoir pressure 3600 psi .

Mud weight 0.468 psi/ 9 ppg .

Cement density 0.468 psi/ft 15.8 ppg.

Gas gradient 0.115 psi/ft 2.21 ppg.

Casing setting depth 9143 ft .

Formation fluid density 0.48 psi/ft 9 ppg.

Fracture gradient 0.7

Casing availability

1000,

WT, Burst, Collapse, Tension, Body yield

Grade ID, (in) (lbs)

(lb/ft) (psi) (psi) STC*1000 1000, (lbs)

BTS

K 55 23 6.366 4360 3270 522 309 366

N 80 26 6.276 7240 5410 519 667 604

N80 32 6.094 8460 8600 676 823 745

C 95 32 6.094 10050 9730 885 891 885

P 110 26 6.276 9960 6210 830 853 830

P 110 32 6.094 1641 10760 1025 1053 1025

Table (5-13)

5.3.1 Burst loading:-

Burst is equal ZERO. Because we using at tubing (drill pipe) to

pumping the cement on the annulus between the hole and

casing.

Then the value of burst is negligible.

75 Casing Design Correction for Well (w5-8) in wafa field

2003-2004

5-3-2 Collapse Loading:

To find the length of the liner.

Length of the liner = casing setting depth Top of liner.

= 9143 8557 = 586 ft.

The hydrostatic pressure = length of liner * 0.052 * cement

density

= 586 * 0.052 *15.8 = 481 psi .

Total hydrostatic pressure = 9143 * 0.052 * 9 = 4271 psi .

= 4271 485 = 3786 psi .

Design factor for collapse * 3786 = 1.1 * 3786 = 4165 psi

Choice of casing :-

The following string can be chosen:-

8557 ft 9147 ft N80 26 lb/ft

76 Casing Design Correction for Well (w5-8) in wafa field

2003-2004

5-3-3 Tension loading: -

W = 26 * 586 = 15340 LB.

F=P*A

Where :-

A = /4 (7^2 6.276 ^2) = 7.55 in^2

P = 0.052 * 9*590 =276 psi

F = 7.55 * 276 = 2084 lb

Casing, Tension, Over pull Apply Df

Depth, (ft)

(lb/ft) (LB) 100000, (lb) *1.6(lb)

8557 13160 113160 181056

N80 26 9143 - 2076 97924

Table (5-14)

Pipe Body strength,

Casing, (lb/ft) BTC, (LB)

(lb)

N 80 26 604000 519000

5-3- 4 Check axial Effects: -

Tension De-rated

Casing Depth(ft) Pipe yield (lb)

(LB) X Y collapse,(lb)

8557 13160 604000 0.02 0.98 5302

N 80 26 9143 - 2076 0.0034 0.999 5410

Table (5-15)

X1 = 13256 / 604000 =0.02, Y = 0.98 from chart (5 - G).

X2 = 2084 / 604000 = 0.0034, Y=0.999 from chart (5 - G).

77 Casing Design Correction for Well (w5-8) in wafa field

2003-2004

78 Casing Design Correction for Well (w5-8) in wafa field

2003-2004

You might also like

- D3755-14 Standard Test Method For Dielectric BreakdowDocument6 pagesD3755-14 Standard Test Method For Dielectric Breakdowjose flores100% (1)

- Design of RCC BuildingDocument5 pagesDesign of RCC Buildingshreejay maneNo ratings yet

- ASTM E92-17 Standard Test Methods For Vickers Hardness and Knoop Hardness of Metallic MaterialsDocument27 pagesASTM E92-17 Standard Test Methods For Vickers Hardness and Knoop Hardness of Metallic MaterialsCarlos Pinto Pradilla88% (8)

- Tank 620 US 0002 API 620 Calculation ReportDocument39 pagesTank 620 US 0002 API 620 Calculation ReportPhượng NguyễnNo ratings yet

- VLF Radio Engineering: International Series of Monographs in Electromagnetic WavesFrom EverandVLF Radio Engineering: International Series of Monographs in Electromagnetic WavesNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Materials Data for Cyclic Loading: Low-Alloy SteelsFrom EverandMaterials Data for Cyclic Loading: Low-Alloy SteelsRating: 5 out of 5 stars5/5 (2)

- Biological ExerciseDocument6 pagesBiological ExerciseTanmoy BasakNo ratings yet

- TK-500MB - DB - Rev. 00Document173 pagesTK-500MB - DB - Rev. 00Daniel GómezNo ratings yet

- NASA ERAST Program Develops High-Altitude UAVsDocument17 pagesNASA ERAST Program Develops High-Altitude UAVsEgz AguilarNo ratings yet

- Wind Load & Blow Off Calculation NMML1Document14 pagesWind Load & Blow Off Calculation NMML1Ankit AgarwalNo ratings yet

- Design of Gantry GirderDocument30 pagesDesign of Gantry GirderSandesh PrajapatiNo ratings yet

- AE20/BE20: SeriesDocument7 pagesAE20/BE20: SeriesPatricio Acuña0% (1)

- Boiler MaintenanceDocument144 pagesBoiler Maintenanceaziz100% (2)

- 1007 DISQ 0 M SS 42005 Air Cooled Heat Exchangers SpecificationDocument18 pages1007 DISQ 0 M SS 42005 Air Cooled Heat Exchangers Specificationeng20072007No ratings yet

- Chapter 4-EDocument42 pagesChapter 4-EMahrouz MadoNo ratings yet

- Mechanical Testing of MaterialsDocument38 pagesMechanical Testing of MaterialsAanand Rishabh DagaNo ratings yet

- OSHA Standard For Fixed Ladders SummaryDocument12 pagesOSHA Standard For Fixed Ladders SummarysesabcdNo ratings yet

- TK-ALCOZAP-2020-01-06-Rev. DDocument65 pagesTK-ALCOZAP-2020-01-06-Rev. DDaniel Gómez100% (1)

- BlocksDrilling Line Rev-Peview PDFDocument11 pagesBlocksDrilling Line Rev-Peview PDFLa Ode Hadi AugustmanNo ratings yet

- Calculation of Zincalume TankDocument20 pagesCalculation of Zincalume TankMr IncognitoNo ratings yet

- Nuclear Radioactivity WorksheetDocument3 pagesNuclear Radioactivity Worksheet14569874No ratings yet

- Column Supporting DiscontinuousDocument40 pagesColumn Supporting DiscontinuousRohan JaiswalNo ratings yet

- Skirt Support TrialDocument11 pagesSkirt Support TrialAbhishek Nag0% (1)

- Ametank ReportDocument96 pagesAmetank ReportMiguel Angel Hernandez FloresNo ratings yet

- Composite Bridge Design Calculation: General InformationDocument16 pagesComposite Bridge Design Calculation: General Informationbakti20No ratings yet

- 1007 DISQ 0 J SS 33030 Control Valve SpecificationDocument18 pages1007 DISQ 0 J SS 33030 Control Valve Specificationeng20072007No ratings yet

- Construction Companies in IndiaDocument11 pagesConstruction Companies in Indiashobhit.goel33% (3)

- Safety ValvesDocument11 pagesSafety Valvesravindra_jivaniNo ratings yet

- Prop Design ExampleDocument7 pagesProp Design Exampleancamardelli100% (1)

- Analisis MaxsurfDocument13 pagesAnalisis MaxsurfVictor Jesus RiosNo ratings yet

- Wind Seismic Calculation DataDocument8 pagesWind Seismic Calculation Dataaknauriyal2013No ratings yet

- ASME Horizontal Vessel Analysis - Friction 0.025 PDFDocument10 pagesASME Horizontal Vessel Analysis - Friction 0.025 PDFSyed Zain AliNo ratings yet

- Panda-1 Well PlanningDocument6 pagesPanda-1 Well PlanningHarold AldayNo ratings yet

- CO2 Condenser 02-03-2023-15 PMDocument37 pagesCO2 Condenser 02-03-2023-15 PMahmad santosoNo ratings yet

- Stage Design For PC Girder BridgeDocument8 pagesStage Design For PC Girder BridgeIstiaque Yeassir100% (1)

- 5-1 13 3/8" Surface Casing DesignDocument10 pages5-1 13 3/8" Surface Casing Designeng20072007No ratings yet

- TMPRO CASABE 1318 Ecopetrol Packer SuperiorDocument10 pagesTMPRO CASABE 1318 Ecopetrol Packer SuperiorDiego CastilloNo ratings yet

- Pad Footing Report2Document4 pagesPad Footing Report2อมรฤทธิ์ พ่วงสมบัติNo ratings yet

- Nozzle Loads - 115-E-0309Document27 pagesNozzle Loads - 115-E-0309Tushar MangratiNo ratings yet

- Pad Footing Report1Document4 pagesPad Footing Report1อมรฤทธิ์ พ่วงสมบัติNo ratings yet

- Reach 1 Stitch Concrete BBS-JP7-JP6Document2 pagesReach 1 Stitch Concrete BBS-JP7-JP6Eticala RohithNo ratings yet

- Patriot6000 8000 9500Document46 pagesPatriot6000 8000 9500Rogelio TafoyaNo ratings yet

- LAMPIRAN Pressure and Formation BreakdownDocument9 pagesLAMPIRAN Pressure and Formation BreakdownDito Andi WNo ratings yet

- WP & MSP sheet for Well Ramdiani-1Document1 pageWP & MSP sheet for Well Ramdiani-1Maaz Bin FurqanNo ratings yet

- Fichas Tecnicas Minisplit MIDEA Inverter (1)Document1 pageFichas Tecnicas Minisplit MIDEA Inverter (1)juan pasiminioNo ratings yet

- Az3 +3mleDocument14 pagesAz3 +3mleMarisol RojasNo ratings yet

- Example3 Design of Mat2016Document13 pagesExample3 Design of Mat2016awetgirmay41No ratings yet

- Drillpipe DesignDocument1 pageDrillpipe DesignRihane BoulahiaNo ratings yet

- Scantling Calc SpreadsheetDocument73 pagesScantling Calc SpreadsheetTapan KhandelwalNo ratings yet

- University of Engineering and Technology Lahore: Steel Structures Lab Design AssignmentDocument18 pagesUniversity of Engineering and Technology Lahore: Steel Structures Lab Design AssignmentQazi Abdul MoeedNo ratings yet

- EC_Pilegroup_BLK 226A_PC4F_14HW31ZDocument2 pagesEC_Pilegroup_BLK 226A_PC4F_14HW31ZJONHCENA13No ratings yet

- RCC13 Punching ShearDocument11 pagesRCC13 Punching ShearMatumbi NaitoNo ratings yet

- At JunctionDocument2 pagesAt Junctionvodugu123No ratings yet

- Screw Conveyor Calcultation SheetDocument11 pagesScrew Conveyor Calcultation Sheethardik033No ratings yet

- Equipment Hose Reel X (MM) y (MM) Z (MM) Mass (Ton)Document6 pagesEquipment Hose Reel X (MM) y (MM) Z (MM) Mass (Ton)rajatchikuNo ratings yet

- FTK 0916 C.compressedDocument19 pagesFTK 0916 C.compressedJeff BannonNo ratings yet

- MB15Document2 pagesMB15abhijitkolheNo ratings yet

- Rob RCD.3Document3,258 pagesRob RCD.3RobbieNo ratings yet

- Properties of Bolts: - Bolt Grades 4.6, 5.6 and 8.8Document2 pagesProperties of Bolts: - Bolt Grades 4.6, 5.6 and 8.8mustfa khedrNo ratings yet

- Homework 5Document26 pagesHomework 5Hadi AeNo ratings yet

- Water Storage Tank Design Calculation SummaryDocument23 pagesWater Storage Tank Design Calculation SummaryPlanet OlineNo ratings yet

- Abrar Rifqi Pratama - Meh - Tugas 3Document15 pagesAbrar Rifqi Pratama - Meh - Tugas 3Abrar RifqiNo ratings yet

- Piso-Cielo 60000Document1 pagePiso-Cielo 60000PabloNo ratings yet

- Result Anlysis 40x60 PDFDocument3,516 pagesResult Anlysis 40x60 PDFJimmy WalkerNo ratings yet

- 21 PSC Design (Eurocode) - Completed ModelDocument72 pages21 PSC Design (Eurocode) - Completed Modelakshay magarNo ratings yet

- Staff Quarter Type-H DBR for Upper Veda WTP 28-12-2023Document25 pagesStaff Quarter Type-H DBR for Upper Veda WTP 28-12-2023PramodNo ratings yet

- Mission Specification For A Jet TransportDocument24 pagesMission Specification For A Jet TransportAdha LuriNo ratings yet

- Answer For TestDocument4 pagesAnswer For TestHẬU ĐINH PHƯỚCNo ratings yet

- Data Sheet Southwire 3c#500kcmilDocument2 pagesData Sheet Southwire 3c#500kcmilNestor-leoNo ratings yet

- Spreadsheets To BS 8110 Beam C1-2, Level 3: CalculationsDocument2 pagesSpreadsheets To BS 8110 Beam C1-2, Level 3: Calculationsmdelacua2No ratings yet

- Buckling and Wellhead Load After CementingDocument12 pagesBuckling and Wellhead Load After CementingscrbdgharaviNo ratings yet

- Five Tubing Move & StressDocument3 pagesFive Tubing Move & StressMohamad TayeaNo ratings yet

- British Commercial Computer Digest: Pergamon Computer Data SeriesFrom EverandBritish Commercial Computer Digest: Pergamon Computer Data SeriesNo ratings yet

- City Director of Public Works Organizational ChartDocument2 pagesCity Director of Public Works Organizational Charteng20072007No ratings yet

- Adding PID Controllers in Aspen HYSYS: Dynamic Simulation Course 2017Document1 pageAdding PID Controllers in Aspen HYSYS: Dynamic Simulation Course 2017eng20072007No ratings yet

- City Director of Public Works Organizational ChartDocument2 pagesCity Director of Public Works Organizational Charteng20072007No ratings yet

- Water Treatment PidDocument1 pageWater Treatment Pideng20072007No ratings yet

- Factory PidDocument1 pageFactory Pideng20072007No ratings yet

- 1.3 Reliability Terminology: An Introduction To Reliability and Risk Assessment 3Document1 page1.3 Reliability Terminology: An Introduction To Reliability and Risk Assessment 3eng20072007No ratings yet

- Envelope Envelope-11Document1 pageEnvelope Envelope-11eng20072007No ratings yet

- Reliability and Risk Assessment: Ace 4 ApDocument1 pageReliability and Risk Assessment: Ace 4 Apeng20072007No ratings yet

- Factory PidDocument1 pageFactory Pideng20072007No ratings yet

- El Sayed Amer Last UpdatedDocument3 pagesEl Sayed Amer Last Updatedeng20072007No ratings yet

- Oklahoma Corporation Commission: Packer Setting ReportDocument2 pagesOklahoma Corporation Commission: Packer Setting Reporteng20072007No ratings yet

- Ngdiploma EnglishDocument2 pagesNgdiploma Englisheng20072007No ratings yet

- Warna Three: What Is Marketing?Document11 pagesWarna Three: What Is Marketing?eng20072007No ratings yet

- DareDocument11 pagesDareeng20072007No ratings yet

- SuperbizDocument11 pagesSuperbizeng20072007No ratings yet

- 1007-Disq-0-L-ss-39154 Rev 2 Supplementary Purchasing Requirements For ValvesDocument14 pages1007-Disq-0-L-ss-39154 Rev 2 Supplementary Purchasing Requirements For Valveseng20072007No ratings yet

- Block ProposalDocument11 pagesBlock Proposaleng20072007No ratings yet

- Previous Well Open Hole Section For Well W5-8 Al-Wafa FieldDocument4 pagesPrevious Well Open Hole Section For Well W5-8 Al-Wafa Fieldeng20072007No ratings yet

- Gad SeparatorDocument3 pagesGad Separatoreng20072007No ratings yet

- Duplicate Cleaner LogDocument1 pageDuplicate Cleaner LogMuhammad Hafizuddin Bin JumadinNo ratings yet

- 1007-Disq-0-L-ss-39151 Rev 2 Spec For Chemical Cleaning of PipingDocument10 pages1007-Disq-0-L-ss-39151 Rev 2 Spec For Chemical Cleaning of Pipingeng20072007No ratings yet

- 0 - Cources IntroductionDocument5 pages0 - Cources Introductioneng20072007No ratings yet

- احدث CVDocument4 pagesاحدث CVeng20072007No ratings yet

- 1007-DISQ-0-M-SS-42026-Rev.3 ValvesDocument13 pages1007-DISQ-0-M-SS-42026-Rev.3 Valveseng20072007No ratings yet

- 1007 Disq 0 G Ae 30033 Rev 5 Equipment ListDocument22 pages1007 Disq 0 G Ae 30033 Rev 5 Equipment Listeng20072007100% (1)

- Avio 550 Max ICP-OES ASTM D5185 In-Service Oils Application NoteDocument4 pagesAvio 550 Max ICP-OES ASTM D5185 In-Service Oils Application Notec1nthiacruzNo ratings yet

- XXXXXXX XXXXXXX: Pour Exemple: Pour Exemple: ArteorDocument5 pagesXXXXXXX XXXXXXX: Pour Exemple: Pour Exemple: ArteorGilbert MartinezNo ratings yet

- Joy Global SolutionsDocument18 pagesJoy Global Solutionsjvr001100% (1)

- Gas Sensors: Jiturvi Chokshi ENPM-808BDocument27 pagesGas Sensors: Jiturvi Chokshi ENPM-808Banon_44955929No ratings yet

- Belgas P630R IOMDocument3 pagesBelgas P630R IOMSMcNo ratings yet

- 06 - 1 Cutting Tools - 2013 - LRDocument17 pages06 - 1 Cutting Tools - 2013 - LRBaggerkingNo ratings yet

- CPU Vs vCPUDocument14 pagesCPU Vs vCPUainseanNo ratings yet

- PalindromeDocument7 pagesPalindromeZy AdrianneNo ratings yet

- Reliance Jio Industry AnalysisDocument45 pagesReliance Jio Industry AnalysisBhavya BhartiNo ratings yet

- Signals and Systems - MjrobertsDocument3 pagesSignals and Systems - Mjrobertspriyakanthr5883100% (1)

- multirab ura signaling issuesDocument1 pagemultirab ura signaling issuessha0% (1)

- Wrf736sdam14 - Tech - Sheet - W10811276 - Rev - B Otro Modelo de La Nevera de Oliva OcoaDocument5 pagesWrf736sdam14 - Tech - Sheet - W10811276 - Rev - B Otro Modelo de La Nevera de Oliva OcoaEdison EspinalNo ratings yet

- Manage Payment Process Profiles - 1Document1 pageManage Payment Process Profiles - 1I'm RangaNo ratings yet

- 2010 Xstrata VOD Implementation - BartschDocument35 pages2010 Xstrata VOD Implementation - BartschFlávia GomesNo ratings yet

- DWTS, WDWTS: Improving MRI Image Reconstruction with Directional Wavelet ThresholdingDocument1 pageDWTS, WDWTS: Improving MRI Image Reconstruction with Directional Wavelet ThresholdingSumit ChakravartyNo ratings yet

- Pump HydraulicsDocument5 pagesPump HydraulicsSiddharth Kharat100% (1)

- Catalogo DeltaDocument2 pagesCatalogo DeltaHelena ChagasNo ratings yet

- Hoisting Systems ExplainedDocument21 pagesHoisting Systems Explainedsparda94No ratings yet

- Dedi Kristiawan: Personal DetailDocument5 pagesDedi Kristiawan: Personal DetaildedyNo ratings yet